-

PDF

- Split View

-

Views

-

Cite

Cite

Hanbing Jia, Feiyue Ren, Hongzhi Liu, Effects and improvements of storage conditions and processing on the bioaccessibility and bioavailability of phytochemicals in fruits and vegetables, International Journal of Food Science and Technology, Volume 60, Issue 1, January 2025, vvae040, https://doi.org/10.1093/ijfood/vvae040

Close - Share Icon Share

Abstract

Phytochemicals found in fruits and vegetables offer health benefits for degenerative diseases, but their bioaccessibility are often limited due to poor stability. Various environmental conditions such as temperature, moisture, pH, as well as different processing methods, significantly impact phytochemicals. These factors are becoming increasingly important in the food industry and are attracting the attention of many researchers. This review examines the advantages and disadvantages of mechanical processing, thermal processing, and non-thermal processing and their effects on content, bioaccessibility, antioxidant activity, and sensory properties of phytochemicals. Non-thermal processing is considered to have the potential to replace traditional thermal processing due to its lesser degradation of phytochemicals. The operations and effects of various non-thermal processing techniques, including high-pressure processing, high-pressure homogenization, pulsed electric field, ultrasound, supercritical carbon dioxide, cold atmospheric plasma, bioprocessing, and encapsulation, are reviewed. The aim of this review is to provide the latest information on processing for future research and innovation.

Introduction

Phytochemicals are biocompounds found in fruits, vegetables, cereals, seeds, and nuts, with fruits and vegetables being the main sources. These compounds can be broadly divided into two categories: hydrophilic phytochemicals, such as polyphenols and pectin, and lipophilic phytochemicals, such as carotenoids, fatty acids, phytosterols, and vitamins. Numerous studies have confirmed that phytochemicals have anti-cancer, anti-diabetes, and anti-inflammatory effects and have the potential to decrease the risks of cardiovascular disease, hypertension, and several other conditions (Abdel-Latif et al., 2023; Sun et al., 2020). Some phytochemicals even exhibit antimicrobial, antidiarrheal, and antiviral activities (Kumar et al., 2023), for which phytochemicals has attracted a lot of attention and employed to prevent metabolic diseases by improving daily diet. In many medical care underdeveloped regions, plant-based foods, which is rich in bioactive compounds, are used as main medicine. Their pharmacological potential as natural remedies for contemporary health challenges also have been recognized by traditional medicine systems. As people’s desire for green, environmentally friendly, and healthy food increases, the consumption of organic fruits and vegetables rich in phytochemicals continues to rise, prompting much research (Liu et al., 2020).

However, many phytochemicals have limited bioaccessibility and bioavailability due to their poor solubility, absorption characteristics, and chemical degradation during harvest, storage, processing, and oral digestion. The interaction between phytochemicals and other ingredients in the food matrix might also restrain the bioavailability of phytochemicals (Kamiloglu et al., 2021). Apart from the effects of the characteristics of phytochemicals and the food matrix, the conditions of storage and processing also significantly impact the bioaccessibility and bioavailability of phytochemicals (Mohamad Salin et al., 2022; Moomin et al., 2023; Tedeschi et al., 2023). Factors such as temperature, moisture, pH, oxygen, and light, especially temperature, greatly affect the properties of fruits and vegetables during storage (Rababah et al., 2023). To ensure the quality of fruits and vegetables, cold chain transportation technology is widely used. Other treatments like ultraviolet light have also been used to improve the bioaccessibility of phytochemicals and reduce degradation after harvest. Thereby, it is necessary to summarize the environment factors affecting the bioaccessibility of phytochemicals and study their mechanisms.

Processing has the greatest effect on phytochemicals, with different effects due to various technologies, processing conditions, and types of crops. Mechanical processing methods like juicing, pressing, and extrusion are widely used in the food industry, improving sensory properties but causing severe waste. Conventional thermal processing methods, including blanching, cooking, steaming, baking, sterilization, and pasteurization, are easy to operate and price-friendly, making them widely used and frequent. Thermal processing may help release phytochemicals from the food matrix but also facilitate their chemical degradation, having a dual effect on phytochemical bioaccessibility (Zou et al., 2024). Non-thermal processing methods, such as high-pressure processing, high-pressure homogenization, pulsed electric field, ultrasound (US), supercritical carbon dioxide (SCCD), freeze-drying, cold atmospheric plasma (CAP), bioprocessing, and encapsulation, are considered to have the potential to replace traditional thermal processing due to better preservation of phytochemicals. Each technique has its advantages and disadvantages, and combined technology might exhibit better outcomes.

The bioaccessibility and bioavailability of phytochemicals is a new hotspot, many researchers have made efforts to review the influencing factors and explore new methods to improve it. However, comprehensive review contains the effects of storage condition, mechanical processing, thermal processing, and non-thermal processing and the potential of emerging encapsulation technology and delivery system to improve the value of phytochemicals is still limited. The synergies between different non-thermal processes are also not clearly understood. This review provides comprehensive information on the action mechanism of non-thermal processing technologies on fruits and vegetables and illustrates cutting edge packaging materials and encapsulation technology, aiming to offer help to future research and development.

Bioaccessibility and bioavailability of phytochemicals in fruits and vegetables

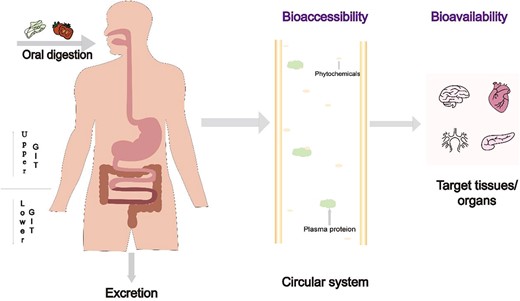

Bioaccessibility refers to the fraction of phytochemicals released from the food matrix that can be readily absorbed (Roasa et al., 2021). Bioavailability, on the other hand, denotes the fraction of phytochemicals absorbed into the bloodstream and utilized or stored by tissues and organs. Dima et al. (2020) consider that bioavailability is crucial for the bioefficiency of food ingredients, linking food to its health effects (Figure 1).

Schematic representation of bioaccessibility and bioavailability of phytochemicals.

The food matrix affects the release of phytochemicals into the gastrointestinal tract. Sensitive phytochemicals can be protected within the food matrix from chemical degradation, but if they are not released at some point during transit, they will remain unbioaccessible (Hu et al., 2023c). Lipids are known to improve the bioaccessibility of phytochemicals by protecting them from degradation, forming mixed micelles, and increasing the permeability of enterocytes (Gu et al., 2020; Yao et al., 2021). Conversely, the presence of proteins, carbohydrates, and minerals may inhibit the bioaccessibility of phytochemicals by preventing their release through non-covalent interactions with the food matrix (Hu et al., 2023c; Shahidi & Pan, 2022).

Food processing plays a significant role in influencing the bioaccessibility of phytochemicals, with the impact depending on the type of processing technologies, the plant species, and processing conditions (e.g., temperature, pH, moisture, enzymes, oxygen, light, time, etc.). Hayes et al. (2021) found that different processing operations have varying effects on the bioaccessibility of spinach genotypes, with juicing resulting in 25.8%–29.3% bioaccessibility, raw consumption in 19.5%–27%, blanching in 14.9%–20.5%, and sterilization in 10.4%–13.0%. Different types of processing technologies and their effects on the bioaccessibility and bioavailability are discussed in the following page 3.2. Food matrix and food processing work together to modify the bioaccessibility and bioavailability of phytochemicals. The content of phytochemicals in raw fruits and vegetables is considerable, but they are unstable and easily degrade during storage and processing. Many polyphenols, especially anthocyanins (AC), are sensitive to heat and may be oxidized to a chalcone structure, reducing their bioaccessibility (Oancea, 2021; Yuan et al., 2022). The bioavailability of AC is determined by factors such as their interaction with the food matrix, biological metabolism by the intestine, liver, and microbiota, and processing (Di Lorenzo et al., 2021). Dietary phytochemicals need to be released from the food matrix during small intestine digestion or colon microbiota metabolism to be available (Ribas-Agustí et al., 2018). Therefore, some studies have shown that the bioaccessibility of AC can increase after thermal treatment due to the rupture of the cytoderm and release from the food matrix (Linhares et al., 2020).

Phytochemicals in fruits and vegetables are unstable and sensitive, so factors such as temperature, pH, enzyme activity, oxygen, light, metal ions, and macromolecules during processing and storage greatly affect their properties. For instance, high temperatures can influence maturity, sugar content, acidity, and the stability of polyphenols, while light is essential for anthocyanin formation (Zhang et al., 2022). Post-harvest loss is a major issue in tomato production, but coating tomatoes with 50% cactus mucilage can improve their quality and shelf life (Tolasa et al., 2021). Tropical fruits are more susceptible to degradation than temperate fruits, but methods like US equipped with controlled atmospheric storage can maintain the overall quality and reduce water redistribution in cucumbers (Indiarto et al., 2020).

Impact of different storage conditions

Fruits and vegetables are perishable and sensitive to temperature, which makes storage and cross-regional transportation crucial. External environmental factors such as temperature, pH, light, and moisture greatly impact phytochemicals (Table 1). Fresh crops are living products and are therefore prone to biological deterioration caused by respiration, mechanical injuries, ethylene production, and water stress. Bernstad et al. (2017) reported that many fruits and vegetables are wasted annually due to poor storage and transportation conditions, especially in Sub-Saharan Africa.

| Fruit/vegetable . | Influence factor . | Storage condition . | Impact . | Reference . |

|---|---|---|---|---|

| Strawberry | Temperature | Storage at 8 °C | Catechin and rutin content has slight increase | Baldwin et al. (2023) |

| Watermelon juice | Temperature | Storage at room temperature, refrigerator cold, refrigerator freeze, freeze-dried respectively | Storage at room temperature cause the most reduction of TPC and TFC, refrigerator freeze and freeze-dried respectively cause most retention of TC and TF | Mohamad Salin et al. (2022) |

| Okra | Moisture/temperature | Storage for 0, 2, 4, 6 months after drying/freezing | Drying/freezing cause less decrease in total phenolic content than no treatment | Rababah et al. (2023) |

| Blood orange | Temperature | Storage at 9 °C | Anthocyanin content increased | Carmona et al. (2021) |

| Blood orange | Moisture and temperature | Curing plus storage at 9 °C | Flavonoid content increased | Carmona et al. (2021) |

| Tomato | Light | 6 days of white and red: far-red LEDs treatment at fluence rate of 476 Wm−2 at 23 °C | Red: far-red LEDs increased the concentration of lycopene compared to white LED light | Nájera et al. (2018) |

| Sweet berry | Light | 10 days for blue (450 nm) LEDs treatment | The content of anthocyanins (cyaniding 3-O-glucoside, cyanidin 3-O-rutinoside) increased | Kokalj et al. (2019) |

| Sweet berry | Ultraviolet | 10 days for UV-B (310 nm) treatment | No significant influence | Kokalj et al. (2019) |

| Carrot juice | pH | Adjusted the pH and storage for 4 days at 4 °C | Content of carotenoid increased at slightly basic conditions | Bell et al. (2016) |

| Fruit/vegetable . | Influence factor . | Storage condition . | Impact . | Reference . |

|---|---|---|---|---|

| Strawberry | Temperature | Storage at 8 °C | Catechin and rutin content has slight increase | Baldwin et al. (2023) |

| Watermelon juice | Temperature | Storage at room temperature, refrigerator cold, refrigerator freeze, freeze-dried respectively | Storage at room temperature cause the most reduction of TPC and TFC, refrigerator freeze and freeze-dried respectively cause most retention of TC and TF | Mohamad Salin et al. (2022) |

| Okra | Moisture/temperature | Storage for 0, 2, 4, 6 months after drying/freezing | Drying/freezing cause less decrease in total phenolic content than no treatment | Rababah et al. (2023) |

| Blood orange | Temperature | Storage at 9 °C | Anthocyanin content increased | Carmona et al. (2021) |

| Blood orange | Moisture and temperature | Curing plus storage at 9 °C | Flavonoid content increased | Carmona et al. (2021) |

| Tomato | Light | 6 days of white and red: far-red LEDs treatment at fluence rate of 476 Wm−2 at 23 °C | Red: far-red LEDs increased the concentration of lycopene compared to white LED light | Nájera et al. (2018) |

| Sweet berry | Light | 10 days for blue (450 nm) LEDs treatment | The content of anthocyanins (cyaniding 3-O-glucoside, cyanidin 3-O-rutinoside) increased | Kokalj et al. (2019) |

| Sweet berry | Ultraviolet | 10 days for UV-B (310 nm) treatment | No significant influence | Kokalj et al. (2019) |

| Carrot juice | pH | Adjusted the pH and storage for 4 days at 4 °C | Content of carotenoid increased at slightly basic conditions | Bell et al. (2016) |

Note. LED = light-emitting diode; UV = ultraviolet.

| Fruit/vegetable . | Influence factor . | Storage condition . | Impact . | Reference . |

|---|---|---|---|---|

| Strawberry | Temperature | Storage at 8 °C | Catechin and rutin content has slight increase | Baldwin et al. (2023) |

| Watermelon juice | Temperature | Storage at room temperature, refrigerator cold, refrigerator freeze, freeze-dried respectively | Storage at room temperature cause the most reduction of TPC and TFC, refrigerator freeze and freeze-dried respectively cause most retention of TC and TF | Mohamad Salin et al. (2022) |

| Okra | Moisture/temperature | Storage for 0, 2, 4, 6 months after drying/freezing | Drying/freezing cause less decrease in total phenolic content than no treatment | Rababah et al. (2023) |

| Blood orange | Temperature | Storage at 9 °C | Anthocyanin content increased | Carmona et al. (2021) |

| Blood orange | Moisture and temperature | Curing plus storage at 9 °C | Flavonoid content increased | Carmona et al. (2021) |

| Tomato | Light | 6 days of white and red: far-red LEDs treatment at fluence rate of 476 Wm−2 at 23 °C | Red: far-red LEDs increased the concentration of lycopene compared to white LED light | Nájera et al. (2018) |

| Sweet berry | Light | 10 days for blue (450 nm) LEDs treatment | The content of anthocyanins (cyaniding 3-O-glucoside, cyanidin 3-O-rutinoside) increased | Kokalj et al. (2019) |

| Sweet berry | Ultraviolet | 10 days for UV-B (310 nm) treatment | No significant influence | Kokalj et al. (2019) |

| Carrot juice | pH | Adjusted the pH and storage for 4 days at 4 °C | Content of carotenoid increased at slightly basic conditions | Bell et al. (2016) |

| Fruit/vegetable . | Influence factor . | Storage condition . | Impact . | Reference . |

|---|---|---|---|---|

| Strawberry | Temperature | Storage at 8 °C | Catechin and rutin content has slight increase | Baldwin et al. (2023) |

| Watermelon juice | Temperature | Storage at room temperature, refrigerator cold, refrigerator freeze, freeze-dried respectively | Storage at room temperature cause the most reduction of TPC and TFC, refrigerator freeze and freeze-dried respectively cause most retention of TC and TF | Mohamad Salin et al. (2022) |

| Okra | Moisture/temperature | Storage for 0, 2, 4, 6 months after drying/freezing | Drying/freezing cause less decrease in total phenolic content than no treatment | Rababah et al. (2023) |

| Blood orange | Temperature | Storage at 9 °C | Anthocyanin content increased | Carmona et al. (2021) |

| Blood orange | Moisture and temperature | Curing plus storage at 9 °C | Flavonoid content increased | Carmona et al. (2021) |

| Tomato | Light | 6 days of white and red: far-red LEDs treatment at fluence rate of 476 Wm−2 at 23 °C | Red: far-red LEDs increased the concentration of lycopene compared to white LED light | Nájera et al. (2018) |

| Sweet berry | Light | 10 days for blue (450 nm) LEDs treatment | The content of anthocyanins (cyaniding 3-O-glucoside, cyanidin 3-O-rutinoside) increased | Kokalj et al. (2019) |

| Sweet berry | Ultraviolet | 10 days for UV-B (310 nm) treatment | No significant influence | Kokalj et al. (2019) |

| Carrot juice | pH | Adjusted the pH and storage for 4 days at 4 °C | Content of carotenoid increased at slightly basic conditions | Bell et al. (2016) |

Note. LED = light-emitting diode; UV = ultraviolet.

Cold storage is the primary method for preventing the browning of fruits and vegetables during storage. It can significantly prolong the shelf life of cabbage, carrots, tomatoes, peppers, and spinach (Makule et al., 2022). Pretreatment methods like precooling can further enhance the freshness and nutritional value of fruits and vegetables, while post-harvest treatments like packaging film and oil applications can significantly reduce water loss and are widely used in the food industry (Chen et al., 2024b). Anthocyanins can be enriched through post-harvest cold storage. A study showed that cured Moro and Sanguinelli Polidori blood oranges contained 191.4 ± 1.4 mg/L of AC in their juice after cold storage, compared to 85.7 ± 3.3 mg/L in fruits after cold storage alone (Carmona et al., 2021). Leng et al. (2020) proposed a cold-chain-based low-carbon location-routing-problem optimization model to optimize transportation. Governments and researchers should integrate cold-chain systems with the Internet of Things and artificial intelligence technology, and promote development towards intelligence, standardization, and technology (Bai et al., 2023).

Ultraviolet (UV) irradiation has been applied in fruits and vegetables postharvest to reduce decay, delay ripening and senescence. UV radiation comprises a small portion of total solar radiation, which can be divided into UV-C (100–280 nm), UV-B (280–315 nm), and UV-A (315–400 nm). The parameters effect the outcomes of UV treatments including wavelengths, dose, intensity, and the properties of food products. UV radiation induces oxidative stress and damage to plant tissue, which exhibits capacity to disrupt membrane, protein, and DNA (Ali et al., 2023). Although UV is often considered deleterious, the elicitation of secondary antioxidant metabolites and natural defenses induced by UV in plants can trigger a range of positive activities (Darré et al., 2022). Rabelo et al. (2020) reported that acerola stored at 10 °C for 7 days after hermetic ultraviolet-C light (UV-C irradiation showed significantly less degradation of vitamin C and phenolic compounds than the control without the UV-C challenge, attributed to the alteration of ascorbic acid and phenolic metabolism through increased mitochondrial activity and a ROS-mediated mechanism. UV radiation employes the energy of UV to kill the microorganisms and pests on food surface, prolong the shelf life of products without additives use. UV-C irradiation affected the expression of ripening related genes in bell pepper fruit, kept its hardness and sensory properties, and contributed to the accumulation of secondary metabolites including flavone and flavonol (Ma et al., 2021). Two main types of signaling pathways have been proposed regarding how plants perceive UV radiation and regulate secondary metabolism of plants (Jacobo-Velázquez et al., 2022). For instance, UV induces and regulates phenolic compounds synthesis and deposition in the outer epidermal layers and produces antioxidant systems. UV treated food products have no radiation residue and less pollution, which is in line with the principles of food safety and sustainable development.

Impact of processing

The products of fruits and vegetables may undergo various operations during manufacturing, which can impact the quality of phytochemicals. Traditional processing methods include mechanical processes (such as washing, sifting, cutting, extrusion, and milling), thermal processes (such as blanching, drying, baking, sterilization, and pasteurization), and non-thermal processes (such as freeze-drying, irradiation processing, high-pressure processing, homogenization, and fermentation) (Domínguez-Fernández et al., 2021; Kaimal et al., 2021). Phytochemicals are easily degraded and can react with other components during processing, which may inhibit their health effects. Different unit operations can be combined and assisted by technologies like US or vacuum to improve the bioactivity of phytochemicals in fruits and vegetables.

Mechanical processes

Mechanical processes are commonly used in the processing of fruits and vegetables to reduce sizes and alter the form of products. However, these processes might disrupt the structural integrity of phytochemicals and remove some beneficial ingredients (Table 2).

| Fruit/vegetable . | Operation . | Impact on phytochemicals . | Reference . |

|---|---|---|---|

| Carrot | Shredding (wounding stress) | Content of free and bound phenolics increased | Viacava et al. (2020) |

| Carrot | Extrusion (moisture content of ~9%) | Content of free and bound phenolics increased | Viacava et al. (2020) |

| Olive | Washing (normal water) | Content of phenolics decreased | Ceylan et al. (2023) |

| Olive | Washing with hydrogen-rich water | Content of phenolics increased | Ceylan et al. (2023) |

| Onion skin | Extrusion | Quercetin content and in vitro bioaccessibility increased due to its strengthened cellular matrix | Tonyali et al. (2020) |

| Tomato | Spiral-filter press | Better prevention of ascorbic acid, phenolics, and carotenoids | Kips et al. (2017) |

| Fruit/vegetable . | Operation . | Impact on phytochemicals . | Reference . |

|---|---|---|---|

| Carrot | Shredding (wounding stress) | Content of free and bound phenolics increased | Viacava et al. (2020) |

| Carrot | Extrusion (moisture content of ~9%) | Content of free and bound phenolics increased | Viacava et al. (2020) |

| Olive | Washing (normal water) | Content of phenolics decreased | Ceylan et al. (2023) |

| Olive | Washing with hydrogen-rich water | Content of phenolics increased | Ceylan et al. (2023) |

| Onion skin | Extrusion | Quercetin content and in vitro bioaccessibility increased due to its strengthened cellular matrix | Tonyali et al. (2020) |

| Tomato | Spiral-filter press | Better prevention of ascorbic acid, phenolics, and carotenoids | Kips et al. (2017) |

| Fruit/vegetable . | Operation . | Impact on phytochemicals . | Reference . |

|---|---|---|---|

| Carrot | Shredding (wounding stress) | Content of free and bound phenolics increased | Viacava et al. (2020) |

| Carrot | Extrusion (moisture content of ~9%) | Content of free and bound phenolics increased | Viacava et al. (2020) |

| Olive | Washing (normal water) | Content of phenolics decreased | Ceylan et al. (2023) |

| Olive | Washing with hydrogen-rich water | Content of phenolics increased | Ceylan et al. (2023) |

| Onion skin | Extrusion | Quercetin content and in vitro bioaccessibility increased due to its strengthened cellular matrix | Tonyali et al. (2020) |

| Tomato | Spiral-filter press | Better prevention of ascorbic acid, phenolics, and carotenoids | Kips et al. (2017) |

| Fruit/vegetable . | Operation . | Impact on phytochemicals . | Reference . |

|---|---|---|---|

| Carrot | Shredding (wounding stress) | Content of free and bound phenolics increased | Viacava et al. (2020) |

| Carrot | Extrusion (moisture content of ~9%) | Content of free and bound phenolics increased | Viacava et al. (2020) |

| Olive | Washing (normal water) | Content of phenolics decreased | Ceylan et al. (2023) |

| Olive | Washing with hydrogen-rich water | Content of phenolics increased | Ceylan et al. (2023) |

| Onion skin | Extrusion | Quercetin content and in vitro bioaccessibility increased due to its strengthened cellular matrix | Tonyali et al. (2020) |

| Tomato | Spiral-filter press | Better prevention of ascorbic acid, phenolics, and carotenoids | Kips et al. (2017) |

By-products such as press cakes, peels, and leaves are often considered to have low commercial value and to negatively impact organoleptic quality, and therefore they are removed during pressing, peeling, and washing. For example, ~18%–21% of pumpkin fruit is discarded in the form of peel or seeds, while pumpkin peel is a source of carotenoids, phenolic compounds, and minerals (Lima et al., 2019). After the production of blackberry juice, the press cakes are usually discarded, even though they have been confirmed to be concentrated sources of dietary fiber and polyphenols (Kosmala et al., 2017). The pomace produced after juicing is perishable, but it has strong potential as a functional additive if processed properly, which can replace artificial food additives to reduce the incidence of diseases of affluence or cancer and relieve pollution (Cardinali et al., 2024; Majerska et al., 2019). Balli et al. (2021) used 7% of dried grape pomace and olive pomace to fortify Italian pasta, which helped preserve polyphenols and increased fiber content by 3%.

Extrusion cooking is widely used in food processing and consists of several unit processes that can physically modify various food matrices (Mironeasa et al., 2023). The advantages of extrusion cooking include manufacturing products with taste, texture, size, and shape favored by consumers and transforming raw ingredients into ready-to-eat products efficiently and continuously (Singh et al., 2019). Cold extrusion is used on-the-farm or by rural cooperatives due to its simple and low-cost mechanical machinery (Vidal et al., 2023). The impact of extrusion processing on phenolic compounds and fiber depends on processing conditions such as temperature, moisture, the type of food matrix components, and their chemical structure. For example, the content of total phenols, total flavonoids, and insoluble dietary fiber in spinach decreases after extrusion, while soluble dietary fiber increases. The higher the temperature, the greater the reduction of phenols and flavonoids (Al-Subhi, 2020).

Thermal processes

Thermal treatments on fruits and vegetables can damage cell walls and interact with the food matrix, making phytochemicals more accessible for absorption and inactivating enzymes. However, they can also accelerate the degradation of phytochemicals, which can have varying effects on their bioaccessibility (Table 3). Traditional thermal processing is the most used method in manufacturing and preservation, including blanching, steaming, cooking, roasting, pasteurization, sterilization, and microwaving. Different processing technologies may have different effects on phytochemical accessibility. The research of Martini et al. (2021) showed after digestion, 45%, 33%, 22% of total phenols in dark purple eggplant are bioaccessible after baking, grilling, and frying respectively. Blanching, widely used for its commercial advantages, typically involves heat transfer by hot air or water (Nayak et al., 2015) and has been confirmed to better maintain anthocyanin content than other processing methods. Pasteurization is a conventional method for commercial preservation (DeBenedictis et al., 2023). It uses high temperatures to destroy active viruses and inactivate spoilage enzymes to prolong shelf life and is widely used in dairy, fruit, and vegetable processing (Juncker et al., 2021; Pitino et al., 2021). Pasteurization causes both increases and decreases in phytochemicals, depending on processing conditions, the food matrix, and the properties of the fruits and vegetables. The content of flavonoids (AC and flavanones) increased by 11% after thermal pasteurization, while high hydrostatic pressure caused a reduction in flavonoid content (Salar et al., 2021). In another study, the content of AC in clery strawberries reduced significantly after pasteurization (85 °C, 3 min) (Garzoli et al., 2020). Using combined technologies such as irradiation + heat, pressure + heat, electroporation + heat, and microwave + heat can replace conventional thermal sterilization and compensate for its shortcomings (Soni & Brightwell, 2022). The vacuum impregnation technique helps to incorporate microorganisms into the porous structure of apples, under which conditions the total phenol and total flavonoid release to the gastrointestinal tract doubled and have the best biological activity (Burca-Busaga et al., 2021). Thermal processes always improve the sensory properties of food products due to softening effects and the releases of aromatic compounds. However, according to Bao et al. (2023), thermosonication sterilization keeps high level of nutrients of black carrot juice, however, causes sensory deterioration.

| Fruit/vegetable . | Type of thermal processing . | Impact on phytochemical . | Reference . |

|---|---|---|---|

| Sweet potato root | Cooking | Bioaccessibility of phenolics, flavonoids, carotenoids, and anthocyanins increased, bioaccessibility of vitamin C decreased | Amagloh et al. (2023) |

| Tatsoi | Steaming | The total polyphenols content increased while the content of vitamin C decreased | Yang et al. (2019b) |

| Jute mallow | Blanching at 92 °C for 2 min | 98% of carotenoids lost | Traoré et al. (2017) |

| Black eggplant | Grilling | Bioaccessibility of phenolic compounds increased (217.4%) | Martini et al. (2021) |

| Black eggplant | Frying | The content of phenolic compounds increased but the bioaccessibility decreased (66.2%) | Martini et al. (2021) |

| Cloudy apple juice | High-temperature short time sterilization | The content of ascorbic acid decreased | Deng et al. (2021) |

| Citrus-Maqui Beverage | Pasteurization (85 °C) | The content of anthocyanins and flavanones increased than non-treatment, while vitamin C content decreased | Salar et al. (2024) |

| Fruit/vegetable . | Type of thermal processing . | Impact on phytochemical . | Reference . |

|---|---|---|---|

| Sweet potato root | Cooking | Bioaccessibility of phenolics, flavonoids, carotenoids, and anthocyanins increased, bioaccessibility of vitamin C decreased | Amagloh et al. (2023) |

| Tatsoi | Steaming | The total polyphenols content increased while the content of vitamin C decreased | Yang et al. (2019b) |

| Jute mallow | Blanching at 92 °C for 2 min | 98% of carotenoids lost | Traoré et al. (2017) |

| Black eggplant | Grilling | Bioaccessibility of phenolic compounds increased (217.4%) | Martini et al. (2021) |

| Black eggplant | Frying | The content of phenolic compounds increased but the bioaccessibility decreased (66.2%) | Martini et al. (2021) |

| Cloudy apple juice | High-temperature short time sterilization | The content of ascorbic acid decreased | Deng et al. (2021) |

| Citrus-Maqui Beverage | Pasteurization (85 °C) | The content of anthocyanins and flavanones increased than non-treatment, while vitamin C content decreased | Salar et al. (2024) |

| Fruit/vegetable . | Type of thermal processing . | Impact on phytochemical . | Reference . |

|---|---|---|---|

| Sweet potato root | Cooking | Bioaccessibility of phenolics, flavonoids, carotenoids, and anthocyanins increased, bioaccessibility of vitamin C decreased | Amagloh et al. (2023) |

| Tatsoi | Steaming | The total polyphenols content increased while the content of vitamin C decreased | Yang et al. (2019b) |

| Jute mallow | Blanching at 92 °C for 2 min | 98% of carotenoids lost | Traoré et al. (2017) |

| Black eggplant | Grilling | Bioaccessibility of phenolic compounds increased (217.4%) | Martini et al. (2021) |

| Black eggplant | Frying | The content of phenolic compounds increased but the bioaccessibility decreased (66.2%) | Martini et al. (2021) |

| Cloudy apple juice | High-temperature short time sterilization | The content of ascorbic acid decreased | Deng et al. (2021) |

| Citrus-Maqui Beverage | Pasteurization (85 °C) | The content of anthocyanins and flavanones increased than non-treatment, while vitamin C content decreased | Salar et al. (2024) |

| Fruit/vegetable . | Type of thermal processing . | Impact on phytochemical . | Reference . |

|---|---|---|---|

| Sweet potato root | Cooking | Bioaccessibility of phenolics, flavonoids, carotenoids, and anthocyanins increased, bioaccessibility of vitamin C decreased | Amagloh et al. (2023) |

| Tatsoi | Steaming | The total polyphenols content increased while the content of vitamin C decreased | Yang et al. (2019b) |

| Jute mallow | Blanching at 92 °C for 2 min | 98% of carotenoids lost | Traoré et al. (2017) |

| Black eggplant | Grilling | Bioaccessibility of phenolic compounds increased (217.4%) | Martini et al. (2021) |

| Black eggplant | Frying | The content of phenolic compounds increased but the bioaccessibility decreased (66.2%) | Martini et al. (2021) |

| Cloudy apple juice | High-temperature short time sterilization | The content of ascorbic acid decreased | Deng et al. (2021) |

| Citrus-Maqui Beverage | Pasteurization (85 °C) | The content of anthocyanins and flavanones increased than non-treatment, while vitamin C content decreased | Salar et al. (2024) |

Non-thermal processes

Traditional thermal treatments induce reduction in the bioaccessibility of phytochemicals, for which non-thermal methods may be promising alternatives to thermal processing. A survey conducted among food experts on the use of novel non-thermal technologies shows that more than 70% of respondents believe these new non-thermal processes can bring better sensory properties (Khouryieh, 2021). Novel non-thermal technologies can retain nutrient properties (especially polyphenols), reduce environmental damage, and improve energy efficiency to the maximum (Khan et al., 2018).

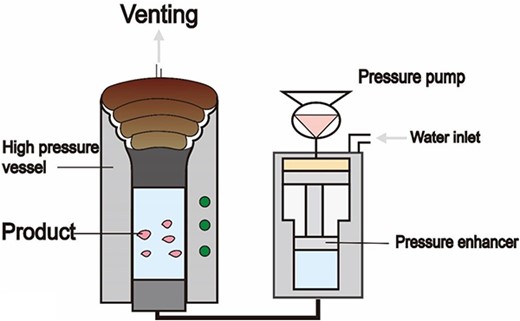

High-pressure processing

High-pressure processing (HPP) is a widely used preservation technology that employs water to transmit pressure from 100 to 800 MPa to food, which can inactivate enzyme activities (Barba et al., 2017). HPP is a type of cold pasteurization technology that introduces products into a vessel and exerts high hydrostatic pressure, which induces less thermal degradation during processing (Houška et al., 2022). However, HPP does not inactivate most microbial spores, so high-pressure processing may be combined with heat, known as high-pressure thermal processing (HPTP). HPP affects the cell wall and structural integrity of plant materials. For example, the tissue integrity of red cabbage is lost, and tissue damage is mostly observed under pressures above 150 MPa (Dhenge et al., 2023; Rux et al., 2020). Treating smoothies made from strawberry, banana, and apple with HPP (450, 600 MPa) altered the structure of cell, induced phytochemical release, and micelle formation, increased the bioaccessibility of lutein, zeaxanthin, and vitamin E (Donda Zbinden et al., 2024). The effects of HPP on phytochemical bioaccessibility can vary depending on the characteristics of the plants and the pressure, temperature, and time applied (Denoya et al., 2021). For instance, the total polyphenol content of fresh pineapple samples was 53.9 mg/g, and after different high-pressure processing treatments, it ranged from 53.77–61.03 mg/g (100–300 MPa, 5–20 min). The total polyphenols in HPP-treated pineapple samples only slightly reduced after storage for 16 days, which might prolong the shelf life (Kundukulangara Pulissery et al., 2021). However, HPP can also have negative impacts on phytochemicals in fruit products. For example, the total flavonoid content in honeydew melon juice decreased after high-pressure processing (Figure 2).

Schematic representation of high-pressure processing equipment.

HPP also exhibits its benefits on improving the sensory properties of juices, which loved by consumers despite its relatively higher prices. And cold storage can further improve its sensory properties (Song et al., 2023).

High-pressure homogenization

High-pressure homogenization (HPH) is a novel nonthermal, green, and easily scalable cell disruption technique that applies pressure from 50 to 600 MPa to raw materials. This process can reduce particle size, disperse material uniformly, and improve sample stability (Liu et al., 2020; Zheng et al., 2024). High-pressure homogenization can recover bioactive compounds from fruit and vegetable residues and has the potential to replace conventional solid/liquid extraction due to its shorter processing time, solvent-free operation, and higher yield of phenol extraction (Pirozzi & Donsì, 2023). The effect of HPH on the bioaccessibility of phytochemicals in fruits and vegetables has attracted attention from researchers. Hu et al. (2023a) investigated the effects of HPH on carotenoids, the result showed that HPH at 100 MPa increased the bioaccessibility of carotenoids in mango juice by 44.33%, and further HPP treatment (400 MPa, pretreated by 100 MPa HPH) significantly increased the bioaccessibility of carotenoids by 71.37%. The total polyphenol content and total flavonoid content of sumac PlantCrystals increased by 30% and nearly 2 times, respectively (Abraham et al., 2021). However, HPH treatment may also have adverse effects on phytochemicals. According to He et al. (2016), after high-pressure homogenization (250 MPa, 10 min), the content of hesperidin, phlorizin, and epigallocatechin gallate in apple juice, rutinoside in orange juice, and epicatechin in grape juice decreased. Therefore, it is important to control the conditions (pressure, time, temperature, pretreatment) during HPH processing.

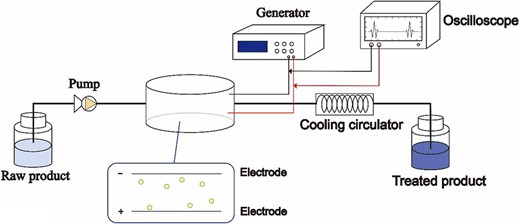

Pulsed electric field

Pulsed electric field (PEF) processing applies electric pulses to products to alter the structure of macromolecules and inactive enzymes and microorganisms. PEF treatments utilize electroporation phenomenon to disrupt the cell walls of microbes to preserve perishable foods. During processing, products are put between two electrical electrodes and exerted pulsed voltage ranging from 0.1 to 80 kV/cm through a continuous chamber. Common parameters of PEF including pulse duration, electric field strength, pulse duration, electric density, pulse shape, ionic strength, and conductivity (Rostamabadi et al., 2023). PEF is known for its shorter duration, lower energy inputs, better retention of phytochemicals, lower harmful gases emission and relatively low cost (Bocker & Silva, 2024). Nevertheless, the fabrication and commercial application of large-scale PEF equipment in food industry is limited by quite high investment (Figure 3).

PEF treatment exhibits excellent potential to improve the bioaccessibility of plant-based foods. PEF facilitates the release of carotenoids and phenols from the food matrix during digestion, thereby increasing the bioaccessibility of total carotenoids by threefold, and even reaching 100% bioaccessibility after treatments (López-Gámez et al., 2021). PEF processing produces less heat than thermal processing, which can reduce the degradation of heat-sensitive phytochemicals. PEF treatment increased the content of bioaccessible 5-caffeoylquinic acid by 61% and bioaccessible total phenolic content by 26% in apple (Ribas-Agustí et al., 2019). For instance, the quercetin content in PEF-treated raspberry and blueberry puree was significantly higher than in raw materials (Medina-Meza et al., 2016). PEF exhibited the most significant improvement in the content of AC and other polyphenols in a strawberry-kale mix, whereas strawberry phytochemicals showed the highest bioaccessibility after HPP (Stübler et al., 2020). Furthermore, PEF has been applied in reduction of toxins, macromolecules modification, and debittering in cutting-edge research (Giancaterino et al., 2023; Yudhistira et al., 2024).

Ultrasound

US is a novel non-thermal technology that has shown significantly beneficial effects on fruits and vegetables (Gao et al., 2020). The power of US produces cavitation bubbles and disrupts membranes. US technology is also widely used in the cleaning of fruits and vegetables, known as ‘brushless cleaning,’ which can remove surface dirt while reducing severe damage to fruits and vegetables (Zhou et al., 2022). Dual-frequency US washing efficiently decreased surface bacteria on freshly cut cauliflower and prolonged its shelf life (Zhang et al., 2022). According to Traore et al. (2020), the content of phenol and flavonoid increased after US treatment for only 8 min (total phenol from 3.2–4.3 mM, 2.8–3.31 mM, respectively in the green part and white part of cabbage). In the same study, when US was combined with 1.5 mg/L ozone (20 min), the ability to inactivate microorganisms improved, while the content of polyphenols decreased significantly. US treatment is often combined with other traditional unit processes such as extraction and sterilization. US-assisted extraction leads to the disruption of cavitation bubbles at the substrate matrix surface, and with US power from 200 to 320 W, the yield of AC significantly increased (Kaur et al., 2023). Beetroot juice after thermosonication showed higher content of vitamin C, B1, B2, and polyphenols (Ramírez-Melo et al., 2022). US technology is also important in the beverage industry, food stabilization, and other applications to improve the bio-functional properties of food (Table 4) (Sharma et al., 2021; Yusoff et al., 2022).

Effects of high-pressure processing, pressure homogenization, pulsed electric field, ultraviolet, and ultrasound on phytochemicals.

| Fruit/vegetable . | Operation . | Impact on phytochemical . | Reference . |

|---|---|---|---|

| Mango juice | HPH100 + HPP400 or HPH100 + HPP500 | Significant reduction in total carotenoids content (<10%) | Hu et al. (2023a) |

| Mango juice | HPH (100 MPa) | The bioaccessibility of carotenoids improved | Hu et al. (2023a) |

| Tomato juice | HPH | Both the bioaccessibility of lycopene and carotenoid increased | Zhang et al. (2019) |

| Spinach | HPP (200, 400, 600 MPa; 5, 10 min; room temperature) | The content of carotenoids increased but had not obvious influence on bioaccessibility | Westphal et al. (2018) |

| Tomato juice | PEF | The carotenoids content slightly increased, but the bioaccessibility decreased | Zhong et al. (2019) |

| Guava juice | Ultraviolet | The lycopene content decreased but in vitro bioaccessibility increased | Campoli et al. (2018) |

| Java plum pomace | Ultrasound (366.25 w, 37.61 °C, 47–48 min) | The content of monomeric anthocyanins, total phenols, total flavonoids increased | Kaur et al. (2023) |

| Fruit/vegetable . | Operation . | Impact on phytochemical . | Reference . |

|---|---|---|---|

| Mango juice | HPH100 + HPP400 or HPH100 + HPP500 | Significant reduction in total carotenoids content (<10%) | Hu et al. (2023a) |

| Mango juice | HPH (100 MPa) | The bioaccessibility of carotenoids improved | Hu et al. (2023a) |

| Tomato juice | HPH | Both the bioaccessibility of lycopene and carotenoid increased | Zhang et al. (2019) |

| Spinach | HPP (200, 400, 600 MPa; 5, 10 min; room temperature) | The content of carotenoids increased but had not obvious influence on bioaccessibility | Westphal et al. (2018) |

| Tomato juice | PEF | The carotenoids content slightly increased, but the bioaccessibility decreased | Zhong et al. (2019) |

| Guava juice | Ultraviolet | The lycopene content decreased but in vitro bioaccessibility increased | Campoli et al. (2018) |

| Java plum pomace | Ultrasound (366.25 w, 37.61 °C, 47–48 min) | The content of monomeric anthocyanins, total phenols, total flavonoids increased | Kaur et al. (2023) |

Note. HPP = high-pressure processing; HPH = high-pressure homogenization; PEF = pulsed electric field.

Effects of high-pressure processing, pressure homogenization, pulsed electric field, ultraviolet, and ultrasound on phytochemicals.

| Fruit/vegetable . | Operation . | Impact on phytochemical . | Reference . |

|---|---|---|---|

| Mango juice | HPH100 + HPP400 or HPH100 + HPP500 | Significant reduction in total carotenoids content (<10%) | Hu et al. (2023a) |

| Mango juice | HPH (100 MPa) | The bioaccessibility of carotenoids improved | Hu et al. (2023a) |

| Tomato juice | HPH | Both the bioaccessibility of lycopene and carotenoid increased | Zhang et al. (2019) |

| Spinach | HPP (200, 400, 600 MPa; 5, 10 min; room temperature) | The content of carotenoids increased but had not obvious influence on bioaccessibility | Westphal et al. (2018) |

| Tomato juice | PEF | The carotenoids content slightly increased, but the bioaccessibility decreased | Zhong et al. (2019) |

| Guava juice | Ultraviolet | The lycopene content decreased but in vitro bioaccessibility increased | Campoli et al. (2018) |

| Java plum pomace | Ultrasound (366.25 w, 37.61 °C, 47–48 min) | The content of monomeric anthocyanins, total phenols, total flavonoids increased | Kaur et al. (2023) |

| Fruit/vegetable . | Operation . | Impact on phytochemical . | Reference . |

|---|---|---|---|

| Mango juice | HPH100 + HPP400 or HPH100 + HPP500 | Significant reduction in total carotenoids content (<10%) | Hu et al. (2023a) |

| Mango juice | HPH (100 MPa) | The bioaccessibility of carotenoids improved | Hu et al. (2023a) |

| Tomato juice | HPH | Both the bioaccessibility of lycopene and carotenoid increased | Zhang et al. (2019) |

| Spinach | HPP (200, 400, 600 MPa; 5, 10 min; room temperature) | The content of carotenoids increased but had not obvious influence on bioaccessibility | Westphal et al. (2018) |

| Tomato juice | PEF | The carotenoids content slightly increased, but the bioaccessibility decreased | Zhong et al. (2019) |

| Guava juice | Ultraviolet | The lycopene content decreased but in vitro bioaccessibility increased | Campoli et al. (2018) |

| Java plum pomace | Ultrasound (366.25 w, 37.61 °C, 47–48 min) | The content of monomeric anthocyanins, total phenols, total flavonoids increased | Kaur et al. (2023) |

Note. HPP = high-pressure processing; HPH = high-pressure homogenization; PEF = pulsed electric field.

Supercritical carbon dioxide

SCCD treatment is a novel non-thermal technology considered to be non-toxic, inexpensive, readily available, non-flammable, environmentally friendly, and safe. It is widely used in fruit and vegetable juice processing. SCCD is used to inactivate microorganisms and enzyme activities, protect nutrient compounds, improve sensory quality, inhibit browning, and prolong shelf life (Silva et al., 2019; Chen et al., 2024a). Trych et al. (2022) used SCCD to treat blackcurrant juice (10, 30, 60 MPa, 45 °C, 10 min), and the results showed that the stability and antioxidant ability of vitamin C and AC improved before in vitro digestion, and this mild thermal treatment (45 °C) contributed to the highest vitamin C and AC bioaccessibility. The low viscosity (3–7 × 10−5 Pa s) and zero surface tension of CO2 help it to penetrate quickly (Xue et al., 2016). Compared to other non-thermal processing, SCCD allows lower temperatures than high-intensity US and lower pressure than high hydrostatic pressure, which can inactivate microorganisms and protect phytochemicals from degradation to the maximum (Silva et al., 2020). Furthermore, SCCD contributes to the extraction of phytochemical from fruits and vegetables. Mihalcea et al. (2023) employed SCCD to extract lipophilic and polyphenolic compounds from red grape pomace, yielding abundant and high anti-bacterial antioxidant capacity phenolic acids and carotenoids at 45 MPa and 45 °C treatment, while lower temperature induced less thermal degradation and higher extraction yield.

Freezing drying

Freezing drying (FD) is a non-thermal technology using sublimation method, which is widely used in fruit and vegetable processing to prolong shelf life and create special texture (Ma et al., 2023). The total polyphenols (phenols, flavonoids, and AC) content and antioxidant ability of okra decreased significantly during storage, however, okra treated by FD exhibited better preservation of phytochemical properties (Rababah et al., 2023). Thus, freeze-dried fruits and vegetables are becoming more and more common in the market. Whereas, FD also might exhibit negative effect on phytochemical bioaccessibility of fruits and vegetables. Sęczyk et al. (2022) considered that FD caused lower bioaccessibility of basil phytochemicals compared to conventional convection drying. And the result of a sensory evaluation experiment shows that freezing had negative effects on aroma, taste, and overall acceptability (Nthabiseng et al., 2023).

Cold atmospheric plasma

CAP is a novel technology that combines reactive oxygen and nitrogen species (ROS/RNS), an electric field, and ultraviolet radiation. Distinct from solid, liquid, and gas, plasma is the fourth state of matter, consisting of positive and negative ions created by ionization or atoms and molecules without electrons (Liu et al., 2024). CAP can minimize the change in phytochemical properties during microorganism inactivation, improve food quality, and prolong the shelf life of perishable fruits and vegetables (Yarabbi et al., 2023). Leite et al. (2021) investigated the influence of CAP processing with different frequencies on the phytochemicals of cashew apple juice. The results showed no obvious effect on total polyphenols but increased the bioaccessibility of vitamin C due to interaction with the food matrix. Carrot juice, pre-enriched with 3% sumac and then treated by CAP, contained 34.36 mg/100 ml more polyphenols and 3.49 mg/100 g more carotenoids than control samples (Osmólska et al., 2024). Cold plasma can also be used in phenol extraction and yields more polyphenols than conventional extraction (Mehta et al., 2022).

Bioprocessing

Bioprocessing, represented by fermentation, also including germination and enzyme treatment, is used to improve phytochemical bioaccessibility in the food industry. Fermentation is widely used to prepare and preserve perishable food, making it more digestible, safer microbiologically, and reducing substrate toxicity (Zhang et al., 2022). Microbial fermentation with lactic bacteria (Lactobacillus plantarum) on chayote leaves and pineapple increased the content of total phenols and carotenoids, making the phenols more accessible during gastrointestinal digestion (Managa et al., 2021). Rivera et al. (2023) investigated the effects of solid-state fermentation on MD2 pineapple, which improved the content and antioxidant capacity of phenolics and was considered an effective bioprocess for the release of phenolic compounds. Sun et al. (2023) transformed wheat straw and fresh fruit and vegetable discards into cattle feeds through fungal bioprocessing, demonstrating the potential to achieve more circular food production. Olamiti et al. (2024) investigated the effects of combined fermentation and malting treatment on pearl millet (Agrigreen and Babala) quality and the optimal processing conditions. The results showed that Agrigreen suits 51.74 hr malting and 51.81 hr fermentation while Babala suits 52.39 hr malting and 33.09 hr fermentation. Combined treatment increased the content and antioxidant capacity of total phenolics and inhibited the growth of Gram-positive Staphylococcus aureus.

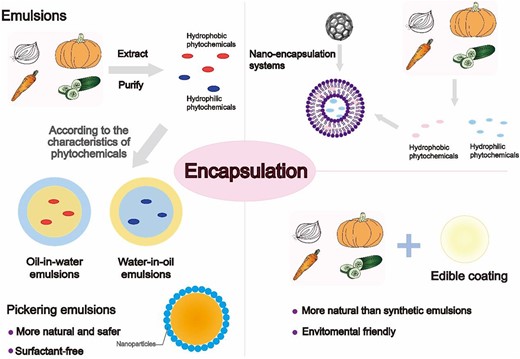

Encapsulation

Encapsulation has become more and more important in food industry due to its significant advantages in increasing the bioavailability of phytochemicals by targeting transport. In addition, it can help phytochemicals to resist environmental stimuli, control the release rate and mask undesirable odors (Nowak et al., 2019).

Emulsions

Emulsions are widely used in the food industry as carriers for phytochemicals due to their ability to encapsulate both hydrophilic and hydrophobic compounds. The interior of the emulsion depends on the characteristics of the phytochemicals (Hu et al., 2023c). Currently, two main types of emulsions are used in the food industry: encapsulation of phytochemicals in delivery systems as functional foods and the consumption of phytochemical-rich foods with excipient foods as part of the daily diet. The former can be further divided into oil-in-water emulsions and water-in-oil emulsions (Liu et al., 2023). The bioavailability of astaxanthin encapsulated in starch-based double emulsion structures prepared with high amylose starch was six times higher than that of unencapsulated astaxanthin (Yang et al., 2021). Encapsulating hydrophobic capsaicin within water-in-oil high internal phase emulsions can control its release, increase bioaccessibility, and reduce the irritation of capsaicin (Wu et al., 2022). Pickering emulsions, a type of surfactant-free emulsion, have been widely used to avoid the potential health risks associated with synthetic surfactants (Hu et al., 2020). These emulsions use solid particles instead of traditional emulsifiers and are widely used to prolong the shelf life and improve the properties of fruits and vegetables (Ngwane et al., 2023). Pickering emulsions improved the properties of sodium alginate composite film, thus maintaining high postharvest quality and long-term bioavailability of mangos (Zhang et al., 2024). With the improvement in quality of life, people are inclined to adopt a healthy lifestyle, such as replacing synthetic food additives with natural extracts. Lycopene, found mainly in tomatoes, has been considered a good choice. According to Li and Yu (2023), combining emulsions with lycopene can enhance its benefits during storage. The combination of black pepper and a canola oil-based emulsion enhanced the bioavailability of carotenoids in raw vegetables in humans, showing a stronger enhancement in females than males (Luo et al., 2022). Yao et al. (2019) investigated the effects of nano-emulsions containing different ratios of medium-chain triglycerides (MCT) and long-chain triglycerides (LCT) on the oral bioavailability of spinach using a simulated gastrointestinal tract. The results showed that as the MCT ratio increased, lutein bioaccessibility increased, whereas β-carotene bioaccessibility decreased due to their different capacities to form micelles. Thus, the content of the lipid phase and the type of oil may also influence the stability and bioaccessibility of phytochemicals (Figure 4).

Nano-encapsulation systems

Organic and inorganic nanoparticles have been applied to enhance the bioavailability of hydrophobic phytochemicals. The rapid development of nanotechnology has made β-lactoglobulin (β-LG), a type of protein, an efficient nanocarrier for delivery, which can enhance the stability and bioavailability of polyphenols (Ren et al., 2022). Salah et al. (2020) used an anti-solvent method to fabricate AC-β-LG nanoparticles, which improved the stability and bioavailability of AC during in vitro digestion. Zhan et al. (2020) investigated the binding mechanism between capsaicin and β-LG, confirming that this complex formation improved the oral bioavailability of capsaicin and reduced the irritation of capsaicin to the gastrointestinal tract. A study based on multi-spectroscopic techniques, molecular docking, and molecular dynamic simulation confirmed that β-LG formed stable formations in nanoform with chlorogenic acid and gallocatechin gallate, which can improve their gastrointestinal stability and accessibility (Ren et al., 2023). Several types of lipid-based nanostructures, like solid lipid nanocarriers, have also been explored to enhance the bioaccessibility of phytochemicals. Both β-carotene and curcumin encapsulated in nanostructured lipid carriers showed better bioaccessibility and antioxidant capacity (Gonçalves et al., 2021; Rohmah et al., 2022). Phytochemicals should be combined with nanostructures properly to ensure their release in the appropriate part of the digestive system. Liposomes can be unstable when environmental conditions change, resulting in the rapid release of encapsulated phytochemicals. The research of Pan et al. (2022) showed that astaxanthin-loaded liposomes coated with whey proteins were more stable under gastrointestinal conditions, which improved the bioaccessibility of astaxanthin. Other plant-based materials also have been applied to fabricate nano particles. Gum Arabic coated nano-nutriosomes exhibited ideal capacity to stabilize cyanidin-3-O-glucoside, controlled its release, and facilitated cellular uptake, which increased the antioxidant activity of cyanidin-3-O-glucoside from 43.64 μg VCE/ml to 50.33 VCE/ml (Xie et al., 2024). Composite coating of postharvest cherry tomatoes with 1% curdlan and 1% chitosan enhanced the antioxidant capacity of lycopene and vitamin C, as well as improved the anti-bacterial ability and sensory properties of it (Yu et al., 2023).

Edible coating

Active film has been widely used in processing to separate antioxidant and antimicrobial compounds from the environment (Dilucia et al., 2020). Edible coatings can also be produced from fruit and vegetable by-products, further reducing waste and pollution (Karimi Sani et al., 2023). Ghafoor et al. (2022) fabricated functional coatings with different ratios of chitosan, olive cake, and orange-peel extracts, which significantly increased the content of phytochemicals during storage. The phenolics and flavonols in sweet berries encapsulated in bioactive coatings after storage for 30 days exhibited better antioxidant capacity than untreated sweet berries, protecting phytochemicals and prolonging shelf life (Asghari et al., 2022). Bassey et al. (2024) applied edible coating pretreatment to improve the infrared drying of red dragon fruit slices, which induced no change in microstructure, protected ascorbic acid from degradation, and improve the color, rehydration, and shrinkage properties of food products. Edible coatings are easier to be accepted by consumers than emulsions because they are more natural and environmentally friendly. The combined application of nano-encapsulation and edible coating has been explored. Hu et al. (2023b) embedded phytochemical-encapsulated nanoparticles in an edible coating on fresh food, which increased the aqueous solubility of trans-resveratrol and bioavailability by 3.5-fold after oral administration. This achieved combined functions of enhancing nutrient delivery and helping preserve perishable fruits and vegetables.

The presence of some coatings may result in changes in sensory characteristics. Vilela et al. (2022) conducted sensory analysis to investigate the influence of coating on food products, in which constant bitter taste and astringent sensation stood out. However, the addition of natural flavors, such as honey, can improve its sensory properties significantly.

Conclusion and future prospects

In conclusion, storage conditions and processing have significant impacts on the bioaccessibility of phytochemicals in fruits and vegetables. Mechanical processing is often used to reduce the size of products but may result in waste, which can be recycled. Thermal processing is commonly used to inactivate microorganisms and enzymes and to soften food. However, high temperatures might induce the degradation of phytochemicals and inhibit their health benefits. Non-thermal processing technologies apply lower temperature and result in better preservation of phytochemicals. Many novel delivery systems, including emulsions, excipient coatings, and nanostructures, have been developed to improve the stability of phytochemicals and to release them at specific tissues and organs. These emerging encapsulation technologies improve the notorious quality of plant-based food to a degree that is impossible with ordinary non-thermal processing.

In recent years, the health benefits of phytochemicals have been recognized and the preference by consumers to natural bioactive agents increased exponentially. Non-thermal processing requires less energy input and produces less pollution, in the line with strategy of sustainable development. Moreover, emerging non-thermal processing technologies including bioprocessing and nano encapsulation exhibit great potential to improve the nutritious value of phytochemicals and improve the sensory profile of products. However, phytochemicals packed in nano particles may generate undesirable flavor due to diffusion of volatile compounds from films to foods, which reduces consumer acceptance. In addition, there is a gap between theory and application, their practical and economic feasibility application is still limited. From this point of view, future reports should pay more attention to the determination of factory feasible parameters of certain non-thermal processing to certain food products and the optimal dosages for the specific application of phytochemicals in different food matrix to closing knowledge gaps. Researchers should strive for more investments, fabricating economically viable, eco-friendly, and profitable large-scale manufacturing.

Author contributions

Hanbing Jia (Writing—original draft, Writing—review & editing, Visualization, Validation, Data curation), Feiyue Ren (Writing—review & editing, Resources, Validation, Project administration), and Hongzhi Liu (Validation, Supervision, Funding acquisition)

Funding

None declared.

Conflicts of interest

There is no conflict of interest.

References