-

PDF

- Split View

-

Views

-

Cite

Cite

Yan Dai, De-hui Chen, Qin Lei, Xiao-li Ren, Chun-hong Li, Jing Zhang, Hai-jun Chang, Effect of rapeseed oil and β-cyclodextrin coatings on the quality of eggs in shell, International Journal of Food Science and Technology, Volume 58, Issue 10, October 2023, Pages 5510–5520, https://doi.org/10.1111/ijfs.16444

Close - Share Icon Share

Abstract

The objective of this research was to investigate and compare the effect of rapeseed oil, 0.5% β-cyclodextrin (β-CD) and rapeseed oil/0.5% β-cyclodextrin coating on egg quality attributes during storage for 28 days at 25 °C. Egg quality attributes such as weight loss (WL), air cell depth and diameter, Haugh unit (HU), albumen pH, yolk index and colour, eggshell strength and morphology were monitored. Similar initial quality attributes of control, rapeseed oil, 0.5% β-CD and rapeseed oil/0.5% β-cyclodextrin-coated eggs were obtained at day 0. Control (uncoated) and β-CD-coated eggs had the worst WL, air cell diameter, air cell depth, albumen pH and a* values after storage for 28 days at 25 °C, while the rapeseed oil/0.5% β-cyclodextrin-coated eggs had lower values of air cell diameter (18.20 mm), air cell depth (7.20 mm) and albumin pH (9.12), higher eggshell breaking strength (51.21 N) and a*(25.33). At day 7 and 21, the best quality attributes were obtained by rapeseed oil/0.5% β-cyclodextrin-coated eggs, being respectively: WL, yolk index and L*. Less obvious micro-cracks on the eggshell surface were detected especially in rapeseed oil/0.5% β-cyclodextrin-coated eggs, which maintained slightly improved egg quality attributes during storage.

Introduction

Eggs have been inexpensive and valuable food due to their high nutritional value and unique multifunctional properties (Yüceer et al., 2016). Hen egg serves as an important food in daily life and is one of the major raw protein materials in the food processing industry all over the world (Xu et al., 2018a, 2018b). Water, CO2 and bacteria are exchanged with the environment through the eggshell pores, which make negative effects on egg quality conservation, thus causing egg quality deterioration and posing a risk for transmission of foodborne diseases to consumers (Sun et al., 2021; Yamak et al., 2021; Yuan et al., 2022). Attracted by huge economic benefits and food waste reduction, many tools such as dry cleaning, water washing, cold storage, non-thermal processing, packaging and coating have been studied for shell egg preservation (Xu et al., 2018a, 2018b; Eddin et al., 2019; Yamak et al., 2021).

Egg coating, an emulsion applied directly onto the egg surface, could seal the pores on eggshell, limit water loss, transport of O2 and CO2, maintain egg quality and lengthen egg shelf life, especially during higher temperature storage (Oliveira et al., 2020; da Silva Pires et al., 2022a, 2022b). Various coating materials, made from plastic solutions, liquid paraffin, mineral oil, antimicrobial compounds as well as other edible natural products (polysaccharides, proteins, lipids), have been evaluated completely in shell egg preservation, food safety and environmental protection (Nongtaodum et al., 2013; de Araújo Soares et al., 2021; Wang et al., 2021, 2022). It was expected to develop more renewable, edible and biodegradable coating materials in shell egg production and preservation.

The β-cyclodextrin (β-CD) is a non-toxic, cyclic and nonreducing α-1,4 linked maltooligosaccharide consisting of seven glucose units (Huang et al., 2009, 2020). It could form non-covalent host-guest inclusion complexes with fats, flavours and pigments in stabilised way (Chen et al., 2014). Previous studies indicated that 0.5 mg/mL β-CD could help preserve the colour of coated freeze-dried strawberry pieces (Huang et al., 2009). The microcapsules of oregano essential oil and 2% β-CD solution could also prevent browning and extend shelf life of purple yam (Huang et al., 2020). The sodium cellulose sulphate film containing 0.6% β-CD and 0.4% mustard essential oil could be applied in preservation of microbial-sensitive food products (Chen & Liu, 2016). The coating of chitosan/gelatine formulation with 7% β-CD/lemon grass essential oil inclusion complex results in a significant longer shelf-life of cherry tomato samples (Erceg et al., 2023). Beef fillet-coated solution of chitosan, β-CD and citral, had prolonged shelf life by approximately 5–7 days (Chen & Liu, 2016).

There are no similar reports on the application of rapeseed oil and β-cyclodextrin combination coating in shell egg preservation. It is hypothesised that β-CD could improve the stability and function of rapeseed oil, thus resulting in better quality attributes of eggs in shell than uncoated, only rapeseed oil and β-CD-coated ones during storage. In order to better understand the effect of rapeseed oil and β-CD combination coating (rapeseed oil/0.5% β-cyclodextrin) on preserved egg quality improvements, we evaluated changes of weight loss (WL), air cell depth and diameter, Haugh unit (HU), albumen pH, yolk index and colour, eggshell strength and morphology in eggs, which were stored at 25 °C for 28 days.

Materials and methods

Materials and chemicals

The rapeseed oil was obtained from Yonghui supermarket (Chongqing, China). β-CD (purity ≥ 98%) was obtained from Moyihuai Food Co., Ltd. (Xiamen, China). A total of 200 clean, coloured shell (Roman pink laying hen breed), unfertile, large, freshly laid (180-days-old) unwashed eggs (49.75 ± 0.48 g) were supplied by Chongqing Changshou egg market Co., Ltd. (Chongqing, China) in August, and used in the present study.

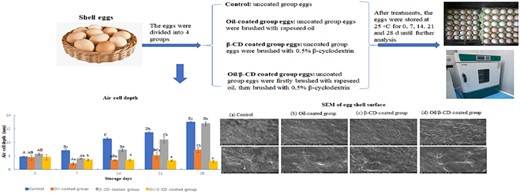

Development of coatings and egg treatments

The β-CD coating solution with a concentration of 0.5% (w/w) was prepared by dissolving certain amount of β-CD, stirring for 30 min at 70 °C in water and then cooled down to 30 ± 2 °C. The eggs were randomly divided into four treatment groups: fifty uncoated eggs served as the control. Oil-coated group: rapeseed oil was brushed on eggshell of fifty uncoated eggs. β-CD-coated group: 0.5% β-CD solution was brushed on eggshell of fifty uncoated eggs. Oil/β-CD (rapeseed oil/0.5% β-cyclodextrin)-coated group: rapeseed oil was firstly brushed on eggshell of fifty uncoated eggs, then brushed on eggshell using 0.5% β-CD solution. Three coated-group eggs were left to dry under a fan in the horizontal position at 75% r.h. (relative humidity) and 25 ± 3 °C (Pujols et al., 2014). All eggs of four groups were placed in plastic trays and stored for 28 days at 25 °C in a LBI-150 biochemical incubator (Shanghai Instrument Equipment Co., Ltd, China) until further analysis.

Quality analysis

Weight loss

According to Ezazi et al. (2021), all eggs were weighed during storage and their weight loss was calculated by eqn 1.

where m0 is the initial egg weight, and m1 is the egg weight during storage.

Air cell depth and diameter

The air cell height (mm) and diameter (mm) were measured using a handheld egg candling lamp and a MNT-150 micrometre (German) during storage (Lewko & Gornowicz, 2011).

Haugh unit (HU)

To determine haugh unit (HU), the eggs were broken on a glass plane to measure thick albumen height (h, mm) using a micrometre and weight (m, g) of the egg (Çelik et al., 2021) during storage, the HU was measured by eqn 2.

Albumen pH

The albumen was separated from yolk, then homogenised using a FSH-2 high-speed homogeniser (Changzhou Jintan LP-Instrument, Co., Ltd, China) at 11 000 g for 20 s, Albumen pH was measured with a laboratory PHS-3C pH metre (Shanghai Precision Scientific Instrument Co., Ltd, China) during storage (Yüceer & Caner, 2022).

Yolk index (YI) and colour

The eggs were cracked onto a flat glass surface, and the height and diameter of the yolk were measured with a MNT-150 micrometre (German) during storage (Xu et al., 2018a, 2018b). Yolk index was determined by eqn 3.

where H is the yolk height (mm) and D is the yolk diameter (mm).

A Digieye Digital Imaging System (Verivide, UK), calibrated for internal light (D65) before analysis, was used to determine the CIELab colour parameters lightness (L*), redness (a*) and yellowness (b*) at three random points of the yolk during storage (Englmaierová et al., 2013). We took our readings with the probe positioned at a constant angle (90°) and distance (45 cm) from the yolk surface.

Eggshell breaking strength

Eggshell breaking strength (puncture strength) was determined during storage using a texture analyser (TA.HD Plus Texture Analyzer, Stable Micro Systems, UK). Each egg was mounted on the platform of texture analyser, punctured using a 3 mm die probe and following the method described by Pires et al. (2019). The force (N) required to puncture the blunt end of shell egg was recorded as the eggshell breaking strength.

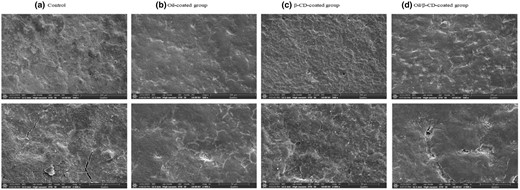

Eggshell ultrastructure

Small pieces (0.5 × 0.5 cm) of eggshells were removed from the eggs, sputter-coated with gold in vacuo for 2 min and three times, and observed using Thermo Scientific™ Quattro (Thermo Fisher Technology Co., Ltd, USA) scanning electron microscopy (SEM) at 10 kv under high vacuum with a 500× and 2000× magnification (Cree & Pliya, 2019).

Statistical analyses

The experiment was replicated four times to calculate the average values and standard errors unless otherwise stated. All the data (except eggshell ultrastructure) were statistically compared among groups by One-way Anova and Duncan's multiple range test with P < 0.05 in SPSS 16.0 software (SPSS Inc., Chicago, IL, USA).

Results and discussion

Weight loss

The water and CO2 loss from the albumen to the environment through the shell pores by evaporation is a natural and continuous process of eggs during storage (de Araújo Soares et al., 2021). The increase of weight loss indicated egg quality deteriorations. As given in Table 1, storage time increased the weight loss (%) of all eggs, and the most significant weight loss occurred in control group (range 0.93%–4.12%), while oil-coated group (range 0.10%–0.46%) and oil/β-CD-coated group (range 0.04%–0.34%) showed lower weight loss respectively, following 25 °C storage for 28 days. At days 7 and 21, oil/β-CD-coated group eggs showed significantly (P < 0.05) lower weight loss (0.04%, 0.33%) relative to oil-coated ones (0.10%, 0.44%). The β-CD-coated group eggs displayed the highest weight loss (4.40%) in all four treatment group eggs after 28 days of storage. These results suggested that oil and 0.5% β-CD coating might offer better effects for retarding egg weight loss during storage, compared with that of chitosan, pectin, shellac, lysozyme-chitosan, whey protein isolate/sodium montmorillonite/sodium metabisulphite coatings during 28 days storage (Pujols et al., 2014; Oliveira et al., 2020; Yüceer & Caner, 2020; de Araújo Soares et al., 2021). The higher water resistance of the oil/β-CD coating is likely due to hydrophobicity of rapeseed oil, compatibility and stabilisation of β-CD as main coating materials (Chen et al., 2014; Homsaard et al., 2021).

Weight loss (%) of control (uncoated), oil-coated, β-CD-coated and oil/β-CD-coated group eggs during 28 days of storage at 25 °C

| Treatments . | Storage time . | |||

|---|---|---|---|---|

| 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 0.93 ± 0.02dA | 2.22 ± 0.06cB | 3.32 ± 0.02cC | 4.12 ± 0.06bD |

| Oil-coated group | 0.10 ± 0.01bA | 0.26 ± 0.01aB | 0.44 ± 0.02bC | 0.46 ± 0.01aC |

| β-CD-coated group | 0.85 ± 0.01cA | 1.71 ± 0.13bB | 3.36 ± 0.04cC | 4.40 ± 0.11cD |

| Oil/β-CD-coated group | 0.04 ± 0.01aA | 0.17 ± 0.01aB | 0.33 ± 0.00aC | 0.34 ± 0.02aC |

| Treatments . | Storage time . | |||

|---|---|---|---|---|

| 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 0.93 ± 0.02dA | 2.22 ± 0.06cB | 3.32 ± 0.02cC | 4.12 ± 0.06bD |

| Oil-coated group | 0.10 ± 0.01bA | 0.26 ± 0.01aB | 0.44 ± 0.02bC | 0.46 ± 0.01aC |

| β-CD-coated group | 0.85 ± 0.01cA | 1.71 ± 0.13bB | 3.36 ± 0.04cC | 4.40 ± 0.11cD |

| Oil/β-CD-coated group | 0.04 ± 0.01aA | 0.17 ± 0.01aB | 0.33 ± 0.00aC | 0.34 ± 0.02aC |

Values are means ± SE of four replicates; A–E in the same row with different superscripts indicate significant differences (P < 0.05). a–e in the same column with different superscripts are significant differences (P < 0.05). Control, the uncoated eggs; Oil-coated group, the eggs coated with rapeseed oil; β-CD-coated group, the eggs coated with 0.5% β-CD using a brush; Oil/β-CD-coated group, the eggs coated with rapeseed oil and 0.5% β-CD respectively using a brush.

Weight loss (%) of control (uncoated), oil-coated, β-CD-coated and oil/β-CD-coated group eggs during 28 days of storage at 25 °C

| Treatments . | Storage time . | |||

|---|---|---|---|---|

| 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 0.93 ± 0.02dA | 2.22 ± 0.06cB | 3.32 ± 0.02cC | 4.12 ± 0.06bD |

| Oil-coated group | 0.10 ± 0.01bA | 0.26 ± 0.01aB | 0.44 ± 0.02bC | 0.46 ± 0.01aC |

| β-CD-coated group | 0.85 ± 0.01cA | 1.71 ± 0.13bB | 3.36 ± 0.04cC | 4.40 ± 0.11cD |

| Oil/β-CD-coated group | 0.04 ± 0.01aA | 0.17 ± 0.01aB | 0.33 ± 0.00aC | 0.34 ± 0.02aC |

| Treatments . | Storage time . | |||

|---|---|---|---|---|

| 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 0.93 ± 0.02dA | 2.22 ± 0.06cB | 3.32 ± 0.02cC | 4.12 ± 0.06bD |

| Oil-coated group | 0.10 ± 0.01bA | 0.26 ± 0.01aB | 0.44 ± 0.02bC | 0.46 ± 0.01aC |

| β-CD-coated group | 0.85 ± 0.01cA | 1.71 ± 0.13bB | 3.36 ± 0.04cC | 4.40 ± 0.11cD |

| Oil/β-CD-coated group | 0.04 ± 0.01aA | 0.17 ± 0.01aB | 0.33 ± 0.00aC | 0.34 ± 0.02aC |

Values are means ± SE of four replicates; A–E in the same row with different superscripts indicate significant differences (P < 0.05). a–e in the same column with different superscripts are significant differences (P < 0.05). Control, the uncoated eggs; Oil-coated group, the eggs coated with rapeseed oil; β-CD-coated group, the eggs coated with 0.5% β-CD using a brush; Oil/β-CD-coated group, the eggs coated with rapeseed oil and 0.5% β-CD respectively using a brush.

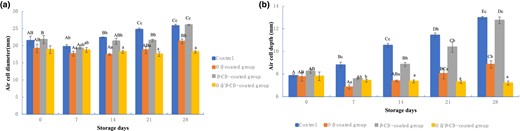

Air cell diameter and depth

Size of egg air cell, which could be affected by weight loss, increased during storage (Akyurek & Agma Okur, 2009; Drabik et al., 2021). In this study, air cell diameter and depth gradually increased in control, oil-coated and β-CD-coated group eggs, except that of oil/β-CD-coated group. The analysis of air cell diameter and depth analysis was given in Fig.1a,b respectively.

(a) Air cell diameter (mm) and (b) air cell depth (mm) of control (uncoated), oil-coated, β-CD-coated and oil/β-CD-coated group eggs during 28 days of storage at 25 °C. Values are means ± SE of four replicates measurements. Error bars represent positive standard errors of the mean. Different lowercase letters (a–e) donate significant difference between treatments in same storage times (P < 0.05). Different capital letters (A–E) donate significant difference between storage times in same treatments (P < 0.05). Control, the uncoated eggs; Oil-coated group, the eggs coated with rapeseed oil; β-CD-coated group, the eggs coated with 0.5% β-CD using a brush; Oil/β-CD-coated group, the eggs coated with rapeseed oil and 0.5% β-CD respectively using a brush.

The initial air cell diameter of control, oil-coated, β-CD-coated and oil/β-CD-coated eggs were 21.49 cm, 19.20 cm, 21.80 cm, and 18.86 cm, respectively. The initial air cell depth of control, oil-coated, β-CD-coated and oil/β-CD-coated eggs were 7.85 mm, 7.75 mm, 8.25 mm, and 7.80 mm, respectively. The oil-coated and oil/β-CD-coated group eggs exhibited significantly (P < 0.05) lower air cell diameter (Fig.1a) and depth (Fig. 1b) than control ones at days 7, 14, 21, and 28. At day 28, oil/β-CD-coated group eggs showed slightly lower (P < 0.05) air cell diameter (18.20 cm) and depth (7.20 mm) than that of the oil-coated group.

The coating of pores on the outer shell especially in the oil/β-CD-coated egg samples caused a lower growth in air cell size, compared to the control ones. Similar to the results obtained in the present study, Akarca et al. (2021) reported that air cell values increased in all egg samples during storage, whereas this increase was slower in sour cherry and almond resin-coated ones. The eggs coated with some preserving agents might show positive effect of limiting the increase of air cell depth during storage (Drabik et al., 2021).

Haugh unit (HU)

The HU is the most used variable to assess albumen quality. Higher HU is an indicator of better egg quality (da Silva Pires et al., 2022a). As can be observed in Table 2, the initial HU and egg grade of control, oil-coated, β-CD-coated and oil/β-CD-coated eggs were 84.05 (AA), 83.76 (AA), 85.75 (AA), and 84.06 (AA), respectively. HU value decreased in all group egg samples during storage (P < 0.05). The lowest HU value is β-CD-coated group (15.52 HU reduction), followed by control (14.68 HU reduction), oil-coated group (13.01 HU reduction), whereas the highest HU value is oil/β-CD-coated group (11.55 HU reduction) was detected in the eggs. On the other hand, the HU values decayed in a 14.3% for the control and oil-coated eggs, and in a 13.6% for oil/β-CD coated eggs, whereas the highest decrease of HU (18.1%) was observed with β-CD coated eggs. The hydrophilic coating of shell was detrimental for preservation of eggs.

Haugh unit and egg grade of control (uncoated), oil-coated, β-CD-coated and oil/β-CD-coated group eggs during 28 days of storage at 25 °C

| Treatments . | Storage time . | ||||

|---|---|---|---|---|---|

| 0 days . | 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 84.05 ± 1.29D (AA) | 78.89 ± 1.02C (AA) | 75.55 ± 0.96abBC (AA) | 69.37 ± 0.89a (A) | 72.02 ± 2.17AB (AA/A) |

| Oil-coated group | 83.76 ± 0.36C (AA) | 77.77 ± 3.07B (AA) | 78.18 ± 1.59Bb (AA) | 70.75 ± 1.69Aa (AA/A) | 71.77 ± 0.69A (AA/A) |

| β-CD-coated group | 85.75 ± 1.37D (AA) | 78.52 ± 1.79C (AA) | 72.95 ± 1.37Aab (AA/A) | 75.70 ± 0.35bBC (AA) | 70.23 ± 0.54A (A) |

| Oil/β-CD-coated group | 84.06 ± 1.59C (AA) | 79.43 ± 0.89B (AA) | 76.24 ± 0.85abAB (AA/A) | 72.51 ± 1.98abA (AA/A) | 72.65 ± 1.44A (AA/A) |

| Treatments . | Storage time . | ||||

|---|---|---|---|---|---|

| 0 days . | 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 84.05 ± 1.29D (AA) | 78.89 ± 1.02C (AA) | 75.55 ± 0.96abBC (AA) | 69.37 ± 0.89a (A) | 72.02 ± 2.17AB (AA/A) |

| Oil-coated group | 83.76 ± 0.36C (AA) | 77.77 ± 3.07B (AA) | 78.18 ± 1.59Bb (AA) | 70.75 ± 1.69Aa (AA/A) | 71.77 ± 0.69A (AA/A) |

| β-CD-coated group | 85.75 ± 1.37D (AA) | 78.52 ± 1.79C (AA) | 72.95 ± 1.37Aab (AA/A) | 75.70 ± 0.35bBC (AA) | 70.23 ± 0.54A (A) |

| Oil/β-CD-coated group | 84.06 ± 1.59C (AA) | 79.43 ± 0.89B (AA) | 76.24 ± 0.85abAB (AA/A) | 72.51 ± 1.98abA (AA/A) | 72.65 ± 1.44A (AA/A) |

Values are means ± SE of four replicates; A–E in the same row with different superscripts indicate significant differences (P < 0.05). a–e in the same column with different superscripts are significant differences (P < 0.05). Egg grades: AA, HU ≥ 72; A, HU = 60–72; B, HU = 31–60; C, HU < 31. Control, the uncoated eggs; Oil-coated group, the eggs coated with rapeseed oil; β-CD-coated group, the eggs coated with 0.5% β-CD using a brush; Oil/β-CD-coated group, the eggs coated with rapeseed oil and 0.5% β-CD respectively using a brush.

Haugh unit and egg grade of control (uncoated), oil-coated, β-CD-coated and oil/β-CD-coated group eggs during 28 days of storage at 25 °C

| Treatments . | Storage time . | ||||

|---|---|---|---|---|---|

| 0 days . | 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 84.05 ± 1.29D (AA) | 78.89 ± 1.02C (AA) | 75.55 ± 0.96abBC (AA) | 69.37 ± 0.89a (A) | 72.02 ± 2.17AB (AA/A) |

| Oil-coated group | 83.76 ± 0.36C (AA) | 77.77 ± 3.07B (AA) | 78.18 ± 1.59Bb (AA) | 70.75 ± 1.69Aa (AA/A) | 71.77 ± 0.69A (AA/A) |

| β-CD-coated group | 85.75 ± 1.37D (AA) | 78.52 ± 1.79C (AA) | 72.95 ± 1.37Aab (AA/A) | 75.70 ± 0.35bBC (AA) | 70.23 ± 0.54A (A) |

| Oil/β-CD-coated group | 84.06 ± 1.59C (AA) | 79.43 ± 0.89B (AA) | 76.24 ± 0.85abAB (AA/A) | 72.51 ± 1.98abA (AA/A) | 72.65 ± 1.44A (AA/A) |

| Treatments . | Storage time . | ||||

|---|---|---|---|---|---|

| 0 days . | 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 84.05 ± 1.29D (AA) | 78.89 ± 1.02C (AA) | 75.55 ± 0.96abBC (AA) | 69.37 ± 0.89a (A) | 72.02 ± 2.17AB (AA/A) |

| Oil-coated group | 83.76 ± 0.36C (AA) | 77.77 ± 3.07B (AA) | 78.18 ± 1.59Bb (AA) | 70.75 ± 1.69Aa (AA/A) | 71.77 ± 0.69A (AA/A) |

| β-CD-coated group | 85.75 ± 1.37D (AA) | 78.52 ± 1.79C (AA) | 72.95 ± 1.37Aab (AA/A) | 75.70 ± 0.35bBC (AA) | 70.23 ± 0.54A (A) |

| Oil/β-CD-coated group | 84.06 ± 1.59C (AA) | 79.43 ± 0.89B (AA) | 76.24 ± 0.85abAB (AA/A) | 72.51 ± 1.98abA (AA/A) | 72.65 ± 1.44A (AA/A) |

Values are means ± SE of four replicates; A–E in the same row with different superscripts indicate significant differences (P < 0.05). a–e in the same column with different superscripts are significant differences (P < 0.05). Egg grades: AA, HU ≥ 72; A, HU = 60–72; B, HU = 31–60; C, HU < 31. Control, the uncoated eggs; Oil-coated group, the eggs coated with rapeseed oil; β-CD-coated group, the eggs coated with 0.5% β-CD using a brush; Oil/β-CD-coated group, the eggs coated with rapeseed oil and 0.5% β-CD respectively using a brush.

HU scores ≥72 correspond to “clear firm egg white”, “well defined yolk” free from obvious defects and grade AA (best quality), 60–72 correspond to grade A (good quality), 31–60 correspond to grade B (average quality), less than 31 correspond to grade C (bad quality), eggs with HU scores below B grade were not suitable for consumption according to USDA-AMS Egg grading manual (Northcutt et al., 2022). The HU of control, oil-coated group eggs changed to grade A after 21 days of storage, while the oil/β-CD-coated group eggs contained grade AA/A during 28 days storage. The lower HU values resulted from albumen liquefaction during ovomucin ageing (Pujols et al., 2014; Yüceer & Caner, 2020). At day 14, the oil-coated group eggs showed significantly (P < 0.05) higher HU relative to β-CD-coated ones, whereas at day 21, HU and grade value (75.70, AA) of the egg samples coated with 0.5% β-CD was slightly higher (P < 0.05) than control (69.37, A) and oil-coated group (70.75, A). No significant differences (P > 0.05) in HU values were detected in oil-coated and oil/β-CD-coated group eggs during 25 °C storage for 28 days. Similar findings were reported by Pujols et al. (2014), who considered that HU differences were partly due to initial albumen quality and coating materials. These results might illustrate the importance of oil application with/without β-CD-coating, in order to maintain higher HU scores of eggs and effectively retard the rate of albumen liquefaction during 25 °C storage in some extent.

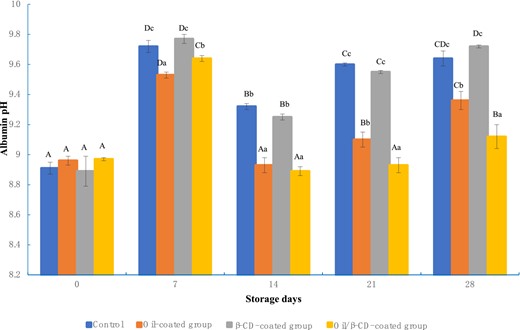

Albumen pH

Albumen pH can be also used as an indicator of egg quality (Sheng et al., 2021), As given in Fig. 2, albumen pH increased from 8.91 to 9.64 (8.91–9.64) for the control, 8.96–9.36 for oil-coated group, 8.89–9.72 for β-CD-coated group, 8.97–9.12 for oil/β-CD-coated group eggs respectively after 25 °C storage for 28 days. The preserved eggs, which undergo more loss of water and CO2, could increase the albumin pH (Liu et al., 2016).

Albumin pH of control (uncoated), oil-coated, β-CD-coated and oil/β-CD-coated group eggs during 28 days of storage at 25 °C. Values are means ± SE of four replicates measurements. Error bars represent positive standard errors of the mean. Different lowercase letters (a-e) donate significant difference between treatments in same storage times (P < 0.05). Different capital letters (A-E) donate significant difference between storage times in same treatments (P < 0.05). Control, the uncoated eggs; Oil-coated group, the eggs coated with rapeseed oil; β-CD-coated group, the eggs coated with 0.5% β-CD using a brush; Oil/β-CD-coated group, the eggs coated with rapeseed oil and 0.5% β-CD respectively using a brush.

The lowest albumen pH value was shown in oil-coated group after 7 days of storage. At days 14, 21 and 28, the albumin pH values of oil-coated group (8.93–9.36) and oil/β-CD-coated group eggs (8.89–9.12) were significantly (P < 0.05) lower than those of the control (9.32–9.64) and β-CD-coated group (9.25–9.72). At days 14 and 28, oil/β-CD-coated group eggs had significantly (P < 0.05) lower albumin pH values (8.89, 9.12) relative to that of oil-coated ones (8.93, 9.36). The application of oil/β-CD-coating might be useful in controlling pH level, thus maintaining albumen stability, The lower albumen pHs of eggs coated with oil/β-CD might have been due to hydrophobic properties of rapeseed oil, excellent, viscous and stabilised sealing properties of β-CD, which could act as effective barrier to gas exchange and water loss through the eggshell surface during longer time storage (Pujols et al., 2014; Wang et al., 2021).

Yolk index (YI)

YI, as an indirect measure of the strength of the yolk vitelline membrane and the spherical shape of the yolk, is one of the important egg quality parameters besides HU, weight loss and albumin pH (Pujols et al., 2014; Xu et al., 2018a, 2018b). Higher YI could be used as a predictor for better egg quality (Malfatti et al., 2021). A fresh, good-quality egg has a yolk index of around 0.45 and an older yolk would have a lower index (Caner, 2005).

Table 3 illustrated the YI changes in all group eggs during storage. All group eggs resulted in decrease in the YI values during storage. During storage, the YI of control eggs reduced from 0.42 to 0.28, while oil-coated, β-CD-coated and oil/β-CD-coated eggs reduced from the initial values (0.42, 0.41, 0.42) to final values (0.32, 0.30, 0.34), respectively. Similarly, YI decreased as the length of storage increases (Abioja et al., 2021). The YI reduction may be caused by osmotic diffusion of water from the albumen, thus inducing gradual breakdown of the vitelline membranes and yolk liquefaction in stored eggs (Yüceer & Caner, 2020). As can be seen in Table 3, YI values of control eggs showed significant and faster (P < 0.05) decrease than the coated ones at days 7, 14, and 21. At days 14 and 28, YI values of oil-coated eggs were similar to oil/β-CD-coated ones. At days 7 and 21, oil/β-CD-coated eggs showed significantly (P < 0.05) higher YI values (0.38, 0.37) compared with that of oil-coated ones (0.36, 0.33). YI value of oil/β-CD-coated eggs at 28 days was similar to that of control ones at 7 days. The application of oil/β-CD-coating was capable of maintaining the yolk stability for at least 21 days, longer than that of control ones during storage at 25° C, which was in agreement with Yüceer & Caner (2020).

Yolk index of control (uncoated), oil-coated, β-CD-coated and oil/β-CD-coated group eggs during 28 days of storage at 25 °C

| Treatments . | Storage time . | . | |||

|---|---|---|---|---|---|

| 0 days . | 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 0.42 ± 0.01C | 0.32 ± 0.00aB | 0.28 ± 0.01aA | 0.26 ± 0.01aA | 0.28 ± 0.00aA |

| Oil-coated group | 0.42 ± 0.00B | 0.36 ± 0.01bA | 0.36 ± 0.01bA | 0.33 ± 0.01bA | 0.32 ± 0.02bcA |

| β-CD-coated group | 0.41 ± 0.00C | 0.35 ± 0.01bB | 0.34 ± 0.01bB | 0.34 ± 0.00bB | 0.30 ± 0.00abA |

| Oil/β-CD-coated group | 0.42 ± 0.01C | 0.38 ± 0.01cB | 0.36 ± 0.00bAB | 0.37 ± 0.00cAB | 0.34 ± 0.01cA |

| Treatments . | Storage time . | . | |||

|---|---|---|---|---|---|

| 0 days . | 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 0.42 ± 0.01C | 0.32 ± 0.00aB | 0.28 ± 0.01aA | 0.26 ± 0.01aA | 0.28 ± 0.00aA |

| Oil-coated group | 0.42 ± 0.00B | 0.36 ± 0.01bA | 0.36 ± 0.01bA | 0.33 ± 0.01bA | 0.32 ± 0.02bcA |

| β-CD-coated group | 0.41 ± 0.00C | 0.35 ± 0.01bB | 0.34 ± 0.01bB | 0.34 ± 0.00bB | 0.30 ± 0.00abA |

| Oil/β-CD-coated group | 0.42 ± 0.01C | 0.38 ± 0.01cB | 0.36 ± 0.00bAB | 0.37 ± 0.00cAB | 0.34 ± 0.01cA |

Values are means ± SE of four replicates; A–E in the same row with different superscripts indicate significant differences (P < 0.05). a–e in the same column with different superscripts are significant differences (P < 0.05). Control, the uncoated eggs; Oil-coated group, the eggs coated with rapeseed oil; β-CD-coated group, the eggs coated with 0.5% β-CD using a brush; Oil/β-CD-coated group, the eggs coated with rapeseed oil and 0.5% β-CD respectively using a brush.

Yolk index of control (uncoated), oil-coated, β-CD-coated and oil/β-CD-coated group eggs during 28 days of storage at 25 °C

| Treatments . | Storage time . | . | |||

|---|---|---|---|---|---|

| 0 days . | 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 0.42 ± 0.01C | 0.32 ± 0.00aB | 0.28 ± 0.01aA | 0.26 ± 0.01aA | 0.28 ± 0.00aA |

| Oil-coated group | 0.42 ± 0.00B | 0.36 ± 0.01bA | 0.36 ± 0.01bA | 0.33 ± 0.01bA | 0.32 ± 0.02bcA |

| β-CD-coated group | 0.41 ± 0.00C | 0.35 ± 0.01bB | 0.34 ± 0.01bB | 0.34 ± 0.00bB | 0.30 ± 0.00abA |

| Oil/β-CD-coated group | 0.42 ± 0.01C | 0.38 ± 0.01cB | 0.36 ± 0.00bAB | 0.37 ± 0.00cAB | 0.34 ± 0.01cA |

| Treatments . | Storage time . | . | |||

|---|---|---|---|---|---|

| 0 days . | 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 0.42 ± 0.01C | 0.32 ± 0.00aB | 0.28 ± 0.01aA | 0.26 ± 0.01aA | 0.28 ± 0.00aA |

| Oil-coated group | 0.42 ± 0.00B | 0.36 ± 0.01bA | 0.36 ± 0.01bA | 0.33 ± 0.01bA | 0.32 ± 0.02bcA |

| β-CD-coated group | 0.41 ± 0.00C | 0.35 ± 0.01bB | 0.34 ± 0.01bB | 0.34 ± 0.00bB | 0.30 ± 0.00abA |

| Oil/β-CD-coated group | 0.42 ± 0.01C | 0.38 ± 0.01cB | 0.36 ± 0.00bAB | 0.37 ± 0.00cAB | 0.34 ± 0.01cA |

Values are means ± SE of four replicates; A–E in the same row with different superscripts indicate significant differences (P < 0.05). a–e in the same column with different superscripts are significant differences (P < 0.05). Control, the uncoated eggs; Oil-coated group, the eggs coated with rapeseed oil; β-CD-coated group, the eggs coated with 0.5% β-CD using a brush; Oil/β-CD-coated group, the eggs coated with rapeseed oil and 0.5% β-CD respectively using a brush.

Eggshell breaking strength

Eggshell protects egg contents from mechanical damages and microbial entry to some extent, and the quality of eggshell is of great economic significance for commercial egg industry. Improved shell strength would result in significant reductions of egg lost (downgraded eggs) and huge economic savings during handling and storage (Caner & Yüceer, 2015; Pires et al., 2019).

Instrumental analysis of eggshell breaking strength was shown in Table 4. The initial eggshell breaking strength values of control, oil-coated, β-CD-coated and oil/β-CD-coated eggs were 31.91 N, 32.29 N, 35.01 N, and 30.29 N, respectively. The breaking strength of the eggs of the control group increased from 31.91 N to 41.48 N during the first 14 days of storage, then slightly decreased to 36.74 N after storage for 28 days. The eggshell breaking strength value of the control eggs stored for 14 days was slightly (P < 0.05) higher than the ones stored for 7 days. No difference (P > 0.05) of eggshell breaking strength was detected in oil-coated group during 28 days storage at 25 ° C. For β-CD-coated and oil/β-CD-coated eggs, the strength values increased significantly (P < 0.05) during storage for 28 days. At day 28, the values of eggshell breaking strength in β-CD-coated and oil/β-CD-coated eggs were significantly (P < 0.05) higher than in control and oil-coated ones. The higher puncture strength values exhibited by β-CD-coated and oil/β-CD-coated eggs probably resulted in higher mechanical properties of β-CD and oil/β-CD. These results were in agreement with Caner & Yüceer (2015) and the eggshell breaking strength changes during storage might be associated with the initial shell properties and coating treatments.

Eggshell breaking strength (N) of control (uncoated), oil-coated, β-CD-coated and oil/β-CD-coated group eggs during 28 days of storage at 25 °C

| Treatments . | Storage time . | . | |||

|---|---|---|---|---|---|

| 0 days . | 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 31.91 ± 1.12AB | 30.89 ± 3.41aA | 41.48 ± 4.71B | 34.57 ± 2.40AB | 36.74 ± 2.19aAB |

| Oil-coated group | 32.29 ± 2.25 | 44.06 ± 3.13ab | 47.57 ± 7.56 | 34.40 ± 7.51 | 38.31 ± 2.87a |

| β-CD-coated group | 35.01 ± 3.12A | 44.28 ± 4.48abAB | 45.56 ± 2.63AB | 38.73 ± 4.34A | 51.46 ± 2.65bB |

| Oil/β-CD-coated group | 30.29 ± 5.85A | 50.97 ± 6.14bB | 49.35 ± 2.12B | 41.06 ± 3.20AB | 51.21 ± 6.51bB |

| Treatments . | Storage time . | . | |||

|---|---|---|---|---|---|

| 0 days . | 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 31.91 ± 1.12AB | 30.89 ± 3.41aA | 41.48 ± 4.71B | 34.57 ± 2.40AB | 36.74 ± 2.19aAB |

| Oil-coated group | 32.29 ± 2.25 | 44.06 ± 3.13ab | 47.57 ± 7.56 | 34.40 ± 7.51 | 38.31 ± 2.87a |

| β-CD-coated group | 35.01 ± 3.12A | 44.28 ± 4.48abAB | 45.56 ± 2.63AB | 38.73 ± 4.34A | 51.46 ± 2.65bB |

| Oil/β-CD-coated group | 30.29 ± 5.85A | 50.97 ± 6.14bB | 49.35 ± 2.12B | 41.06 ± 3.20AB | 51.21 ± 6.51bB |

Values are means ± SE of four replicates; A–E in the same row with different superscripts indicate significant differences (P < 0.05). a–e in the same column with different superscripts are significant differences (P < 0.05). Control, the uncoated eggs; Oil-coated group, the eggs coated with rapeseed oil; β-CD-coated group, the eggs coated with 0.5% β-CD using a brush; Oil/β-CD-coated group, the eggs coated with rapeseed oil and 0.5% β-CD respectively using a brush.

Eggshell breaking strength (N) of control (uncoated), oil-coated, β-CD-coated and oil/β-CD-coated group eggs during 28 days of storage at 25 °C

| Treatments . | Storage time . | . | |||

|---|---|---|---|---|---|

| 0 days . | 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 31.91 ± 1.12AB | 30.89 ± 3.41aA | 41.48 ± 4.71B | 34.57 ± 2.40AB | 36.74 ± 2.19aAB |

| Oil-coated group | 32.29 ± 2.25 | 44.06 ± 3.13ab | 47.57 ± 7.56 | 34.40 ± 7.51 | 38.31 ± 2.87a |

| β-CD-coated group | 35.01 ± 3.12A | 44.28 ± 4.48abAB | 45.56 ± 2.63AB | 38.73 ± 4.34A | 51.46 ± 2.65bB |

| Oil/β-CD-coated group | 30.29 ± 5.85A | 50.97 ± 6.14bB | 49.35 ± 2.12B | 41.06 ± 3.20AB | 51.21 ± 6.51bB |

| Treatments . | Storage time . | . | |||

|---|---|---|---|---|---|

| 0 days . | 7 days . | 14 days . | 21 days . | 28 days . | |

| Control | 31.91 ± 1.12AB | 30.89 ± 3.41aA | 41.48 ± 4.71B | 34.57 ± 2.40AB | 36.74 ± 2.19aAB |

| Oil-coated group | 32.29 ± 2.25 | 44.06 ± 3.13ab | 47.57 ± 7.56 | 34.40 ± 7.51 | 38.31 ± 2.87a |

| β-CD-coated group | 35.01 ± 3.12A | 44.28 ± 4.48abAB | 45.56 ± 2.63AB | 38.73 ± 4.34A | 51.46 ± 2.65bB |

| Oil/β-CD-coated group | 30.29 ± 5.85A | 50.97 ± 6.14bB | 49.35 ± 2.12B | 41.06 ± 3.20AB | 51.21 ± 6.51bB |

Values are means ± SE of four replicates; A–E in the same row with different superscripts indicate significant differences (P < 0.05). a–e in the same column with different superscripts are significant differences (P < 0.05). Control, the uncoated eggs; Oil-coated group, the eggs coated with rapeseed oil; β-CD-coated group, the eggs coated with 0.5% β-CD using a brush; Oil/β-CD-coated group, the eggs coated with rapeseed oil and 0.5% β-CD respectively using a brush.

Yüceer & Caner (2014) considered that the coatings based on various proteins, chitosan, and chitosan/lysozyme could improve preserved eggshell strength. This clearly indicated the potential application of β-CD coating with or without oil in enhancing eggshell strength, minimising eggshell breakage, and allowing significant egg quality preservation. The lipid-based materials have relatively high melting point and specific gravity, which could increase the mechanical and tensile strength of coatings (Eddin et al., 2019). The polysaccharides-based coatings could have thickening and viscous effects, which could increase the mechanical properties of coatings (Eddin et al., 2019).

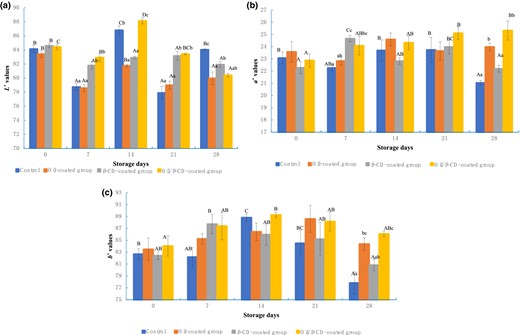

Egg yolk colour

Yolk colour, as one of the main parameters by which the quality of eggs is judged, is mainly dependent upon the content of yolk carotenoids (Beardsworth & Hernandez, 2004; Caner & Cansiz, 2008). Instrumental analysis of colour changes of four group yolk surface layer was shown in Fig. 3. At day 0, the initial lightness (L*) values of control, oil-coated, β-CD-coated and oil/β-CD-coated group eggs were 84.13, 83.42, 84.60, 84.45, redness (a*) values were 23.08, 23.58, 22.28, 22.88, and yellowness/brownness (b*) values were 82.67, 83.49, 82.42, 84.04, respectively.

Yolk colour (a) L*, (b) a* and (c) b* of control (uncoated), oil-coated, β-CD-coated and oil/β-CD-coated group eggs during 28 days of storage at 25 °C. Values are means ± SE of four replicates measurements. Error bars represent positive standard errors of the mean. Different lowercase letters (a–e) donate significant difference between treatments in same storage times (P < 0.05). Different capital letters (A–E) donate significant difference between storage times in same treatments (P < 0.05). Control, the uncoated eggs; Oil-coated group, the eggs coated with rapeseed oil; β-CD-coated group, the eggs coated with 0.5% β-CD using a brush; Oil/β-CD-coated group, the eggs coated with rapeseed oil and 0.5% β-CD respectively using a brush.

L* values for control group eggs ranged from 77.91 to 86.80 during 28 days storage, Significant decrease (P < 0.05) in L* values of the control group was shown at days 7 and 21. L* values gradually decreased in other three coated eggs. At days 7 and 21, the β-CD-coated and oil/β-CD-coated group eggs showed significantly (P < 0.05) lighter or brighter (i.e. higher L* values) yolk surface colour than the control and oil-coated ones. Larger the L* value is, the brighter the colour is and vice versa (Wang et al., 2021).

In general, a* and b* values in control, β-CD-coated and oil/β-CD-coated group eggs firstly increased and then levelled off. No significant differences (P > 0.05) in yolk a* and b* values were observed in oil-coated eggs during the entire storage period. At days 7 and 28, the surface a* values of the oil/β-CD-coated eggs were significantly (P < 0.05) higher than control ones. Higher a* value indicated that the yolk colour is deeper red than green (Wang et al., 2021).

At day 28, oil/β-CD-coated egg yolk had a significantly (P < 0.05) higher b* value (86.08), when compared to control and oil-coated ones. Higher b* value indicates that the yolk colour is deeper yellow than blue (Wang et al., 2021). In general, lower L* and b* values induced eventual discolourations rather in control and oil-coated group yolk. The slightly deeper red and yellow colour was expected in the yolk of the oil/β-CD-coated eggs due to the absence of air contact during storage (Wang et al., 2021).

Ultrastructure of eggshells

SEM analysis can reveal the compatibilities and microstructures of composite coatings, which are closely related to their barrier properties (Xu et al., 2018a, 2018b; Sheng et al., 2021). The SEM images of the eggshell surface in this study are shown in Fig. 4. Oil/β-CD-coated group eggs had smooth surface and nearly disappeared micro-cracks, while control, β-CD-coated ones had obvious, deep and wide micro-cracks on their surfaces. These micro-cracks in eggshell surface, which were probably produced during the whole egg production chain, could accelerate exchange rate of gas, moisture and bacteria from preserved eggs to surrounding, thus inducing egg quality deteriorations (Xu et al., 2018a, 2018b; Sheng et al., 2021). These results clearly showed that CaCO3 (the main component of the eggshell) could react with oil and β-CD, obtain better properties of filling up more micro-cracks on the eggshell surface. Therefore, quality attributes of the eggs treated by oil/β-CD coating might be better than those of control, oil-coated and β-CD-coated ones due to superior, stabilised barrier layers of oil and β-CD coating, thus providing more effective protections to eggs in shelf life.

Scanning electron microscopy (SEM) micrographs of (a) control, (b) oil-coated, (c) β-CD-coated and (d) oil/β-CD-coated group eggshell surfaces at day 0. 500× (scale bars, 300 μm) and 2000× (scale bars, 50 μm). Control, the uncoated eggs; Oil-coated group, the eggs coated with rapeseed oil; β-CD-coated group, the eggs coated with 0.5% β-CD using a brush; Oil/β-CD-coated group, the eggs coated with rapeseed oil and 0.5% β-CD respectively using a brush.

Conclusion

Control (uncoated) group eggs, which suffered from severe quality attributes loss, were stored at 25 °C (room temperature) for less than 7 days of shelf life. In contrast, the eggs coated with rapeseed oil and 0.5% β-CD (oil/β-CD) preserved better egg quality attributes for up to 28 days of shelf life. The eggs coated with rapeseed oil and 0.5% β-CD (oil/β-CD) had lower weight loss, air cell diameter, air cell depth, albumin pH, and improved yolk index, eggshell breaking strength and colour parameters during 25 °C storage for 28 days. The eggs, coated by rapeseed oil and 0.5% β-CD, stored at 25 °C for 28 days could have comparable or similar quality attributes, compared with those uncoated ones stored at 4 °C. The ultrastructure of eggshell surface analysed by SEM showed that addition of 0.5% β-CD and oil (oil/β-CD group) could obviously improve the coating stability and maintain preserved egg quality by filling up deeper and wider micro-cracks on the eggshell surface. This study provides a certain insight into the preparation and application of multicomponent-based (such as oil/β-CD) coating in shell egg industry. Therefore, from egg preservation and environmental protection perspectives, the toxic-free and edible oil/0.5% β-CD coating had considerable industrial potential to yield shell eggs with comparable or improved quality attributes compared with those achieved by uncoated and other materials-coated ones. Future research might shed light on sensory properties changes during various egg coating treatments, oil/β-CD coating mechanisms and procedure optimisations, thus producing preserved eggs with better quality attributes.

Acknowledgments

This work was supported by the Science and Technology Research Project of Chongqing Municipal Education Commission (KJQN202204057, KJQN202000817, KJZD-K20220806), and Training Project for College Students' Innovation and Entrepreneurship (HZY202214315013).

Author contributions

Yan Dai: Conceptualization (equal); data curation (equal); formal analysis (equal); investigation (equal); writing – original draft (lead). De hui Chen: Conceptualization (supporting); data curation (equal); funding acquisition (equal); investigation (equal); project administration (equal); writing – original draft (equal). Qin Lei: Conceptualization (equal); writing – review and editing (equal). Xiao li Ren: Writing – review and editing (supporting). Chun hong Li: Project administration (equal). Jing Zhang: Resources (supporting); software (equal); supervision (equal). Haijun Chang: Conceptualization (equal); investigation (equal); supervision (equal).

Conflict of interest

All authors declare no conflict of interest.

Ethical approval

Ethics approval was not required for this research.

Peer review

The peer review history for this article is available at https://www.webofscience.com/api/gateway/wos/peer-review/10.1111/ijfs.16444.

Data availability statement

Research data are not shared.