-

PDF

- Split View

-

Views

-

Cite

Cite

Sumin Ma, Haiming Shi, Caixia Ding, Yanlan Bi, Hong Zhang, Xuebing Xu, Impact of different water treatments of peanuts during the roasting process on the flavour profile and chemical qualities of the peanut oil, International Journal of Food Science and Technology, Volume 60, Issue 1, January 2025, vvaf063, https://doi.org/10.1093/ijfood/vvaf063

Close - Share Icon Share

Abstract

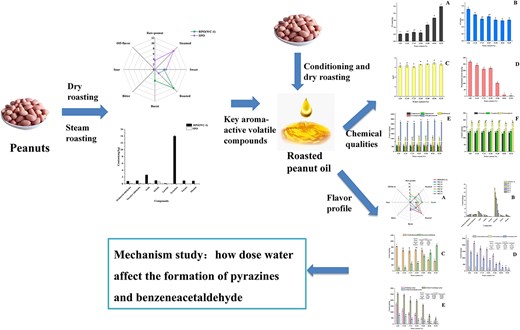

The objective of this study was to investigate the impact of different water treatments with different water contents in peanut kernels on the flavour profile and chemical qualities of roasted peanut oil (RPO). Based on relative odour activity value, the key aroma-active compounds of steamed peanut oil (SPO) and RPO were selected as the evaluation objects. An increase in water content in peanut kernels from 4.20% to 52.55% significantly enhances the intensity of sweet and steamed flavour attributes of RPOs. The enhancement observed can be attributed to a 7.26-fold increase in the content of benzeneacetaldehyde and an 8.03-fold decrease in 6 key aroma-active pyrazines. These 6 pyrazines are: 2,6-dimethylpyrazine, trimethylpyrazine, 2,3-dimethylpyrazine, methylpyrazine, 2-ethyl-5-methylpyrazine, and 2-ethyl-6-methylpyrazine. Model experiments verified the effect of water on the formation of pyrazines and Strecker aldehydes. From the quality point of view, an elevation in water content leads to a reduction in both acid value and phospholipid content. However, excessive water content can decrease the stability of RPOs. Thus, taking consideration of achieving mellow flavour characteristics and a better chemical quality, an optimal water content of 22.05% in peanut kernels is recommended. This finding offers a potential approach for optimising the flavour characteristics of RPOs through targeted adjustment of peanut kernel’s initial water content.

Introduction

Peanuts are widespread and valuable oilseeds in many regions, such as Europe, the United States, Asia, and Africa, commonly used as instant snacks (Akhtar et al., 2014; Ghorbani & Hosseini, 2017). Fragrant peanut oil is widely consumed in China due to its desirable flavour characteristics (Liu et al., 2022). The predominant flavour attributes of fragrant peanut oils are the roasted, burnt, sweet, steamed, and raw-peanut, etc. (Hu et al., 2023; Liu et al., 2022). These attributes are closely associated with volatile compounds, including pyrazines, pyrrolines, phenols, aldehydes, and furanones (Lykomitros et al., 2016; Ma et al., 2024a). The optimal ratio of these compounds is crucial for the overall flavour of peanut oils and peanuts. The absence or excessive concentration of specific compounds can hinder the precise recombination of the flavour of peanut oils or peanuts (Chetschik et al., 2010). Consequently, studying the formation mechanism and influential factors of key flavour compounds holds practical significance for achieving enhanced harmonisation of peanut flavours (Ma et al., 2024a). For example, oxidised aldehydes are associated with raw-peanut flavours, and they are products of oil oxidation. Their formation is highly related to fatty acid compositions of the oils in peanuts, which are highly related to cultivars (Giuffrè et al., 2016), growing season (Gulluoglu et al., 2016), and irrigation (Akçura et al., 2021). As is well known, pyrazines and benzeneacetaldehyde (BA) are products of the Maillard reaction, which are related to roasted and sweet flavour attributes. Multiple studies have explored the formation of pyrazines (Liu et al., 2011; Suri et al., 2019). Being one of the most important flavour attributes, limited studies have focused on investigating the flavour compounds associated with sweet flavour attributes in peanut oils, specifically BA. Benzeneacetaldehyde is a product generated through the Maillard reaction between phenylalanine and sugar (Hofmann et al., 2000).

Roasting is an important process in the industrial production of peanut oil. Steam roasting and traditional roasting (dry roasting) processes are both widely used and present together in practical production, which can lead to very different flavour characteristics in peanut oil. Extensive research across diverse food systems, including cocoa beans, malts, crackers, and chocolates, has demonstrated a significant impact of water on the augmentation of Strecker aldehyde concentration (Buhr et al., 2010; Ullrich et al., 2021). As reported, water has the potential to modify the conversion rate of substrates and alter the composition of products during thermal reactions, such as the Maillard reaction (Lu et al., 2005; Scalone et al., 2015; Yoo, 1997).

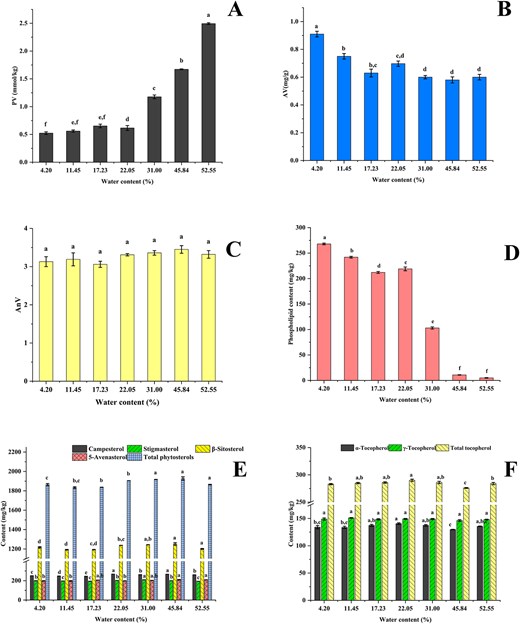

We therefore hypothesised that different water content during roasting may lead to significant differences in sensory characteristics of peanut oils. To test this hypothesis, we pretreated the peanut kernels with water to achieve a wide range of water content (4.20%–52.55%) and subsequently roasted and pressed them to produce roasted peanut oils (RPOs). The flavour compounds composition and sensory characteristics of the RPO were conducted to investigate the influence on their flavour profile. According to the literature, steam roasting and dry roasting exhibit distinct impacts on the chemical indicators of peanut oil (Idrus et al., 2017). Consequently, the chemical quality of these RPOs, including peroxide value, acid value, fatty acid composition, phospholipid content, phytosterol content, and tocopherol content, was also evaluated.

Materials and methods

Materials

The Huayu 22 variety was selected as the raw material due to its widespread cultivation and superior quality. All standard chemicals, including 1,3-dichlorobenzene, hexanal, octanal, (E)-2-heptenal, (E)-2-octenal, (E,E)-2,4-decadienal, 3-methylbutanal, BA, acetic acid, 3-methylbutyric acid, pentanoic acid, hexanoic acid, 1-nonanol, phenylethyl alcohol, butyrolactone, methylpyrazine, 2,5-dimethylpyrazine, 2,6-dimethylpyrazine, 2,3-dimethylpyrazine, ethylpyrazine, 2-ethyl-6-methylpyrazine, 2-ethyl-5-methylpyrazine, trimethylpyrazine, 3-ethyl-2,5-dimethylpyrazine, 2-ethenyl-6-methylpyrazine, 2-acetylpyridine, 2-pyrrolaldehyde, furfural, 5-methylfurfural, 2-furanmethanol, 3-phenylfuran, 2-methoxyphenol, and 2-methoxy-4-vinylphenol, were obtained from Sigma-Aldrich Co. Ltd. (Shanghai, China) and Titan search platform.

Conditioning (water treatment) of the peanut kernels

A quantity of 300 g of peanut kernels was placed in a tray equipped with an overflow tank. They were then soaked with a fixed amount of water for a set duration (0, 15, 30, 60, 120, 300, and 600 min) to ensure complete absorption. After soaking the peanut kernels for the set time, the water contents were measured as 4.20%, 11.45%, 17.23%, 22.05%, 31.00%, 45.84%, and 52.55%, respectively.

The water content of peanut kernels was calculated as follows:

where A0—peanut kernels’ initial water content, m1—peanut kernels’ weight before water soaked, and m2—peanut kernels’ weight after being water-soaked, A0 was determined using the 105 °C direct drying method, as specified in GB 5009.3—2016. Significantly, prior to water content determination, it is crucial to ensure that the surface water of peanut kernels is thoroughly and naturally eliminated. To ensure the accuracy and reproducibility of the experimental data, all experiments were conducted in duplicate. The water content in the defatted protein powder after pressing and RPO was also investigated. The water contents of peanut oils obtained from WC-1 to WC-7 were 0.19%, 0.45%, 0.33%, 0.24%, 0.35%, 0.39%, and 0.27%, respectively. The water contents of defatted protein powder obtained from WC-1 to WC-7 were 6.00%, 6.53%, 6.48%, 7.08%, 6.42%, 6.51%, and 6.27%, respectively.

Laboratory production trials of RPOs and steamed peanut oil

The production technology for the RPO produced has been optimised. The detailed processing conditions are as follows: Initially, the peanut kernels were roasted in a coffee bean roaster at 160 °C for 30 min. Subsequently, the kernels were pressed in an oil press expeller maintained at 160 °C, followed by centrifugation at 6,000 rpm for 5 min to obtain RPO samples. The RPOs obtained from peanut kernels with varying water contents (4.20%, 11.45%, 17.23%, 22.05%, 31.00%, 45.84%, and 52.55%) were labelled from WC-1 to WC-7, respectively. The production of steamed peanut oil (SPO) involves steaming followed by subsequent processes, namely, pressing and centrifugation. A total of 300 g of peanut kernels was steamed in a steamer for 30 min. To ensure the accuracy and reproducibility of the experimental data, all experiments were performed in duplicate.

Sensory analysis of peanut oils

The sensory properties of peanut oils were evaluated using quantitative descriptive analysis (QDA), as described in the published work (Ma et al., 2024b). All experiments were performed in duplicate. A sensory panel consisting of 10 members (five males and five females aged 20–30 years) was recruited for conducting QDA in the laboratory. Panellists were selected based on their prior experience with peanut oil QDA. Each sample (15 ml) was poured into a 50 ml plastic bottle, and the temperature of the sensory laboratory was carefully maintained at 25 °C. Peanut oil samples were assigned randomly generated three-digit codes and distributed to each panellist in a randomised order. Prior to quantitative scoring, descriptive terms were derived through three rounds of group discussions. Consequently, eight descriptors were identified for the samples, including raw-peanut, steamed, sweet, roasted, burnt, bitter, sour, and off-flavour (primarily oxidised flavour). The sensory evaluation of peanut oil was conducted using a 15-point scale, where 1 indicated very weak perception and 15 indicated very strong perception. The sensory evaluation was carried out in a dedicated laboratory for peanut oils, with testing sessions scheduled on consecutive afternoons over several weeks. Each round of sensory evaluation included a maximum of four samples. Before conducting the sensory analysis, a 5-day training session was held to ensure that the panellists could accurately describe the sensory attributes of peanut oil.

Analysis of key aroma-active volatile compounds composition of peanut oils

Analysis of key aroma-active volatile compounds by headspace solid-phase microextraction coupled with gas chromatography–mass spectrometry

Volatile compounds in peanut oil were analysed using headspace solid-phase microextraction coupled with gas chromatography–mass spectrometry (HS-SPME/GC-MS). The HS-SPME and GC-MS conditions were used as a published paper with minor modifications (Xu et al., 2021). Five grams of oil was placed in a 20 ml vial sealed with an aluminium crimp cap equipped with a needle-pierceable polytetrafluoroethylene/silicone septum. The quantitative method is the internal standard method. 1,3-Dichlorobenzene (50 μg/g in ODO) was used as the internal standard for this semiquantitative analysis, with an additional amount of 50 μL per 5 g of oil. The qualitative analysis of compounds is conducted as follows: matching of the national institute of standards and technology (NIST) database, retention index, and standard compound. The detailed operational procedures and conditions were conducted; refer to the published paper (Ma et al., 2024b). All analyses were performed in duplicate.

Calculation of relative odour activity value

The relative odour activity value (ROAV) was used to quantitatively assess the contribution of an individual volatile compound to the overall flavour profile. It was calculated according to the methodology outlined in the published paper (Wang et al., 2020). The calculation formula is as follows:

The OAVi was calculated using the formula OAVi = Ci/OTi, where Ci represents the concentration of a compound within the sample, and OTi signifies the odour threshold (OT) of the specific compound. The OAVmax was determined by identifying the maximum OAVi among all compounds present in each sample. The compound exhibiting the highest OAV is designated as the reference compound, assigned an ROAV of 100.

Analysis of free amino acids and soluble sugar content of defatted peanut protein powder

Defatted peanut protein powder is obtained from peanut meal through the extraction of oil three times using n-hexane. The composition of free amino acids is determined according to the GB/T 18246-2019 with minor modifications. Soluble sugar content was determined by ion chromatography according to GB 5009.8-2023 and a published paper (Li et al., 2009).

Analysis of chemical indicators of RPOs

The tocopherol content was quantified in accordance with the procedures outlined in ISO 9936:2006. The phospholipid content was measured according to American oil chemists' society (AOCS) Official Method Ca 12-55. The phytosterol content was determined according to ISO 12228-1:2014 (E). The fatty acid composition was determined according to AOCS Official Method Ce 1-62. The acid value (AV) and peroxide value (PV) were analysed following AOCS Official Method Cd 3d-63 and AOCS Official Method Cd 8-53, respectively. The polyphenol content in peanut oil is determined through ultraviolet spectrophotometric analysis (Zhang et al., 2021b). The anisidine value (AnV) was analysed following ISO 6885:2016.

Model experiments of amino acid and glucose to verify the effect on the formation of pyrazines and Strecker aldehydes

Seventeen amino acids were recombined and mixed in a ratio based on the defatted peanut protein powder content in raw peanut samples, as presented in Table 1. Four portions of 150 mg of amino acid and 150 mg of glucose were weighed into a headspace injection bottle, thoroughly mixed, and then added into 0, 10, 25, and 50 μL water, respectively. The substrate composition for each experiment is shown in Table 2. These mixtures were heated in a specialised device. As shown in Table 2, the heat treatment conditions are as follows: 160 °C for 30 min or 100 °C for 30 min.

Odour activity value (OAV) and relative odour activity value (ROAV) of key aroma-active volatile compounds in roasted peanut oil (RPO) and steamed peanut oil (SPO).

| NO . | Odorants . | CAS . | RIa . | Quantitation ion . | Odour description . | OT, μg/kg oil . | SPO . | RPO (WC-1) . | ||

|---|---|---|---|---|---|---|---|---|---|---|

| OAV . | ROAV . | OAV . | ROAV . | |||||||

| 1 | 2-Methylbutanal | 96-17-3 | 990 | 41 | Malty | 2.2 (Hu et al., 2023) | 4.98 ± 0.11 | 100.00 | 375.71 ± 3.47 | 100.00 |

| 2 | 2,6-Dimethylpyrazine | 108-50-9 | 1,344 | 41 | Roasty, cocoa, roast beef | 20 (Hu et al., 2023) | – | – | 117.35 ± 0.13 | 30.95 ± 0.03 |

| 3 | Trimethylpyrazine | 14667-55-1 | 1,417 | 122 | Roasted, potato, musty | 22 (Hu et al., 2023) | – | – | 64.56 ± 1.37 | 17.03 ± 0.36 |

| 4 | 2-Methoxy-4-vinylphenol | 7786-61-0 | 2,210 | 150 | Smoky, clove-like | 20 (Hu et al., 2023) | – | – | 41.12 ± 2.65 | 10.85 ± 0.70 |

| 5 | 2,3-Dimethylpyrazine | 5910-89-4 | 1,361 | 108 | Nutty, nut skin, cocoa, peanut butter, coffee, walnut | 8 (Hu et al., 2023; Yin et al., 2022) | – | – | 27.88 ± 0.39 | 7.35 ± 0.10 |

| 6 | Acetic acid | 64-19-7 | 1,452 | 43 | Vinegar-like, pungent | 124 (Chetschik et al., 2008; Hu et al., 2023) | 1.36 ± 0.10 | 26.78 ± 1.89 | 18.44 ± 0.33 | 4.86 ± 0.09 |

| 7 | Methylpyrazine | 109-08-0 | 1,282 | 94 | Roasted | 200 (Hu et al., 2023) | – | – | 8.14 ± 0.02 | 2.15 ± 0.01 |

| 8 | 1-Nonanol | 143-08-8 | 1,661 | 56 | Fat, green | 2 (Hu et al., 2023) | – | – | 7.88 ± 0.03 | 2.08 ± 0.01 |

| 9 | 2-Ethyl-5-methylpyrazine | 13360-64-0 | 1,405 | 121 | Nutty, potato, roasted | 320 (Hu et al., 2023) | – | – | 7.88 ± 0.08 | 2.08 ± 0.02 |

| 10 | (E)-2-Octenal | 2548-87-0 | 1,442 | 41 | Fatty, nutty, roasty | 4.0 (Hu et al., 2023) | – | – | 5.40 ± 0.04 | 1.42 ± 0.01 |

| 11 | 2-Ethyl-6-methylpyrazine | 13925-03-6 | 1,386 | 121 | Roasted, baked potato | 150 (Yin et al., 2022) | – | – | 5.03 ± 0.06 | 1.33 ± 0.02 |

| 12 | 2-Methylbutyric acid | 503-74-2 | 1,669 | 60 | Sweaty | 11 (Yin et al., 2022) | 1.21 ± 0.00 | 23.77 ± 0.00 | 5.02 ± 0.11 | 1.32 ± 0.03 |

| 13 | Benzeneacetaldehyde | 122-78-1 | 1,664 | 91 | Honey-like | 22.0 (Hu et al., 2023) | 4.18 ± 0.13 | 82.01 ± 2.54 | 4.72 ± 0.32 | 1.24 ± 0.08 |

| 14 | Hexanal | 66-25-1 | 1,103 | 44 | Green, grassy | 73.0 (Hu et al., 2023) | 2.49 ± 0.05 | 48.82 ± 1.06 | 2.50 ± 0.14 | 0.66 ± 0.04 |

| 15 | Butyrolactone | 96-48-0 | 1,647 | 42 | Caramel, sweet | 60 (Hu et al., 2023) | – | – | 2.50 ± 0.02 | 0.66 ± 0.01 |

| 16 | Ethylpyrazine | 1392-00-3 | 1,347 | 107 | Roasty, buttery | 200 (Hu et al., 2023) | – | – | 2.30 ± 0.01 | 0.61 ± 0.00 |

| 17 | 2,5-Dimethylpyrazine | 123-32-0 | 1,337 | 108 | Peanut | 2000 (Hu et al., 2023) | – | – | 2.24 ± 0.07 | 0.59 ± 0.02 |

| 18 | 2-Methoxyphenol | 90-05-1 | 1871 | 109 | Smoky, burnt | 13 (Yin et al., 2022) | – | – | 2.16 ± 0.10 | 0.57 ± 0.03 |

| 19 | Octanal | 124-13-0 | 1,301 | 43 | Citrus-like, fatty | 140 (Neugebauer et al., 2020) | 0.12 ± 0.00 | 2.39 ± 0.01 | 1.96 ± 0.00 | 0.52 ± 0.00 |

| 20 | Phenylethyl Alcohol | 60-12-8 | 1920 | 122 | Honey-like | 211 (Pollner & Schieberle, 2016) | – | – | 1.05 ± 0.04 | 0.28 ± 0.01 |

| 21 | (E,E)-2,4-Decadienal | 25152-84-5 | 1819 | 81 | Deep-fried, fatty | 66 (Hu et al., 2023) | – | – | 0.99 ± 0.06 | 0.26 ± 0.02 |

| 22 | Furfural | 98-01-1 | 1,478 | 96 | Bread, almond, sweet | 700 (Hu et al., 2023) | – | – | 0.72 ± 0.02 | 0.19 ± 0.00 |

| 23 | Hexanoic acid | 142-62-1 | 1846 | 60 | Sweaty, pungent | 460 (Hu et al., 2023) | 0.04 ± 0.00 | 0.71 ± 0.03 | 0.63 ± 0.05 | 0.17 ± 0.01 |

| 24 | 2-Acetylpyridine | 1122-62-9 | 1,619 | 79 | Steamed rice | 100 (Yin et al., 2022) | – | – | 0.62 ± 0.00 | 0.16 ± 0.00 |

| 25 | 2-Furanmethanol | 98-00-0 | 1,658 | 120 | Burnt | 680 (Hu et al., 2023) | – | – | 0.48 ± 0.01 | 0.13 ± 0.00 |

| 26 | 2-Pyrrolaldehyde | 1003-29-8 | 2000 | 95 | Musty, beefy, coffee | 104 (Hu et al., 2023) | – | – | 0.33 ± 0.00 | 0.09 ± 0.00 |

| 27 | 5-Methylfurfural | 620-02-0 | 1,588 | 110 | Almond, caramel | 260 (Hu et al., 2023) | – | – | 0.29 ± 0.01 | 0.08 ± 0.00 |

| 28 | 3-Ethyl-2,5-dimethylpyrazine | 13360-65-1 | 1,470 | 43 | Earthy, roasted, nut | 76 (Hu et al., 2023) | – | – | 0.15 ± 0.00 | 0.04 ± 0.00 |

| 29 | 3-Phenylfuran | 3777-69-3 | 1,236 | 81 | Fruity, green, earthy, beany, vegetable, metallic, | 130 (Hu et al., 2023) | – | – | 0.12 ± 0.01 | 0.03 ± 0.00 |

| 30 | Pentanoic acid | 109-52-4 | 1,546 | 60 | Sweaty, fruity | 400 (Pollner & Schieberle, 2016) | – | – | 0.08 ± 0.00 | 0.02 ± 0.00 |

| NO . | Odorants . | CAS . | RIa . | Quantitation ion . | Odour description . | OT, μg/kg oil . | SPO . | RPO (WC-1) . | ||

|---|---|---|---|---|---|---|---|---|---|---|

| OAV . | ROAV . | OAV . | ROAV . | |||||||

| 1 | 2-Methylbutanal | 96-17-3 | 990 | 41 | Malty | 2.2 (Hu et al., 2023) | 4.98 ± 0.11 | 100.00 | 375.71 ± 3.47 | 100.00 |

| 2 | 2,6-Dimethylpyrazine | 108-50-9 | 1,344 | 41 | Roasty, cocoa, roast beef | 20 (Hu et al., 2023) | – | – | 117.35 ± 0.13 | 30.95 ± 0.03 |

| 3 | Trimethylpyrazine | 14667-55-1 | 1,417 | 122 | Roasted, potato, musty | 22 (Hu et al., 2023) | – | – | 64.56 ± 1.37 | 17.03 ± 0.36 |

| 4 | 2-Methoxy-4-vinylphenol | 7786-61-0 | 2,210 | 150 | Smoky, clove-like | 20 (Hu et al., 2023) | – | – | 41.12 ± 2.65 | 10.85 ± 0.70 |

| 5 | 2,3-Dimethylpyrazine | 5910-89-4 | 1,361 | 108 | Nutty, nut skin, cocoa, peanut butter, coffee, walnut | 8 (Hu et al., 2023; Yin et al., 2022) | – | – | 27.88 ± 0.39 | 7.35 ± 0.10 |

| 6 | Acetic acid | 64-19-7 | 1,452 | 43 | Vinegar-like, pungent | 124 (Chetschik et al., 2008; Hu et al., 2023) | 1.36 ± 0.10 | 26.78 ± 1.89 | 18.44 ± 0.33 | 4.86 ± 0.09 |

| 7 | Methylpyrazine | 109-08-0 | 1,282 | 94 | Roasted | 200 (Hu et al., 2023) | – | – | 8.14 ± 0.02 | 2.15 ± 0.01 |

| 8 | 1-Nonanol | 143-08-8 | 1,661 | 56 | Fat, green | 2 (Hu et al., 2023) | – | – | 7.88 ± 0.03 | 2.08 ± 0.01 |

| 9 | 2-Ethyl-5-methylpyrazine | 13360-64-0 | 1,405 | 121 | Nutty, potato, roasted | 320 (Hu et al., 2023) | – | – | 7.88 ± 0.08 | 2.08 ± 0.02 |

| 10 | (E)-2-Octenal | 2548-87-0 | 1,442 | 41 | Fatty, nutty, roasty | 4.0 (Hu et al., 2023) | – | – | 5.40 ± 0.04 | 1.42 ± 0.01 |

| 11 | 2-Ethyl-6-methylpyrazine | 13925-03-6 | 1,386 | 121 | Roasted, baked potato | 150 (Yin et al., 2022) | – | – | 5.03 ± 0.06 | 1.33 ± 0.02 |

| 12 | 2-Methylbutyric acid | 503-74-2 | 1,669 | 60 | Sweaty | 11 (Yin et al., 2022) | 1.21 ± 0.00 | 23.77 ± 0.00 | 5.02 ± 0.11 | 1.32 ± 0.03 |

| 13 | Benzeneacetaldehyde | 122-78-1 | 1,664 | 91 | Honey-like | 22.0 (Hu et al., 2023) | 4.18 ± 0.13 | 82.01 ± 2.54 | 4.72 ± 0.32 | 1.24 ± 0.08 |

| 14 | Hexanal | 66-25-1 | 1,103 | 44 | Green, grassy | 73.0 (Hu et al., 2023) | 2.49 ± 0.05 | 48.82 ± 1.06 | 2.50 ± 0.14 | 0.66 ± 0.04 |

| 15 | Butyrolactone | 96-48-0 | 1,647 | 42 | Caramel, sweet | 60 (Hu et al., 2023) | – | – | 2.50 ± 0.02 | 0.66 ± 0.01 |

| 16 | Ethylpyrazine | 1392-00-3 | 1,347 | 107 | Roasty, buttery | 200 (Hu et al., 2023) | – | – | 2.30 ± 0.01 | 0.61 ± 0.00 |

| 17 | 2,5-Dimethylpyrazine | 123-32-0 | 1,337 | 108 | Peanut | 2000 (Hu et al., 2023) | – | – | 2.24 ± 0.07 | 0.59 ± 0.02 |

| 18 | 2-Methoxyphenol | 90-05-1 | 1871 | 109 | Smoky, burnt | 13 (Yin et al., 2022) | – | – | 2.16 ± 0.10 | 0.57 ± 0.03 |

| 19 | Octanal | 124-13-0 | 1,301 | 43 | Citrus-like, fatty | 140 (Neugebauer et al., 2020) | 0.12 ± 0.00 | 2.39 ± 0.01 | 1.96 ± 0.00 | 0.52 ± 0.00 |

| 20 | Phenylethyl Alcohol | 60-12-8 | 1920 | 122 | Honey-like | 211 (Pollner & Schieberle, 2016) | – | – | 1.05 ± 0.04 | 0.28 ± 0.01 |

| 21 | (E,E)-2,4-Decadienal | 25152-84-5 | 1819 | 81 | Deep-fried, fatty | 66 (Hu et al., 2023) | – | – | 0.99 ± 0.06 | 0.26 ± 0.02 |

| 22 | Furfural | 98-01-1 | 1,478 | 96 | Bread, almond, sweet | 700 (Hu et al., 2023) | – | – | 0.72 ± 0.02 | 0.19 ± 0.00 |

| 23 | Hexanoic acid | 142-62-1 | 1846 | 60 | Sweaty, pungent | 460 (Hu et al., 2023) | 0.04 ± 0.00 | 0.71 ± 0.03 | 0.63 ± 0.05 | 0.17 ± 0.01 |

| 24 | 2-Acetylpyridine | 1122-62-9 | 1,619 | 79 | Steamed rice | 100 (Yin et al., 2022) | – | – | 0.62 ± 0.00 | 0.16 ± 0.00 |

| 25 | 2-Furanmethanol | 98-00-0 | 1,658 | 120 | Burnt | 680 (Hu et al., 2023) | – | – | 0.48 ± 0.01 | 0.13 ± 0.00 |

| 26 | 2-Pyrrolaldehyde | 1003-29-8 | 2000 | 95 | Musty, beefy, coffee | 104 (Hu et al., 2023) | – | – | 0.33 ± 0.00 | 0.09 ± 0.00 |

| 27 | 5-Methylfurfural | 620-02-0 | 1,588 | 110 | Almond, caramel | 260 (Hu et al., 2023) | – | – | 0.29 ± 0.01 | 0.08 ± 0.00 |

| 28 | 3-Ethyl-2,5-dimethylpyrazine | 13360-65-1 | 1,470 | 43 | Earthy, roasted, nut | 76 (Hu et al., 2023) | – | – | 0.15 ± 0.00 | 0.04 ± 0.00 |

| 29 | 3-Phenylfuran | 3777-69-3 | 1,236 | 81 | Fruity, green, earthy, beany, vegetable, metallic, | 130 (Hu et al., 2023) | – | – | 0.12 ± 0.01 | 0.03 ± 0.00 |

| 30 | Pentanoic acid | 109-52-4 | 1,546 | 60 | Sweaty, fruity | 400 (Pollner & Schieberle, 2016) | – | – | 0.08 ± 0.00 | 0.02 ± 0.00 |

Note. “–” means not detected; “a” means FFAP polar column; OAV = odour activity value; OT = odour threshold; RI = retention index; ROAV = relative odour activity value; RPO = dry roasted peanut oil; SPO = steamed peanut oil.

Odour activity value (OAV) and relative odour activity value (ROAV) of key aroma-active volatile compounds in roasted peanut oil (RPO) and steamed peanut oil (SPO).

| NO . | Odorants . | CAS . | RIa . | Quantitation ion . | Odour description . | OT, μg/kg oil . | SPO . | RPO (WC-1) . | ||

|---|---|---|---|---|---|---|---|---|---|---|

| OAV . | ROAV . | OAV . | ROAV . | |||||||

| 1 | 2-Methylbutanal | 96-17-3 | 990 | 41 | Malty | 2.2 (Hu et al., 2023) | 4.98 ± 0.11 | 100.00 | 375.71 ± 3.47 | 100.00 |

| 2 | 2,6-Dimethylpyrazine | 108-50-9 | 1,344 | 41 | Roasty, cocoa, roast beef | 20 (Hu et al., 2023) | – | – | 117.35 ± 0.13 | 30.95 ± 0.03 |

| 3 | Trimethylpyrazine | 14667-55-1 | 1,417 | 122 | Roasted, potato, musty | 22 (Hu et al., 2023) | – | – | 64.56 ± 1.37 | 17.03 ± 0.36 |

| 4 | 2-Methoxy-4-vinylphenol | 7786-61-0 | 2,210 | 150 | Smoky, clove-like | 20 (Hu et al., 2023) | – | – | 41.12 ± 2.65 | 10.85 ± 0.70 |

| 5 | 2,3-Dimethylpyrazine | 5910-89-4 | 1,361 | 108 | Nutty, nut skin, cocoa, peanut butter, coffee, walnut | 8 (Hu et al., 2023; Yin et al., 2022) | – | – | 27.88 ± 0.39 | 7.35 ± 0.10 |

| 6 | Acetic acid | 64-19-7 | 1,452 | 43 | Vinegar-like, pungent | 124 (Chetschik et al., 2008; Hu et al., 2023) | 1.36 ± 0.10 | 26.78 ± 1.89 | 18.44 ± 0.33 | 4.86 ± 0.09 |

| 7 | Methylpyrazine | 109-08-0 | 1,282 | 94 | Roasted | 200 (Hu et al., 2023) | – | – | 8.14 ± 0.02 | 2.15 ± 0.01 |

| 8 | 1-Nonanol | 143-08-8 | 1,661 | 56 | Fat, green | 2 (Hu et al., 2023) | – | – | 7.88 ± 0.03 | 2.08 ± 0.01 |

| 9 | 2-Ethyl-5-methylpyrazine | 13360-64-0 | 1,405 | 121 | Nutty, potato, roasted | 320 (Hu et al., 2023) | – | – | 7.88 ± 0.08 | 2.08 ± 0.02 |

| 10 | (E)-2-Octenal | 2548-87-0 | 1,442 | 41 | Fatty, nutty, roasty | 4.0 (Hu et al., 2023) | – | – | 5.40 ± 0.04 | 1.42 ± 0.01 |

| 11 | 2-Ethyl-6-methylpyrazine | 13925-03-6 | 1,386 | 121 | Roasted, baked potato | 150 (Yin et al., 2022) | – | – | 5.03 ± 0.06 | 1.33 ± 0.02 |

| 12 | 2-Methylbutyric acid | 503-74-2 | 1,669 | 60 | Sweaty | 11 (Yin et al., 2022) | 1.21 ± 0.00 | 23.77 ± 0.00 | 5.02 ± 0.11 | 1.32 ± 0.03 |

| 13 | Benzeneacetaldehyde | 122-78-1 | 1,664 | 91 | Honey-like | 22.0 (Hu et al., 2023) | 4.18 ± 0.13 | 82.01 ± 2.54 | 4.72 ± 0.32 | 1.24 ± 0.08 |

| 14 | Hexanal | 66-25-1 | 1,103 | 44 | Green, grassy | 73.0 (Hu et al., 2023) | 2.49 ± 0.05 | 48.82 ± 1.06 | 2.50 ± 0.14 | 0.66 ± 0.04 |

| 15 | Butyrolactone | 96-48-0 | 1,647 | 42 | Caramel, sweet | 60 (Hu et al., 2023) | – | – | 2.50 ± 0.02 | 0.66 ± 0.01 |

| 16 | Ethylpyrazine | 1392-00-3 | 1,347 | 107 | Roasty, buttery | 200 (Hu et al., 2023) | – | – | 2.30 ± 0.01 | 0.61 ± 0.00 |

| 17 | 2,5-Dimethylpyrazine | 123-32-0 | 1,337 | 108 | Peanut | 2000 (Hu et al., 2023) | – | – | 2.24 ± 0.07 | 0.59 ± 0.02 |

| 18 | 2-Methoxyphenol | 90-05-1 | 1871 | 109 | Smoky, burnt | 13 (Yin et al., 2022) | – | – | 2.16 ± 0.10 | 0.57 ± 0.03 |

| 19 | Octanal | 124-13-0 | 1,301 | 43 | Citrus-like, fatty | 140 (Neugebauer et al., 2020) | 0.12 ± 0.00 | 2.39 ± 0.01 | 1.96 ± 0.00 | 0.52 ± 0.00 |

| 20 | Phenylethyl Alcohol | 60-12-8 | 1920 | 122 | Honey-like | 211 (Pollner & Schieberle, 2016) | – | – | 1.05 ± 0.04 | 0.28 ± 0.01 |

| 21 | (E,E)-2,4-Decadienal | 25152-84-5 | 1819 | 81 | Deep-fried, fatty | 66 (Hu et al., 2023) | – | – | 0.99 ± 0.06 | 0.26 ± 0.02 |

| 22 | Furfural | 98-01-1 | 1,478 | 96 | Bread, almond, sweet | 700 (Hu et al., 2023) | – | – | 0.72 ± 0.02 | 0.19 ± 0.00 |

| 23 | Hexanoic acid | 142-62-1 | 1846 | 60 | Sweaty, pungent | 460 (Hu et al., 2023) | 0.04 ± 0.00 | 0.71 ± 0.03 | 0.63 ± 0.05 | 0.17 ± 0.01 |

| 24 | 2-Acetylpyridine | 1122-62-9 | 1,619 | 79 | Steamed rice | 100 (Yin et al., 2022) | – | – | 0.62 ± 0.00 | 0.16 ± 0.00 |

| 25 | 2-Furanmethanol | 98-00-0 | 1,658 | 120 | Burnt | 680 (Hu et al., 2023) | – | – | 0.48 ± 0.01 | 0.13 ± 0.00 |

| 26 | 2-Pyrrolaldehyde | 1003-29-8 | 2000 | 95 | Musty, beefy, coffee | 104 (Hu et al., 2023) | – | – | 0.33 ± 0.00 | 0.09 ± 0.00 |

| 27 | 5-Methylfurfural | 620-02-0 | 1,588 | 110 | Almond, caramel | 260 (Hu et al., 2023) | – | – | 0.29 ± 0.01 | 0.08 ± 0.00 |

| 28 | 3-Ethyl-2,5-dimethylpyrazine | 13360-65-1 | 1,470 | 43 | Earthy, roasted, nut | 76 (Hu et al., 2023) | – | – | 0.15 ± 0.00 | 0.04 ± 0.00 |

| 29 | 3-Phenylfuran | 3777-69-3 | 1,236 | 81 | Fruity, green, earthy, beany, vegetable, metallic, | 130 (Hu et al., 2023) | – | – | 0.12 ± 0.01 | 0.03 ± 0.00 |

| 30 | Pentanoic acid | 109-52-4 | 1,546 | 60 | Sweaty, fruity | 400 (Pollner & Schieberle, 2016) | – | – | 0.08 ± 0.00 | 0.02 ± 0.00 |

| NO . | Odorants . | CAS . | RIa . | Quantitation ion . | Odour description . | OT, μg/kg oil . | SPO . | RPO (WC-1) . | ||

|---|---|---|---|---|---|---|---|---|---|---|

| OAV . | ROAV . | OAV . | ROAV . | |||||||

| 1 | 2-Methylbutanal | 96-17-3 | 990 | 41 | Malty | 2.2 (Hu et al., 2023) | 4.98 ± 0.11 | 100.00 | 375.71 ± 3.47 | 100.00 |

| 2 | 2,6-Dimethylpyrazine | 108-50-9 | 1,344 | 41 | Roasty, cocoa, roast beef | 20 (Hu et al., 2023) | – | – | 117.35 ± 0.13 | 30.95 ± 0.03 |

| 3 | Trimethylpyrazine | 14667-55-1 | 1,417 | 122 | Roasted, potato, musty | 22 (Hu et al., 2023) | – | – | 64.56 ± 1.37 | 17.03 ± 0.36 |

| 4 | 2-Methoxy-4-vinylphenol | 7786-61-0 | 2,210 | 150 | Smoky, clove-like | 20 (Hu et al., 2023) | – | – | 41.12 ± 2.65 | 10.85 ± 0.70 |

| 5 | 2,3-Dimethylpyrazine | 5910-89-4 | 1,361 | 108 | Nutty, nut skin, cocoa, peanut butter, coffee, walnut | 8 (Hu et al., 2023; Yin et al., 2022) | – | – | 27.88 ± 0.39 | 7.35 ± 0.10 |

| 6 | Acetic acid | 64-19-7 | 1,452 | 43 | Vinegar-like, pungent | 124 (Chetschik et al., 2008; Hu et al., 2023) | 1.36 ± 0.10 | 26.78 ± 1.89 | 18.44 ± 0.33 | 4.86 ± 0.09 |

| 7 | Methylpyrazine | 109-08-0 | 1,282 | 94 | Roasted | 200 (Hu et al., 2023) | – | – | 8.14 ± 0.02 | 2.15 ± 0.01 |

| 8 | 1-Nonanol | 143-08-8 | 1,661 | 56 | Fat, green | 2 (Hu et al., 2023) | – | – | 7.88 ± 0.03 | 2.08 ± 0.01 |

| 9 | 2-Ethyl-5-methylpyrazine | 13360-64-0 | 1,405 | 121 | Nutty, potato, roasted | 320 (Hu et al., 2023) | – | – | 7.88 ± 0.08 | 2.08 ± 0.02 |

| 10 | (E)-2-Octenal | 2548-87-0 | 1,442 | 41 | Fatty, nutty, roasty | 4.0 (Hu et al., 2023) | – | – | 5.40 ± 0.04 | 1.42 ± 0.01 |

| 11 | 2-Ethyl-6-methylpyrazine | 13925-03-6 | 1,386 | 121 | Roasted, baked potato | 150 (Yin et al., 2022) | – | – | 5.03 ± 0.06 | 1.33 ± 0.02 |

| 12 | 2-Methylbutyric acid | 503-74-2 | 1,669 | 60 | Sweaty | 11 (Yin et al., 2022) | 1.21 ± 0.00 | 23.77 ± 0.00 | 5.02 ± 0.11 | 1.32 ± 0.03 |

| 13 | Benzeneacetaldehyde | 122-78-1 | 1,664 | 91 | Honey-like | 22.0 (Hu et al., 2023) | 4.18 ± 0.13 | 82.01 ± 2.54 | 4.72 ± 0.32 | 1.24 ± 0.08 |

| 14 | Hexanal | 66-25-1 | 1,103 | 44 | Green, grassy | 73.0 (Hu et al., 2023) | 2.49 ± 0.05 | 48.82 ± 1.06 | 2.50 ± 0.14 | 0.66 ± 0.04 |

| 15 | Butyrolactone | 96-48-0 | 1,647 | 42 | Caramel, sweet | 60 (Hu et al., 2023) | – | – | 2.50 ± 0.02 | 0.66 ± 0.01 |

| 16 | Ethylpyrazine | 1392-00-3 | 1,347 | 107 | Roasty, buttery | 200 (Hu et al., 2023) | – | – | 2.30 ± 0.01 | 0.61 ± 0.00 |

| 17 | 2,5-Dimethylpyrazine | 123-32-0 | 1,337 | 108 | Peanut | 2000 (Hu et al., 2023) | – | – | 2.24 ± 0.07 | 0.59 ± 0.02 |

| 18 | 2-Methoxyphenol | 90-05-1 | 1871 | 109 | Smoky, burnt | 13 (Yin et al., 2022) | – | – | 2.16 ± 0.10 | 0.57 ± 0.03 |

| 19 | Octanal | 124-13-0 | 1,301 | 43 | Citrus-like, fatty | 140 (Neugebauer et al., 2020) | 0.12 ± 0.00 | 2.39 ± 0.01 | 1.96 ± 0.00 | 0.52 ± 0.00 |

| 20 | Phenylethyl Alcohol | 60-12-8 | 1920 | 122 | Honey-like | 211 (Pollner & Schieberle, 2016) | – | – | 1.05 ± 0.04 | 0.28 ± 0.01 |

| 21 | (E,E)-2,4-Decadienal | 25152-84-5 | 1819 | 81 | Deep-fried, fatty | 66 (Hu et al., 2023) | – | – | 0.99 ± 0.06 | 0.26 ± 0.02 |

| 22 | Furfural | 98-01-1 | 1,478 | 96 | Bread, almond, sweet | 700 (Hu et al., 2023) | – | – | 0.72 ± 0.02 | 0.19 ± 0.00 |

| 23 | Hexanoic acid | 142-62-1 | 1846 | 60 | Sweaty, pungent | 460 (Hu et al., 2023) | 0.04 ± 0.00 | 0.71 ± 0.03 | 0.63 ± 0.05 | 0.17 ± 0.01 |

| 24 | 2-Acetylpyridine | 1122-62-9 | 1,619 | 79 | Steamed rice | 100 (Yin et al., 2022) | – | – | 0.62 ± 0.00 | 0.16 ± 0.00 |

| 25 | 2-Furanmethanol | 98-00-0 | 1,658 | 120 | Burnt | 680 (Hu et al., 2023) | – | – | 0.48 ± 0.01 | 0.13 ± 0.00 |

| 26 | 2-Pyrrolaldehyde | 1003-29-8 | 2000 | 95 | Musty, beefy, coffee | 104 (Hu et al., 2023) | – | – | 0.33 ± 0.00 | 0.09 ± 0.00 |

| 27 | 5-Methylfurfural | 620-02-0 | 1,588 | 110 | Almond, caramel | 260 (Hu et al., 2023) | – | – | 0.29 ± 0.01 | 0.08 ± 0.00 |

| 28 | 3-Ethyl-2,5-dimethylpyrazine | 13360-65-1 | 1,470 | 43 | Earthy, roasted, nut | 76 (Hu et al., 2023) | – | – | 0.15 ± 0.00 | 0.04 ± 0.00 |

| 29 | 3-Phenylfuran | 3777-69-3 | 1,236 | 81 | Fruity, green, earthy, beany, vegetable, metallic, | 130 (Hu et al., 2023) | – | – | 0.12 ± 0.01 | 0.03 ± 0.00 |

| 30 | Pentanoic acid | 109-52-4 | 1,546 | 60 | Sweaty, fruity | 400 (Pollner & Schieberle, 2016) | – | – | 0.08 ± 0.00 | 0.02 ± 0.00 |

Note. “–” means not detected; “a” means FFAP polar column; OAV = odour activity value; OT = odour threshold; RI = retention index; ROAV = relative odour activity value; RPO = dry roasted peanut oil; SPO = steamed peanut oil.

| Samples . | Palmitic acid (16:0) . | Stearic acid (18:0) . | Oleic acid (18:1) . | Linoleic acid (18:2) . | Arachidic acid (20:0) . | Linolenic acid (18:3) . | Behenic acid (22:0) . |

|---|---|---|---|---|---|---|---|

| WC-1 | 10.16 ± 0.03a,b,c | 4.12 ± 0.00a,b | 50.97 ± 0.01d | 30.27 ± 0.04b | 1.51 ± 0.04a | 0.62 ± 0.01a | 1.92 ± 0.01c |

| WC-2 | 10.09 ± 0.04c | 4.05 ± 0.00c,d | 51.41 ± 0.03a,b | 29.91 ± 0.01e,f | 1.51 ± 0.02a | 0.64 ± 0.02a | 1.96 ± 0.02b,c |

| WC-3 | 10.25 ± 0.03a | 3.97 ± 0.03e | 51.06 ± 0.03d | 30.17 ± 0.04b,c | 1.51 ± 0.03a | 0.64 ± 0.02a | 1.98 ± 0.02a,b,c |

| WC-4 | 10.15 ± 0.02a,b,c | 4.08 ± 0.02a,b,c,d | 51.03 ± 0.02d | 30.09 ± 0.03c | 1.54 ± 0.03a | 0.65 ± 0.02a | 2.04 ± 0.02a |

| WC-5 | 10.22 ± 0.02a,b | 4.06 ± 0.02b,c,d | 50.62 ± 0.07e | 30.47 ± 0.03a | 1.53 ± 0.03a | 0.65 ± 0.04a | 2.03 ± 0.00a |

| WC-6 | 10.12 ± 0.02b,c | 4.08 ± 0.03a,b,c,d | 51.20 ± 0.02c | 30.05 ± 0.03c,d | 1.51 ± 0.04a | 0.64 ± 0.03a | 1.96 ± 0.01b,c |

| WC-7 | 10.14 ± 0.03b,c | 4.11 ± 0.02a,b,c | 51.01 ± 0.03d | 30.10 ± 0.05c | 1.55 ± 0.03a | 0.64 ± 0.02a | 2.02 ± 0.01a,b |

| Samples . | Palmitic acid (16:0) . | Stearic acid (18:0) . | Oleic acid (18:1) . | Linoleic acid (18:2) . | Arachidic acid (20:0) . | Linolenic acid (18:3) . | Behenic acid (22:0) . |

|---|---|---|---|---|---|---|---|

| WC-1 | 10.16 ± 0.03a,b,c | 4.12 ± 0.00a,b | 50.97 ± 0.01d | 30.27 ± 0.04b | 1.51 ± 0.04a | 0.62 ± 0.01a | 1.92 ± 0.01c |

| WC-2 | 10.09 ± 0.04c | 4.05 ± 0.00c,d | 51.41 ± 0.03a,b | 29.91 ± 0.01e,f | 1.51 ± 0.02a | 0.64 ± 0.02a | 1.96 ± 0.02b,c |

| WC-3 | 10.25 ± 0.03a | 3.97 ± 0.03e | 51.06 ± 0.03d | 30.17 ± 0.04b,c | 1.51 ± 0.03a | 0.64 ± 0.02a | 1.98 ± 0.02a,b,c |

| WC-4 | 10.15 ± 0.02a,b,c | 4.08 ± 0.02a,b,c,d | 51.03 ± 0.02d | 30.09 ± 0.03c | 1.54 ± 0.03a | 0.65 ± 0.02a | 2.04 ± 0.02a |

| WC-5 | 10.22 ± 0.02a,b | 4.06 ± 0.02b,c,d | 50.62 ± 0.07e | 30.47 ± 0.03a | 1.53 ± 0.03a | 0.65 ± 0.04a | 2.03 ± 0.00a |

| WC-6 | 10.12 ± 0.02b,c | 4.08 ± 0.03a,b,c,d | 51.20 ± 0.02c | 30.05 ± 0.03c,d | 1.51 ± 0.04a | 0.64 ± 0.03a | 1.96 ± 0.01b,c |

| WC-7 | 10.14 ± 0.03b,c | 4.11 ± 0.02a,b,c | 51.01 ± 0.03d | 30.10 ± 0.05c | 1.55 ± 0.03a | 0.64 ± 0.02a | 2.02 ± 0.01a,b |

Note. RPO = roasted peanut oil; different letters in the same row represent significant differences (P < .05).

| Samples . | Palmitic acid (16:0) . | Stearic acid (18:0) . | Oleic acid (18:1) . | Linoleic acid (18:2) . | Arachidic acid (20:0) . | Linolenic acid (18:3) . | Behenic acid (22:0) . |

|---|---|---|---|---|---|---|---|

| WC-1 | 10.16 ± 0.03a,b,c | 4.12 ± 0.00a,b | 50.97 ± 0.01d | 30.27 ± 0.04b | 1.51 ± 0.04a | 0.62 ± 0.01a | 1.92 ± 0.01c |

| WC-2 | 10.09 ± 0.04c | 4.05 ± 0.00c,d | 51.41 ± 0.03a,b | 29.91 ± 0.01e,f | 1.51 ± 0.02a | 0.64 ± 0.02a | 1.96 ± 0.02b,c |

| WC-3 | 10.25 ± 0.03a | 3.97 ± 0.03e | 51.06 ± 0.03d | 30.17 ± 0.04b,c | 1.51 ± 0.03a | 0.64 ± 0.02a | 1.98 ± 0.02a,b,c |

| WC-4 | 10.15 ± 0.02a,b,c | 4.08 ± 0.02a,b,c,d | 51.03 ± 0.02d | 30.09 ± 0.03c | 1.54 ± 0.03a | 0.65 ± 0.02a | 2.04 ± 0.02a |

| WC-5 | 10.22 ± 0.02a,b | 4.06 ± 0.02b,c,d | 50.62 ± 0.07e | 30.47 ± 0.03a | 1.53 ± 0.03a | 0.65 ± 0.04a | 2.03 ± 0.00a |

| WC-6 | 10.12 ± 0.02b,c | 4.08 ± 0.03a,b,c,d | 51.20 ± 0.02c | 30.05 ± 0.03c,d | 1.51 ± 0.04a | 0.64 ± 0.03a | 1.96 ± 0.01b,c |

| WC-7 | 10.14 ± 0.03b,c | 4.11 ± 0.02a,b,c | 51.01 ± 0.03d | 30.10 ± 0.05c | 1.55 ± 0.03a | 0.64 ± 0.02a | 2.02 ± 0.01a,b |

| Samples . | Palmitic acid (16:0) . | Stearic acid (18:0) . | Oleic acid (18:1) . | Linoleic acid (18:2) . | Arachidic acid (20:0) . | Linolenic acid (18:3) . | Behenic acid (22:0) . |

|---|---|---|---|---|---|---|---|

| WC-1 | 10.16 ± 0.03a,b,c | 4.12 ± 0.00a,b | 50.97 ± 0.01d | 30.27 ± 0.04b | 1.51 ± 0.04a | 0.62 ± 0.01a | 1.92 ± 0.01c |

| WC-2 | 10.09 ± 0.04c | 4.05 ± 0.00c,d | 51.41 ± 0.03a,b | 29.91 ± 0.01e,f | 1.51 ± 0.02a | 0.64 ± 0.02a | 1.96 ± 0.02b,c |

| WC-3 | 10.25 ± 0.03a | 3.97 ± 0.03e | 51.06 ± 0.03d | 30.17 ± 0.04b,c | 1.51 ± 0.03a | 0.64 ± 0.02a | 1.98 ± 0.02a,b,c |

| WC-4 | 10.15 ± 0.02a,b,c | 4.08 ± 0.02a,b,c,d | 51.03 ± 0.02d | 30.09 ± 0.03c | 1.54 ± 0.03a | 0.65 ± 0.02a | 2.04 ± 0.02a |

| WC-5 | 10.22 ± 0.02a,b | 4.06 ± 0.02b,c,d | 50.62 ± 0.07e | 30.47 ± 0.03a | 1.53 ± 0.03a | 0.65 ± 0.04a | 2.03 ± 0.00a |

| WC-6 | 10.12 ± 0.02b,c | 4.08 ± 0.03a,b,c,d | 51.20 ± 0.02c | 30.05 ± 0.03c,d | 1.51 ± 0.04a | 0.64 ± 0.03a | 1.96 ± 0.01b,c |

| WC-7 | 10.14 ± 0.03b,c | 4.11 ± 0.02a,b,c | 51.01 ± 0.03d | 30.10 ± 0.05c | 1.55 ± 0.03a | 0.64 ± 0.02a | 2.02 ± 0.01a,b |

Note. RPO = roasted peanut oil; different letters in the same row represent significant differences (P < .05).

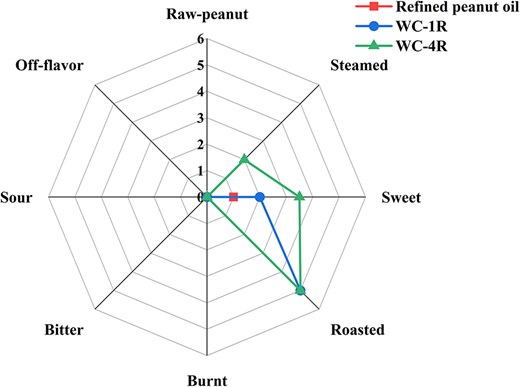

Aroma recombination experiments

To investigate the contribution of BA and key aroma-active pyrazines (OAV > 1) to the sweet and roasted flavours in peanut oil, flavour recombination experiments were conducted. These pyrazines included: 2,6-dimethylpyrazine, trimethylpyrazine, 2,3-dimethylpyrazine, methylpyrazine, 2-ethyl-6-methylpyrazine, and 2-ethyl-5-methylpyrazine. The compounds were incorporated into 15 g of refined peanut oil at concentrations derived from the WC-1 and WC-4 and labelled as WC1R and WC4R, respectively. Sensory evaluation was performed as described in the Sensory Analysis of Peanut Oils section, with the results presented in Figure 1.

Statistical analysis

The differences between groups were carried out by ANOVA and Duncan’s multiple range tests (SPSS version 24.0) with the level of statistical significance set at p < .05.

Results and discussions

Sensory profiles of RPO (WC-1) and SPO

Sensory characteristics of RPO (WC-1) and SPO

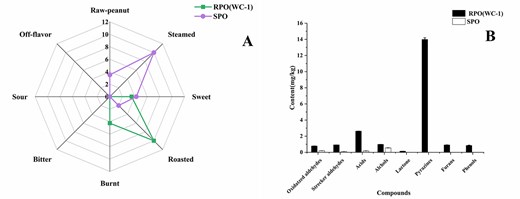

The QDA was employed to analyse the sensory characteristics of SPO and RPO (WC-1). Results are presented in Figure 2A; the sensory characteristics of RPO and SPO are quite different. The primary flavour attribute of SPO is steamed with a score of 10.0. Additionally, the flavour attributes of sweet and raw-peanut are also notable, scoring 4.3 and 3.5, respectively. While the primary flavour attribute of RPO is the roasted, scoring 10.0. The sensory attributes of the sweet and burnt notes of RPO are also notable, with scores of 3.5 and 4.3, respectively. The underlying reasons for the sensory differences exhibited between these two oils deserve further investigation. Previous studies have indicated that the composition of volatile compounds plays a vital role in determining the flavour profiles of peanut oils (Hu et al., 2023; Lykomitros et al., 2016). Consequently, a detailed discussion of the key aroma-active compounds present in SPO and RPO will be presented in the following section.

Sensory evaluation and volatile compounds composition of SPO and RPO. (A) Sensory evaluation; (B) volatile compounds composition. SPO = steamed peanut oil; RPO = roasted peanut oil.

Identification of key aroma-active compounds of the RPO (WC-1) and the SPO

The composition of volatile compounds in peanut oils, specifically SPO and RPO (WC-1), was investigated. As shown in Figure 2B, the composition of volatile compounds in SPO significantly varies from that of RPO (WC-1), exhibiting differences in both types and intensities. A comprehensive summary of 30 volatile compounds is presented in Table 3. The ROAV is commonly utilised as an index to quantify the contribution of volatile compounds to substrate flavour (Fang et al., 2022). In this study, compounds with an ROAV exceeding 1 were selected as the key aroma-active compounds of peanut oils.

| Amino acid . | Content, mg/kg . | |||||||

|---|---|---|---|---|---|---|---|---|

| WC-1 . | WC-2 . | WC-3 . | WC-4 . | WC-5 . | WC-6 . | WC-7 . | Raw peanut . | |

| Aspartic acid | 153.31 ± 6.10d | 133.19 ± 7.54d | 141.46 ± 3.78d | 153.87 ± 3.66d | 291.06 ± 10.31b | 352.60 ± 5.03a | 282.82 ± 4.44b | 183.01 ± 4.21c |

| Threonine | 9.07 ± 0.84e | 17.44 ± 0.88c,d | 19.30 ± 0.95c | 11.95 ± 1.86d,e | 22.97 ± 2.31c | 31.00 ± 1.02b | 39.83 ± 4.51a | 21.52 ± 1.73c |

| Serine | 58.03 ± 2.16e | 91.01 ± 2.78c | 87.57 ± 5.53c,d | 74.76 ± 1.85d | 127.05 ± 3.72b | 164.46 ± 4.11a | 160.64 ± 5.37a | 116.84 ± 3.86b |

| Glutamic acid | 560.08 ± 20.15d,e | 511.23 ± 8.89e,f | 493.13 ± 16.46f | 572.66 ± 4.79d | 694.88 ± 17.09c | 846.07 ± 10.51b | 875.09 ± 6.81b | 1550.14 ± 30.24a |

| Glycine | 44.57 ± 4.08b | 60.94 ± 3.95a | 52.71 ± 4.51a,b | 47.80 ± 2.34b | 48.10 ± 1.95b | 54.27 ± 1.71a,b | 62.37 ± 4.00a | 51.65 ± 1.87a,b |

| Alanine | 137.12 ± 8.17e | 193.11 ± 5.76b,c | 175.17 ± 6.84c,d | 167.85 ± 3.60d | 164.20 ± 3.26d | 199.93 ± 11.94b | 260.48 ± 4.85a | 191.59 ± 4.81b,c |

| Cysteine | 136.37 ± 8.08e | 195.27 ± 4.08d | 193.41 ± 3.97d | 190.23 ± 5.09d | 261.96 ± 3.40c | 287.20 ± 1.91b | 278.97 ± 7.81b,c | 335.52 ± 13.15a |

| Valine | 65.80 ± 6.44e | 89.11 ± 3.45c,d | 88.04 ± 2.19d | 82.22 ± 3.53d | 106.33 ± 3.84b | 127.24 ± 1.66a | 126.82 ± 5.53a | 103.71 ± 6.42b,c |

| Methionine | 2.83 ± 0.39c | 6.54 ± 1.06c | 6.94 ± 0.84c | 5.38 ± 0.90c | 16.90 ± 0.88b | 26.14 ± 1.85a | 26.52 ± 1.23a | 16.73 ± 3.46b |

| Isoleucine | 23.33 ± 0.91e | 37.55 ± 2.76c,d | 37.79 ± 2.50c,d | 35.01 ± 2.78d | 46.16 ± 3.74b,c | 63.65 ± 2.98a | 64.54 ± 3.17a | 48.23 ± 2.35b |

| Leucine | 11.16 ± 0.95d | 11.88 ± 1.13d | 12.71 ± 1.61d | 11.33 ± 0.34d | 20.67 ± 2.57c | 35.83 ± 2.93b | 41.07 ± 4.18a,b | 44.09 ± 1.72a |

| Tyrosine | 114.93 ± 6.19d | 136.43 ± 5.78b,c | 130.72 ± 3.37c,d | 129.18 ± 6.21c,d | 146.09 ± 4.46b,c | 153.73 ± 3.45b | 154.02 ± 3.73b | 248.86 ± 8.58a |

| Phenylalanine | 489.60 ± 10.93d | 609.87 ± 12.67b | 546.86 ± 13.69c | 539.51 ± 9.22c | 593.84 ± 6.44b | 587.72 ± 8.47b | 551.52 ± 4.13c | 705.41 ± 8.73a |

| Lysine | 39.37 ± 3.06e | 63.03 ± 3.75c,d | 58.66 ± 3.34c,d | 52.45 ± 2.93d,e | 73.79 ± 4.42b,c | 105.60 ± 4.58a | 113.64 ± 7.26a | 83.35 ± 4.57b |

| Histidine | 17.04 ± 0.21e | 23.94 ± 1.45d | 22.22 ± 1.23d,e | 18.85 ± 0.43d,e | 30.91 ± 2.44c | 46.97 ± 1.28a,b | 45.13 ± 2.84b | 51.46 ± 2.68a |

| Arginine | 496.08 ± 8.40e | 699.07 ± 4.69c | 595.67 ± 6.46d | 609.52 ± 9.76d | 679.15 ± 9.2c | 774.56 ± 8.22a | 763.52 ± 5.94a,b | 747.80 ± 7.47b |

| Proline | 35.47 ± 5.19c | 55.77 ± 3.50b | 55.64 ± 1.75b | 37.99 ± 2.70c | 58.77 ± 3.51b | 57.36 ± 0.91b | 74.18 ± 3.89a | 22.38 ± 1.30d |

| Total content, mg/kg | 2394.16 ± 23.11f | 2935.38 ± 31.94d | 2718.00 ± 13.70e | 2740.55 ± 37.58e | 3382.84 ± 34.89c | 3914.32 ± 34.79b | 3921.15 ± 44.64b | 4522.30 ± 29.14a |

| Percentage of phenylalanine, % | 20.45 ± 0.65a | 20.78 ± 0.21a | 20.12 ± 0.61a | 19.69 ± 0.08a | 17.55 ± 0.04b | 15.01 ± 0.35c,d | 14.07 ± 0.05e | 15.60 ± 0.09c |

| Amino acid . | Content, mg/kg . | |||||||

|---|---|---|---|---|---|---|---|---|

| WC-1 . | WC-2 . | WC-3 . | WC-4 . | WC-5 . | WC-6 . | WC-7 . | Raw peanut . | |

| Aspartic acid | 153.31 ± 6.10d | 133.19 ± 7.54d | 141.46 ± 3.78d | 153.87 ± 3.66d | 291.06 ± 10.31b | 352.60 ± 5.03a | 282.82 ± 4.44b | 183.01 ± 4.21c |

| Threonine | 9.07 ± 0.84e | 17.44 ± 0.88c,d | 19.30 ± 0.95c | 11.95 ± 1.86d,e | 22.97 ± 2.31c | 31.00 ± 1.02b | 39.83 ± 4.51a | 21.52 ± 1.73c |

| Serine | 58.03 ± 2.16e | 91.01 ± 2.78c | 87.57 ± 5.53c,d | 74.76 ± 1.85d | 127.05 ± 3.72b | 164.46 ± 4.11a | 160.64 ± 5.37a | 116.84 ± 3.86b |

| Glutamic acid | 560.08 ± 20.15d,e | 511.23 ± 8.89e,f | 493.13 ± 16.46f | 572.66 ± 4.79d | 694.88 ± 17.09c | 846.07 ± 10.51b | 875.09 ± 6.81b | 1550.14 ± 30.24a |

| Glycine | 44.57 ± 4.08b | 60.94 ± 3.95a | 52.71 ± 4.51a,b | 47.80 ± 2.34b | 48.10 ± 1.95b | 54.27 ± 1.71a,b | 62.37 ± 4.00a | 51.65 ± 1.87a,b |

| Alanine | 137.12 ± 8.17e | 193.11 ± 5.76b,c | 175.17 ± 6.84c,d | 167.85 ± 3.60d | 164.20 ± 3.26d | 199.93 ± 11.94b | 260.48 ± 4.85a | 191.59 ± 4.81b,c |

| Cysteine | 136.37 ± 8.08e | 195.27 ± 4.08d | 193.41 ± 3.97d | 190.23 ± 5.09d | 261.96 ± 3.40c | 287.20 ± 1.91b | 278.97 ± 7.81b,c | 335.52 ± 13.15a |

| Valine | 65.80 ± 6.44e | 89.11 ± 3.45c,d | 88.04 ± 2.19d | 82.22 ± 3.53d | 106.33 ± 3.84b | 127.24 ± 1.66a | 126.82 ± 5.53a | 103.71 ± 6.42b,c |

| Methionine | 2.83 ± 0.39c | 6.54 ± 1.06c | 6.94 ± 0.84c | 5.38 ± 0.90c | 16.90 ± 0.88b | 26.14 ± 1.85a | 26.52 ± 1.23a | 16.73 ± 3.46b |

| Isoleucine | 23.33 ± 0.91e | 37.55 ± 2.76c,d | 37.79 ± 2.50c,d | 35.01 ± 2.78d | 46.16 ± 3.74b,c | 63.65 ± 2.98a | 64.54 ± 3.17a | 48.23 ± 2.35b |

| Leucine | 11.16 ± 0.95d | 11.88 ± 1.13d | 12.71 ± 1.61d | 11.33 ± 0.34d | 20.67 ± 2.57c | 35.83 ± 2.93b | 41.07 ± 4.18a,b | 44.09 ± 1.72a |

| Tyrosine | 114.93 ± 6.19d | 136.43 ± 5.78b,c | 130.72 ± 3.37c,d | 129.18 ± 6.21c,d | 146.09 ± 4.46b,c | 153.73 ± 3.45b | 154.02 ± 3.73b | 248.86 ± 8.58a |

| Phenylalanine | 489.60 ± 10.93d | 609.87 ± 12.67b | 546.86 ± 13.69c | 539.51 ± 9.22c | 593.84 ± 6.44b | 587.72 ± 8.47b | 551.52 ± 4.13c | 705.41 ± 8.73a |

| Lysine | 39.37 ± 3.06e | 63.03 ± 3.75c,d | 58.66 ± 3.34c,d | 52.45 ± 2.93d,e | 73.79 ± 4.42b,c | 105.60 ± 4.58a | 113.64 ± 7.26a | 83.35 ± 4.57b |

| Histidine | 17.04 ± 0.21e | 23.94 ± 1.45d | 22.22 ± 1.23d,e | 18.85 ± 0.43d,e | 30.91 ± 2.44c | 46.97 ± 1.28a,b | 45.13 ± 2.84b | 51.46 ± 2.68a |

| Arginine | 496.08 ± 8.40e | 699.07 ± 4.69c | 595.67 ± 6.46d | 609.52 ± 9.76d | 679.15 ± 9.2c | 774.56 ± 8.22a | 763.52 ± 5.94a,b | 747.80 ± 7.47b |

| Proline | 35.47 ± 5.19c | 55.77 ± 3.50b | 55.64 ± 1.75b | 37.99 ± 2.70c | 58.77 ± 3.51b | 57.36 ± 0.91b | 74.18 ± 3.89a | 22.38 ± 1.30d |

| Total content, mg/kg | 2394.16 ± 23.11f | 2935.38 ± 31.94d | 2718.00 ± 13.70e | 2740.55 ± 37.58e | 3382.84 ± 34.89c | 3914.32 ± 34.79b | 3921.15 ± 44.64b | 4522.30 ± 29.14a |

| Percentage of phenylalanine, % | 20.45 ± 0.65a | 20.78 ± 0.21a | 20.12 ± 0.61a | 19.69 ± 0.08a | 17.55 ± 0.04b | 15.01 ± 0.35c,d | 14.07 ± 0.05e | 15.60 ± 0.09c |

Different letters in the same row represent significant differences (P < .05).

| Amino acid . | Content, mg/kg . | |||||||

|---|---|---|---|---|---|---|---|---|

| WC-1 . | WC-2 . | WC-3 . | WC-4 . | WC-5 . | WC-6 . | WC-7 . | Raw peanut . | |

| Aspartic acid | 153.31 ± 6.10d | 133.19 ± 7.54d | 141.46 ± 3.78d | 153.87 ± 3.66d | 291.06 ± 10.31b | 352.60 ± 5.03a | 282.82 ± 4.44b | 183.01 ± 4.21c |

| Threonine | 9.07 ± 0.84e | 17.44 ± 0.88c,d | 19.30 ± 0.95c | 11.95 ± 1.86d,e | 22.97 ± 2.31c | 31.00 ± 1.02b | 39.83 ± 4.51a | 21.52 ± 1.73c |

| Serine | 58.03 ± 2.16e | 91.01 ± 2.78c | 87.57 ± 5.53c,d | 74.76 ± 1.85d | 127.05 ± 3.72b | 164.46 ± 4.11a | 160.64 ± 5.37a | 116.84 ± 3.86b |

| Glutamic acid | 560.08 ± 20.15d,e | 511.23 ± 8.89e,f | 493.13 ± 16.46f | 572.66 ± 4.79d | 694.88 ± 17.09c | 846.07 ± 10.51b | 875.09 ± 6.81b | 1550.14 ± 30.24a |

| Glycine | 44.57 ± 4.08b | 60.94 ± 3.95a | 52.71 ± 4.51a,b | 47.80 ± 2.34b | 48.10 ± 1.95b | 54.27 ± 1.71a,b | 62.37 ± 4.00a | 51.65 ± 1.87a,b |

| Alanine | 137.12 ± 8.17e | 193.11 ± 5.76b,c | 175.17 ± 6.84c,d | 167.85 ± 3.60d | 164.20 ± 3.26d | 199.93 ± 11.94b | 260.48 ± 4.85a | 191.59 ± 4.81b,c |

| Cysteine | 136.37 ± 8.08e | 195.27 ± 4.08d | 193.41 ± 3.97d | 190.23 ± 5.09d | 261.96 ± 3.40c | 287.20 ± 1.91b | 278.97 ± 7.81b,c | 335.52 ± 13.15a |

| Valine | 65.80 ± 6.44e | 89.11 ± 3.45c,d | 88.04 ± 2.19d | 82.22 ± 3.53d | 106.33 ± 3.84b | 127.24 ± 1.66a | 126.82 ± 5.53a | 103.71 ± 6.42b,c |

| Methionine | 2.83 ± 0.39c | 6.54 ± 1.06c | 6.94 ± 0.84c | 5.38 ± 0.90c | 16.90 ± 0.88b | 26.14 ± 1.85a | 26.52 ± 1.23a | 16.73 ± 3.46b |

| Isoleucine | 23.33 ± 0.91e | 37.55 ± 2.76c,d | 37.79 ± 2.50c,d | 35.01 ± 2.78d | 46.16 ± 3.74b,c | 63.65 ± 2.98a | 64.54 ± 3.17a | 48.23 ± 2.35b |

| Leucine | 11.16 ± 0.95d | 11.88 ± 1.13d | 12.71 ± 1.61d | 11.33 ± 0.34d | 20.67 ± 2.57c | 35.83 ± 2.93b | 41.07 ± 4.18a,b | 44.09 ± 1.72a |

| Tyrosine | 114.93 ± 6.19d | 136.43 ± 5.78b,c | 130.72 ± 3.37c,d | 129.18 ± 6.21c,d | 146.09 ± 4.46b,c | 153.73 ± 3.45b | 154.02 ± 3.73b | 248.86 ± 8.58a |

| Phenylalanine | 489.60 ± 10.93d | 609.87 ± 12.67b | 546.86 ± 13.69c | 539.51 ± 9.22c | 593.84 ± 6.44b | 587.72 ± 8.47b | 551.52 ± 4.13c | 705.41 ± 8.73a |

| Lysine | 39.37 ± 3.06e | 63.03 ± 3.75c,d | 58.66 ± 3.34c,d | 52.45 ± 2.93d,e | 73.79 ± 4.42b,c | 105.60 ± 4.58a | 113.64 ± 7.26a | 83.35 ± 4.57b |

| Histidine | 17.04 ± 0.21e | 23.94 ± 1.45d | 22.22 ± 1.23d,e | 18.85 ± 0.43d,e | 30.91 ± 2.44c | 46.97 ± 1.28a,b | 45.13 ± 2.84b | 51.46 ± 2.68a |

| Arginine | 496.08 ± 8.40e | 699.07 ± 4.69c | 595.67 ± 6.46d | 609.52 ± 9.76d | 679.15 ± 9.2c | 774.56 ± 8.22a | 763.52 ± 5.94a,b | 747.80 ± 7.47b |

| Proline | 35.47 ± 5.19c | 55.77 ± 3.50b | 55.64 ± 1.75b | 37.99 ± 2.70c | 58.77 ± 3.51b | 57.36 ± 0.91b | 74.18 ± 3.89a | 22.38 ± 1.30d |

| Total content, mg/kg | 2394.16 ± 23.11f | 2935.38 ± 31.94d | 2718.00 ± 13.70e | 2740.55 ± 37.58e | 3382.84 ± 34.89c | 3914.32 ± 34.79b | 3921.15 ± 44.64b | 4522.30 ± 29.14a |

| Percentage of phenylalanine, % | 20.45 ± 0.65a | 20.78 ± 0.21a | 20.12 ± 0.61a | 19.69 ± 0.08a | 17.55 ± 0.04b | 15.01 ± 0.35c,d | 14.07 ± 0.05e | 15.60 ± 0.09c |

| Amino acid . | Content, mg/kg . | |||||||

|---|---|---|---|---|---|---|---|---|

| WC-1 . | WC-2 . | WC-3 . | WC-4 . | WC-5 . | WC-6 . | WC-7 . | Raw peanut . | |

| Aspartic acid | 153.31 ± 6.10d | 133.19 ± 7.54d | 141.46 ± 3.78d | 153.87 ± 3.66d | 291.06 ± 10.31b | 352.60 ± 5.03a | 282.82 ± 4.44b | 183.01 ± 4.21c |

| Threonine | 9.07 ± 0.84e | 17.44 ± 0.88c,d | 19.30 ± 0.95c | 11.95 ± 1.86d,e | 22.97 ± 2.31c | 31.00 ± 1.02b | 39.83 ± 4.51a | 21.52 ± 1.73c |

| Serine | 58.03 ± 2.16e | 91.01 ± 2.78c | 87.57 ± 5.53c,d | 74.76 ± 1.85d | 127.05 ± 3.72b | 164.46 ± 4.11a | 160.64 ± 5.37a | 116.84 ± 3.86b |

| Glutamic acid | 560.08 ± 20.15d,e | 511.23 ± 8.89e,f | 493.13 ± 16.46f | 572.66 ± 4.79d | 694.88 ± 17.09c | 846.07 ± 10.51b | 875.09 ± 6.81b | 1550.14 ± 30.24a |

| Glycine | 44.57 ± 4.08b | 60.94 ± 3.95a | 52.71 ± 4.51a,b | 47.80 ± 2.34b | 48.10 ± 1.95b | 54.27 ± 1.71a,b | 62.37 ± 4.00a | 51.65 ± 1.87a,b |

| Alanine | 137.12 ± 8.17e | 193.11 ± 5.76b,c | 175.17 ± 6.84c,d | 167.85 ± 3.60d | 164.20 ± 3.26d | 199.93 ± 11.94b | 260.48 ± 4.85a | 191.59 ± 4.81b,c |

| Cysteine | 136.37 ± 8.08e | 195.27 ± 4.08d | 193.41 ± 3.97d | 190.23 ± 5.09d | 261.96 ± 3.40c | 287.20 ± 1.91b | 278.97 ± 7.81b,c | 335.52 ± 13.15a |

| Valine | 65.80 ± 6.44e | 89.11 ± 3.45c,d | 88.04 ± 2.19d | 82.22 ± 3.53d | 106.33 ± 3.84b | 127.24 ± 1.66a | 126.82 ± 5.53a | 103.71 ± 6.42b,c |

| Methionine | 2.83 ± 0.39c | 6.54 ± 1.06c | 6.94 ± 0.84c | 5.38 ± 0.90c | 16.90 ± 0.88b | 26.14 ± 1.85a | 26.52 ± 1.23a | 16.73 ± 3.46b |

| Isoleucine | 23.33 ± 0.91e | 37.55 ± 2.76c,d | 37.79 ± 2.50c,d | 35.01 ± 2.78d | 46.16 ± 3.74b,c | 63.65 ± 2.98a | 64.54 ± 3.17a | 48.23 ± 2.35b |

| Leucine | 11.16 ± 0.95d | 11.88 ± 1.13d | 12.71 ± 1.61d | 11.33 ± 0.34d | 20.67 ± 2.57c | 35.83 ± 2.93b | 41.07 ± 4.18a,b | 44.09 ± 1.72a |

| Tyrosine | 114.93 ± 6.19d | 136.43 ± 5.78b,c | 130.72 ± 3.37c,d | 129.18 ± 6.21c,d | 146.09 ± 4.46b,c | 153.73 ± 3.45b | 154.02 ± 3.73b | 248.86 ± 8.58a |

| Phenylalanine | 489.60 ± 10.93d | 609.87 ± 12.67b | 546.86 ± 13.69c | 539.51 ± 9.22c | 593.84 ± 6.44b | 587.72 ± 8.47b | 551.52 ± 4.13c | 705.41 ± 8.73a |

| Lysine | 39.37 ± 3.06e | 63.03 ± 3.75c,d | 58.66 ± 3.34c,d | 52.45 ± 2.93d,e | 73.79 ± 4.42b,c | 105.60 ± 4.58a | 113.64 ± 7.26a | 83.35 ± 4.57b |

| Histidine | 17.04 ± 0.21e | 23.94 ± 1.45d | 22.22 ± 1.23d,e | 18.85 ± 0.43d,e | 30.91 ± 2.44c | 46.97 ± 1.28a,b | 45.13 ± 2.84b | 51.46 ± 2.68a |

| Arginine | 496.08 ± 8.40e | 699.07 ± 4.69c | 595.67 ± 6.46d | 609.52 ± 9.76d | 679.15 ± 9.2c | 774.56 ± 8.22a | 763.52 ± 5.94a,b | 747.80 ± 7.47b |

| Proline | 35.47 ± 5.19c | 55.77 ± 3.50b | 55.64 ± 1.75b | 37.99 ± 2.70c | 58.77 ± 3.51b | 57.36 ± 0.91b | 74.18 ± 3.89a | 22.38 ± 1.30d |

| Total content, mg/kg | 2394.16 ± 23.11f | 2935.38 ± 31.94d | 2718.00 ± 13.70e | 2740.55 ± 37.58e | 3382.84 ± 34.89c | 3914.32 ± 34.79b | 3921.15 ± 44.64b | 4522.30 ± 29.14a |

| Percentage of phenylalanine, % | 20.45 ± 0.65a | 20.78 ± 0.21a | 20.12 ± 0.61a | 19.69 ± 0.08a | 17.55 ± 0.04b | 15.01 ± 0.35c,d | 14.07 ± 0.05e | 15.60 ± 0.09c |

Different letters in the same row represent significant differences (P < .05).

All 30 volatile compounds were detected in the RPO (WC-1). Thirteen volatile compounds exhibited an OAV higher than 1, indicating that they play an important role in the overall flavour of RPO (WC-1). Among them, there are six pyrazines and two Strecker aldehydes, including 2-methylbutanal (100), 2,6-dimethylpyrazine (30.95), trimethylpyrazine (17.03), 2,3-dimethylpyrazine (7.35), methylpyrazine (2.15), 2-ethyl-5-methylpyrazine (2.08), 2-ethyl-6-methylpyrazine (1.33), and benzeneacetaldehyde (1.24). Only seven volatile compounds were identified in SPO, and six volatile compounds exhibit an ROAV exceeding 1. Two volatile compounds, namely, 2-methylbutanal (100) and BA (82.01), are Maillard reaction products we focused on.

Consequently, our primary focus in the subsequent sections is on elucidating the impact of water content in peanut kernels on the formation of these pyrazines and Strecker aldehydes. In short, we will primarily concentrate on analysing the content change of eight volatile compounds, namely, 2,6-dimethylpyrazine, trimethylpyrazine, 2,3-dimethylpyrazine, methylpyrazine, 2-ethyl-5-methylpyrazine, 2-ethyl-6-methylpyrazine, 2-methylbutanal, and BA.

Impact of different water treatments on flavour profiles of RPOs

Impact on sensory characteristics of RPOs

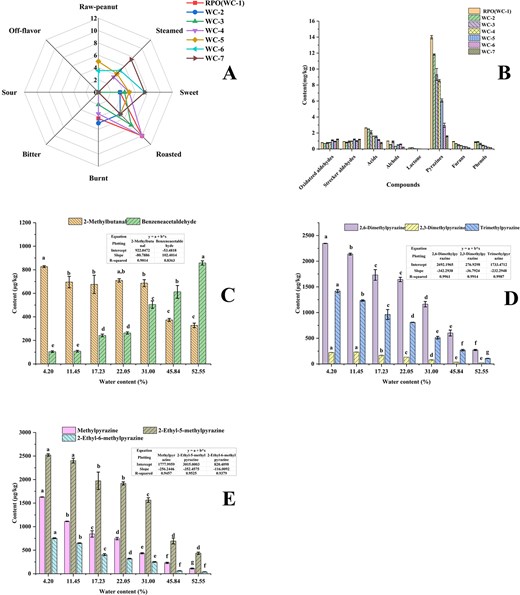

The QDA score of 7 RPOs is presented in Figure 3A. The sensory characteristics of peanut oil primarily display two distinct trends as the water content increases. On one hand, the sweet and steamed flavour attributes of peanut oils gradually increased with an increase in water content in peanut kernels. In detail, the steamed flavour score significantly increased, rising from 0 to 7.5. Similarly, the sweet score rose from 3.5 to 7.5. The raw-peanut flavour attribute demonstrates a relatively high intensity at water content levels of 31.00%, scoring 5.0. The raw-peanut flavour attribute is not significant when the water content reaches 52.55%. This observation may be attributed to the interaction among flavour compounds (Dietz et al., 2020; Ianni et al., 2020). On the other hand, as the water content increases, the intensity of the burnt and roasted flavour attributes decreases. Notably, as the water content increased from 4.20% to 52.55%, the sensory score of the burnt significantly decreased from 4.3 to 0. Although the intensity of roasted flavour does not linearly increase with water content, the overall trend of decrease is unmistakable. Notably, peanut oil samples exhibited the mellowest sensory properties at a water content of 22.05%. Specifically, the sensory scores were 3.5, 5.0, 10.0, and 3.5 for the attributes of steamed, sweet, roasted, and burnt, respectively.

Sensory evaluation and volatile compounds composition of RPOs obtained from peanut kernels with different water content. (A) Sensory evaluation; (B) volatile compounds composition; (C) Strecker aldehydes; (D) and (E) pyrazines. SPO = steamed peanut oil; RPOs = roasted peanut oils.

As a result, the water content in peanut kernels significantly affects the sensory characteristics of peanut oils. As is well known, the sensory characteristics of fragrant oil are closely related to the composition of flavour compounds, especially the key aroma-active compounds (Hu et al., 2023). Consequently, the impact of water content on the intensity of key aroma-active compounds will be the focus of our following discussion.

Impact on key aroma-active compounds composition of RPOs

As shown in Table 4, a total of 30 flavour-related compounds are outlined. As illustrated in Figure 3B, these compounds have been categorised into nine types. The relationship between these nine types and water content predominantly displays two distinct trends. Notably, oxidised aldehydes and Strecker aldehydes demonstrate a positive correlation in their concentration changes with water content variations. Conversely, opposite trends are observed in other categories, such as pyrazines, furans, and phenols. We speculate that the changes in the content of key aroma-active compounds in different categories caused by water content are the main factors leading to sensory variation of RPO.

The content changes of pyrazines and Strecker aldehydes in amino acid and glucose model experiments.

| NO . | Substrate . | Heating condition . | Water content, μL . | 2-Methylbutanal . | Benzeneacetaldehyde . | Methylpyrazine . | 2,6-Dimethylpyrazine . | 2,3-Dimethylpyrazine . | 2-Ethyl-6-methylpyrazine . | 2-Ethyl-5-methylpyrazine . | Trimethylpyrazine . | Total pyrazine content, mg/kg . |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MV1 | Arginine + glucose | 160 °C—30 min | 0 | – | – | 13.80 ± 0.72 | 24.52 ± 0.73 | 2.92 ± 0 | 6.69 ± 0.05 | 20.67 ± 0.91 | 44.24 ± 2.82 | 220.58 ± 8.85 |

| 10 | – | – | 13.62 ± 0.22 | 24.84 ± 0.29 | 3.50 ± 0.29 | 7.80 ± 0.24 | 20.60 ± 2.10 | 45.46 ± 3.38 | 215.57 ± 11.85 | |||

| 25 | – | – | 17.56 ± 0.34 | 30.29 ± 0.38 | 4.48 ± 0.07 | 10.99 ± 0.42 | 16.84 ± 0.57 | 41.84 ± 0.64 | 211.87 ± 5.95 | |||

| 50 | – | – | 17.76 ± 1.24 | 29.91 ± 2.21 | 4.19 ± 0.23 | 13.01 ± 0.48 | 11.37 ± 0.09 | 29.11 ± 0.50 | 170.44 ± 7.23 | |||

| MV2 | Phenylalanine+ glucose | 0 | – | 20.33 ± 1.46 | 1.28 ± 0.39 | 0.60 ± 0.15 | 0.17 ± 0.02 | 0.21 ± 0.04 | 0.86 ± 0.17 | 0.62 ± 0.14 | 7.24 ± 1.87 | |

| 10 | – | 29.69 ± 1.65 | 1.93 ± 0.06 | 1.01 ± 0.12 | 0.22 ± 0.01 | 0.37 ± 0 | 1.78 ± 0.03 | 1.19 ± 0 | 12.32 ± 0.74 | |||

| 25 | – | 31.47 ± 1.40 | 1.83 ± 0.08 | 0.88 ± 0.06 | 0.20 ± 0.01 | 0.37 ± 0.03 | 1.96 ± 0.03 | 1.28 ± 0.02 | 12.74 ± 0.39 | |||

| 50 | – | 33.27 ± 1.06 | 2.11 ± 0.05 | 1.62 ± 0.03 | 0.54 ± 0.01 | 0.60 ± 0.03 | 3.31 ± 0.14 | 2.26 ± 0.09 | 19.98 ± 0.47 | |||

| MV3 | Raw peanut recombinate amino acid + glucose | 0 | 6.01 ± 0.53 | 1.43 ± 0.32 | 2.92 ± 0.09 | 1.85 ± 0.21 | 0.50 ± 0.03 | 1.98 ± 0.06 | 4.14 ± 0.13 | 6.19 ± 0.38 | 36.00 ± 0.52 | |

| 10 | 12.64 ± 0.11 | 3.44 ± 0.56 | 3.42 ± 0.01 | 2.23 ± 0.11 | 0.52 ± 0.03 | 2.95 ± 0.16 | 5.51 ± 0.18 | 4.96 ± 0.04 | 39.28 ± 0.77 | |||

| 25 | 20.75 ± 0.56 | 3.51 ± 0.55 | 2.21 ± 0.34 | 1.34 ± 0.20 | 0.35 ± 0.01 | 2.74 ± 0.01 | 6.18 ± 0.21 | 3.49 ± 0.23 | 33.71 ± 0.72 | |||

| 50 | 21.10 ± 0.53 | 4.57 ± 1.28 | 2.69 ± 0.19 | 1.41 ± 0.14 | 0.30 ± 0.01 | 3.13 ± 0.15 | 7.54 ± 0.55 | 2.83 ± 0.08 | 34.96 ± 0.59 | |||

| MV4 | Phenylalanine + glucose | 100 °C—30 min | 0 | 0 | 1.05 ± 0.10 | – | – | – | – | – | – | – |

| 10 | 0 | 42.36 ± 3.03 | – | – | – | – | – | – | – | |||

| 25 | 0 | 41.95 ± 1.57 | – | – | – | – | – | – | – | |||

| 50 | 0 | 41.58 ± 2.37 | – | – | – | – | – | – | – |

| NO . | Substrate . | Heating condition . | Water content, μL . | 2-Methylbutanal . | Benzeneacetaldehyde . | Methylpyrazine . | 2,6-Dimethylpyrazine . | 2,3-Dimethylpyrazine . | 2-Ethyl-6-methylpyrazine . | 2-Ethyl-5-methylpyrazine . | Trimethylpyrazine . | Total pyrazine content, mg/kg . |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MV1 | Arginine + glucose | 160 °C—30 min | 0 | – | – | 13.80 ± 0.72 | 24.52 ± 0.73 | 2.92 ± 0 | 6.69 ± 0.05 | 20.67 ± 0.91 | 44.24 ± 2.82 | 220.58 ± 8.85 |

| 10 | – | – | 13.62 ± 0.22 | 24.84 ± 0.29 | 3.50 ± 0.29 | 7.80 ± 0.24 | 20.60 ± 2.10 | 45.46 ± 3.38 | 215.57 ± 11.85 | |||

| 25 | – | – | 17.56 ± 0.34 | 30.29 ± 0.38 | 4.48 ± 0.07 | 10.99 ± 0.42 | 16.84 ± 0.57 | 41.84 ± 0.64 | 211.87 ± 5.95 | |||

| 50 | – | – | 17.76 ± 1.24 | 29.91 ± 2.21 | 4.19 ± 0.23 | 13.01 ± 0.48 | 11.37 ± 0.09 | 29.11 ± 0.50 | 170.44 ± 7.23 | |||

| MV2 | Phenylalanine+ glucose | 0 | – | 20.33 ± 1.46 | 1.28 ± 0.39 | 0.60 ± 0.15 | 0.17 ± 0.02 | 0.21 ± 0.04 | 0.86 ± 0.17 | 0.62 ± 0.14 | 7.24 ± 1.87 | |

| 10 | – | 29.69 ± 1.65 | 1.93 ± 0.06 | 1.01 ± 0.12 | 0.22 ± 0.01 | 0.37 ± 0 | 1.78 ± 0.03 | 1.19 ± 0 | 12.32 ± 0.74 | |||

| 25 | – | 31.47 ± 1.40 | 1.83 ± 0.08 | 0.88 ± 0.06 | 0.20 ± 0.01 | 0.37 ± 0.03 | 1.96 ± 0.03 | 1.28 ± 0.02 | 12.74 ± 0.39 | |||

| 50 | – | 33.27 ± 1.06 | 2.11 ± 0.05 | 1.62 ± 0.03 | 0.54 ± 0.01 | 0.60 ± 0.03 | 3.31 ± 0.14 | 2.26 ± 0.09 | 19.98 ± 0.47 | |||

| MV3 | Raw peanut recombinate amino acid + glucose | 0 | 6.01 ± 0.53 | 1.43 ± 0.32 | 2.92 ± 0.09 | 1.85 ± 0.21 | 0.50 ± 0.03 | 1.98 ± 0.06 | 4.14 ± 0.13 | 6.19 ± 0.38 | 36.00 ± 0.52 | |

| 10 | 12.64 ± 0.11 | 3.44 ± 0.56 | 3.42 ± 0.01 | 2.23 ± 0.11 | 0.52 ± 0.03 | 2.95 ± 0.16 | 5.51 ± 0.18 | 4.96 ± 0.04 | 39.28 ± 0.77 | |||

| 25 | 20.75 ± 0.56 | 3.51 ± 0.55 | 2.21 ± 0.34 | 1.34 ± 0.20 | 0.35 ± 0.01 | 2.74 ± 0.01 | 6.18 ± 0.21 | 3.49 ± 0.23 | 33.71 ± 0.72 | |||

| 50 | 21.10 ± 0.53 | 4.57 ± 1.28 | 2.69 ± 0.19 | 1.41 ± 0.14 | 0.30 ± 0.01 | 3.13 ± 0.15 | 7.54 ± 0.55 | 2.83 ± 0.08 | 34.96 ± 0.59 | |||

| MV4 | Phenylalanine + glucose | 100 °C—30 min | 0 | 0 | 1.05 ± 0.10 | – | – | – | – | – | – | – |

| 10 | 0 | 42.36 ± 3.03 | – | – | – | – | – | – | – | |||

| 25 | 0 | 41.95 ± 1.57 | – | – | – | – | – | – | – | |||

| 50 | 0 | 41.58 ± 2.37 | – | – | – | – | – | – | – |

Note. “–” not detected.

The content changes of pyrazines and Strecker aldehydes in amino acid and glucose model experiments.

| NO . | Substrate . | Heating condition . | Water content, μL . | 2-Methylbutanal . | Benzeneacetaldehyde . | Methylpyrazine . | 2,6-Dimethylpyrazine . | 2,3-Dimethylpyrazine . | 2-Ethyl-6-methylpyrazine . | 2-Ethyl-5-methylpyrazine . | Trimethylpyrazine . | Total pyrazine content, mg/kg . |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MV1 | Arginine + glucose | 160 °C—30 min | 0 | – | – | 13.80 ± 0.72 | 24.52 ± 0.73 | 2.92 ± 0 | 6.69 ± 0.05 | 20.67 ± 0.91 | 44.24 ± 2.82 | 220.58 ± 8.85 |

| 10 | – | – | 13.62 ± 0.22 | 24.84 ± 0.29 | 3.50 ± 0.29 | 7.80 ± 0.24 | 20.60 ± 2.10 | 45.46 ± 3.38 | 215.57 ± 11.85 | |||

| 25 | – | – | 17.56 ± 0.34 | 30.29 ± 0.38 | 4.48 ± 0.07 | 10.99 ± 0.42 | 16.84 ± 0.57 | 41.84 ± 0.64 | 211.87 ± 5.95 | |||

| 50 | – | – | 17.76 ± 1.24 | 29.91 ± 2.21 | 4.19 ± 0.23 | 13.01 ± 0.48 | 11.37 ± 0.09 | 29.11 ± 0.50 | 170.44 ± 7.23 | |||

| MV2 | Phenylalanine+ glucose | 0 | – | 20.33 ± 1.46 | 1.28 ± 0.39 | 0.60 ± 0.15 | 0.17 ± 0.02 | 0.21 ± 0.04 | 0.86 ± 0.17 | 0.62 ± 0.14 | 7.24 ± 1.87 | |

| 10 | – | 29.69 ± 1.65 | 1.93 ± 0.06 | 1.01 ± 0.12 | 0.22 ± 0.01 | 0.37 ± 0 | 1.78 ± 0.03 | 1.19 ± 0 | 12.32 ± 0.74 | |||

| 25 | – | 31.47 ± 1.40 | 1.83 ± 0.08 | 0.88 ± 0.06 | 0.20 ± 0.01 | 0.37 ± 0.03 | 1.96 ± 0.03 | 1.28 ± 0.02 | 12.74 ± 0.39 | |||

| 50 | – | 33.27 ± 1.06 | 2.11 ± 0.05 | 1.62 ± 0.03 | 0.54 ± 0.01 | 0.60 ± 0.03 | 3.31 ± 0.14 | 2.26 ± 0.09 | 19.98 ± 0.47 | |||

| MV3 | Raw peanut recombinate amino acid + glucose | 0 | 6.01 ± 0.53 | 1.43 ± 0.32 | 2.92 ± 0.09 | 1.85 ± 0.21 | 0.50 ± 0.03 | 1.98 ± 0.06 | 4.14 ± 0.13 | 6.19 ± 0.38 | 36.00 ± 0.52 | |

| 10 | 12.64 ± 0.11 | 3.44 ± 0.56 | 3.42 ± 0.01 | 2.23 ± 0.11 | 0.52 ± 0.03 | 2.95 ± 0.16 | 5.51 ± 0.18 | 4.96 ± 0.04 | 39.28 ± 0.77 | |||

| 25 | 20.75 ± 0.56 | 3.51 ± 0.55 | 2.21 ± 0.34 | 1.34 ± 0.20 | 0.35 ± 0.01 | 2.74 ± 0.01 | 6.18 ± 0.21 | 3.49 ± 0.23 | 33.71 ± 0.72 | |||

| 50 | 21.10 ± 0.53 | 4.57 ± 1.28 | 2.69 ± 0.19 | 1.41 ± 0.14 | 0.30 ± 0.01 | 3.13 ± 0.15 | 7.54 ± 0.55 | 2.83 ± 0.08 | 34.96 ± 0.59 | |||

| MV4 | Phenylalanine + glucose | 100 °C—30 min | 0 | 0 | 1.05 ± 0.10 | – | – | – | – | – | – | – |

| 10 | 0 | 42.36 ± 3.03 | – | – | – | – | – | – | – | |||

| 25 | 0 | 41.95 ± 1.57 | – | – | – | – | – | – | – | |||

| 50 | 0 | 41.58 ± 2.37 | – | – | – | – | – | – | – |

| NO . | Substrate . | Heating condition . | Water content, μL . | 2-Methylbutanal . | Benzeneacetaldehyde . | Methylpyrazine . | 2,6-Dimethylpyrazine . | 2,3-Dimethylpyrazine . | 2-Ethyl-6-methylpyrazine . | 2-Ethyl-5-methylpyrazine . | Trimethylpyrazine . | Total pyrazine content, mg/kg . |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MV1 | Arginine + glucose | 160 °C—30 min | 0 | – | – | 13.80 ± 0.72 | 24.52 ± 0.73 | 2.92 ± 0 | 6.69 ± 0.05 | 20.67 ± 0.91 | 44.24 ± 2.82 | 220.58 ± 8.85 |

| 10 | – | – | 13.62 ± 0.22 | 24.84 ± 0.29 | 3.50 ± 0.29 | 7.80 ± 0.24 | 20.60 ± 2.10 | 45.46 ± 3.38 | 215.57 ± 11.85 | |||

| 25 | – | – | 17.56 ± 0.34 | 30.29 ± 0.38 | 4.48 ± 0.07 | 10.99 ± 0.42 | 16.84 ± 0.57 | 41.84 ± 0.64 | 211.87 ± 5.95 | |||

| 50 | – | – | 17.76 ± 1.24 | 29.91 ± 2.21 | 4.19 ± 0.23 | 13.01 ± 0.48 | 11.37 ± 0.09 | 29.11 ± 0.50 | 170.44 ± 7.23 | |||

| MV2 | Phenylalanine+ glucose | 0 | – | 20.33 ± 1.46 | 1.28 ± 0.39 | 0.60 ± 0.15 | 0.17 ± 0.02 | 0.21 ± 0.04 | 0.86 ± 0.17 | 0.62 ± 0.14 | 7.24 ± 1.87 | |

| 10 | – | 29.69 ± 1.65 | 1.93 ± 0.06 | 1.01 ± 0.12 | 0.22 ± 0.01 | 0.37 ± 0 | 1.78 ± 0.03 | 1.19 ± 0 | 12.32 ± 0.74 | |||

| 25 | – | 31.47 ± 1.40 | 1.83 ± 0.08 | 0.88 ± 0.06 | 0.20 ± 0.01 | 0.37 ± 0.03 | 1.96 ± 0.03 | 1.28 ± 0.02 | 12.74 ± 0.39 | |||

| 50 | – | 33.27 ± 1.06 | 2.11 ± 0.05 | 1.62 ± 0.03 | 0.54 ± 0.01 | 0.60 ± 0.03 | 3.31 ± 0.14 | 2.26 ± 0.09 | 19.98 ± 0.47 | |||

| MV3 | Raw peanut recombinate amino acid + glucose | 0 | 6.01 ± 0.53 | 1.43 ± 0.32 | 2.92 ± 0.09 | 1.85 ± 0.21 | 0.50 ± 0.03 | 1.98 ± 0.06 | 4.14 ± 0.13 | 6.19 ± 0.38 | 36.00 ± 0.52 | |

| 10 | 12.64 ± 0.11 | 3.44 ± 0.56 | 3.42 ± 0.01 | 2.23 ± 0.11 | 0.52 ± 0.03 | 2.95 ± 0.16 | 5.51 ± 0.18 | 4.96 ± 0.04 | 39.28 ± 0.77 | |||

| 25 | 20.75 ± 0.56 | 3.51 ± 0.55 | 2.21 ± 0.34 | 1.34 ± 0.20 | 0.35 ± 0.01 | 2.74 ± 0.01 | 6.18 ± 0.21 | 3.49 ± 0.23 | 33.71 ± 0.72 | |||

| 50 | 21.10 ± 0.53 | 4.57 ± 1.28 | 2.69 ± 0.19 | 1.41 ± 0.14 | 0.30 ± 0.01 | 3.13 ± 0.15 | 7.54 ± 0.55 | 2.83 ± 0.08 | 34.96 ± 0.59 | |||

| MV4 | Phenylalanine + glucose | 100 °C—30 min | 0 | 0 | 1.05 ± 0.10 | – | – | – | – | – | – | – |

| 10 | 0 | 42.36 ± 3.03 | – | – | – | – | – | – | – | |||

| 25 | 0 | 41.95 ± 1.57 | – | – | – | – | – | – | – | |||

| 50 | 0 | 41.58 ± 2.37 | – | – | – | – | – | – | – |

Note. “–” not detected.

In this section, we will examine the impact of water content in peanut kernels on the generation of eight key aroma-active compounds derived from Maillard reactions, as selected in the Sensory Profiles of RPO (WC-1) and SPO section. Most importantly, the contribution of these compounds is verified through aroma recombination experiment, with the results presented in Figure 1. The addition of six pyrazines and BA can significantly increase the intensity of roasted and sweet flavours of refined peanut oils, respectively.

As presented in Figure 3C–E, the varying patterns of these eight compounds with water content can primarily be categorised into two types. Initially, as presented in Figure 3C, BA contributes a honey-like flavour in peanuts or peanut oils (Chetschik et al., 2008; Ma et al., 2024b), whose content is increased exponentially with water content increasing. Specifically, as the water content rose from 4.20% to 52.55%, there was a 7.26-fold increase in BA content. The same observations have also been reported in other foods (Buhr et al., 2010; Ullrich et al., 2021). The mechanism underlying the role of water in BA generation via Strecker degradation–catalysed hydrolysis has been elucidated (Ma et al., 2024b).

2-Methylbutanal, a crucial Strecker aldehyde, imparts a malt-like flavour that diminishes gradually with increasing water content. The reason might be that the formation of Strecker aldehydes is much complicated, significantly influenced by processing conditions such as temperature, pressure, and time (Hidalgo et al., 2013; Kebede et al., 2017). 3-Methylbutanal and 2-methylbutanal, being isomers, exhibit comparable physical properties and share a similar formation pathway. The formation rate of 3-methylbutanal exhibits a strong correlation with temperature at 0.1 MPa, whereas at elevated pressures of 600 MPa, the formation rate undergoes a marked decrease (Kebede et al., 2017). Each peanut kernel functions as a pressurised reactor during the roasting process, and the water content within the kernels contributes to increasing the pressure. The evaporation of water is an endothermic process. During the roasting process of peanut kernels, as the water content in the system increases, the endothermic process resulting from water evaporation intensifies, ultimately leading to a significant decrease in the internal temperature of the peanut kernels. Therefore, as the water content increases in peanut kernels, the subsequent decrease in 2-methylbutanal content might be attributed to variations in system pressure and temperature.

As shown in Figure 3D and E, six pyrazines, namely, methylpyrazine, 2,6-dimethylpyrazine, trimethylpyrazine, 2,3-dimethylpyrazine, 2-ethyl-6-methylpyrazine, and 2-ethyl-5-methylpyrazine, displayed a linear negative correlation with water content (R2 > 0.96). They are usually contributing to the roasted and nutty attributes of peanut oils. An increase in water content within peanut kernels can partly explain the reduction in the intensity of the roasted flavour attributes, due to the corresponding decrease in their concentrations. Specifically, as the water content rose from 4.20% to 52.55%, the content of the six pyrazines decreased by a factor of 8.03. Generally, low water activity (0.33) is conducive to the formation of pyrazines, as evidenced before (Scalone et al., 2015).

Based on the early studies and hypothesis (Jousse et al., 2002; Nursten & Nursten, 2005; Yu et al., 2021), the following reactions can be proposed:

Abbreviations are referred to as Glu, glucose; AA, amino acid; NSG, N-substituted glycosylamine; α-DCs, α-dicarbonyl compounds, which can be produced through Maillard reaction, caramelisation, lipid-peroxidation, etc. (Yan et al., 2023); DCSB, decarboxylated Schiff base; α-AK, α-aminoketone; Py, pyrazine; K is the equilibrium reaction constant. Of course, the actual reactions could be much more complicated. However, the above reactions, which are mostly from hypothesis, can also give something for discussion and inspiration.

From Equations 3 to 7, the following equations can be generated:

Based on the equations from Equations 8 to 12, the following equation can be generated:

As illustrated from Equations 3 to 7, water plays a dual role in Maillard reactions, acting as both a promoter and an inhibitor depending on the reaction steps, as previously reported (Yoo, 1997). As illustrated in the equations, water plays a crucial role in deciding the flavour formation kinetics. As elucidated in Equation 13, water content will affect the concentration of pyrazines in general. This is in agreement with the observations from early studies (Feng et al., 2024; Ullrich et al., 2021).

Comparison of the formation of pyrazines and Strecker aldehydes using model experiments

At the same time, the effect of the initial water content of peanut kernels on the generation of volatile compounds was evaluated from the perspective of the substrates. Soluble small molecules, specifically free amino acids and soluble sugars, serve as the primary precursors of the Maillard reaction (Yu et al., 2021). The changes in their content before and after roasting were investigated. The content of free amino acids and soluble sugars in defatted protein powder from WC-1 to WC-7, as well as in raw materials, is presented in Table 1 and 5. There is no significant difference in the content of soluble sugars between samples. However, the total content of free amino acids increased progressively from WC-1 to WC-7, surpassing the levels found in raw peanuts. The concentration of each free amino acid increases as water content rises. The study showed that variations in initial water content in peanuts affect the composition of free amino acids, subsequently impacting the formation of volatile compounds.

| NO . | Compounds . | Content, μg/kg . | Average OAV . | ||||||

|---|---|---|---|---|---|---|---|---|---|

| WC-1 . | WC-2 . | WC-3 . | WC-4 . | WC-5 . | WC-6 . | WC-7 . | |||

| 1 | 2-Methylbutanal | 826.55 ± 7.65a | 695.25 ± 48.65b | 675.75 ± 77.25b | 709.90 ± 14.20a,b | 686.50 ± 29.80b | 373.68 ± 12.90c | 327.40 ± 19.30c | 278.90 ± 4.47 |

| 2 | 2,6-Dimethylpyrazine | 2,346.95 ± 2.65a | 2,137.80 ± 18.80b | 1,732.30 ± 103.70c | 1,644.20 ± 42.40c | 1,163.40 ± 52.80d | 602.04 ± 57.56e | 271.15 ± 11.55f | 70.70 ± 0.33 |

| 3 | Trimethylpyrazine | 1,420.40 ± 30.10a | 1,235.15 ± 13.45b | 962.70 ± 97.20c | 809.90 ± 2.90d | 511.60 ± 25.60e | 269.11 ± 14.91f | 107.60 ± 2.70g | 34.52 ± 0.45 |

| 4 | 2-Methoxy-4-vinylphenol | 822.50 ± 53.10a | 866.50 ± 46.00a | 615.35 ± 80.25b | 427.65 ± 39.55c | 344.85 ± 15.35c,d | 217.38 ± 9.02d,e | 169.80 ± 1.00e | 24.74 ± 0.38 |

| 5 | Benzeneacetaldehyde | 103.90 ± 7.00e | 107.95 ± 7.75e | 241.90 ± 11.60d | 262.95 ± 9.85d | 504.75 ± 31.45c | 612.05 ± 54.57b | 857.95 ± 18.25a | 17.48 ± 0.68 |

| 6 | 2,3-Dimethylpyrazine | 223.05 ± 3.15a | 231.10 ± 4.00a | 166.70 ± 12.20b | 131.75 ± 1.05c | 78.20 ± 7.90d | 33.79 ± 2.61e | 19.40 ± 0.10e | 15.79 ± 0.08 |

| 7 | Acetic acid | 2,286.95 ± 41.25a | 2,188.70 ± 14.00a | 1,538.65 ± 145.35b | 1,346.40 ± 16.30b,c | 1,155.00 ± 54.50c | 919.34 ± 57.78d | 505.90 ± 35.50e | 11.45 ± 0.12 |

| 8 | Hexanal | 182.40 ± 10.40d | 180.35 ± 2.95d | 313.40 ± 16.20c | 383.95 ± 2.25c | 712.10 ± 44.30b | 646.15 ± 40.25b | 928.05 ± 32.75a | 6.55 ± 0.29 |

| 9 | (E)-2-Octenal | 21.55 ± 0.15b,c | 18.65 ± 1.25c,d | 16.60 ± 1.20d | 16.40 ± 0.20d | 22.30 ± 0.80b | 23.71 ± 0.99b | 29.45 ± 0.65a | 5.31 ± 0.08 |

| 10 | 2-Ethyl-5-methylpyrazine | 2,521.90 ± 26.10a | 2,402.45 ± 50.85a | 1,973.60 ± 185.20b | 1,918.65 ± 33.15b | 1,564.95 ± 49.55c | 695.56 ± 62.84d | 434.95 ± 24.35d | 5.14 ± 0.04 |

| 11 | 2-Methylbutyric acid | 55.22 ± 1.21a,b | 57.42 ± 0.33a | 53.19 ± 2.92a,b | 50.88 ± 1.93a,b,c | 39.98 ± 3.25d | 40.35 ± 10.85b,c,d | 42.12 ± 2.38c,d | 4.48 ± 0.14 |

| 12 | Methylpyrazine | 1,628.95 ± 4.55a | 1,112.45 ± 5.05b | 845.55 ± 68.25c | 746.15 ± 25.55d | 434.80 ± 12.20e | 230.58 ± 13.42f | 111.75 ± 9.75g | 3.65 ± 0.03 |

| 13 | 1-Nonanol | 15.75 ± 0.05a | 4.45 ± 0.25c | 9.85 ± 1.65b | 3.35 ± 0.05c | 3.10 ± 0.20c | – | – | 2.60 ± 0.12 |

| 14 | 2-Ethyl-6-methylpyrazine | 754.35 ± 8.85a | 649.60 ± 6.90b | 405.95 ± 20.65c | 320.65 ± 7.55d | 250.70 ± 7.10e | 61.28 ± 2.78f | 39.85 ± 2.15f | 2.36 ± 0.01 |

| 15 | Ethylpyrazine | 460.05 ± 2.05a | 385.60 ± 8.10b | 308.85 ± 28.05c | 297.35 ± 6.05c | 215.00 ± 7.60d | 92.06 ± 2.06e | 50.40 ± 3.10f | 1.29 ± 0.02 |

| 16 | Octanal | 273.85 ± 0.45a | 199.30 ± 2.70b | 199.95 ± 10.85b | 174.20 ± 12.70c | 148.55 ± 3.85d | 94.51 ± 3.49e | 77.00 ± 3.30e | 1.19 ± 0.01 |

| 17 | 2,5-Dimethylpyrazine | 4,487.65 ± 132.35a | 3,543.45 ± 23.45b | 2,831.75 ± 231.75c | 2,605.60 ± 34.40c | 1,795.30 ± 55.30d | 957.51 ± 122.49e | 536.35 ± 16.35f | 1.20 ± 0.00 |

| 18 | (E,E)-2,4-Decadienal | 65.30 ± 3.90c | 65.70 ± 3.50c | 67.70 ± 8.70b,c | 59.50 ± 5.30c | 82.30 ± 1.90b | 55.81 ± 4.25c | 105.05 ± 2.25a | 1.09 ± 0.01 |

| 19 | Butyrolactone | 150.05 ± 1.15b | 165.75 ± 7.25a | 37.50 ± 3.20c | 19.85 ± 0.65d | 10.05 ± 0.05d,e | – | – | 0.91 ± 0.01 |

| 20 | 2-Methoxyphenol | 28.10 ± 1.30a | 19.05 ± 0.55b | 12.00 ± 1.20c | 8.40 ± 0.10d | 4.70 ± 0.30e | – | – | 0.79 ± 0.00 |

| 21 | Hexanoic acid | 291.25 ± 23.75b,c | 244.45 ± 3.75c,d | 462.35 ± 25.95a | 219.85 ± 14.35d,e | 333.40 ± 20.70b | 154.60 ± 6.40e | 216.45 ± 26.85d,e | 0.60 ± 0.02 |

| 22 | Phenylethyl alcohol | 220.55 ± 9.15a | 191.40 ± 11.20a | 81.30 ± 11.20b | 30.85 ± 1.25c | 23.85 ± 1.45c | 111.07 ± 28.19b | 14.60 ± 0.70c | 0.46 ± 0.02 |

| 23 | 2-Acetylpyridine | 61.95 ± 0.35a | 54.15 ± 0.15a | 45.10 ± 3.00b | 39.40 ± 1.50b | 27.00 ± 0.80c | 19.78 ± 5.22c,d | 12.00 ± 0.40d | 0.37 ± 0.00 |

| 24 | Furfural | 507.25 ± 11.65a | 311.15 ± 6.85b | 232.40 ± 17.10c | 198.40 ± 7.20c,d | 160.95 ± 7.15d | 195.66 ± 35.34c,d | 99.20 ± 4.50e | 0.35 ± 0.01 |

| 25 | 2-Furanmethanol | 323.30 ± 4.20a | 295.25 ± 4.35b | 234.30 ± 17.00c | 194.60 ± 10.00d | 132.35 ± 2.45e | 68.85 ± 23.05f | 42.10 ± 2.40f | 0.27 ± 0.01 |

| 26 | 5-Methylfurfural | 74.45 ± 2.45a | 44.75 ± 1.55b | 31.55 ± 3.05c | 25.20 ± 0.80d | 16.00 ± 0.60e | – | – | 0.11 ± 0.00 |

| 27 | 2-Pyrrolaldehyde | 34.60 ± 0.20a | 15.90 ± 0.10b | 8.55 ± 0.75c | 6.30 ± 0.00d | – | – | – | 0.09 ± 0.00 |

| 28 | 3-Ethyl-2,5-dimethylpyrazine | 11.40 ± 0.10a | 10.30 ± 0.40a | 6.40 ± 0.80b | 5.55 ± 0.05b,c | 4.75 ± 0.25c | 1.56 ± 0.04d | 0.95 ± 0.05d | 0.08 ± 0.00 |

| 29 | Pentanoic acid | 31.15 ± 0.65b | 24.20 ± 0.70c | 58.95 ± 2.25a | 12.70 ± 1.10d | 21.15 ± 1.15c | 13.51 ± 2.49d | 13.95 ± 0.85d | 0.06 ± 0.00 |

| 30 | 3-Phenylfuran | 14.95 ± 0.95a | 13.80 ± 1.20a | 7.65 ± 0.95b | 5.75 ± 0.25b,c | 4.10 ± 0.00c | – | – | 0.05 ± 0.00 |

| NO . | Compounds . | Content, μg/kg . | Average OAV . | ||||||

|---|---|---|---|---|---|---|---|---|---|

| WC-1 . | WC-2 . | WC-3 . | WC-4 . | WC-5 . | WC-6 . | WC-7 . | |||

| 1 | 2-Methylbutanal | 826.55 ± 7.65a | 695.25 ± 48.65b | 675.75 ± 77.25b | 709.90 ± 14.20a,b | 686.50 ± 29.80b | 373.68 ± 12.90c | 327.40 ± 19.30c | 278.90 ± 4.47 |

| 2 | 2,6-Dimethylpyrazine | 2,346.95 ± 2.65a | 2,137.80 ± 18.80b | 1,732.30 ± 103.70c | 1,644.20 ± 42.40c | 1,163.40 ± 52.80d | 602.04 ± 57.56e | 271.15 ± 11.55f | 70.70 ± 0.33 |

| 3 | Trimethylpyrazine | 1,420.40 ± 30.10a | 1,235.15 ± 13.45b | 962.70 ± 97.20c | 809.90 ± 2.90d | 511.60 ± 25.60e | 269.11 ± 14.91f | 107.60 ± 2.70g | 34.52 ± 0.45 |

| 4 | 2-Methoxy-4-vinylphenol | 822.50 ± 53.10a | 866.50 ± 46.00a | 615.35 ± 80.25b | 427.65 ± 39.55c | 344.85 ± 15.35c,d | 217.38 ± 9.02d,e | 169.80 ± 1.00e | 24.74 ± 0.38 |

| 5 | Benzeneacetaldehyde | 103.90 ± 7.00e | 107.95 ± 7.75e | 241.90 ± 11.60d | 262.95 ± 9.85d | 504.75 ± 31.45c | 612.05 ± 54.57b | 857.95 ± 18.25a | 17.48 ± 0.68 |

| 6 | 2,3-Dimethylpyrazine | 223.05 ± 3.15a | 231.10 ± 4.00a | 166.70 ± 12.20b | 131.75 ± 1.05c | 78.20 ± 7.90d | 33.79 ± 2.61e | 19.40 ± 0.10e | 15.79 ± 0.08 |