-

PDF

- Split View

-

Views

-

Cite

Cite

Fetriyuna Fetriyuna, Afif Ziyadi Rafi, Zaida Zaida, Ratna Chrismiari Purwestri, Adi Md Sikin, From forest to fork: a systematic review of mushroom-based meat analogues, International Journal of Food Science and Technology, Volume 60, Issue 1, January 2025, vvaf030, https://doi.org/10.1093/ijfood/vvaf030

Close - Share Icon Share

Abstract

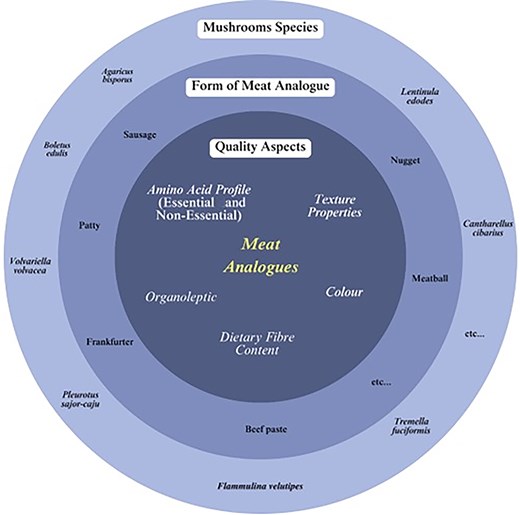

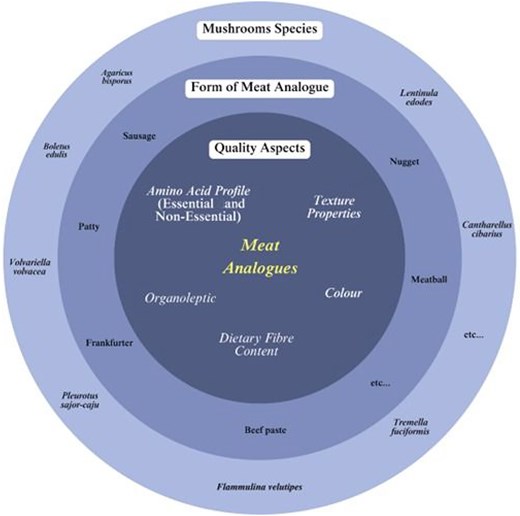

The consumption of meat analogues is steadily increasing due to factors such as concerns about protein intake, meat availability, health, and environmental issues. Mushrooms provide a potential solution for substituting or replacing animal protein due to their high nutritional value and unique sensory properties. This review examines the differences in physical characteristics, organoleptic qualities, amino acid profiles, and dietary fibre content of meat analogues derived from various mushroom species. The review employed a textual narrative synthesis approach and adhered to the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) guidelines. A comprehensive analysis of 38 relevant publications reveals that the incorporation of mushrooms can influence the colour and texture of meat analogues. Additionally, the review highlights the impact of mushroom addition or substitution on the amino acid and dietary fibre content of meat analogues. It underscores the potential of mushrooms to create meat analogues with enhanced nutritional profiles, benefiting consumers, particularly those facing nutritional challenges like stunting. This article emphasises the importance of considering the specific mushroom species and processing techniques to optimise the quality of meat analogues.

Introduction

Food is a fundamental human need that must always be available in sufficient quantities, as well as being safe, nutritious, and diverse while also aligning with cultural and religious beliefs. However, the growing global population, particularly in developing nations like Indonesia, has created challenges in providing adequate food for all. According to data from Indonesia’s Central Statistics Agency (Badan Pusat Statistik/BPS), the country’s population reached 278.69 million by mid-2023, an increase of 1.05% compared to mid-2022 (BPS, 2023). If this growth rate continues, Indonesia’s population is projected to reach 343.81 million within the next 20 years, which will exacerbate challenges in food availability, particularly in sources of protein. Additionally, meat consumption in Indonesia tends to increase each year. Projections by Tenrisanna and Kasim (2020) using the Double Exponential Smoothing method estimate that by 2027, Indonesian meat production and consumption will reach 4,449,286 tons and 5,061,993 tons, respectively, indicating that meat consumption will exceed domestic production by that time.

A lack of adequate protein sources can lead to health issues such as muscular dystrophy, stunted growth, and a weakened immune system (Hashempour-Baltork et al., 2020). One solution to address this protein deficiency is through the increased production of meat alternatives, such as meat analogues, which can help ensure sufficient meat availability.

Meat analogues are products designed to closely resemble the aesthetic qualities such as texture, taste, and appearance and/or chemical properties of specific types of meat and can be shaped into sheets, disks, patties, strips, and other forms (Joshi & Kumar, 2015). The popularity of meat analogues continues to grow, driven by factors such as the demand for food security, adequate protein intake, and considerations of health and environmental impact. According to Table 1, the production of meat analogues has a lower environmental impact, with a carbon footprint of 1.62–1.8 kg CO2 per kg and land and energy use of 3.3–3.6 m2/kg and 16.4–19.9 MJ/kg, respectively (Smetana et al., 2021).

Comparison of carbon footprint, water, land, and energy use in meat and mushroom-based meat analogue production.

| Type of meat . | Carbon footprint (kg CO2 eq./kg) . | Water use (m3/kg) . | Land use (m2/kg) . | Energy use (MJ/kg) . | References . |

|---|---|---|---|---|---|

| Chicken | 5.2–5.82 | 3.91 | 3.85–3.89 | 51.64–63.4 | Smetana et al. (2015) and Kumar et al. (2017) |

| Beef | 27.3 | 15.5 | 42.9 | 59.2 | Smetana et al. (2015) and de Vries et al. (2015) |

| Meat analogue (Mushroom) | 1.62–1.8 | NA | 3.3–3.6 | 16.4–19.9 | Smetana et al. (2021) |

| Type of meat . | Carbon footprint (kg CO2 eq./kg) . | Water use (m3/kg) . | Land use (m2/kg) . | Energy use (MJ/kg) . | References . |

|---|---|---|---|---|---|

| Chicken | 5.2–5.82 | 3.91 | 3.85–3.89 | 51.64–63.4 | Smetana et al. (2015) and Kumar et al. (2017) |

| Beef | 27.3 | 15.5 | 42.9 | 59.2 | Smetana et al. (2015) and de Vries et al. (2015) |

| Meat analogue (Mushroom) | 1.62–1.8 | NA | 3.3–3.6 | 16.4–19.9 | Smetana et al. (2021) |

Comparison of carbon footprint, water, land, and energy use in meat and mushroom-based meat analogue production.

| Type of meat . | Carbon footprint (kg CO2 eq./kg) . | Water use (m3/kg) . | Land use (m2/kg) . | Energy use (MJ/kg) . | References . |

|---|---|---|---|---|---|

| Chicken | 5.2–5.82 | 3.91 | 3.85–3.89 | 51.64–63.4 | Smetana et al. (2015) and Kumar et al. (2017) |

| Beef | 27.3 | 15.5 | 42.9 | 59.2 | Smetana et al. (2015) and de Vries et al. (2015) |

| Meat analogue (Mushroom) | 1.62–1.8 | NA | 3.3–3.6 | 16.4–19.9 | Smetana et al. (2021) |

| Type of meat . | Carbon footprint (kg CO2 eq./kg) . | Water use (m3/kg) . | Land use (m2/kg) . | Energy use (MJ/kg) . | References . |

|---|---|---|---|---|---|

| Chicken | 5.2–5.82 | 3.91 | 3.85–3.89 | 51.64–63.4 | Smetana et al. (2015) and Kumar et al. (2017) |

| Beef | 27.3 | 15.5 | 42.9 | 59.2 | Smetana et al. (2015) and de Vries et al. (2015) |

| Meat analogue (Mushroom) | 1.62–1.8 | NA | 3.3–3.6 | 16.4–19.9 | Smetana et al. (2021) |

An alternative raw material for producing meat analogues is edible mushrooms. However, mushrooms have not yet been widely used as a primary ingredient in meat analogue production. Data from Mintel (2020) showed that the primary sources of plant-based protein used in meat analogue formulations are soy protein (63.3% of total products; including 20.3% isolate, 33.4% concentrate, and 9.6% textured), followed by wheat (46.8% of total products; including 14.7% wheat protein and 32.1% gluten), legumes (40.2% of total products; including 12.2% isolate and 28.4% concentrate), rice protein (7.2%), and other vegetable proteins (4.7%).

Table 2 presents the chemical composition of various mushroom varieties, which is crucial for understanding their potential as meat analogues. Mushrooms are known for their unique nutritional profiles, providing a good source of protein, dietary fibre, and phenolic compounds with strong antioxidant potential (Banerjee et al., 2020). Mushroom protein contains eight essential amino acids required by humans, most of which are close to the ideal pattern, which is a complete ratio of essential amino acids. Ideal amino acid profiles can be found in various mushroom species, including Agaricus bisporus, Flammulina velutipes, Tricholoma matsutake, and Pleurotus eryngii (Wang & Zhao, 2023).

Summary of important nutrients of selected wild edible mushrooms (per 100 g).

| Species . | Location . | Protein . | Carbohydrate . | Fat . | Vit B1 . | Vit B2 . | Vit B3 . | Fe . | Zn . | Ca . | Na . | P . | Mg . | References . |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| . | . | g . | g . | g . | mg . | mg . | mg . | mg . | mg . | mg . | mg . | mg . | mg . | . |

| Cultivated | ||||||||||||||

| A. bisporus | Czechia | 2.9 | 3.1 | 0.3 | 0.1 | 0.4 | 1.3 | 8 | 8 | 123 | 13 | Institute of Agricultural Economics and Information (2020) | ||

| B. edulis | Spain | 6.6 | 59.1 | 1.6 | – | – | – | – | – | – | – | – | – | Mena García et al. (2021) |

| C. cibarius | Czechia | 2.1 | 1.9 | 5.5 | – | – | – | – | – | – | 2 | – | – | Institute of Agricultural Economics and Information (2020) |

| Wild mushrooms | ||||||||||||||

| Agaricus arvensis | Europe | 2.7 | – | – | – | – | – | – | – | – | – | – | – | Procházka et al. (2023) |

| Portugal | 2.9 | 1.9 | 0.1 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) | |

| A. bisporus | Poland | – | – | – | – | – | – | – | 0.6 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) |

| B. edulis | Europe | 5.6 | – | – | – | – | – | – | – | – | – | – | – | Procházka et al. (2023) |

| Poland | – | – | – | – | – | – | – | – | 20.0 | 523.0 | 243.0 | 77.0 | Malinowski et al. (2021) | |

| Poland | – | – | – | – | – | – | – | 1.7 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Poland | 2.3 | 7.4 | – | 0.9 | 2.6 | 22.9 | – | – | – | – | – | – | Jaworska et al. (2015) | |

| Cortinarius caperatus | Poland | – | – | – | – | – | – | – | 9.0 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) |

| Imleria badia | Poland | – | – | – | – | – | – | – | – | 6.0 | 475.0 | 262.0 | 359.0 | Malinowski et al. (2021) |

| Poland | – | – | – | – | – | – | – | 1.4 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Lactarius deliciosus | Greece | – | – | – | – | – | – | 3.0 | 8.1 | – | – | – | – | Aloupi et al. (2012) |

| Poland | – | – | – | – | – | – | – | 12.9 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Portugal | 3.0 | 6.3 | 0.2 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) | |

| Leccinum scabrum | Poland | – | – | – | – | – | – | – | – | 8.0 | 406.0 | 279.0 | 62.0 | Malinowski et al. (2021) |

| Poland | – | – | – | – | – | – | – | 0.9 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Leucopaxillus giganteus | Portugal | 3.4 | 3.1 | 0.4 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) |

| Morchella esculenta | Bulgaria | 11.3 | 78.3 | – | – | – | – | – | – | – | – | – | – | Papazav et al. (2020) |

| Portugal | 11.5 | 74.6 | – | – | – | – | – | – | – | – | – | – | Heleno et al. (2013) | |

| Serbia | 11.5 | 78.4 | – | – | – | – | – | – | – | – | – | – | Heleno et al. (2013) | |

| Sarcodon imbricatus | Portugal | 2.4 | 3.4 | 0.9 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) |

| Tricholoma portentosum | Poland | – | – | – | – | – | – | – | 1.1 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) |

| Portugal | 2.1 | 3.6 | 0.4 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) |

| Species . | Location . | Protein . | Carbohydrate . | Fat . | Vit B1 . | Vit B2 . | Vit B3 . | Fe . | Zn . | Ca . | Na . | P . | Mg . | References . |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| . | . | g . | g . | g . | mg . | mg . | mg . | mg . | mg . | mg . | mg . | mg . | mg . | . |

| Cultivated | ||||||||||||||

| A. bisporus | Czechia | 2.9 | 3.1 | 0.3 | 0.1 | 0.4 | 1.3 | 8 | 8 | 123 | 13 | Institute of Agricultural Economics and Information (2020) | ||

| B. edulis | Spain | 6.6 | 59.1 | 1.6 | – | – | – | – | – | – | – | – | – | Mena García et al. (2021) |

| C. cibarius | Czechia | 2.1 | 1.9 | 5.5 | – | – | – | – | – | – | 2 | – | – | Institute of Agricultural Economics and Information (2020) |

| Wild mushrooms | ||||||||||||||

| Agaricus arvensis | Europe | 2.7 | – | – | – | – | – | – | – | – | – | – | – | Procházka et al. (2023) |

| Portugal | 2.9 | 1.9 | 0.1 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) | |

| A. bisporus | Poland | – | – | – | – | – | – | – | 0.6 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) |

| B. edulis | Europe | 5.6 | – | – | – | – | – | – | – | – | – | – | – | Procházka et al. (2023) |

| Poland | – | – | – | – | – | – | – | – | 20.0 | 523.0 | 243.0 | 77.0 | Malinowski et al. (2021) | |

| Poland | – | – | – | – | – | – | – | 1.7 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Poland | 2.3 | 7.4 | – | 0.9 | 2.6 | 22.9 | – | – | – | – | – | – | Jaworska et al. (2015) | |

| Cortinarius caperatus | Poland | – | – | – | – | – | – | – | 9.0 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) |

| Imleria badia | Poland | – | – | – | – | – | – | – | – | 6.0 | 475.0 | 262.0 | 359.0 | Malinowski et al. (2021) |

| Poland | – | – | – | – | – | – | – | 1.4 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Lactarius deliciosus | Greece | – | – | – | – | – | – | 3.0 | 8.1 | – | – | – | – | Aloupi et al. (2012) |

| Poland | – | – | – | – | – | – | – | 12.9 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Portugal | 3.0 | 6.3 | 0.2 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) | |

| Leccinum scabrum | Poland | – | – | – | – | – | – | – | – | 8.0 | 406.0 | 279.0 | 62.0 | Malinowski et al. (2021) |

| Poland | – | – | – | – | – | – | – | 0.9 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Leucopaxillus giganteus | Portugal | 3.4 | 3.1 | 0.4 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) |

| Morchella esculenta | Bulgaria | 11.3 | 78.3 | – | – | – | – | – | – | – | – | – | – | Papazav et al. (2020) |

| Portugal | 11.5 | 74.6 | – | – | – | – | – | – | – | – | – | – | Heleno et al. (2013) | |

| Serbia | 11.5 | 78.4 | – | – | – | – | – | – | – | – | – | – | Heleno et al. (2013) | |

| Sarcodon imbricatus | Portugal | 2.4 | 3.4 | 0.9 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) |

| Tricholoma portentosum | Poland | – | – | – | – | – | – | – | 1.1 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) |

| Portugal | 2.1 | 3.6 | 0.4 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) |

Summary of important nutrients of selected wild edible mushrooms (per 100 g).

| Species . | Location . | Protein . | Carbohydrate . | Fat . | Vit B1 . | Vit B2 . | Vit B3 . | Fe . | Zn . | Ca . | Na . | P . | Mg . | References . |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| . | . | g . | g . | g . | mg . | mg . | mg . | mg . | mg . | mg . | mg . | mg . | mg . | . |

| Cultivated | ||||||||||||||

| A. bisporus | Czechia | 2.9 | 3.1 | 0.3 | 0.1 | 0.4 | 1.3 | 8 | 8 | 123 | 13 | Institute of Agricultural Economics and Information (2020) | ||

| B. edulis | Spain | 6.6 | 59.1 | 1.6 | – | – | – | – | – | – | – | – | – | Mena García et al. (2021) |

| C. cibarius | Czechia | 2.1 | 1.9 | 5.5 | – | – | – | – | – | – | 2 | – | – | Institute of Agricultural Economics and Information (2020) |

| Wild mushrooms | ||||||||||||||

| Agaricus arvensis | Europe | 2.7 | – | – | – | – | – | – | – | – | – | – | – | Procházka et al. (2023) |

| Portugal | 2.9 | 1.9 | 0.1 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) | |

| A. bisporus | Poland | – | – | – | – | – | – | – | 0.6 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) |

| B. edulis | Europe | 5.6 | – | – | – | – | – | – | – | – | – | – | – | Procházka et al. (2023) |

| Poland | – | – | – | – | – | – | – | – | 20.0 | 523.0 | 243.0 | 77.0 | Malinowski et al. (2021) | |

| Poland | – | – | – | – | – | – | – | 1.7 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Poland | 2.3 | 7.4 | – | 0.9 | 2.6 | 22.9 | – | – | – | – | – | – | Jaworska et al. (2015) | |

| Cortinarius caperatus | Poland | – | – | – | – | – | – | – | 9.0 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) |

| Imleria badia | Poland | – | – | – | – | – | – | – | – | 6.0 | 475.0 | 262.0 | 359.0 | Malinowski et al. (2021) |

| Poland | – | – | – | – | – | – | – | 1.4 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Lactarius deliciosus | Greece | – | – | – | – | – | – | 3.0 | 8.1 | – | – | – | – | Aloupi et al. (2012) |

| Poland | – | – | – | – | – | – | – | 12.9 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Portugal | 3.0 | 6.3 | 0.2 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) | |

| Leccinum scabrum | Poland | – | – | – | – | – | – | – | – | 8.0 | 406.0 | 279.0 | 62.0 | Malinowski et al. (2021) |

| Poland | – | – | – | – | – | – | – | 0.9 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Leucopaxillus giganteus | Portugal | 3.4 | 3.1 | 0.4 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) |

| Morchella esculenta | Bulgaria | 11.3 | 78.3 | – | – | – | – | – | – | – | – | – | – | Papazav et al. (2020) |

| Portugal | 11.5 | 74.6 | – | – | – | – | – | – | – | – | – | – | Heleno et al. (2013) | |

| Serbia | 11.5 | 78.4 | – | – | – | – | – | – | – | – | – | – | Heleno et al. (2013) | |

| Sarcodon imbricatus | Portugal | 2.4 | 3.4 | 0.9 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) |

| Tricholoma portentosum | Poland | – | – | – | – | – | – | – | 1.1 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) |

| Portugal | 2.1 | 3.6 | 0.4 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) |

| Species . | Location . | Protein . | Carbohydrate . | Fat . | Vit B1 . | Vit B2 . | Vit B3 . | Fe . | Zn . | Ca . | Na . | P . | Mg . | References . |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| . | . | g . | g . | g . | mg . | mg . | mg . | mg . | mg . | mg . | mg . | mg . | mg . | . |

| Cultivated | ||||||||||||||

| A. bisporus | Czechia | 2.9 | 3.1 | 0.3 | 0.1 | 0.4 | 1.3 | 8 | 8 | 123 | 13 | Institute of Agricultural Economics and Information (2020) | ||

| B. edulis | Spain | 6.6 | 59.1 | 1.6 | – | – | – | – | – | – | – | – | – | Mena García et al. (2021) |

| C. cibarius | Czechia | 2.1 | 1.9 | 5.5 | – | – | – | – | – | – | 2 | – | – | Institute of Agricultural Economics and Information (2020) |

| Wild mushrooms | ||||||||||||||

| Agaricus arvensis | Europe | 2.7 | – | – | – | – | – | – | – | – | – | – | – | Procházka et al. (2023) |

| Portugal | 2.9 | 1.9 | 0.1 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) | |

| A. bisporus | Poland | – | – | – | – | – | – | – | 0.6 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) |

| B. edulis | Europe | 5.6 | – | – | – | – | – | – | – | – | – | – | – | Procházka et al. (2023) |

| Poland | – | – | – | – | – | – | – | – | 20.0 | 523.0 | 243.0 | 77.0 | Malinowski et al. (2021) | |

| Poland | – | – | – | – | – | – | – | 1.7 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Poland | 2.3 | 7.4 | – | 0.9 | 2.6 | 22.9 | – | – | – | – | – | – | Jaworska et al. (2015) | |

| Cortinarius caperatus | Poland | – | – | – | – | – | – | – | 9.0 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) |

| Imleria badia | Poland | – | – | – | – | – | – | – | – | 6.0 | 475.0 | 262.0 | 359.0 | Malinowski et al. (2021) |

| Poland | – | – | – | – | – | – | – | 1.4 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Lactarius deliciosus | Greece | – | – | – | – | – | – | 3.0 | 8.1 | – | – | – | – | Aloupi et al. (2012) |

| Poland | – | – | – | – | – | – | – | 12.9 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Portugal | 3.0 | 6.3 | 0.2 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) | |

| Leccinum scabrum | Poland | – | – | – | – | – | – | – | – | 8.0 | 406.0 | 279.0 | 62.0 | Malinowski et al. (2021) |

| Poland | – | – | – | – | – | – | – | 0.9 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) | |

| Leucopaxillus giganteus | Portugal | 3.4 | 3.1 | 0.4 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) |

| Morchella esculenta | Bulgaria | 11.3 | 78.3 | – | – | – | – | – | – | – | – | – | – | Papazav et al. (2020) |

| Portugal | 11.5 | 74.6 | – | – | – | – | – | – | – | – | – | – | Heleno et al. (2013) | |

| Serbia | 11.5 | 78.4 | – | – | – | – | – | – | – | – | – | – | Heleno et al. (2013) | |

| Sarcodon imbricatus | Portugal | 2.4 | 3.4 | 0.9 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) |

| Tricholoma portentosum | Poland | – | – | – | – | – | – | – | 1.1 | – | – | – | – | Mirończuk-Chodakowska et al. (2019) |

| Portugal | 2.1 | 3.6 | 0.4 | – | – | – | – | – | – | – | – | – | Barros et al. (2007) |

The development of mushroom-based meat analogues should consider not only their nutritional value, such as amino acid and dietary fibre content but also their physical and sensory (organoleptic) qualities. Consumers choose meat analogues not only to meet nutritional needs but also to enjoy the taste and texture. This literature review examines the physical characteristics, sensory properties, amino acid profiles, and dietary fibre content of meat analogues derived from various mushroom species. The aim of this review was to provide insights and guidance for optimising the quality of mushroom-based meat analogues. Accordingly, it also covered the nutritional aspects, specifically the essential and non-essential amino acid profiles, along with the dietary fibre content of these products.

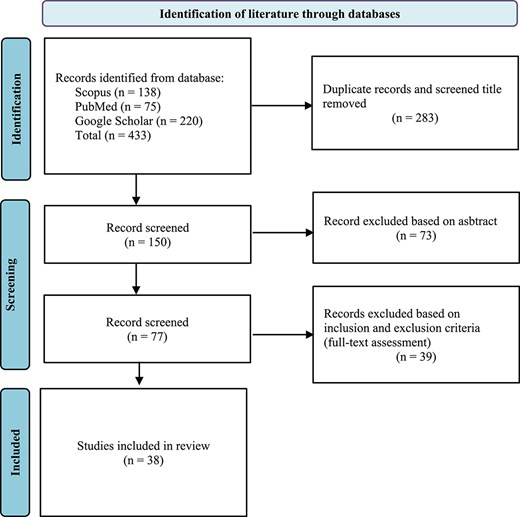

Research design

The systematic literature review method was employed in this research. This method is a way of conducting a study or review that includes the identification, evaluation, and synthesis of research or ideas produced by researchers (Okoli & Schabram, 2012). Descriptive analysis in the form of textual narrative synthesis (TNS) was used. TNS is a descriptive analysis method that categorises studies into more homogeneous subgroups. The TNS method was conducted using the PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) guidelines. This outlines the procedure for study selection and rejection (Figure 1). A flowchart of the systematic review search process based on PRISMA guidelines is shown in Figure 1. The sorting of the literature began with a literature search using keywords through Google Scholar, Scopus, and PubMed. Literature searches on these sites used relevant keywords so that literature with appropriate topics could be found.

Flowchart of the systematic review search process based on PRISMA guidelines.

Overall framework for the influence of mushroom addition and/or substitution on physicochemical properties and sensorial quality of meat analogue products.

A literature search was done in the Scopus database, continuing with the PubMed database to collect other papers that were not published in Scopus. Additional relevant databases from other source such as Web of Sciences (WoS) were also used to ensure a more comprehensive retrieval of all related articles. The following keywords were used: “meat analogue mushrooms,” OR “application mushroom on meat analogue,” OR “mushroom meat analogue,” OR “quality of mushroom meat analogue,” OR “acceptance of mushroom meat analogue” as well using the combination of mushroom meat analogue with the name of products like sausage, burger, frankfurter, and patty.

The articles were then selected based on the following criteria: (1) the relevancy of the paper’s content to answer the research objectives; thus, whether the literature describe the process of making mushroom meat analogue, the nutritional and physical characteristic as well the sensory properties of mushroom meat analogue. It would be more interesting if the article also featured amino acid profiles and dietary fibre. (2) The studies recruited using one or more species of mushroom in the production of mushroom meat analogue, (3) papers written in English, (4) papers published within 1994–2023. The following are the data analysis and interpretations from the sorted literature:

Comparing the physical attributes of meat substitutes made from various mushroom species, including hardness, elasticity, compactness, chewiness, and hunter colour L*a*b.

Comparing the organoleptic properties of meat substitutes derived from various mushroom species.

Comparing the essential and non-essential amino acid profiles of meat substitutes derived from various mushroom species.

Comparison of the dietary fibre content of meat substitutes derived from various mushroom species.

The sorted literature was used for data analysis and interpretation, specifically by comparing data from one literature with that of other related or supporting literature. While verified data will be expanded upon and assembled into a descriptive review, unconfirmed data will be rearranged or contrasted with other data to ascertain its applicability to the subject under discussion.

Searching the literature using certain keywords resulted in 433 literatures that will then be sorted. Of the 433 literatures, 220 literatures were obtained from Google Scholar, 138 literatures were obtained from Scopus, and 75 literatures were obtained from PubMed. From 433 literatures, 283 literatures were excluded based on the title and duplication, leaving 150 literatures. Furthermore, 150 literatures were filtered based on their abstracts, and 73 literatures were excluded so that 77 literatures remained. Then, the 77 literatures will be filtered based on the inclusion and exclusion criteria so that 38 literatures remain. Thus, 38 literatures were selected for further analysis after a thorough literature assessment will be included in the discussion of literature review. Details of these 38 literatures are shown in Appendix A.

Results and discussion

Mushroom species commonly used as raw material for the production of meat analogue belong to the Basidiomycota and Ascomycota phyla (Cheung, 2009). These phyla contain a wide variety of families and species. They are a suitable choice due to their nutritional content and their glutamate, nucleotides, and umami compounds could create desirable sensory effects that appeal to consumers (Sun et al., 2020). Furthermore, the similarity in texture and colour between mushrooms and some meat products makes mushrooms a strong potential raw material for meat analogues (Giacalone et al., 2022). Meat analogues are generally produced in the form of processed meat products, such as burgers, nuggets, chicken cutlets or steaks, and emulsified products, such as Frankfurter and Mortadella-type sausages (Kyriakopoulou et al., 2019).

The impact of mushroom addition and/or substitution on colour parameters and textural properties of meat analogues

Meat analogues need to be evaluated for its physical characteristics, especially colour for its highly noticeable physical attribute by comparing the colour of meat analogues to that of conventional meat (Bohrer, 2019). The colour of the meat analogues will affect the meat quality and consumer’s motivation to purchase meat analogues. The colour parameters of such as lightness (L*), red/green value (a*), and blue/yellow value (b*) are shown in Table 3.

Several studies examined the effects of different mushroom species on the colour characteristics of meat analogues as shown in Table 3. Patinho et al. (2019) found that adding A. bisporus to beef burgers (15%–30%) resulted in decreased lightness (L*) and increased a* and b* values. Similar findings were reported by multiple authors regarding the incorporation of A. bisporus into meat analogues, which consistently showed reduced lightness levels. Other mushrooms, like Boletus edulis and Cantharellus cibarius, also led to decreased lightness and increased a* and b* values in beef frankfurter.

Wang et al. (2019) noted that 1% F. velutipes reduced lightness in chicken sausage while increasing a* and b* values. A study on pork sausage substitution with Lentinula edodes showed decreased lightness with increasing substitution levels, although a* and b* values remained stable. Conversely, substituting pork patty with Tremella fuciformis resulted in increased lightness and b* values.

Overall, these studies indicated that the addition of mushrooms can change the colour characteristics of meat analogues, primarily affecting lightness (L*). Factors influencing these changes include the original colour of the mushroom, polyphenol oxidase (PPO) content, Maillard reactions, and dietary fibre content. While most studies showed decreased lightness, it was noteworthy that the addition of T. fuciformis, resulted in increased lightness, highlighting the complexity of mushroom impacts on meat analogue colour.

Polyphenol oxidase is an enzyme that browns meals by catalysing the oxidation of phenolic substances, which can result in the creation of brown pigments. PPO in meat analogues, particularly plant-based ones, can alter the product’s brightness by creating discolouration after storage or cooking, making it look darker. The amount of browning is determined by the PPO activity in the plant components (such as soy, pea, or lentil proteins) utilised to manufacture the meat analogue (Abdullah et al., 2022). High PPO activity in the raw material (such as certain legumes or fruits) might cause greater browning, reducing the lightness of the meat counterpart (Zawawi et al., 2022). Conversely, if PPO activity is reduced (e.g., by blanching or using PPO inhibitors), the product may remain lighter in colour (Sui et al., 2023).

The Maillard reaction is a non-enzymatic browning process in which reducing sugars react with amino acids or proteins. This reaction is critical for the formation of flavour, aroma, and colour in many processed foods, including meat substitutes (Kathuria et al., 2023; Li & Li, 2020). When meat analogues are cooked, particularly at high temperatures (such as grilling or frying), Maillard reactions can cause the production of dark pigments, diminishing the product’s lightness (Silva Barbosa Correia et al., 2024; Sun et al., 2022). A high concentration of reducing sugars or amino acids in the formulation (e.g., from the protein source or additional carbohydrates) may result in higher Maillard reactions, darkening the meat equivalent. The Maillard reaction contributes to a more “meaty” appearance and flavour; however, excessive browning might be undesirable in terms of lightness and overall appearance (Zhang et al., 2024).

Effect of mushroom addition and/or substitution on colour parameters of meat analogues.

| Species . | Amount (%) . | Meat product . | L* . | a* . | b* . | References . |

|---|---|---|---|---|---|---|

| A. bisporus | 0 | Beef burger | 50.2 ± 3.28 | 13.7 ± 1.92 | 12.6 ± 1.90 | Patinho et al. (2019) |

| 15 | Beef burger | 48.9 ± 3.33 | 15.1 ± 1.80 | 14.3 ± 1.26 | ||

| 30 | Beef burger | 49.8 ± 3.95 | 15.7 ± 1.91 | 13.0 ± 1.56 | ||

| 0 | Sucuk beef sausage | 33.60 ± 7.53 | 14.16 ± 2.91 | 16.48 ± 6.11 | Gençcelep (2012) | |

| 1 | Sucuk beef sausage | 30.15 ± 6.17 | 10.93 ± 2.75 | 11.05 ± 5.33 | ||

| 2 | Sucuk beef sausage | 30.08 ± 6.57 | 10.14 ± 3.25 | 10.45 ± 6.72 | ||

| 0 | Beef patty | 44.21 ± 1.58 | 15.31 ± 1.12 | 14.86 ± 0.73 | Cerón-Guevara et al. (2020a) | |

| 2.5 | Beef patty | 41.91 ± 2.44 | 13.21 ± 0.72 | 15.55 ± 1.49 | ||

| 5.0 | Beef patty | 40.12 ± 1.90 | 13.57 ± 1.11 | 17.20 ± 1.42 | ||

| 0 | Beef emulsion | 84.19 ± 0.99 | −0.34 ± 0.03 | 17.19 ± 0.64 | Kurt and Gençcelep (2018) | |

| 1 | Beef emulsion | 77.39 ± 1.12 | −0.04 ± 0.03 | 18.88 ± 0.69 | ||

| 2 | Beef emulsion | 75.51 ± 1.01 | 0.18 ± 0.04 | 16.51 ± 0.89 | ||

| 3 | Beef emulsion | 70.82 ± 1.03 | 0.70 ± 0.09 | 16.08 ± 0.18 | ||

| 0 | Ground beef | 38.6 ± 0.56 | 5.60 ± 0.22 | 14.4 ± 0.80 | Wong et al. (2017) | |

| 25 | Ground beef | 38.5 ± 0.22 | 4.49 ± 0.16 | 15.0 ± 0.32 | ||

| 50 | Ground beef | 37.5 ± 0.40 | 4.60 ± 0.40 | 14.8 ± 0.87 | ||

| 75 | Ground beef | 35.6 ± 0.34 | 4.90 ± 0.34 | 14.7 ± 0.34 | ||

| 100 | Ground beef | 31.0 ± 0.36 | 5.33 ± 0.36 | 12.7 ± 0.36 | ||

| 5 | Beef paste | 35.09 ± 0.5 | 3.83 ± 0.06 | 16.19 ± 0.58 | Qing et al. (2021) | |

| 20 | Chicken nugget | 71.75 | 0.6 | 13.57 | Akesowan and Jariyawaranugoon (2021) | |

| B. edulis | 0 | Beef frankfurter | 75.28 ± 1.88 | 7.48 ± 0.86 | 4.17 ± 0.73 | Novakovic et al. (2020) |

| 0.75 | Beef frankfurter | 69.23 ± 2.09 | 8.89 ± 0.89 | 8.48 ± 0.89 | ||

| 1.5 | Beef frankfurter | 64.52 ± 2.3 | 9.05 ± 0.71 | 10.59 ± 0.84 | ||

| C. cibarius | 0 | Beef frankfurter | 75.63 ± 1.88 | 7.45 ± 0.82 | 4.14 ± 0.71 | Novakovic et al. (2019) |

| 0.75 | Beef frankfurter | 75.03 ± 1.71 | 7.49 ± 0.92 | 6.42 ± 0.93 | ||

| 1.5 | Beef frankfurter | 72.11 ± 2.08 | 8.9 ± 0.91 | 8.27 ± 1.01 | ||

| F. velutipes | 0 | Pork sausage | 46.62 ± 0.30 | 11.10 ± 0.18 | 15.21 ± 0.14 | Wang et al. (2019) |

| 2.5 | Pork sausage | 44.37 ± 0.24 | 11.09 ± 0.65 | 16.82 ± 0.26 | ||

| 5.0 | Pork sausage | 43.66 ± 0.74 | 10.40 ± 0.60 | 17.93 ± 0.99 | ||

| 0 | Pork sausage | 67.46 | 8.03 | 11.41 | Choe et al. (2018) | |

| 1 | Pork sausage | 69.07 | 7.96 | 11.5 | ||

| 2 | Pork sausage | 69.21 | 7.79 | 11.83 | ||

| 0 | Goat sausage | 47.42 ± 0.22 | 7.62 ± 0.20 | 13.24 ± 0.32 | Banerjee et al. (2020) | |

| 4 | Goat sausage | 49.42 ± 0.24 | 7.22 ± 0.16 | 13.18 ± 0.22 | ||

| 6 | Goat sausage | 52.02 ± 0.20 | 6.32 ± 0.14 | 13.20 ± 0.24 | ||

| 0 | Chicken sausage | 84.4 | 1.64 | 11.34 | Jo et al. (2018) | |

| 1 | Chicken sausage | 83.52 | 1.85 | 11.67 | ||

| Hypsizygus marmoreus | 5 | Beef paste | 45.71 ± 0.45 | 5.55 ± 0.38 | 15.69 ± 0.19 | Qing et al. (2021) |

| L. edodes | 0 | Pork sausage | 45.49 ± 0.09 | 18.59 ± 0.19 | 18.63 ± 0.24 | Wang et al. (2019) |

| 25 | Pork sausage | 44.86 ± 0.24 | 18.30 ± 0.07 | 18.24 ± 0.19 | ||

| 50 | Pork sausage | 43.43 ± 0.33 | 18.41 ± 0.24 | 18.76 ± 0.26 | ||

| 75 | Pork sausage | 42.52 ± 0.38 | 18.68 ± 0.03 | 18.32 ± 0.38 | ||

| 100 | Mushroom sausage | 41.49 ± 0.33 | 18.36 ± 0.19 | 18.42 ± 0.30 | ||

| 0 | Beef burger | 60.22 ± 2.35 | 11.56 ± 0.51 | 14.75 ± 0.67 | Mattar et al. (2018) | |

| 5 | Beef burger | 62.31 ± 0.17 | 10.77 ± 0.66 | 15.78 ± 0.78 | ||

| 20 | Beef burger | 59.27 ± 0.99 | 10.90 ± 0.68 | 15.34 ± 0.72 | ||

| 0 | Pork frankfurter | 74.63 | 2.77 | 10.33 | Pil-Nam et al. (2015) | |

| 0.4 | Pork frankfurter | 72.98 | 2.77 | 10.16 | ||

| 1.2 | Pork frankfurter | 70.29 | 2.54 | 11.39 | ||

| 0 | Chicken nugget | 63.89 ± 0.29 | 1.62 ± 0.05 | – | Akesowan (2016) | |

| 1.84 | Chicken nugget | 65.45 ± 0.57 | 1.85 ± 0.09 | – | Mattar et al. (2018) | |

| P. eryngii | 0 | Pork sausage | 55.64 ± 1.82 | 17.68 ± 1.75 | 12.05 ± 0.35 | Wang et al. (2019) |

| 25 | Pork sausage | 55.14 ± 1.69 | 18.76 ± 0.36 | 13.18 ± 0.62 | ||

| 20 | Extruded analogue meat | 44.13 ± 0.80 | 9.95 ± 0.19 | 20.96 ± 0.34 | Mandliya et al. (2022) | |

| 40 | Extruded analogue meat | 36.95 ± 1.08 | 9.86 ± 0.22 | 15.99 ± 1.06 | ||

| P. ostreatus | 2.5 | Beef patty | 46.88 ± 2.38 | 16.44 ± 0.58 | 20.06 ± 1.15 | Cerón-Guevara et al. (2020a) |

| 5.0 | Beef patty | 41.50 ± 2.80 | 14.81 ± 0.62 | 19.65 ± 1.63 | ||

| 5 | Beef paste | 40.09 ± 0.38 | 6.68 ± 0.36 | 16.62 ± 0.19 | Qing et al. (2021) | |

| P. sajor-caju | 0 | Chicken nugget | 54.72 | 10.23 | 29.2 | Husain and Huda-Faujan (2020) |

| 60 | Chicken nugget | 59.33 | 9.59 | 29.53 | ||

| 50 | Chicken nugget | 57.24 | 9.51 | 30.02 | ||

| 0 | Chicken patty | 57.86 + 0.84 | 3.46 + 0.26 | 21.03 + 0.29 | Rosli et al. (2011) | |

| 25 | Chicken patty | 51.02+ 1.94 | 3.61 + 0.29 | 18.77 + 0.47 | ||

| 50 | Chicken patty | 52.65+ 1.16 | 3.24 + 0.41 | 18.12 + 0.84 | ||

| P. sapidus | 0 | Chicken sausage | 72.35 ± 0.01 | 11.56 ± 0.01 | 12.52 ± 0.01 | Stephan et al. (2018) |

| 100 | Mushroom sausage | 66.23 ± 0.01 | 13.09 ± 0.01 | 20.52 ± 0.01 | ||

| Volvariella volvacea | 0 | Beef paste | 43.89 ± 0.74 | 5.92 ± 0.16 | 15.06 ± 0.46 | Qing et al. (2021) |

| 5 | Beef paste | 38.80 ± 0.68 | 4.62 ± 0.22 | 16.81 ± 0.07 | ||

| 0 | Pork sausage | 55.1 ± 0.87 | 10.27 ± 0.16 | 14.16 ± 0.58 | Wang et al. (2018) | |

| 2 | Pork sausage | 48.4 ± 0.24 | 6.69 ± 0.14 | 14.85 ± 0.17 | ||

| 4 | Pork sausage | 47. 6 ± 0.32 | 5.83 ± 0.07 | 16.67 ± 0.03 | ||

| Tremella uciformis | 0 | Pork patty | 61.73 ± 2.9 | 4.36 ± 0.04 | 14.20 ± 0.01 | Cha et al. (2014) |

| 10 | Pork patty | 64.31 ± 4.49 | 3.75 ± 0.14 | 14.39 ± 0.16 | ||

| 20 | Pork patty | 65.65 ± 0.08 | 3.94 ± 0.09 | 14.51 ± 0.1 | ||

| 30 | Pork patty | 67.23 ± 0.15 | 3.26 ± 0.04 | 14.60 ± 0.21 |

| Species . | Amount (%) . | Meat product . | L* . | a* . | b* . | References . |

|---|---|---|---|---|---|---|

| A. bisporus | 0 | Beef burger | 50.2 ± 3.28 | 13.7 ± 1.92 | 12.6 ± 1.90 | Patinho et al. (2019) |

| 15 | Beef burger | 48.9 ± 3.33 | 15.1 ± 1.80 | 14.3 ± 1.26 | ||

| 30 | Beef burger | 49.8 ± 3.95 | 15.7 ± 1.91 | 13.0 ± 1.56 | ||

| 0 | Sucuk beef sausage | 33.60 ± 7.53 | 14.16 ± 2.91 | 16.48 ± 6.11 | Gençcelep (2012) | |

| 1 | Sucuk beef sausage | 30.15 ± 6.17 | 10.93 ± 2.75 | 11.05 ± 5.33 | ||

| 2 | Sucuk beef sausage | 30.08 ± 6.57 | 10.14 ± 3.25 | 10.45 ± 6.72 | ||

| 0 | Beef patty | 44.21 ± 1.58 | 15.31 ± 1.12 | 14.86 ± 0.73 | Cerón-Guevara et al. (2020a) | |

| 2.5 | Beef patty | 41.91 ± 2.44 | 13.21 ± 0.72 | 15.55 ± 1.49 | ||

| 5.0 | Beef patty | 40.12 ± 1.90 | 13.57 ± 1.11 | 17.20 ± 1.42 | ||

| 0 | Beef emulsion | 84.19 ± 0.99 | −0.34 ± 0.03 | 17.19 ± 0.64 | Kurt and Gençcelep (2018) | |

| 1 | Beef emulsion | 77.39 ± 1.12 | −0.04 ± 0.03 | 18.88 ± 0.69 | ||

| 2 | Beef emulsion | 75.51 ± 1.01 | 0.18 ± 0.04 | 16.51 ± 0.89 | ||

| 3 | Beef emulsion | 70.82 ± 1.03 | 0.70 ± 0.09 | 16.08 ± 0.18 | ||

| 0 | Ground beef | 38.6 ± 0.56 | 5.60 ± 0.22 | 14.4 ± 0.80 | Wong et al. (2017) | |

| 25 | Ground beef | 38.5 ± 0.22 | 4.49 ± 0.16 | 15.0 ± 0.32 | ||

| 50 | Ground beef | 37.5 ± 0.40 | 4.60 ± 0.40 | 14.8 ± 0.87 | ||

| 75 | Ground beef | 35.6 ± 0.34 | 4.90 ± 0.34 | 14.7 ± 0.34 | ||

| 100 | Ground beef | 31.0 ± 0.36 | 5.33 ± 0.36 | 12.7 ± 0.36 | ||

| 5 | Beef paste | 35.09 ± 0.5 | 3.83 ± 0.06 | 16.19 ± 0.58 | Qing et al. (2021) | |

| 20 | Chicken nugget | 71.75 | 0.6 | 13.57 | Akesowan and Jariyawaranugoon (2021) | |

| B. edulis | 0 | Beef frankfurter | 75.28 ± 1.88 | 7.48 ± 0.86 | 4.17 ± 0.73 | Novakovic et al. (2020) |

| 0.75 | Beef frankfurter | 69.23 ± 2.09 | 8.89 ± 0.89 | 8.48 ± 0.89 | ||

| 1.5 | Beef frankfurter | 64.52 ± 2.3 | 9.05 ± 0.71 | 10.59 ± 0.84 | ||

| C. cibarius | 0 | Beef frankfurter | 75.63 ± 1.88 | 7.45 ± 0.82 | 4.14 ± 0.71 | Novakovic et al. (2019) |

| 0.75 | Beef frankfurter | 75.03 ± 1.71 | 7.49 ± 0.92 | 6.42 ± 0.93 | ||

| 1.5 | Beef frankfurter | 72.11 ± 2.08 | 8.9 ± 0.91 | 8.27 ± 1.01 | ||

| F. velutipes | 0 | Pork sausage | 46.62 ± 0.30 | 11.10 ± 0.18 | 15.21 ± 0.14 | Wang et al. (2019) |

| 2.5 | Pork sausage | 44.37 ± 0.24 | 11.09 ± 0.65 | 16.82 ± 0.26 | ||

| 5.0 | Pork sausage | 43.66 ± 0.74 | 10.40 ± 0.60 | 17.93 ± 0.99 | ||

| 0 | Pork sausage | 67.46 | 8.03 | 11.41 | Choe et al. (2018) | |

| 1 | Pork sausage | 69.07 | 7.96 | 11.5 | ||

| 2 | Pork sausage | 69.21 | 7.79 | 11.83 | ||

| 0 | Goat sausage | 47.42 ± 0.22 | 7.62 ± 0.20 | 13.24 ± 0.32 | Banerjee et al. (2020) | |

| 4 | Goat sausage | 49.42 ± 0.24 | 7.22 ± 0.16 | 13.18 ± 0.22 | ||

| 6 | Goat sausage | 52.02 ± 0.20 | 6.32 ± 0.14 | 13.20 ± 0.24 | ||

| 0 | Chicken sausage | 84.4 | 1.64 | 11.34 | Jo et al. (2018) | |

| 1 | Chicken sausage | 83.52 | 1.85 | 11.67 | ||

| Hypsizygus marmoreus | 5 | Beef paste | 45.71 ± 0.45 | 5.55 ± 0.38 | 15.69 ± 0.19 | Qing et al. (2021) |

| L. edodes | 0 | Pork sausage | 45.49 ± 0.09 | 18.59 ± 0.19 | 18.63 ± 0.24 | Wang et al. (2019) |

| 25 | Pork sausage | 44.86 ± 0.24 | 18.30 ± 0.07 | 18.24 ± 0.19 | ||

| 50 | Pork sausage | 43.43 ± 0.33 | 18.41 ± 0.24 | 18.76 ± 0.26 | ||

| 75 | Pork sausage | 42.52 ± 0.38 | 18.68 ± 0.03 | 18.32 ± 0.38 | ||

| 100 | Mushroom sausage | 41.49 ± 0.33 | 18.36 ± 0.19 | 18.42 ± 0.30 | ||

| 0 | Beef burger | 60.22 ± 2.35 | 11.56 ± 0.51 | 14.75 ± 0.67 | Mattar et al. (2018) | |

| 5 | Beef burger | 62.31 ± 0.17 | 10.77 ± 0.66 | 15.78 ± 0.78 | ||

| 20 | Beef burger | 59.27 ± 0.99 | 10.90 ± 0.68 | 15.34 ± 0.72 | ||

| 0 | Pork frankfurter | 74.63 | 2.77 | 10.33 | Pil-Nam et al. (2015) | |

| 0.4 | Pork frankfurter | 72.98 | 2.77 | 10.16 | ||

| 1.2 | Pork frankfurter | 70.29 | 2.54 | 11.39 | ||

| 0 | Chicken nugget | 63.89 ± 0.29 | 1.62 ± 0.05 | – | Akesowan (2016) | |

| 1.84 | Chicken nugget | 65.45 ± 0.57 | 1.85 ± 0.09 | – | Mattar et al. (2018) | |

| P. eryngii | 0 | Pork sausage | 55.64 ± 1.82 | 17.68 ± 1.75 | 12.05 ± 0.35 | Wang et al. (2019) |

| 25 | Pork sausage | 55.14 ± 1.69 | 18.76 ± 0.36 | 13.18 ± 0.62 | ||

| 20 | Extruded analogue meat | 44.13 ± 0.80 | 9.95 ± 0.19 | 20.96 ± 0.34 | Mandliya et al. (2022) | |

| 40 | Extruded analogue meat | 36.95 ± 1.08 | 9.86 ± 0.22 | 15.99 ± 1.06 | ||

| P. ostreatus | 2.5 | Beef patty | 46.88 ± 2.38 | 16.44 ± 0.58 | 20.06 ± 1.15 | Cerón-Guevara et al. (2020a) |

| 5.0 | Beef patty | 41.50 ± 2.80 | 14.81 ± 0.62 | 19.65 ± 1.63 | ||

| 5 | Beef paste | 40.09 ± 0.38 | 6.68 ± 0.36 | 16.62 ± 0.19 | Qing et al. (2021) | |

| P. sajor-caju | 0 | Chicken nugget | 54.72 | 10.23 | 29.2 | Husain and Huda-Faujan (2020) |

| 60 | Chicken nugget | 59.33 | 9.59 | 29.53 | ||

| 50 | Chicken nugget | 57.24 | 9.51 | 30.02 | ||

| 0 | Chicken patty | 57.86 + 0.84 | 3.46 + 0.26 | 21.03 + 0.29 | Rosli et al. (2011) | |

| 25 | Chicken patty | 51.02+ 1.94 | 3.61 + 0.29 | 18.77 + 0.47 | ||

| 50 | Chicken patty | 52.65+ 1.16 | 3.24 + 0.41 | 18.12 + 0.84 | ||

| P. sapidus | 0 | Chicken sausage | 72.35 ± 0.01 | 11.56 ± 0.01 | 12.52 ± 0.01 | Stephan et al. (2018) |

| 100 | Mushroom sausage | 66.23 ± 0.01 | 13.09 ± 0.01 | 20.52 ± 0.01 | ||

| Volvariella volvacea | 0 | Beef paste | 43.89 ± 0.74 | 5.92 ± 0.16 | 15.06 ± 0.46 | Qing et al. (2021) |

| 5 | Beef paste | 38.80 ± 0.68 | 4.62 ± 0.22 | 16.81 ± 0.07 | ||

| 0 | Pork sausage | 55.1 ± 0.87 | 10.27 ± 0.16 | 14.16 ± 0.58 | Wang et al. (2018) | |

| 2 | Pork sausage | 48.4 ± 0.24 | 6.69 ± 0.14 | 14.85 ± 0.17 | ||

| 4 | Pork sausage | 47. 6 ± 0.32 | 5.83 ± 0.07 | 16.67 ± 0.03 | ||

| Tremella uciformis | 0 | Pork patty | 61.73 ± 2.9 | 4.36 ± 0.04 | 14.20 ± 0.01 | Cha et al. (2014) |

| 10 | Pork patty | 64.31 ± 4.49 | 3.75 ± 0.14 | 14.39 ± 0.16 | ||

| 20 | Pork patty | 65.65 ± 0.08 | 3.94 ± 0.09 | 14.51 ± 0.1 | ||

| 30 | Pork patty | 67.23 ± 0.15 | 3.26 ± 0.04 | 14.60 ± 0.21 |

Note. L* value denotes lightness while a* and b* are coordinates of chromaticity.

a* value indicates red-green component of a colour, where a* (positive) and a* (negative) indicate red and green values, respectively.

b* value is represented on the axis as b* (positive) and b* (negative) values the yellow and blue, respectively.

Effect of mushroom addition and/or substitution on colour parameters of meat analogues.

| Species . | Amount (%) . | Meat product . | L* . | a* . | b* . | References . |

|---|---|---|---|---|---|---|

| A. bisporus | 0 | Beef burger | 50.2 ± 3.28 | 13.7 ± 1.92 | 12.6 ± 1.90 | Patinho et al. (2019) |

| 15 | Beef burger | 48.9 ± 3.33 | 15.1 ± 1.80 | 14.3 ± 1.26 | ||

| 30 | Beef burger | 49.8 ± 3.95 | 15.7 ± 1.91 | 13.0 ± 1.56 | ||

| 0 | Sucuk beef sausage | 33.60 ± 7.53 | 14.16 ± 2.91 | 16.48 ± 6.11 | Gençcelep (2012) | |

| 1 | Sucuk beef sausage | 30.15 ± 6.17 | 10.93 ± 2.75 | 11.05 ± 5.33 | ||

| 2 | Sucuk beef sausage | 30.08 ± 6.57 | 10.14 ± 3.25 | 10.45 ± 6.72 | ||

| 0 | Beef patty | 44.21 ± 1.58 | 15.31 ± 1.12 | 14.86 ± 0.73 | Cerón-Guevara et al. (2020a) | |

| 2.5 | Beef patty | 41.91 ± 2.44 | 13.21 ± 0.72 | 15.55 ± 1.49 | ||

| 5.0 | Beef patty | 40.12 ± 1.90 | 13.57 ± 1.11 | 17.20 ± 1.42 | ||

| 0 | Beef emulsion | 84.19 ± 0.99 | −0.34 ± 0.03 | 17.19 ± 0.64 | Kurt and Gençcelep (2018) | |

| 1 | Beef emulsion | 77.39 ± 1.12 | −0.04 ± 0.03 | 18.88 ± 0.69 | ||

| 2 | Beef emulsion | 75.51 ± 1.01 | 0.18 ± 0.04 | 16.51 ± 0.89 | ||

| 3 | Beef emulsion | 70.82 ± 1.03 | 0.70 ± 0.09 | 16.08 ± 0.18 | ||

| 0 | Ground beef | 38.6 ± 0.56 | 5.60 ± 0.22 | 14.4 ± 0.80 | Wong et al. (2017) | |

| 25 | Ground beef | 38.5 ± 0.22 | 4.49 ± 0.16 | 15.0 ± 0.32 | ||

| 50 | Ground beef | 37.5 ± 0.40 | 4.60 ± 0.40 | 14.8 ± 0.87 | ||

| 75 | Ground beef | 35.6 ± 0.34 | 4.90 ± 0.34 | 14.7 ± 0.34 | ||

| 100 | Ground beef | 31.0 ± 0.36 | 5.33 ± 0.36 | 12.7 ± 0.36 | ||

| 5 | Beef paste | 35.09 ± 0.5 | 3.83 ± 0.06 | 16.19 ± 0.58 | Qing et al. (2021) | |

| 20 | Chicken nugget | 71.75 | 0.6 | 13.57 | Akesowan and Jariyawaranugoon (2021) | |

| B. edulis | 0 | Beef frankfurter | 75.28 ± 1.88 | 7.48 ± 0.86 | 4.17 ± 0.73 | Novakovic et al. (2020) |

| 0.75 | Beef frankfurter | 69.23 ± 2.09 | 8.89 ± 0.89 | 8.48 ± 0.89 | ||

| 1.5 | Beef frankfurter | 64.52 ± 2.3 | 9.05 ± 0.71 | 10.59 ± 0.84 | ||

| C. cibarius | 0 | Beef frankfurter | 75.63 ± 1.88 | 7.45 ± 0.82 | 4.14 ± 0.71 | Novakovic et al. (2019) |

| 0.75 | Beef frankfurter | 75.03 ± 1.71 | 7.49 ± 0.92 | 6.42 ± 0.93 | ||

| 1.5 | Beef frankfurter | 72.11 ± 2.08 | 8.9 ± 0.91 | 8.27 ± 1.01 | ||

| F. velutipes | 0 | Pork sausage | 46.62 ± 0.30 | 11.10 ± 0.18 | 15.21 ± 0.14 | Wang et al. (2019) |

| 2.5 | Pork sausage | 44.37 ± 0.24 | 11.09 ± 0.65 | 16.82 ± 0.26 | ||

| 5.0 | Pork sausage | 43.66 ± 0.74 | 10.40 ± 0.60 | 17.93 ± 0.99 | ||

| 0 | Pork sausage | 67.46 | 8.03 | 11.41 | Choe et al. (2018) | |

| 1 | Pork sausage | 69.07 | 7.96 | 11.5 | ||

| 2 | Pork sausage | 69.21 | 7.79 | 11.83 | ||

| 0 | Goat sausage | 47.42 ± 0.22 | 7.62 ± 0.20 | 13.24 ± 0.32 | Banerjee et al. (2020) | |

| 4 | Goat sausage | 49.42 ± 0.24 | 7.22 ± 0.16 | 13.18 ± 0.22 | ||

| 6 | Goat sausage | 52.02 ± 0.20 | 6.32 ± 0.14 | 13.20 ± 0.24 | ||

| 0 | Chicken sausage | 84.4 | 1.64 | 11.34 | Jo et al. (2018) | |

| 1 | Chicken sausage | 83.52 | 1.85 | 11.67 | ||

| Hypsizygus marmoreus | 5 | Beef paste | 45.71 ± 0.45 | 5.55 ± 0.38 | 15.69 ± 0.19 | Qing et al. (2021) |

| L. edodes | 0 | Pork sausage | 45.49 ± 0.09 | 18.59 ± 0.19 | 18.63 ± 0.24 | Wang et al. (2019) |

| 25 | Pork sausage | 44.86 ± 0.24 | 18.30 ± 0.07 | 18.24 ± 0.19 | ||

| 50 | Pork sausage | 43.43 ± 0.33 | 18.41 ± 0.24 | 18.76 ± 0.26 | ||

| 75 | Pork sausage | 42.52 ± 0.38 | 18.68 ± 0.03 | 18.32 ± 0.38 | ||

| 100 | Mushroom sausage | 41.49 ± 0.33 | 18.36 ± 0.19 | 18.42 ± 0.30 | ||

| 0 | Beef burger | 60.22 ± 2.35 | 11.56 ± 0.51 | 14.75 ± 0.67 | Mattar et al. (2018) | |

| 5 | Beef burger | 62.31 ± 0.17 | 10.77 ± 0.66 | 15.78 ± 0.78 | ||

| 20 | Beef burger | 59.27 ± 0.99 | 10.90 ± 0.68 | 15.34 ± 0.72 | ||

| 0 | Pork frankfurter | 74.63 | 2.77 | 10.33 | Pil-Nam et al. (2015) | |

| 0.4 | Pork frankfurter | 72.98 | 2.77 | 10.16 | ||

| 1.2 | Pork frankfurter | 70.29 | 2.54 | 11.39 | ||

| 0 | Chicken nugget | 63.89 ± 0.29 | 1.62 ± 0.05 | – | Akesowan (2016) | |

| 1.84 | Chicken nugget | 65.45 ± 0.57 | 1.85 ± 0.09 | – | Mattar et al. (2018) | |

| P. eryngii | 0 | Pork sausage | 55.64 ± 1.82 | 17.68 ± 1.75 | 12.05 ± 0.35 | Wang et al. (2019) |

| 25 | Pork sausage | 55.14 ± 1.69 | 18.76 ± 0.36 | 13.18 ± 0.62 | ||

| 20 | Extruded analogue meat | 44.13 ± 0.80 | 9.95 ± 0.19 | 20.96 ± 0.34 | Mandliya et al. (2022) | |

| 40 | Extruded analogue meat | 36.95 ± 1.08 | 9.86 ± 0.22 | 15.99 ± 1.06 | ||

| P. ostreatus | 2.5 | Beef patty | 46.88 ± 2.38 | 16.44 ± 0.58 | 20.06 ± 1.15 | Cerón-Guevara et al. (2020a) |

| 5.0 | Beef patty | 41.50 ± 2.80 | 14.81 ± 0.62 | 19.65 ± 1.63 | ||

| 5 | Beef paste | 40.09 ± 0.38 | 6.68 ± 0.36 | 16.62 ± 0.19 | Qing et al. (2021) | |

| P. sajor-caju | 0 | Chicken nugget | 54.72 | 10.23 | 29.2 | Husain and Huda-Faujan (2020) |

| 60 | Chicken nugget | 59.33 | 9.59 | 29.53 | ||

| 50 | Chicken nugget | 57.24 | 9.51 | 30.02 | ||

| 0 | Chicken patty | 57.86 + 0.84 | 3.46 + 0.26 | 21.03 + 0.29 | Rosli et al. (2011) | |

| 25 | Chicken patty | 51.02+ 1.94 | 3.61 + 0.29 | 18.77 + 0.47 | ||

| 50 | Chicken patty | 52.65+ 1.16 | 3.24 + 0.41 | 18.12 + 0.84 | ||

| P. sapidus | 0 | Chicken sausage | 72.35 ± 0.01 | 11.56 ± 0.01 | 12.52 ± 0.01 | Stephan et al. (2018) |

| 100 | Mushroom sausage | 66.23 ± 0.01 | 13.09 ± 0.01 | 20.52 ± 0.01 | ||

| Volvariella volvacea | 0 | Beef paste | 43.89 ± 0.74 | 5.92 ± 0.16 | 15.06 ± 0.46 | Qing et al. (2021) |

| 5 | Beef paste | 38.80 ± 0.68 | 4.62 ± 0.22 | 16.81 ± 0.07 | ||

| 0 | Pork sausage | 55.1 ± 0.87 | 10.27 ± 0.16 | 14.16 ± 0.58 | Wang et al. (2018) | |

| 2 | Pork sausage | 48.4 ± 0.24 | 6.69 ± 0.14 | 14.85 ± 0.17 | ||

| 4 | Pork sausage | 47. 6 ± 0.32 | 5.83 ± 0.07 | 16.67 ± 0.03 | ||

| Tremella uciformis | 0 | Pork patty | 61.73 ± 2.9 | 4.36 ± 0.04 | 14.20 ± 0.01 | Cha et al. (2014) |

| 10 | Pork patty | 64.31 ± 4.49 | 3.75 ± 0.14 | 14.39 ± 0.16 | ||

| 20 | Pork patty | 65.65 ± 0.08 | 3.94 ± 0.09 | 14.51 ± 0.1 | ||

| 30 | Pork patty | 67.23 ± 0.15 | 3.26 ± 0.04 | 14.60 ± 0.21 |

| Species . | Amount (%) . | Meat product . | L* . | a* . | b* . | References . |

|---|---|---|---|---|---|---|

| A. bisporus | 0 | Beef burger | 50.2 ± 3.28 | 13.7 ± 1.92 | 12.6 ± 1.90 | Patinho et al. (2019) |

| 15 | Beef burger | 48.9 ± 3.33 | 15.1 ± 1.80 | 14.3 ± 1.26 | ||

| 30 | Beef burger | 49.8 ± 3.95 | 15.7 ± 1.91 | 13.0 ± 1.56 | ||

| 0 | Sucuk beef sausage | 33.60 ± 7.53 | 14.16 ± 2.91 | 16.48 ± 6.11 | Gençcelep (2012) | |

| 1 | Sucuk beef sausage | 30.15 ± 6.17 | 10.93 ± 2.75 | 11.05 ± 5.33 | ||

| 2 | Sucuk beef sausage | 30.08 ± 6.57 | 10.14 ± 3.25 | 10.45 ± 6.72 | ||

| 0 | Beef patty | 44.21 ± 1.58 | 15.31 ± 1.12 | 14.86 ± 0.73 | Cerón-Guevara et al. (2020a) | |

| 2.5 | Beef patty | 41.91 ± 2.44 | 13.21 ± 0.72 | 15.55 ± 1.49 | ||

| 5.0 | Beef patty | 40.12 ± 1.90 | 13.57 ± 1.11 | 17.20 ± 1.42 | ||

| 0 | Beef emulsion | 84.19 ± 0.99 | −0.34 ± 0.03 | 17.19 ± 0.64 | Kurt and Gençcelep (2018) | |

| 1 | Beef emulsion | 77.39 ± 1.12 | −0.04 ± 0.03 | 18.88 ± 0.69 | ||

| 2 | Beef emulsion | 75.51 ± 1.01 | 0.18 ± 0.04 | 16.51 ± 0.89 | ||

| 3 | Beef emulsion | 70.82 ± 1.03 | 0.70 ± 0.09 | 16.08 ± 0.18 | ||

| 0 | Ground beef | 38.6 ± 0.56 | 5.60 ± 0.22 | 14.4 ± 0.80 | Wong et al. (2017) | |

| 25 | Ground beef | 38.5 ± 0.22 | 4.49 ± 0.16 | 15.0 ± 0.32 | ||

| 50 | Ground beef | 37.5 ± 0.40 | 4.60 ± 0.40 | 14.8 ± 0.87 | ||

| 75 | Ground beef | 35.6 ± 0.34 | 4.90 ± 0.34 | 14.7 ± 0.34 | ||

| 100 | Ground beef | 31.0 ± 0.36 | 5.33 ± 0.36 | 12.7 ± 0.36 | ||

| 5 | Beef paste | 35.09 ± 0.5 | 3.83 ± 0.06 | 16.19 ± 0.58 | Qing et al. (2021) | |

| 20 | Chicken nugget | 71.75 | 0.6 | 13.57 | Akesowan and Jariyawaranugoon (2021) | |

| B. edulis | 0 | Beef frankfurter | 75.28 ± 1.88 | 7.48 ± 0.86 | 4.17 ± 0.73 | Novakovic et al. (2020) |

| 0.75 | Beef frankfurter | 69.23 ± 2.09 | 8.89 ± 0.89 | 8.48 ± 0.89 | ||

| 1.5 | Beef frankfurter | 64.52 ± 2.3 | 9.05 ± 0.71 | 10.59 ± 0.84 | ||

| C. cibarius | 0 | Beef frankfurter | 75.63 ± 1.88 | 7.45 ± 0.82 | 4.14 ± 0.71 | Novakovic et al. (2019) |

| 0.75 | Beef frankfurter | 75.03 ± 1.71 | 7.49 ± 0.92 | 6.42 ± 0.93 | ||

| 1.5 | Beef frankfurter | 72.11 ± 2.08 | 8.9 ± 0.91 | 8.27 ± 1.01 | ||

| F. velutipes | 0 | Pork sausage | 46.62 ± 0.30 | 11.10 ± 0.18 | 15.21 ± 0.14 | Wang et al. (2019) |

| 2.5 | Pork sausage | 44.37 ± 0.24 | 11.09 ± 0.65 | 16.82 ± 0.26 | ||

| 5.0 | Pork sausage | 43.66 ± 0.74 | 10.40 ± 0.60 | 17.93 ± 0.99 | ||

| 0 | Pork sausage | 67.46 | 8.03 | 11.41 | Choe et al. (2018) | |

| 1 | Pork sausage | 69.07 | 7.96 | 11.5 | ||

| 2 | Pork sausage | 69.21 | 7.79 | 11.83 | ||

| 0 | Goat sausage | 47.42 ± 0.22 | 7.62 ± 0.20 | 13.24 ± 0.32 | Banerjee et al. (2020) | |

| 4 | Goat sausage | 49.42 ± 0.24 | 7.22 ± 0.16 | 13.18 ± 0.22 | ||

| 6 | Goat sausage | 52.02 ± 0.20 | 6.32 ± 0.14 | 13.20 ± 0.24 | ||

| 0 | Chicken sausage | 84.4 | 1.64 | 11.34 | Jo et al. (2018) | |

| 1 | Chicken sausage | 83.52 | 1.85 | 11.67 | ||

| Hypsizygus marmoreus | 5 | Beef paste | 45.71 ± 0.45 | 5.55 ± 0.38 | 15.69 ± 0.19 | Qing et al. (2021) |

| L. edodes | 0 | Pork sausage | 45.49 ± 0.09 | 18.59 ± 0.19 | 18.63 ± 0.24 | Wang et al. (2019) |

| 25 | Pork sausage | 44.86 ± 0.24 | 18.30 ± 0.07 | 18.24 ± 0.19 | ||

| 50 | Pork sausage | 43.43 ± 0.33 | 18.41 ± 0.24 | 18.76 ± 0.26 | ||

| 75 | Pork sausage | 42.52 ± 0.38 | 18.68 ± 0.03 | 18.32 ± 0.38 | ||

| 100 | Mushroom sausage | 41.49 ± 0.33 | 18.36 ± 0.19 | 18.42 ± 0.30 | ||

| 0 | Beef burger | 60.22 ± 2.35 | 11.56 ± 0.51 | 14.75 ± 0.67 | Mattar et al. (2018) | |

| 5 | Beef burger | 62.31 ± 0.17 | 10.77 ± 0.66 | 15.78 ± 0.78 | ||

| 20 | Beef burger | 59.27 ± 0.99 | 10.90 ± 0.68 | 15.34 ± 0.72 | ||

| 0 | Pork frankfurter | 74.63 | 2.77 | 10.33 | Pil-Nam et al. (2015) | |

| 0.4 | Pork frankfurter | 72.98 | 2.77 | 10.16 | ||

| 1.2 | Pork frankfurter | 70.29 | 2.54 | 11.39 | ||

| 0 | Chicken nugget | 63.89 ± 0.29 | 1.62 ± 0.05 | – | Akesowan (2016) | |

| 1.84 | Chicken nugget | 65.45 ± 0.57 | 1.85 ± 0.09 | – | Mattar et al. (2018) | |

| P. eryngii | 0 | Pork sausage | 55.64 ± 1.82 | 17.68 ± 1.75 | 12.05 ± 0.35 | Wang et al. (2019) |

| 25 | Pork sausage | 55.14 ± 1.69 | 18.76 ± 0.36 | 13.18 ± 0.62 | ||

| 20 | Extruded analogue meat | 44.13 ± 0.80 | 9.95 ± 0.19 | 20.96 ± 0.34 | Mandliya et al. (2022) | |

| 40 | Extruded analogue meat | 36.95 ± 1.08 | 9.86 ± 0.22 | 15.99 ± 1.06 | ||

| P. ostreatus | 2.5 | Beef patty | 46.88 ± 2.38 | 16.44 ± 0.58 | 20.06 ± 1.15 | Cerón-Guevara et al. (2020a) |

| 5.0 | Beef patty | 41.50 ± 2.80 | 14.81 ± 0.62 | 19.65 ± 1.63 | ||

| 5 | Beef paste | 40.09 ± 0.38 | 6.68 ± 0.36 | 16.62 ± 0.19 | Qing et al. (2021) | |

| P. sajor-caju | 0 | Chicken nugget | 54.72 | 10.23 | 29.2 | Husain and Huda-Faujan (2020) |

| 60 | Chicken nugget | 59.33 | 9.59 | 29.53 | ||

| 50 | Chicken nugget | 57.24 | 9.51 | 30.02 | ||

| 0 | Chicken patty | 57.86 + 0.84 | 3.46 + 0.26 | 21.03 + 0.29 | Rosli et al. (2011) | |

| 25 | Chicken patty | 51.02+ 1.94 | 3.61 + 0.29 | 18.77 + 0.47 | ||

| 50 | Chicken patty | 52.65+ 1.16 | 3.24 + 0.41 | 18.12 + 0.84 | ||

| P. sapidus | 0 | Chicken sausage | 72.35 ± 0.01 | 11.56 ± 0.01 | 12.52 ± 0.01 | Stephan et al. (2018) |

| 100 | Mushroom sausage | 66.23 ± 0.01 | 13.09 ± 0.01 | 20.52 ± 0.01 | ||

| Volvariella volvacea | 0 | Beef paste | 43.89 ± 0.74 | 5.92 ± 0.16 | 15.06 ± 0.46 | Qing et al. (2021) |

| 5 | Beef paste | 38.80 ± 0.68 | 4.62 ± 0.22 | 16.81 ± 0.07 | ||

| 0 | Pork sausage | 55.1 ± 0.87 | 10.27 ± 0.16 | 14.16 ± 0.58 | Wang et al. (2018) | |

| 2 | Pork sausage | 48.4 ± 0.24 | 6.69 ± 0.14 | 14.85 ± 0.17 | ||

| 4 | Pork sausage | 47. 6 ± 0.32 | 5.83 ± 0.07 | 16.67 ± 0.03 | ||

| Tremella uciformis | 0 | Pork patty | 61.73 ± 2.9 | 4.36 ± 0.04 | 14.20 ± 0.01 | Cha et al. (2014) |

| 10 | Pork patty | 64.31 ± 4.49 | 3.75 ± 0.14 | 14.39 ± 0.16 | ||

| 20 | Pork patty | 65.65 ± 0.08 | 3.94 ± 0.09 | 14.51 ± 0.1 | ||

| 30 | Pork patty | 67.23 ± 0.15 | 3.26 ± 0.04 | 14.60 ± 0.21 |

Note. L* value denotes lightness while a* and b* are coordinates of chromaticity.

a* value indicates red-green component of a colour, where a* (positive) and a* (negative) indicate red and green values, respectively.

b* value is represented on the axis as b* (positive) and b* (negative) values the yellow and blue, respectively.

Dietary fibre, particularly from plant-based sources, can affect the texture and appearance of meat substitutes. Fibre absorbs water, altering the product’s moisture content and structure. The fibre’s interaction with the proteins and carbs in the meat analogue formulation may also influence how the product performs when cooked (Dinalia et al., 2024). A high amount of fibre can impact the lightness in two main ways. First, fibres could reflect light in various ways, leading to either a lighter or denser look. Second, dietary fibres may attach to certain pigments or engage with enzymes such as PPO, potentially minimising browning. However, elevated fibre content might not directly stop Maillard reactions, so the effect on lightness will be influenced by the source of the fibre and the overall makeup of the meat substitute (da Silva et al., 2024).

PPO can promote browning through enzymatic oxidation, which results in a darker look. Maillard reactions can introduce non-enzymatic browning, further darkening the product when subject to heat. Dietary fibre may lessen the severity of browning by either affecting PPO activity or changing the texture and cooking process, although it may not directly block Maillard reactions. It’s crucial to manage the activity of PPO (for instance, by choosing ingredients with low PPO levels or using inhibitors), limit excessive Maillard reactions (by controlling heat and duration during cooking), and fine-tune the fibre content to achieve the right texture without causing excessive browning. Modifying these elements can aid in creating a meat substitute with an attractive lightness and appealing visual traits.

The texture properties of meat analogues assessed using a texture profile analyser (TPA), which include attributes like hardness, springiness, cohesiveness, gumminess, and chewiness, significantly affect consumer perception. As shown in Table 4, addition of certain species of mushrooms such as A. bisporus and F. velutipes resulted in decreased texture parameters in meat products. For example, Patinho et al. (2019) found that incorporating A. bisporus into beef burgers reduced hardness and chewiness. Similarly, multiple studies, including those by Cerón-Guevara et al. (2020a) and Banerjee et al. (2020), noted decreased texture values in sausage products with mushroom additions. Conversely, some mushrooms like B. edulis and C. cibarius could enhance texture properties, increasing hardness and chewiness when added to products. For example, Novakovic et al. (2020) highlighted that the addition of B. edulis led to improved hardness and cohesiveness in beef frankfurter.

Effect of mushroom addition and/or substitution on textural properties of meat analogues.

| Species . | Amount (%) . | Meat product . | Hardness (N) . | Springiness (mm) . | Cohesiveness (mm/mm) . | Gumminess (N) . | Chewiness (N.mm) . | References . |

|---|---|---|---|---|---|---|---|---|

| A. bisporus | 0 | Beef burger | 13,126 ± 559 g | 0.841 ± 0.019 | 0.466 ± 0.050 | – | 5,106 ± 577 g.mm | Patinho et al. (2019) |

| 15 | Beef burger | 6,207 ± 439 g | 0.881 ± 0.007 | 0.701 ± 0.009 | – | 3,836 ± 308 g.mm | ||

| 30 | Beef burger | 2,628 ± 270 g | 0.816 ± 0.032 | 0.575 ± 0.035 | – | 1,242 ± 218 g.mm | ||

| 0 | Beef patty | 53.62 ± 6.76 | 0.78 ± 0.01 | 0.58 ± 0.02 | 31.06 ± 3.92 | 24.08 ± 3.13 | Cerón-Guevara et al. (2020b) | |

| 2.5 | Beef patty | 40.83 ± 6.51 | 0.70 ± 0.05 | 0.54 ± 0.02 | 22.33 ± 4.25 | 15.81 ± 36.23 | ||

| 5.0 | Beef patty | 51.14 ± 3.98 | 0.68 ± 0.05 | 0.49 ± 0.03 | 25.19 ± 2.84 | 17.14 ± 2.79 | ||

| 0 | Beef patty | 29.31 | 6.75 | 0.35 | 10.27 | 69.96 | Kim et al. (2011) | |

| 27 | Beef patty | 17.73 | 2.26 | 0.06 | 0.98 | 2.22 | ||

| 0 | Beef emulsion | 56.86 ± 2.34 g | 0.89 ± 0.01 | 0.76 ± 0.04 | 42.61 ± 0.15 g | 37.92 ± 0.46 g.mm | Kurt and Gençcelep (2018) | |

| 1 | Beef emulsion | 60.15 ± 2.60 g | 0.92 ± 0.00 | 0.82 ± 0.00 | 49.63 ± 2.57 g | 45.65 ± 2.36 g.mm | ||

| 2 | Beef emulsion | 72.70 ± 5.23 g | 0.93 ± 0.00 | 0.84 ± 0.00 | 61.45 ± 4.93 g | 57.47 ± 5.04 g.mm | ||

| 3 | Beef emulsion | 54.71 ± 2.84 g | 0.89 ± 0.00 | 0.77 ± 0.02 | 42.42 ± 3.35 g | 37.75 ± 2.99 g.mm | ||

| 0 | Beef frankfurter | 20.56 ± 1.01 | 0.78 ± 0.03 | 0.38 ± 0.01 | 7.73 ± 0.32 | 6.01 ± 0.46 | Cerón-Guevara et al. (2020a) | |

| 2.5 | Beef frankfurter | 15.33 ± 2.63 | 0.70 ± 0.04 | 0.34 ± 0.01 | 5.24 ± 1.27 | 3.67 ± 0.98 | ||

| 5.0 | Beef frankfurter | 12.07 ± 1.25 | 0.66 ± 0.02 | 0.34 ± 0.01 | 4.10 ± 0.53 | 2.70 ± 0.34 | ||

| 5.0 | Beef paste | 10002.93 ± 193.2 g | 0.94 ± 0.03 | 0.90 ± 0.02 | 8934.32 ± 220.47 g | 8570.11 ± 181.63 g.mm | Qing et al. (2021) | |

| B. edulis | 0 | Beef frankfurter | 2.00 ± 0.15 | 0.95 ± 0.02 | 0.82 ± 0.02 | 1.65 ± 0.10 | 1.56 ± 0.11 | Novakovic et al. (2020) |

| 0.75 | Beef frankfurter | 2.08 ± 0.11 | 0.95 ± 0.02 | 0.85 ± 0.02 | 1.76 ± 0.10 | 1.66 ± 0.08 | ||

| 1.5 | Beef frankfurter | 2.11 ± 0.12 | 0.95 ± 0.02 | 0.85 ± 0.01 | 1.80 ± 0.10 | 1.70 ± 0.11 | ||

| C. cibarius | 0 | Beef frankfurter | 1.98 ± 0.32 | 0.96 ± 0.02 | 0.83 ± 0.02 | – | 1.62 ± 0.25 | Novakovic et al. (2019) |

| 0.75 | Beef frankfurter | 1.99 ± 0.28 | 0.96 ± 0.03 | 0.84 ± 0.02 | – | 1.63 ± 0.20 | ||

| 1.5 | Beef frankfurter | 2.00 ± 0.21 | 0.95 ± 0.03 | 0.83 ± 0.02 | – | 1.68 ± 0.24 | ||

| F. velutipes | 0 | Pork sausage | 8,813 ± 109 | 0.934 ± 0.017 cm | 0.710 ± 0.023 cm/cm | – | 6,080 ± 99 N.cm | Wang et al. (2019) |

| 2.5 | Pork sausage | 7,569 ± 161 | 0.875 ± 0.009 cm | 0.614 ± 0.052 cm/cm | – | 4,774 ± 88 N.cm | ||

| 5.0 | Pork sausage | 5,945 ± 72 | 0.826 ± 0.021 cm | 0.520 ± 0.012 cm/cm | – | 3,361 ± 64 N.cm | ||

| 0 | Pork sausage | 48.90 | 0.53 cm | 0.23 cm/cm | 11.17 | 5.96 N.cm | Choe et al. (2018) | |

| 1 | Pork sausage | 37.1 | 0.48 cm | 0.21 cm/cm | 7.88 | 3.76 N.cm | ||

| 2 | Pork sausage | 35.51 | 0.42 cm | 0.2 cm/cm | 7.22 | 3.01 N.cm | ||

| 0 | Goat sausage | 42.42 ± 1.86 | 0.86 ± 0.01 cm | 0.48 ± 0.02 cm/cm | 14.79 ± 1.04 | 14.05 ± 0.82 N.cm | Banerjee et al. (2020) | |

| 4 | Goat sausage | 36.33 ± 2.08 | 0.83 ± 0.02 cm | 0.45 ± 0.01 cm/cm | 12.83 ± 1.34 | 11.75 ± 0.91 N.cm | ||

| 6 | Goat sausage | 34.33 ± 2.12 | 0.83 ± 0.02 cm | 0.44 ± 0.01 cm/cm | 12.08 ± 1.57 | 9.46 ± 0.84 N.cm | ||

| 0 | Chicken sausage | 75.98 | 0.74 cm | 0.3 cm/cm | 22.38 | 16.64 N.cm | Jo et al. (2018) | |

| 1 | Chicken sausage | 68.48 | 0.67 cm | 0.28 cm/cm | 19.34 | 13.04 N.cm | ||

| A. bisporus and P. ostreatus | 2.5/2.5 | Beef frankfurter | 11.50 ± 0.95 | 0.59 ± 0.03 | 0.31 ± 0.03 | 3.66 ± 0.71 | 2.17 ± 0.51 | Cerón-Guevara et al. (2020a) |

| P. ostreatus | 2.5 | Beef patty | 46.77 ± 1.13 | 0.64 ± 0.04 | 0.51 ± 0.03 | 23.96 ± 1.49 | 15.49 ± 1.80 | Cerón-Guevara et al. (2020b) |

| 5.0 | Beef patty | 44.48 ± 8.30 | 0.59 ± 0.10 | 0.47 ± 0.05 | 21.08 ± 6.08 | 12.84 ± 5.65 | ||

| 2.5 | Beef frankfurter | 13.53 ± 2.26 | 0.59 ± 0.04 | 0.29 ± 0.03 | 3.99 ± 1.03 | 2.37 ± 0.75 | Cerón-Guevara et al. (2020a) | |

| 5.0 | Beef frankfurter | 10.84 ± 0.44 | 0.55 ± 0.02 | 0.31 ± 0.02 | 3.39 ± 0.26 | 1.87 ± 0.20 | ||

| 5.0 | Beef paste | 6516.58 ± 535.75 g | 0.83 ± 0.04 | 0.79 ± 0.03 | 5188.21 ± 437.75 g | 4508.99 ± 449.27 g.mm | Qing et al. (2021) | |

| P. sajor-caju | 0 | Commercial chicken nugget | 6.14 | 0.76 cm | 0.45 cm/cm | – | 2.05 N.cm | Husain and Huda-Faujan (2020) |

| 60 | Chicken nugget | 6.12 | 0.94 cm | 0.53 cm/cm | – | 3.06 N.cm | ||

| 50 | Chicken nugget | 5.81 | 0.9 cm | 0.46 cm/cm | – | 2.38 N.cm | ||

| 0 | Chicken frankfurter | 0.13 ± 0.01 kg | 1.39 ± 0.01 | 0.68 ± 0.04 | – | – | Rosli et al. (2015) | |

| 2 | Chicken frankfurter | 0.06 ± 0.01 kg | 1.41 ± 0.00 | 0.74 ± 0.48 | – | – | ||

| 4 | Chicken frankfurter | 0.08 ± 0.01 kg | 1.43 ± 0.01 | 0.74 ± 0.03 | – | – | ||

| 6 | Chicken frankfurter | 0.06 ± 0.00 kg | 1.42 ± 0.01 | 0.77 ± 0.01 | – | – | ||

| 0 | Beef patty | 22.96 + 1.82 kg | 0.35 + 0.06 | 0.46 + 0.02 | 8.06 + 0.90 kg | 2.87 + 0.79 kg.mm | Rosli et al., (2011) | |

| 25 | Beef patty | 13.20+ 1.07 kg | 0.36 + 0.04 | 0.37 + 0.04 | 4.75 + 0.61 kg | 1.72 + 0.41 kg.mm | ||

| 50 | Beef patty | 11.20+ 1.69 kg | 0.40 + 0.03 | 0.32 + 0.03 | 4.46 + 0.63 kg | 1.78 + 0.29 kg.mm | ||

| P. sapidus | 0 | Chicken sausage | 796 ± 133 | 1.05 ± 0.10 | 0.041 ± 0.010 | 310 ± 49 | 326 ± 64 | Stephan et al., (2018) |

| 100 | Mushroom sausage | 1,360 ± 116 | 0.98 ± 0.09 | 0.019 ± 0.008 | 392 ± 52 | 387 ± 72 | ||

| P. eryngii | 0 | Pork sausage | 116.17 ± 4.21 | 4.05 ± 0.53 | 0.58 ± 0.02 | 67.70 ± 1.28 | 281.20 ± 4.85 | Wang et al. (2019) |

| 25 | Pork sausage | 99.37 ± 1.95 | 3.82 ± 0.14 | 0.52 ± 0.08 | 54.10 ± 4.52 | 217.60 ± 7.96 | ||

| L. edodes | 0 | Pork frankfurter | 0.49 kg | 15.84 | 0.64 | 0.36 kg | 6.18 kg.mm | Pil-Nam et al. (2015) |

| 0.4 | Pork frankfurter | 0.49 kg | 15.86 | 0.8 | 0.58 kg | 9.47 kg.mm | ||

| 1.2 | Pork frankfurter | 0.42 kg | 18.5 | 1.67 | 0.73 kg | 10.51 kg.mm | ||

| 0 | Chicken nugget | 45.74 ± 1.49 | 5.27 ± 0.34 | 0.45 ± 0.08 | – | 97.63 ± 2.63 | Akesowan (2016) | |

| 1.84 | Chicken nugget | 38.65 ± 1.36 | 5.07 ± 0.15 | 0.41 ± 0.06 | – | 84.62 ± 2.84 | ||

| 0 | Pork sausage | 286.63 ± 13.19 | 4.34 ± 0.04 | 0.73 ± 0.03 | 195.60 ± 3.76 | 822.03 ± 33.43 | Wang et al. (2019) | |

| 25 | Pork sausage | 257.93 ± 11.55 | 4.08 ± 0.14 | 0.71 ± 0.06 | 184.70 ± 4.33 | 712.78 ± 32.10 | ||

| 50 | Pork sausage | 191.60 ± 12.04 | 3.84 ± 0.04 | 0.67 ± 0.03 | 164.60 ± 9.27 | 557.38 ± 45.56 | ||

| 75 | Pork sausage | 150.27 ± 19.75 | 3.47 ± 0.22 | 0.52 ± 0.05 | 144.33 ± 6.38 | 390.09 ± 14.36 | ||

| 100 | Mushroom sausage | 98.77 ± 10.55 | 2.80 ± 0.15 | 0.34 ± 0.04 | 100.83 ± 10.83 | 206.92 ± 20.20 | ||

| V. volvacea | 0 | Beef paste | 7549.01 ± 447.45 g | 0.94 ± 0.03 | 0.91 ± 0.01 | 6767.03 ± 581.61 g | 6520.57 ± 546 g.mm | Qing et al. (2021) |

| 5 | Beef paste | 6787.32 ± 157.88 g | 0.89 ± 0.02 | 0.83 ± 0.01 | 5596.72 ± 348.48 g | 5100.18 ± 351.28 g.mm | ||

| 0 | Pork sausage | 9948.0 ± 98.8 | 0.86 ± 0.02 cm | 0.78 ± 0.02 | – | 6920.4 ± 453.7 N.cm | Wang et al. (2018) | |

| 2 | Pork sausage | 8978.0 ± 121.9 | 0.79 ± 0.02 cm | 0.64 ± 0.01 | – | 5604.7 ± 283.7 N.cm | ||

| 4 | Pork sausage | 6108.3 ± 87.9 | 0.70 ± 0.08 cm | 0.49 ± 0.01 | – | 4937.4 ± 597.5 N.cm | ||

| H. marmoreus | 5 | Beef paste | 8940.93 ± 426.39 g | 0.91 ± 0.03 | 0.85 ± 0.02 | 7678.91 ± 437.56 g | 7184.82 ± 479.65 g.mm | Qing et al. (2021) |

| Species . | Amount (%) . | Meat product . | Hardness (N) . | Springiness (mm) . | Cohesiveness (mm/mm) . | Gumminess (N) . | Chewiness (N.mm) . | References . |

|---|---|---|---|---|---|---|---|---|

| A. bisporus | 0 | Beef burger | 13,126 ± 559 g | 0.841 ± 0.019 | 0.466 ± 0.050 | – | 5,106 ± 577 g.mm | Patinho et al. (2019) |

| 15 | Beef burger | 6,207 ± 439 g | 0.881 ± 0.007 | 0.701 ± 0.009 | – | 3,836 ± 308 g.mm | ||

| 30 | Beef burger | 2,628 ± 270 g | 0.816 ± 0.032 | 0.575 ± 0.035 | – | 1,242 ± 218 g.mm | ||

| 0 | Beef patty | 53.62 ± 6.76 | 0.78 ± 0.01 | 0.58 ± 0.02 | 31.06 ± 3.92 | 24.08 ± 3.13 | Cerón-Guevara et al. (2020b) | |

| 2.5 | Beef patty | 40.83 ± 6.51 | 0.70 ± 0.05 | 0.54 ± 0.02 | 22.33 ± 4.25 | 15.81 ± 36.23 | ||

| 5.0 | Beef patty | 51.14 ± 3.98 | 0.68 ± 0.05 | 0.49 ± 0.03 | 25.19 ± 2.84 | 17.14 ± 2.79 | ||

| 0 | Beef patty | 29.31 | 6.75 | 0.35 | 10.27 | 69.96 | Kim et al. (2011) | |

| 27 | Beef patty | 17.73 | 2.26 | 0.06 | 0.98 | 2.22 | ||

| 0 | Beef emulsion | 56.86 ± 2.34 g | 0.89 ± 0.01 | 0.76 ± 0.04 | 42.61 ± 0.15 g | 37.92 ± 0.46 g.mm | Kurt and Gençcelep (2018) | |

| 1 | Beef emulsion | 60.15 ± 2.60 g | 0.92 ± 0.00 | 0.82 ± 0.00 | 49.63 ± 2.57 g | 45.65 ± 2.36 g.mm | ||

| 2 | Beef emulsion | 72.70 ± 5.23 g | 0.93 ± 0.00 | 0.84 ± 0.00 | 61.45 ± 4.93 g | 57.47 ± 5.04 g.mm | ||

| 3 | Beef emulsion | 54.71 ± 2.84 g | 0.89 ± 0.00 | 0.77 ± 0.02 | 42.42 ± 3.35 g | 37.75 ± 2.99 g.mm | ||

| 0 | Beef frankfurter | 20.56 ± 1.01 | 0.78 ± 0.03 | 0.38 ± 0.01 | 7.73 ± 0.32 | 6.01 ± 0.46 | Cerón-Guevara et al. (2020a) | |

| 2.5 | Beef frankfurter | 15.33 ± 2.63 | 0.70 ± 0.04 | 0.34 ± 0.01 | 5.24 ± 1.27 | 3.67 ± 0.98 | ||

| 5.0 | Beef frankfurter | 12.07 ± 1.25 | 0.66 ± 0.02 | 0.34 ± 0.01 | 4.10 ± 0.53 | 2.70 ± 0.34 | ||

| 5.0 | Beef paste | 10002.93 ± 193.2 g | 0.94 ± 0.03 | 0.90 ± 0.02 | 8934.32 ± 220.47 g | 8570.11 ± 181.63 g.mm | Qing et al. (2021) | |

| B. edulis | 0 | Beef frankfurter | 2.00 ± 0.15 | 0.95 ± 0.02 | 0.82 ± 0.02 | 1.65 ± 0.10 | 1.56 ± 0.11 | Novakovic et al. (2020) |

| 0.75 | Beef frankfurter | 2.08 ± 0.11 | 0.95 ± 0.02 | 0.85 ± 0.02 | 1.76 ± 0.10 | 1.66 ± 0.08 | ||

| 1.5 | Beef frankfurter | 2.11 ± 0.12 | 0.95 ± 0.02 | 0.85 ± 0.01 | 1.80 ± 0.10 | 1.70 ± 0.11 | ||

| C. cibarius | 0 | Beef frankfurter | 1.98 ± 0.32 | 0.96 ± 0.02 | 0.83 ± 0.02 | – | 1.62 ± 0.25 | Novakovic et al. (2019) |

| 0.75 | Beef frankfurter | 1.99 ± 0.28 | 0.96 ± 0.03 | 0.84 ± 0.02 | – | 1.63 ± 0.20 | ||

| 1.5 | Beef frankfurter | 2.00 ± 0.21 | 0.95 ± 0.03 | 0.83 ± 0.02 | – | 1.68 ± 0.24 | ||

| F. velutipes | 0 | Pork sausage | 8,813 ± 109 | 0.934 ± 0.017 cm | 0.710 ± 0.023 cm/cm | – | 6,080 ± 99 N.cm | Wang et al. (2019) |

| 2.5 | Pork sausage | 7,569 ± 161 | 0.875 ± 0.009 cm | 0.614 ± 0.052 cm/cm | – | 4,774 ± 88 N.cm | ||

| 5.0 | Pork sausage | 5,945 ± 72 | 0.826 ± 0.021 cm | 0.520 ± 0.012 cm/cm | – | 3,361 ± 64 N.cm | ||

| 0 | Pork sausage | 48.90 | 0.53 cm | 0.23 cm/cm | 11.17 | 5.96 N.cm | Choe et al. (2018) | |

| 1 | Pork sausage | 37.1 | 0.48 cm | 0.21 cm/cm | 7.88 | 3.76 N.cm | ||

| 2 | Pork sausage | 35.51 | 0.42 cm | 0.2 cm/cm | 7.22 | 3.01 N.cm | ||

| 0 | Goat sausage | 42.42 ± 1.86 | 0.86 ± 0.01 cm | 0.48 ± 0.02 cm/cm | 14.79 ± 1.04 | 14.05 ± 0.82 N.cm | Banerjee et al. (2020) | |

| 4 | Goat sausage | 36.33 ± 2.08 | 0.83 ± 0.02 cm | 0.45 ± 0.01 cm/cm | 12.83 ± 1.34 | 11.75 ± 0.91 N.cm | ||

| 6 | Goat sausage | 34.33 ± 2.12 | 0.83 ± 0.02 cm | 0.44 ± 0.01 cm/cm | 12.08 ± 1.57 | 9.46 ± 0.84 N.cm | ||

| 0 | Chicken sausage | 75.98 | 0.74 cm | 0.3 cm/cm | 22.38 | 16.64 N.cm | Jo et al. (2018) | |

| 1 | Chicken sausage | 68.48 | 0.67 cm | 0.28 cm/cm | 19.34 | 13.04 N.cm | ||

| A. bisporus and P. ostreatus | 2.5/2.5 | Beef frankfurter | 11.50 ± 0.95 | 0.59 ± 0.03 | 0.31 ± 0.03 | 3.66 ± 0.71 | 2.17 ± 0.51 | Cerón-Guevara et al. (2020a) |

| P. ostreatus | 2.5 | Beef patty | 46.77 ± 1.13 | 0.64 ± 0.04 | 0.51 ± 0.03 | 23.96 ± 1.49 | 15.49 ± 1.80 | Cerón-Guevara et al. (2020b) |

| 5.0 | Beef patty | 44.48 ± 8.30 | 0.59 ± 0.10 | 0.47 ± 0.05 | 21.08 ± 6.08 | 12.84 ± 5.65 | ||

| 2.5 | Beef frankfurter | 13.53 ± 2.26 | 0.59 ± 0.04 | 0.29 ± 0.03 | 3.99 ± 1.03 | 2.37 ± 0.75 | Cerón-Guevara et al. (2020a) | |

| 5.0 | Beef frankfurter | 10.84 ± 0.44 | 0.55 ± 0.02 | 0.31 ± 0.02 | 3.39 ± 0.26 | 1.87 ± 0.20 | ||

| 5.0 | Beef paste | 6516.58 ± 535.75 g | 0.83 ± 0.04 | 0.79 ± 0.03 | 5188.21 ± 437.75 g | 4508.99 ± 449.27 g.mm | Qing et al. (2021) | |

| P. sajor-caju | 0 | Commercial chicken nugget | 6.14 | 0.76 cm | 0.45 cm/cm | – | 2.05 N.cm | Husain and Huda-Faujan (2020) |

| 60 | Chicken nugget | 6.12 | 0.94 cm | 0.53 cm/cm | – | 3.06 N.cm | ||

| 50 | Chicken nugget | 5.81 | 0.9 cm | 0.46 cm/cm | – | 2.38 N.cm | ||

| 0 | Chicken frankfurter | 0.13 ± 0.01 kg | 1.39 ± 0.01 | 0.68 ± 0.04 | – | – | Rosli et al. (2015) | |

| 2 | Chicken frankfurter | 0.06 ± 0.01 kg | 1.41 ± 0.00 | 0.74 ± 0.48 | – | – | ||

| 4 | Chicken frankfurter | 0.08 ± 0.01 kg | 1.43 ± 0.01 | 0.74 ± 0.03 | – | – | ||

| 6 | Chicken frankfurter | 0.06 ± 0.00 kg | 1.42 ± 0.01 | 0.77 ± 0.01 | – | – | ||

| 0 | Beef patty | 22.96 + 1.82 kg | 0.35 + 0.06 | 0.46 + 0.02 | 8.06 + 0.90 kg | 2.87 + 0.79 kg.mm | Rosli et al., (2011) | |

| 25 | Beef patty | 13.20+ 1.07 kg | 0.36 + 0.04 | 0.37 + 0.04 | 4.75 + 0.61 kg | 1.72 + 0.41 kg.mm | ||

| 50 | Beef patty | 11.20+ 1.69 kg | 0.40 + 0.03 | 0.32 + 0.03 | 4.46 + 0.63 kg | 1.78 + 0.29 kg.mm | ||

| P. sapidus | 0 | Chicken sausage | 796 ± 133 | 1.05 ± 0.10 | 0.041 ± 0.010 | 310 ± 49 | 326 ± 64 | Stephan et al., (2018) |

| 100 | Mushroom sausage | 1,360 ± 116 | 0.98 ± 0.09 | 0.019 ± 0.008 | 392 ± 52 | 387 ± 72 | ||

| P. eryngii | 0 | Pork sausage | 116.17 ± 4.21 | 4.05 ± 0.53 | 0.58 ± 0.02 | 67.70 ± 1.28 | 281.20 ± 4.85 | Wang et al. (2019) |

| 25 | Pork sausage | 99.37 ± 1.95 | 3.82 ± 0.14 | 0.52 ± 0.08 | 54.10 ± 4.52 | 217.60 ± 7.96 | ||

| L. edodes | 0 | Pork frankfurter | 0.49 kg | 15.84 | 0.64 | 0.36 kg | 6.18 kg.mm | Pil-Nam et al. (2015) |

| 0.4 | Pork frankfurter | 0.49 kg | 15.86 | 0.8 | 0.58 kg | 9.47 kg.mm | ||

| 1.2 | Pork frankfurter | 0.42 kg | 18.5 | 1.67 | 0.73 kg | 10.51 kg.mm | ||

| 0 | Chicken nugget | 45.74 ± 1.49 | 5.27 ± 0.34 | 0.45 ± 0.08 | – | 97.63 ± 2.63 | Akesowan (2016) | |

| 1.84 | Chicken nugget | 38.65 ± 1.36 | 5.07 ± 0.15 | 0.41 ± 0.06 | – | 84.62 ± 2.84 | ||

| 0 | Pork sausage | 286.63 ± 13.19 | 4.34 ± 0.04 | 0.73 ± 0.03 | 195.60 ± 3.76 | 822.03 ± 33.43 | Wang et al. (2019) | |

| 25 | Pork sausage | 257.93 ± 11.55 | 4.08 ± 0.14 | 0.71 ± 0.06 | 184.70 ± 4.33 | 712.78 ± 32.10 | ||

| 50 | Pork sausage | 191.60 ± 12.04 | 3.84 ± 0.04 | 0.67 ± 0.03 | 164.60 ± 9.27 | 557.38 ± 45.56 | ||

| 75 | Pork sausage | 150.27 ± 19.75 | 3.47 ± 0.22 | 0.52 ± 0.05 | 144.33 ± 6.38 | 390.09 ± 14.36 | ||

| 100 | Mushroom sausage | 98.77 ± 10.55 | 2.80 ± 0.15 | 0.34 ± 0.04 | 100.83 ± 10.83 | 206.92 ± 20.20 | ||

| V. volvacea | 0 | Beef paste | 7549.01 ± 447.45 g | 0.94 ± 0.03 | 0.91 ± 0.01 | 6767.03 ± 581.61 g | 6520.57 ± 546 g.mm | Qing et al. (2021) |

| 5 | Beef paste | 6787.32 ± 157.88 g | 0.89 ± 0.02 | 0.83 ± 0.01 | 5596.72 ± 348.48 g | 5100.18 ± 351.28 g.mm | ||

| 0 | Pork sausage | 9948.0 ± 98.8 | 0.86 ± 0.02 cm | 0.78 ± 0.02 | – | 6920.4 ± 453.7 N.cm | Wang et al. (2018) | |

| 2 | Pork sausage | 8978.0 ± 121.9 | 0.79 ± 0.02 cm | 0.64 ± 0.01 | – | 5604.7 ± 283.7 N.cm | ||

| 4 | Pork sausage | 6108.3 ± 87.9 | 0.70 ± 0.08 cm | 0.49 ± 0.01 | – | 4937.4 ± 597.5 N.cm | ||

| H. marmoreus | 5 | Beef paste | 8940.93 ± 426.39 g | 0.91 ± 0.03 | 0.85 ± 0.02 | 7678.91 ± 437.56 g | 7184.82 ± 479.65 g.mm | Qing et al. (2021) |

Effect of mushroom addition and/or substitution on textural properties of meat analogues.

| Species . | Amount (%) . | Meat product . | Hardness (N) . | Springiness (mm) . | Cohesiveness (mm/mm) . | Gumminess (N) . | Chewiness (N.mm) . | References . |

|---|---|---|---|---|---|---|---|---|

| A. bisporus | 0 | Beef burger | 13,126 ± 559 g | 0.841 ± 0.019 | 0.466 ± 0.050 | – | 5,106 ± 577 g.mm | Patinho et al. (2019) |

| 15 | Beef burger | 6,207 ± 439 g | 0.881 ± 0.007 | 0.701 ± 0.009 | – | 3,836 ± 308 g.mm | ||

| 30 | Beef burger | 2,628 ± 270 g | 0.816 ± 0.032 | 0.575 ± 0.035 | – | 1,242 ± 218 g.mm | ||

| 0 | Beef patty | 53.62 ± 6.76 | 0.78 ± 0.01 | 0.58 ± 0.02 | 31.06 ± 3.92 | 24.08 ± 3.13 | Cerón-Guevara et al. (2020b) | |

| 2.5 | Beef patty | 40.83 ± 6.51 | 0.70 ± 0.05 | 0.54 ± 0.02 | 22.33 ± 4.25 | 15.81 ± 36.23 | ||

| 5.0 | Beef patty | 51.14 ± 3.98 | 0.68 ± 0.05 | 0.49 ± 0.03 | 25.19 ± 2.84 | 17.14 ± 2.79 | ||

| 0 | Beef patty | 29.31 | 6.75 | 0.35 | 10.27 | 69.96 | Kim et al. (2011) | |

| 27 | Beef patty | 17.73 | 2.26 | 0.06 | 0.98 | 2.22 | ||

| 0 | Beef emulsion | 56.86 ± 2.34 g | 0.89 ± 0.01 | 0.76 ± 0.04 | 42.61 ± 0.15 g | 37.92 ± 0.46 g.mm | Kurt and Gençcelep (2018) | |

| 1 | Beef emulsion | 60.15 ± 2.60 g | 0.92 ± 0.00 | 0.82 ± 0.00 | 49.63 ± 2.57 g | 45.65 ± 2.36 g.mm | ||

| 2 | Beef emulsion | 72.70 ± 5.23 g | 0.93 ± 0.00 | 0.84 ± 0.00 | 61.45 ± 4.93 g | 57.47 ± 5.04 g.mm | ||

| 3 | Beef emulsion | 54.71 ± 2.84 g | 0.89 ± 0.00 | 0.77 ± 0.02 | 42.42 ± 3.35 g | 37.75 ± 2.99 g.mm | ||

| 0 | Beef frankfurter | 20.56 ± 1.01 | 0.78 ± 0.03 | 0.38 ± 0.01 | 7.73 ± 0.32 | 6.01 ± 0.46 | Cerón-Guevara et al. (2020a) | |

| 2.5 | Beef frankfurter | 15.33 ± 2.63 | 0.70 ± 0.04 | 0.34 ± 0.01 | 5.24 ± 1.27 | 3.67 ± 0.98 | ||

| 5.0 | Beef frankfurter | 12.07 ± 1.25 | 0.66 ± 0.02 | 0.34 ± 0.01 | 4.10 ± 0.53 | 2.70 ± 0.34 | ||

| 5.0 | Beef paste | 10002.93 ± 193.2 g | 0.94 ± 0.03 | 0.90 ± 0.02 | 8934.32 ± 220.47 g | 8570.11 ± 181.63 g.mm | Qing et al. (2021) | |

| B. edulis | 0 | Beef frankfurter | 2.00 ± 0.15 | 0.95 ± 0.02 | 0.82 ± 0.02 | 1.65 ± 0.10 | 1.56 ± 0.11 | Novakovic et al. (2020) |

| 0.75 | Beef frankfurter | 2.08 ± 0.11 | 0.95 ± 0.02 | 0.85 ± 0.02 | 1.76 ± 0.10 | 1.66 ± 0.08 | ||

| 1.5 | Beef frankfurter | 2.11 ± 0.12 | 0.95 ± 0.02 | 0.85 ± 0.01 | 1.80 ± 0.10 | 1.70 ± 0.11 | ||

| C. cibarius | 0 | Beef frankfurter | 1.98 ± 0.32 | 0.96 ± 0.02 | 0.83 ± 0.02 | – | 1.62 ± 0.25 | Novakovic et al. (2019) |

| 0.75 | Beef frankfurter | 1.99 ± 0.28 | 0.96 ± 0.03 | 0.84 ± 0.02 | – | 1.63 ± 0.20 | ||

| 1.5 | Beef frankfurter | 2.00 ± 0.21 | 0.95 ± 0.03 | 0.83 ± 0.02 | – | 1.68 ± 0.24 | ||

| F. velutipes | 0 | Pork sausage | 8,813 ± 109 | 0.934 ± 0.017 cm | 0.710 ± 0.023 cm/cm | – | 6,080 ± 99 N.cm | Wang et al. (2019) |

| 2.5 | Pork sausage | 7,569 ± 161 | 0.875 ± 0.009 cm | 0.614 ± 0.052 cm/cm | – | 4,774 ± 88 N.cm | ||

| 5.0 | Pork sausage | 5,945 ± 72 | 0.826 ± 0.021 cm | 0.520 ± 0.012 cm/cm | – | 3,361 ± 64 N.cm | ||

| 0 | Pork sausage | 48.90 | 0.53 cm | 0.23 cm/cm | 11.17 | 5.96 N.cm | Choe et al. (2018) | |

| 1 | Pork sausage | 37.1 | 0.48 cm | 0.21 cm/cm | 7.88 | 3.76 N.cm | ||

| 2 | Pork sausage | 35.51 | 0.42 cm | 0.2 cm/cm | 7.22 | 3.01 N.cm | ||

| 0 | Goat sausage | 42.42 ± 1.86 | 0.86 ± 0.01 cm | 0.48 ± 0.02 cm/cm | 14.79 ± 1.04 | 14.05 ± 0.82 N.cm | Banerjee et al. (2020) | |

| 4 | Goat sausage | 36.33 ± 2.08 | 0.83 ± 0.02 cm | 0.45 ± 0.01 cm/cm | 12.83 ± 1.34 | 11.75 ± 0.91 N.cm | ||

| 6 | Goat sausage | 34.33 ± 2.12 | 0.83 ± 0.02 cm | 0.44 ± 0.01 cm/cm | 12.08 ± 1.57 | 9.46 ± 0.84 N.cm | ||

| 0 | Chicken sausage | 75.98 | 0.74 cm | 0.3 cm/cm | 22.38 | 16.64 N.cm | Jo et al. (2018) | |

| 1 | Chicken sausage | 68.48 | 0.67 cm | 0.28 cm/cm | 19.34 | 13.04 N.cm | ||

| A. bisporus and P. ostreatus | 2.5/2.5 | Beef frankfurter | 11.50 ± 0.95 | 0.59 ± 0.03 | 0.31 ± 0.03 | 3.66 ± 0.71 | 2.17 ± 0.51 | Cerón-Guevara et al. (2020a) |

| P. ostreatus | 2.5 | Beef patty | 46.77 ± 1.13 | 0.64 ± 0.04 | 0.51 ± 0.03 | 23.96 ± 1.49 | 15.49 ± 1.80 | Cerón-Guevara et al. (2020b) |

| 5.0 | Beef patty | 44.48 ± 8.30 | 0.59 ± 0.10 | 0.47 ± 0.05 | 21.08 ± 6.08 | 12.84 ± 5.65 | ||

| 2.5 | Beef frankfurter | 13.53 ± 2.26 | 0.59 ± 0.04 | 0.29 ± 0.03 | 3.99 ± 1.03 | 2.37 ± 0.75 | Cerón-Guevara et al. (2020a) | |