-

PDF

- Split View

-

Views

-

Cite

Cite

Shima Jahanfar, Mehrdad Gahavami, Kianoush Khosravi-Darani, Mahshid Jahadi, Hareem Mohsin, Svetoslav Dimitrov Todorov, Abhishek Dutt Tripathid, The effect of antioxidant properties of free and encapsulated rosemary extract in liposome on the oxidation process of canola oil, International Journal of Food Science and Technology, Volume 58, Issue 10, October 2023, Pages 5521–5529, https://doi.org/10.1111/ijfs.16450

Close - Share Icon Share

Abstract

The antioxidant property of rosemary extract as a natural antioxidant on the oxidation process of canola oil has been reported and compared with the synthetic antioxidant butylated hydroxytoluene (BHT) (at 200 mg Lˉ1). The effect of free and liposomal encapsulated rosemary extract at concentrations of 200, 600 and 1000 mg Lˉ1 was evaluated on improving the oxidative stability of canola oil at 120°C using the Rancimat method. The changes in peroxide value, anisidine, TOTOX and thiobarbituric acid (TBA) have been determined by the Schaal oven test at 60°C. Liposomal rosemary extracts were prepared by the Mozafari method. Then physicochemical properties (Z-potential, particle size and encapsulation efficiency (EE)) were determined. EE and the Z-potential of liposomes were obtained at 54.59% and −65.1 mV, respectively. The particle size of empty and extract containing liposomes was determined 583.5 nm and 265.4 nm, respectively. The total polyphenol content of the rosemary extract by reagent of the Folin–Ciocalteu's phenol was determined as 164.2 mg gallic acid gˉ1 extract. Also, the activity of free radical scavenging of both liposomal encapsulated and free extracts, by the 2-2-diphenyl-1-picrylhydrazyl (DPPH) method, were 84.57% and 92.5%, respectively. The induction periods of oil containing liposomal rosemary extract at 600, 1000 mg Lˉ1 and free extract in level 1000 mg Lˉ1 was higher in comparison with samples containing BHT and blank (P ≤ 0.05). The incorporation of rosemary extract especially in liposome form into oil delayed the oxidation process. Based on the results of this study, to inhibit oil oxidation, rosemary extract, especially in the liposomal form, can be applied instead of synthetic antioxidants such as BHT.

Introduction

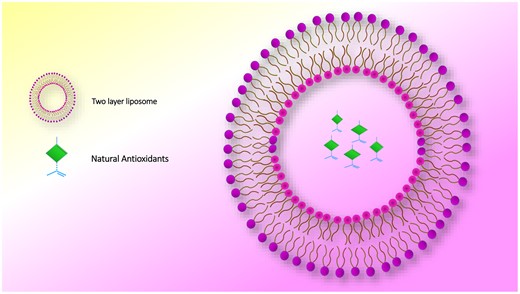

Oxidation of lipid is one of the foremost imperative variables influencing the shelf life and quality of oil (Da Silva & Jorge, 2014) due to unfavourable changes in colour, flavour, taste and texture of product. One way to prevent oxidation reactions is using antioxidants (Jahanfar et al., 2020). Although synthetic antioxidants can reduce oxidation reactions, however, their harmful effects on health have caused the use of natural antioxidants to expand (Cordeiro et al., 2013). Herbal extracts as natural antioxidants can delay the oxidation processes by scavenging oxygen and free radicals decomposing peroxides (Zheng et al., 2012). Rosemary extract has strong antioxidant properties (Dilas et al., 2012; Shah et al., 2014). The most effective antioxidant compound in rosemary extract is carnosic acid (Terpinc et al., 2009; Thorsen & Hildebrandt, 2003). Although polyphenols have high antioxidant properties, they are sensitive to oxygen and alkaline pH (Dehkharghanian et al., 2009). One of the effective ways to increase the efficiency of polyphenols is to encapsulate these compounds in a liposome. Liposomes which consist of two phospholipid layers have the potential of carrying both hydrophilic and lipophilic bioactive materials (Bummer, 2004; De Leeuw et al., 2009; Tan et al., 2014). One method of liposome preparation is the Mozafari method (or heating method), which is based on the hydration of phospholipid compounds in an aqueous solution with a concentration of 3% glycerol. The most important advantage of this method is that it does not use any toxic solvents (Colas et al., 2007; Jahanfar et al., 2021a).

Encapsulation of essential oil and herbal extract as natural antioxidants have been introduced (Jahanfar et al., 2020, 2021a,b). Yang et al. (2016) showed efficiency of rosemary extract compared to synthetic antioxidants in delaying the oxidation process in soybean oil, rice oil and cottonseed oil. The effect of antioxidant properties of rosemary extract in two concentrations of 800 and 1600 mg Lˉ1 in two forms, free and encapsulated in a liposome, was investigated in the oxidation process of beef meat. The results showed that the form trapped in liposome was more effective than the free form (Rashidaie Abandansarie et al., 2019). Jahanfar et al. (2021b) reported that the antioxidant properties of rosemary extract in a liposome-encapsulated state are more than in free form.

In a recent research, it was found that when rosemary extract was used as an antioxidant in sunflower oil for deep-frying potatoes, it not only reduced the polymerisation in the oil but also reduced the oxidation rate of the oil during the frying process (Urbancic et al., 2014).

Yang et al. (2016) reported that the addition of rosemary extract reduced oxidation, during the 24-day storage, in rice bran, soybean and cottonseed oils, respectively. This research aimed to evaluate the antioxidant property of rosemary extract in free form and encapsulated in liposome on the oxidation process of canola oil during storage (60 °C) and its comparison with synthetic antioxidants such as butylated hydroxytoluene (BHT).

Materials and methods

Materials

Canola oil without added antioxidants was prepared by Behshahr Co, Tehran, Iran. Rosemary plant (Rosmarinus officinalis L.) to produce the rosemary extract was collected from Isfahan province, Iran. Ethanol, Folin–Ciocalteu reagent and glycerol, 2-2-diphenyl-1-picrylhydrazyl (DPPH) were purchased from Merck (Darmstadt, Germany).

Extraction of rosemary extract from leaves

Leaves of rosemary were collected from Isfahan Province, Iran. The extraction process was exactly the same that described elsewhere (Jahanfar et al., 2021b).

Liposome preparation

The heating method was selected to produce liposome vesicle based on Mozafari et al. (2002), with some modifications which have been described elsewhere (Jahanfar et al., 2021a,b). Encapsulation efficiency (EE) was measured based on eqn 1:

where S is the quantity of unentrapped phenolic compounds in the supernatant and P is the concentration of phenolic compounds inside the liposome measured after liposome disruption by Triton X-100. Then, the best concentrations of rosemary extract and phosphatidylcholine along time and temperature were selected in the optimal formulation which had the highest EE. Then produced liposome containing different contents of rosemary extract (200, 600 and 1000 mg Lˉˡ) was added to canola oil. The particle size and Z-potential were measured by a light scattering method and Zeta-Sizer analyser (Horiba Scientific Instruments, SZ-100 Series). Also, total polyphenol content (TPC) in rosemary extract was measured using a modified Folin–Ciocalteu method described by George et al. (2005).

Determination of oxidative stability of canola oil under a Schaal oven test

This test was done according to the previous methods with some modifications (Poyato et al., 2013). Canola oil samples (250 g) were transferred into 300 mL dark glass bottles and incubated at 60 °C in the oven. Then, oxidative stability of the samples was assessed at 0, 4, 8, 12, 16, 20, 24, 28 and 32 day intervals by measuring peroxide value, anisidine value, Botox and thiobarbituric acid (TBA) value of oil samples.

Rancimat test

Rancimat testing has been done according to Laubli and Bruttel with a small modification (Läubli & Bruttel, 1986). In the Rancimet test, the volatile acids formed during the oxidation process are measured.

Peroxide value

To assess the peroxide value, the AOAC (1984) method was used. Two grams of oil samples were weighed in conical flasks. In the next step, mixture of acetic acid and chloroform solution was added to the oil samples. The procedure has been described in our previous report (Jahanfar et al., 2020). The peroxide value was measured by eqn 2:

where W is the quantity of the oil (2 g), V1 and V₂ are volumes of blank and sodium thiosulfate, respectively, and N was the normality of sodium thiosulfate.

Anisidine value (AV)

In order to determine anisidinevalue, 2 g of the sample were brought to volume in a 25-mL volumetric flask with isooctane. Then, using a spectrophotometer, the absorbance of the solution, both before and after reaction with p-anisidine reagent, was determined at a wavelength of 350 nm. The anisidine value was calculated as eqn 3: (AOCS, 1998a).

where, As, Ab and m were expressive of solution adsorption before and after reaction with p-anisidine solution and weight of canola oil sample (g), respectively.

TOTOX value

Totox value was calculated by peroxide value and anisidine value as eqn 4 (Sun-Waterhouse et al., 2011):

Thiobarbituric acid

TBA value was assessed based on AOCS Official Method Cd, 19–90 (1998b) and was measured as mg of malonaldehyde per L of sample.

Statistical analysis

Statistical analyses were carried out using one-way ANOVA using SPSS software v.26 (IBM Analytics, IBM, Armonk, NY, USA). Significant differences between variables were shown using Duncan's multiple range test and SPSS software v.26 (IBM Analytics). Differences were statistically considered significant at P ≤ 0.05. Sample preparation and tests were carried out in triplicate, and data were expressed as the mean and ±SD.

Results and discussion

Characterisation of the rosemary extract

The density, solids content and pH of the obtained rosemary extract were 0.874 ± 0.003 g.mLˉ1, 8.25 ± 0.03 (% w/w) and 4.83 ± 0.00, respectively.

Antioxidant activity of rosemary extract and its Total polyphenolic content

According to obtained results, the amount of polyphenol in the optimal sample of rosemary was 151.38 mg gallic acid gˉ1 extract. The optimum sample is the sample that had the highest EE among 30 formulations produced at different temperatures and times and with different concentrations of rosemary extract and phosphatidylcholine. The number of polyphenol compounds of rosemary extract, in different studies, was 174.25 ± 4.9 mg gallic acid gˉ1 (Jafari et al., 2022), 136.66 ± 7.41 mg gallic acid gˉ1 (Saini et al., 2020) and 128.97 mg GAE gˉ1 (Teruel et al., 2015). Free radical scavenging activities of free and liposomal rosemary extract were obtained to be 84.57% and 92.5%, respectively. Chammem et al. (2015) compared different concentrations (0.02%, 0.05% and 0.08%) of rosemary extract to a synthetic BHT antioxidant. Data determined that rosemary extract had more antioxidant and radical scavenging activity than BHT (Chammem et al., 2015).

Physicochemical characterisation of liposome

Physicochemical characterisation of the optimal liposome such as EE, Z-potential, and particle size of empty liposome and liposome samples containing rosemary extract was obtained at 54.59%, −65.1 mV, 265.4 and 583 ± 2 nm, respectively. Higher values of the Z-potential cause a stronger repulsive force between the particles. As a result, the particles have less tendency to accumulate (Mady et al., 2009). The leakage of substances from inside the liposome is the cause of physical instability, which mainly depends on the particle size and the liposome constituent. Increased physical stability of liposomes may be achieved by change in structural compositions, as well as particle sizes and the surface charge. More physical stability in liposomes causes a slower release of antioxidants trapped inside them, which in turn increases the effectiveness of antioxidants against oil oxidation. To reduce the size of liposome particles, various methods are used such as sonication, homogenisation and extrusion, which destroy the liposome membrane and increase production steps. Therefore, in this research, smaller liposomal particles were produce by using a magnetic stirrer and with thermal treatment at a stirring speed of 1000× rpm. In this study, liposomes containing rosemary extract were produced by the Mozafari method, in which no solvent or detergent was used due to its toxicity.

Oil tests

Rancimat analysis

The Rancimet test is one of the methods by which the stability of oil can be determined with accelerated oxidation tests (Nogueira et al., 2019). Evaluation of the stability of canola oil by the Rancimet test showed that free and liposomal rosemary extract decreased oil oxidation. Figure 1 illustrated the results of the Rancimat test. The highest induction time achieved when liposomal rosemary extracts were used at concentrations of 1000 mg Lˉ1. The induction period in oil samples with liposome containing rosemary extract was longer than the samples to which rosemary extract was freely added.

![Rosemary extracts influence on canola oil stability, expressed as the induction period value (Ip[h]), under Rancimat test conditions. a,b, c, d, e, f, g and h mean values with different letters differ statistically between lines. Influence of rosemary extract (ER) at 200, 600, and 1000 mg Lˉ1, liposome without green tea extract (L), and green tea extract liposome (LR) at 200, 600, and 1000 ppm on canola oil stability, expressed as induction period value (Ip[h]), under Rancimat test conditions. Mean values with different letters statistically differ.](https://oup.silverchair-cdn.com/oup/backfile/Content_public/Journal/ijfst/58/10/10.1111_ijfs.16450/2/m_ijfs16450-fig-0001-m.jpeg?Expires=1750194900&Signature=IlnGflX6DmrrapwL~opMFsEWvhvFv5u9T8ik0cOsTS3dBNWi0M8JdfxOqxQqJrTDhxidxDrP2FScl5ntd96CZDeTvRV7C-ugrZiWR~I7N3gnIjpLwteFMFNJ3maU~X8LlqXfWnhF884Ab8L-GoSIqWEj1mLmR7SKYlKYyPZ6E9ZwcUCBPuiM3ZSDUD8d7BhxBUAxHlYpNKrYutKKijerYOoDafuK~868rX8KmJ4RX9x4nIJb43Xo8Iq~MCff8-2edGVj2AXWiT0c1fRaZSBdj2phjR22AYYFjT8L8KWQJ93T2sLIZTEkkN-ywER8xBuEVSeSHeV~U7tl5fJBSP9XdQ__&Key-Pair-Id=APKAIE5G5CRDK6RD3PGA)

Rosemary extracts influence on canola oil stability, expressed as the induction period value (Ip[h]), under Rancimat test conditions. a,b, c, d, e, f, g and h mean values with different letters differ statistically between lines. Influence of rosemary extract (ER) at 200, 600, and 1000 mg Lˉ1, liposome without green tea extract (L), and green tea extract liposome (LR) at 200, 600, and 1000 ppm on canola oil stability, expressed as induction period value (Ip[h]), under Rancimat test conditions. Mean values with different letters statistically differ.

As shown in Fig. 1, the induction period of the BHT was lower than the samples containing liposome rosemary extract at 600 and 1000 concentrations and the sample with free rosemary extract at 1000 concentrations. Turan (2014) reported an induction period of 15.13 h for canola oil containing 250 μg gˉ1 of rosemary extract. Yang et al. (2016) reported that rice bran oil containing rosemary extract had a longer induction period than samples without extract and oil with synthetic antioxidant BHT and BHA.

Peroxide value

This value is calculated by measuring the amount of peroxide in the initial stages of oil and fat oxidation (Malheiro et al., 2013; Ganji & Sayyed-Alangi, 2017). Antioxidant properties of the free and liposomal extract rosemary on canola oil are shown in Table 1. All canola oil samples showed increased the peroxide value over time (Asadi & Farahmandfar, 2020). Also, data indicates a difference in the amount of peroxide between canola oil containing free and liposomal rosemary extract during storage time. The control sample had the highest peroxide value compared to samples containing antioxidants. Yang et al. (2016) stated that the amount of peroxide in soybean oil samples increased over time, but oxidation decreased in samples containing rosemary extract in comparison to samples without natural antioxidants. Similarly, in this research, oxidation decreased in the canola oil samples containing liposomal rosemary extract in comparison to oil samples with free rosemary extract. The delay release of rosemary extract from liposome may cause increased EE. The samples containing 1000 mg Lˉ1 liposomal rosemary extract showed the highest amount of peroxide values (P ≤ 0.05). Rosemary extract in liposome form in concentrations of 600 and 1000 mg Lˉ1 showed more antioxidant properties than synthetic antioxidant BHT. Wang et al. (2018) showed a higher antioxidant properties in samples containing rosemary extract in comparison to samples with BHT and α-tocopherol. Chen et al. (2014) showed peroxide value in sunflower oil containing rosemary extract, synthetic antioxidant BHT, and BHA was equal to 75.7 ± 0.47 meq kgˉ1, 204 ± 0.68 meq kgˉ1, and 159 ± 0.55 meq kgˉ1, respectively.

Peroxide values (m Eq kgˉ1) in canola oil with various values free and encapsulated rosemary extract during storage

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 0.41 ± 0.01A | 3.71 ± 0.02aB | 7.65 ± 0.04aC | 9.28 ± 0.0aD | 18.35 ± 0.04aE | 31.97 ± 0.07aF | 41.42 ± 0.04aG | 49.87 ± 0.01aH | 61.72 ± 0.03aI |

| ER 200 | 0.41 ± 0.03A | 3.20 ± 0.04cB | 6.22 ± 0.02cC | 8.52 ± 0.03cD | 16.85 ± 0.05cE | 27.22 ± 0.02cF | 37.21 ± 0.03cG | 45.42 ± 0.03cH | 57.22 ± 0.02cI |

| ER 600 | 0.41 ± 0.04A | 2.88 ± 0.05dB | 5.34 ± 0.01dC | 7.82 ± 0.05dD | 15.63 ± 0.01dE | 24.24 ± 0.01dF | 33.64 ± 0.02dG | 40.36 ± 0.02dH | 54.82 ± 0.04dI |

| ER 1000 | 0.41 ± 0.01A | 2.82 ± 0.04dB | 4.75 ± 0.02eC | 7.13 ± 0.04eD | 14.77 ± 0.01eE | 22.24 ± 0.03eF | 31.10 ± 0.05eG | 38.56 ± 0.05eH | 48.62 ± 0.03eI |

| L | 0.41 ± 0.03A | 3.51 ± 0.01bB | 8.1 ± 0.10bC | 9.11 ± 0.02bD | 17.61 ± 0.02bE | 31.41 ± 0.05bF | 40.50 ± 0.05bG | 48.45 ± 0.04bH | 59.12 ± 0.02bI |

| LR 200 | 0.41 ± 0.07A | 1.65 ± 0.02eB | 3.25 ± 0.03fC | 6.65 ± 0.01fD | 14.14 ± 0.04fE | 21.44 ± 0.03fF | 25.27 ± 0.01fG | 34.52 ± 0.03fH | 43.11 ± 0.07fI |

| LR 600 | 0.41 ± 0.02A | 0.76 ± 0.03fB | 2.78 ± 0.05gC | 5.32 ± 0.02hD | 7.05 ± 0.02hE | 20.25 ± 0.04gF | 23.27 ± 0.06gG | 31.82 ± 0.06hH | 37.42 ± 0.05hI |

| LR 1000 | 0.41 ± 0.03A | 0.58 ± 0.02gB | 2.13 ± 0.01hC | 4.92 ± 0.03iD | 6.51 ± 0.05iE | 13.67 ± 0.02iF | 21.63 ± 0.04hG | 28.64 ± 0.01iH | 36.43 ± 0.04iI |

| BHT 200 | 0.41 ± 0.04A | 0.81 ± 0.01fB | 3.15 ± 0.03fC | 5.65 ± 0.03gD | 7.51 ± 0.01gE | 14.63 ± 0.04hF | 25.41 ± 0.02fG | 32.44 ± 0.05gH | 45.55 ± 0.06gI |

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 0.41 ± 0.01A | 3.71 ± 0.02aB | 7.65 ± 0.04aC | 9.28 ± 0.0aD | 18.35 ± 0.04aE | 31.97 ± 0.07aF | 41.42 ± 0.04aG | 49.87 ± 0.01aH | 61.72 ± 0.03aI |

| ER 200 | 0.41 ± 0.03A | 3.20 ± 0.04cB | 6.22 ± 0.02cC | 8.52 ± 0.03cD | 16.85 ± 0.05cE | 27.22 ± 0.02cF | 37.21 ± 0.03cG | 45.42 ± 0.03cH | 57.22 ± 0.02cI |

| ER 600 | 0.41 ± 0.04A | 2.88 ± 0.05dB | 5.34 ± 0.01dC | 7.82 ± 0.05dD | 15.63 ± 0.01dE | 24.24 ± 0.01dF | 33.64 ± 0.02dG | 40.36 ± 0.02dH | 54.82 ± 0.04dI |

| ER 1000 | 0.41 ± 0.01A | 2.82 ± 0.04dB | 4.75 ± 0.02eC | 7.13 ± 0.04eD | 14.77 ± 0.01eE | 22.24 ± 0.03eF | 31.10 ± 0.05eG | 38.56 ± 0.05eH | 48.62 ± 0.03eI |

| L | 0.41 ± 0.03A | 3.51 ± 0.01bB | 8.1 ± 0.10bC | 9.11 ± 0.02bD | 17.61 ± 0.02bE | 31.41 ± 0.05bF | 40.50 ± 0.05bG | 48.45 ± 0.04bH | 59.12 ± 0.02bI |

| LR 200 | 0.41 ± 0.07A | 1.65 ± 0.02eB | 3.25 ± 0.03fC | 6.65 ± 0.01fD | 14.14 ± 0.04fE | 21.44 ± 0.03fF | 25.27 ± 0.01fG | 34.52 ± 0.03fH | 43.11 ± 0.07fI |

| LR 600 | 0.41 ± 0.02A | 0.76 ± 0.03fB | 2.78 ± 0.05gC | 5.32 ± 0.02hD | 7.05 ± 0.02hE | 20.25 ± 0.04gF | 23.27 ± 0.06gG | 31.82 ± 0.06hH | 37.42 ± 0.05hI |

| LR 1000 | 0.41 ± 0.03A | 0.58 ± 0.02gB | 2.13 ± 0.01hC | 4.92 ± 0.03iD | 6.51 ± 0.05iE | 13.67 ± 0.02iF | 21.63 ± 0.04hG | 28.64 ± 0.01iH | 36.43 ± 0.04iI |

| BHT 200 | 0.41 ± 0.04A | 0.81 ± 0.01fB | 3.15 ± 0.03fC | 5.65 ± 0.03gD | 7.51 ± 0.01gE | 14.63 ± 0.04hF | 25.41 ± 0.02fG | 32.44 ± 0.05gH | 45.55 ± 0.06gI |

(a–z): Within a column, different letters indicate significant differences (P < 0.05); (A–Z): Within a row, different letters indicate significant differences (P ≤ 0.05).

ER 200, ER 600 and ER1000: rosemary extract at 200, 600 and 1000 mg Lˉ1; L: liposome without rosemary extract; LR 200, LR 600 and LR1000: rosemary extract liposome (LR) at 200, 600 and 1000 mg Lˉ1.

Peroxide values (m Eq kgˉ1) in canola oil with various values free and encapsulated rosemary extract during storage

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 0.41 ± 0.01A | 3.71 ± 0.02aB | 7.65 ± 0.04aC | 9.28 ± 0.0aD | 18.35 ± 0.04aE | 31.97 ± 0.07aF | 41.42 ± 0.04aG | 49.87 ± 0.01aH | 61.72 ± 0.03aI |

| ER 200 | 0.41 ± 0.03A | 3.20 ± 0.04cB | 6.22 ± 0.02cC | 8.52 ± 0.03cD | 16.85 ± 0.05cE | 27.22 ± 0.02cF | 37.21 ± 0.03cG | 45.42 ± 0.03cH | 57.22 ± 0.02cI |

| ER 600 | 0.41 ± 0.04A | 2.88 ± 0.05dB | 5.34 ± 0.01dC | 7.82 ± 0.05dD | 15.63 ± 0.01dE | 24.24 ± 0.01dF | 33.64 ± 0.02dG | 40.36 ± 0.02dH | 54.82 ± 0.04dI |

| ER 1000 | 0.41 ± 0.01A | 2.82 ± 0.04dB | 4.75 ± 0.02eC | 7.13 ± 0.04eD | 14.77 ± 0.01eE | 22.24 ± 0.03eF | 31.10 ± 0.05eG | 38.56 ± 0.05eH | 48.62 ± 0.03eI |

| L | 0.41 ± 0.03A | 3.51 ± 0.01bB | 8.1 ± 0.10bC | 9.11 ± 0.02bD | 17.61 ± 0.02bE | 31.41 ± 0.05bF | 40.50 ± 0.05bG | 48.45 ± 0.04bH | 59.12 ± 0.02bI |

| LR 200 | 0.41 ± 0.07A | 1.65 ± 0.02eB | 3.25 ± 0.03fC | 6.65 ± 0.01fD | 14.14 ± 0.04fE | 21.44 ± 0.03fF | 25.27 ± 0.01fG | 34.52 ± 0.03fH | 43.11 ± 0.07fI |

| LR 600 | 0.41 ± 0.02A | 0.76 ± 0.03fB | 2.78 ± 0.05gC | 5.32 ± 0.02hD | 7.05 ± 0.02hE | 20.25 ± 0.04gF | 23.27 ± 0.06gG | 31.82 ± 0.06hH | 37.42 ± 0.05hI |

| LR 1000 | 0.41 ± 0.03A | 0.58 ± 0.02gB | 2.13 ± 0.01hC | 4.92 ± 0.03iD | 6.51 ± 0.05iE | 13.67 ± 0.02iF | 21.63 ± 0.04hG | 28.64 ± 0.01iH | 36.43 ± 0.04iI |

| BHT 200 | 0.41 ± 0.04A | 0.81 ± 0.01fB | 3.15 ± 0.03fC | 5.65 ± 0.03gD | 7.51 ± 0.01gE | 14.63 ± 0.04hF | 25.41 ± 0.02fG | 32.44 ± 0.05gH | 45.55 ± 0.06gI |

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 0.41 ± 0.01A | 3.71 ± 0.02aB | 7.65 ± 0.04aC | 9.28 ± 0.0aD | 18.35 ± 0.04aE | 31.97 ± 0.07aF | 41.42 ± 0.04aG | 49.87 ± 0.01aH | 61.72 ± 0.03aI |

| ER 200 | 0.41 ± 0.03A | 3.20 ± 0.04cB | 6.22 ± 0.02cC | 8.52 ± 0.03cD | 16.85 ± 0.05cE | 27.22 ± 0.02cF | 37.21 ± 0.03cG | 45.42 ± 0.03cH | 57.22 ± 0.02cI |

| ER 600 | 0.41 ± 0.04A | 2.88 ± 0.05dB | 5.34 ± 0.01dC | 7.82 ± 0.05dD | 15.63 ± 0.01dE | 24.24 ± 0.01dF | 33.64 ± 0.02dG | 40.36 ± 0.02dH | 54.82 ± 0.04dI |

| ER 1000 | 0.41 ± 0.01A | 2.82 ± 0.04dB | 4.75 ± 0.02eC | 7.13 ± 0.04eD | 14.77 ± 0.01eE | 22.24 ± 0.03eF | 31.10 ± 0.05eG | 38.56 ± 0.05eH | 48.62 ± 0.03eI |

| L | 0.41 ± 0.03A | 3.51 ± 0.01bB | 8.1 ± 0.10bC | 9.11 ± 0.02bD | 17.61 ± 0.02bE | 31.41 ± 0.05bF | 40.50 ± 0.05bG | 48.45 ± 0.04bH | 59.12 ± 0.02bI |

| LR 200 | 0.41 ± 0.07A | 1.65 ± 0.02eB | 3.25 ± 0.03fC | 6.65 ± 0.01fD | 14.14 ± 0.04fE | 21.44 ± 0.03fF | 25.27 ± 0.01fG | 34.52 ± 0.03fH | 43.11 ± 0.07fI |

| LR 600 | 0.41 ± 0.02A | 0.76 ± 0.03fB | 2.78 ± 0.05gC | 5.32 ± 0.02hD | 7.05 ± 0.02hE | 20.25 ± 0.04gF | 23.27 ± 0.06gG | 31.82 ± 0.06hH | 37.42 ± 0.05hI |

| LR 1000 | 0.41 ± 0.03A | 0.58 ± 0.02gB | 2.13 ± 0.01hC | 4.92 ± 0.03iD | 6.51 ± 0.05iE | 13.67 ± 0.02iF | 21.63 ± 0.04hG | 28.64 ± 0.01iH | 36.43 ± 0.04iI |

| BHT 200 | 0.41 ± 0.04A | 0.81 ± 0.01fB | 3.15 ± 0.03fC | 5.65 ± 0.03gD | 7.51 ± 0.01gE | 14.63 ± 0.04hF | 25.41 ± 0.02fG | 32.44 ± 0.05gH | 45.55 ± 0.06gI |

(a–z): Within a column, different letters indicate significant differences (P < 0.05); (A–Z): Within a row, different letters indicate significant differences (P ≤ 0.05).

ER 200, ER 600 and ER1000: rosemary extract at 200, 600 and 1000 mg Lˉ1; L: liposome without rosemary extract; LR 200, LR 600 and LR1000: rosemary extract liposome (LR) at 200, 600 and 1000 mg Lˉ1.

Anisidine value

This value is a measurement of secondary oxidative products of lipid peroxidation such as α and β unsaturated aldehydes (Miraliakbari & Shahidi, 2008). Table 2 shows the anisidine value of samples of canola oil. It can be concluded from Table 2 that rosemary extract acted as an effective natural antioxidant and reduced the amount of anisidine in canola oil. In addition, liposome rosemary extract had more antioxidant properties than free extracts. The concentration of rosemary extract and the duration of incubation showed significant impact (P ≤ 0.05) on the anisidine values in canola oil. The sample containing rosemary extract liposomes at 1000 mg kgˉ1 concentration after 32 days of storage showed the lowest anisidine value. After that, the oil with rosemary extract liposomes at 600 and 200 mg Lˉ1 levels and rosemary free extract at 1000 mg Lˉ1 concentration had the lowest anisidine value, respectively. BHT antioxidants had better results than rosemary extract in the free form at concentrations of 200 and 600 mg Lˉ1. The ideal efficiency of rosemary extract is probably due to phenolic compounds such as rosmarinic acid and carnosol (de Conto et al., 2012). The obtained results in this study were consistent with those reported by Wang et al. (2018) and Chen et al. (2014).

Anisidine values in canola oil with various values free and encapsulated rosemary extract during storage

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 0.22 ± 0.02A | 3.02 ± 0.01aB | 4.43 ± 0.01aC | 5.62 ± 0.03aD | 6.82 ± 0.01aE | 9.51 ± 0.01aF | 10.74 ± 0.07aG | 14.26 ± 0.05aH | 16.05 ± 0.07aI |

| ER 200 | 0.22 ± 0.05A | 2.84 ± 0.02cB | 3.95 ± 0.1cC | 5.12 ± 0.01cD | 6.18 ± 0.03cE | 9.06 ± 0.04cF | 10.14 ± 0.05bG | 13.68 ± 0.02cH | 15.57 ± 0.04cI |

| ER 600 | 0.22 ± 0.01A | 2.48 ± 0.01dB | 3.25 ± 0.02dC | 4.46 ± 0.02dD | 5.92 ± 0.03dE | 7.54 ± 0.03dF | 8.92 ± 0.04cG | 12.30 ± 0.04dH | 14.26 ± 0.05dI |

| ER 1000 | 0.22 ± 0.03A | 1.84 ± 0.05fB | 2.05 ± 0.05fC | 3.02 ± 0.01fD | 4.72 ± 0.05fE | 5.66 ± 0.04fF | 7.14 ± 0.01eG | 11.07 ± 0.01eH | 12.56 ± 0.03fI |

| L | 0.22 ± 0.03A | 2.97 ± 0.04bB | 4.12 ± 0.02bC | 5.22 ± 0.07bD | 6.26 ± 0.02bE | 9.16 ± 0.03bF | 10.22 ± 0.06bG | 13.81 ± 0.02bH | 15.91 ± 0.02bI |

| LR 200 | 0.22 ± 0.05A | 1.49 ± 0.03gB | 1.85 ± 0.0gC | 2.85 ± 0.03gD | 3.67 ± 0.01gE | 5.55 ± 0.02gF | 6.77 ± 0.02fG | 10.67 ± 0.05fH | 11.83 ± 0.01gI |

| LR 600 | 0.22 ± 0.01A | 1.12 ± 0.02hB | 1.56 ± 0.02hC | 2.55 ± 0.02hD | 3.43 ± 0.03hE | 4.75 ± 0.05hF | 5.77 ± 0.03gG | 9.85 ± 0.03gH | 10.64 ± 0.02hI |

| LR 1000 | 0.22 ± 0.01A | 1.04 ± 0.07iA | 1.40 ± 0.01iB | 2.24 ± 0.05iC | 2.85 ± 0.04iD | 3.61 ± 0.13iE | 4.58 ± 0.01hF | 8.63 ± 0.06hG | 9.22 ± 0.02iH |

| BHT 200 | 0.22 ± 0.03A | 1.96 ± 0.01eB | 2.14 ± 0.03eC | 3.08 ± 0.04eD | 4.85 ± 0.02eE | 6.13 ± 0.01eF | 7.24 ± 0.02dG | 11.16 ± 0.01eH | 13.16 ± 0.03eI |

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 0.22 ± 0.02A | 3.02 ± 0.01aB | 4.43 ± 0.01aC | 5.62 ± 0.03aD | 6.82 ± 0.01aE | 9.51 ± 0.01aF | 10.74 ± 0.07aG | 14.26 ± 0.05aH | 16.05 ± 0.07aI |

| ER 200 | 0.22 ± 0.05A | 2.84 ± 0.02cB | 3.95 ± 0.1cC | 5.12 ± 0.01cD | 6.18 ± 0.03cE | 9.06 ± 0.04cF | 10.14 ± 0.05bG | 13.68 ± 0.02cH | 15.57 ± 0.04cI |

| ER 600 | 0.22 ± 0.01A | 2.48 ± 0.01dB | 3.25 ± 0.02dC | 4.46 ± 0.02dD | 5.92 ± 0.03dE | 7.54 ± 0.03dF | 8.92 ± 0.04cG | 12.30 ± 0.04dH | 14.26 ± 0.05dI |

| ER 1000 | 0.22 ± 0.03A | 1.84 ± 0.05fB | 2.05 ± 0.05fC | 3.02 ± 0.01fD | 4.72 ± 0.05fE | 5.66 ± 0.04fF | 7.14 ± 0.01eG | 11.07 ± 0.01eH | 12.56 ± 0.03fI |

| L | 0.22 ± 0.03A | 2.97 ± 0.04bB | 4.12 ± 0.02bC | 5.22 ± 0.07bD | 6.26 ± 0.02bE | 9.16 ± 0.03bF | 10.22 ± 0.06bG | 13.81 ± 0.02bH | 15.91 ± 0.02bI |

| LR 200 | 0.22 ± 0.05A | 1.49 ± 0.03gB | 1.85 ± 0.0gC | 2.85 ± 0.03gD | 3.67 ± 0.01gE | 5.55 ± 0.02gF | 6.77 ± 0.02fG | 10.67 ± 0.05fH | 11.83 ± 0.01gI |

| LR 600 | 0.22 ± 0.01A | 1.12 ± 0.02hB | 1.56 ± 0.02hC | 2.55 ± 0.02hD | 3.43 ± 0.03hE | 4.75 ± 0.05hF | 5.77 ± 0.03gG | 9.85 ± 0.03gH | 10.64 ± 0.02hI |

| LR 1000 | 0.22 ± 0.01A | 1.04 ± 0.07iA | 1.40 ± 0.01iB | 2.24 ± 0.05iC | 2.85 ± 0.04iD | 3.61 ± 0.13iE | 4.58 ± 0.01hF | 8.63 ± 0.06hG | 9.22 ± 0.02iH |

| BHT 200 | 0.22 ± 0.03A | 1.96 ± 0.01eB | 2.14 ± 0.03eC | 3.08 ± 0.04eD | 4.85 ± 0.02eE | 6.13 ± 0.01eF | 7.24 ± 0.02dG | 11.16 ± 0.01eH | 13.16 ± 0.03eI |

(a-z): Within a column, different letters indicate significant differences (P < 0.05); (A–Z): Within a row, different letters indicate significant differences (P ≤ 0.05).

ER 200, ER 600 and ER1000: rosemary extract at 200, 600 and 1000 mg Lˉ1; L: liposome without rosemary extract; LR 200, LR 600 and LR1000: rosemary extract liposome (LR) at 200, 600 and 1000 mg Lˉ1.

Anisidine values in canola oil with various values free and encapsulated rosemary extract during storage

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 0.22 ± 0.02A | 3.02 ± 0.01aB | 4.43 ± 0.01aC | 5.62 ± 0.03aD | 6.82 ± 0.01aE | 9.51 ± 0.01aF | 10.74 ± 0.07aG | 14.26 ± 0.05aH | 16.05 ± 0.07aI |

| ER 200 | 0.22 ± 0.05A | 2.84 ± 0.02cB | 3.95 ± 0.1cC | 5.12 ± 0.01cD | 6.18 ± 0.03cE | 9.06 ± 0.04cF | 10.14 ± 0.05bG | 13.68 ± 0.02cH | 15.57 ± 0.04cI |

| ER 600 | 0.22 ± 0.01A | 2.48 ± 0.01dB | 3.25 ± 0.02dC | 4.46 ± 0.02dD | 5.92 ± 0.03dE | 7.54 ± 0.03dF | 8.92 ± 0.04cG | 12.30 ± 0.04dH | 14.26 ± 0.05dI |

| ER 1000 | 0.22 ± 0.03A | 1.84 ± 0.05fB | 2.05 ± 0.05fC | 3.02 ± 0.01fD | 4.72 ± 0.05fE | 5.66 ± 0.04fF | 7.14 ± 0.01eG | 11.07 ± 0.01eH | 12.56 ± 0.03fI |

| L | 0.22 ± 0.03A | 2.97 ± 0.04bB | 4.12 ± 0.02bC | 5.22 ± 0.07bD | 6.26 ± 0.02bE | 9.16 ± 0.03bF | 10.22 ± 0.06bG | 13.81 ± 0.02bH | 15.91 ± 0.02bI |

| LR 200 | 0.22 ± 0.05A | 1.49 ± 0.03gB | 1.85 ± 0.0gC | 2.85 ± 0.03gD | 3.67 ± 0.01gE | 5.55 ± 0.02gF | 6.77 ± 0.02fG | 10.67 ± 0.05fH | 11.83 ± 0.01gI |

| LR 600 | 0.22 ± 0.01A | 1.12 ± 0.02hB | 1.56 ± 0.02hC | 2.55 ± 0.02hD | 3.43 ± 0.03hE | 4.75 ± 0.05hF | 5.77 ± 0.03gG | 9.85 ± 0.03gH | 10.64 ± 0.02hI |

| LR 1000 | 0.22 ± 0.01A | 1.04 ± 0.07iA | 1.40 ± 0.01iB | 2.24 ± 0.05iC | 2.85 ± 0.04iD | 3.61 ± 0.13iE | 4.58 ± 0.01hF | 8.63 ± 0.06hG | 9.22 ± 0.02iH |

| BHT 200 | 0.22 ± 0.03A | 1.96 ± 0.01eB | 2.14 ± 0.03eC | 3.08 ± 0.04eD | 4.85 ± 0.02eE | 6.13 ± 0.01eF | 7.24 ± 0.02dG | 11.16 ± 0.01eH | 13.16 ± 0.03eI |

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 0.22 ± 0.02A | 3.02 ± 0.01aB | 4.43 ± 0.01aC | 5.62 ± 0.03aD | 6.82 ± 0.01aE | 9.51 ± 0.01aF | 10.74 ± 0.07aG | 14.26 ± 0.05aH | 16.05 ± 0.07aI |

| ER 200 | 0.22 ± 0.05A | 2.84 ± 0.02cB | 3.95 ± 0.1cC | 5.12 ± 0.01cD | 6.18 ± 0.03cE | 9.06 ± 0.04cF | 10.14 ± 0.05bG | 13.68 ± 0.02cH | 15.57 ± 0.04cI |

| ER 600 | 0.22 ± 0.01A | 2.48 ± 0.01dB | 3.25 ± 0.02dC | 4.46 ± 0.02dD | 5.92 ± 0.03dE | 7.54 ± 0.03dF | 8.92 ± 0.04cG | 12.30 ± 0.04dH | 14.26 ± 0.05dI |

| ER 1000 | 0.22 ± 0.03A | 1.84 ± 0.05fB | 2.05 ± 0.05fC | 3.02 ± 0.01fD | 4.72 ± 0.05fE | 5.66 ± 0.04fF | 7.14 ± 0.01eG | 11.07 ± 0.01eH | 12.56 ± 0.03fI |

| L | 0.22 ± 0.03A | 2.97 ± 0.04bB | 4.12 ± 0.02bC | 5.22 ± 0.07bD | 6.26 ± 0.02bE | 9.16 ± 0.03bF | 10.22 ± 0.06bG | 13.81 ± 0.02bH | 15.91 ± 0.02bI |

| LR 200 | 0.22 ± 0.05A | 1.49 ± 0.03gB | 1.85 ± 0.0gC | 2.85 ± 0.03gD | 3.67 ± 0.01gE | 5.55 ± 0.02gF | 6.77 ± 0.02fG | 10.67 ± 0.05fH | 11.83 ± 0.01gI |

| LR 600 | 0.22 ± 0.01A | 1.12 ± 0.02hB | 1.56 ± 0.02hC | 2.55 ± 0.02hD | 3.43 ± 0.03hE | 4.75 ± 0.05hF | 5.77 ± 0.03gG | 9.85 ± 0.03gH | 10.64 ± 0.02hI |

| LR 1000 | 0.22 ± 0.01A | 1.04 ± 0.07iA | 1.40 ± 0.01iB | 2.24 ± 0.05iC | 2.85 ± 0.04iD | 3.61 ± 0.13iE | 4.58 ± 0.01hF | 8.63 ± 0.06hG | 9.22 ± 0.02iH |

| BHT 200 | 0.22 ± 0.03A | 1.96 ± 0.01eB | 2.14 ± 0.03eC | 3.08 ± 0.04eD | 4.85 ± 0.02eE | 6.13 ± 0.01eF | 7.24 ± 0.02dG | 11.16 ± 0.01eH | 13.16 ± 0.03eI |

(a-z): Within a column, different letters indicate significant differences (P < 0.05); (A–Z): Within a row, different letters indicate significant differences (P ≤ 0.05).

ER 200, ER 600 and ER1000: rosemary extract at 200, 600 and 1000 mg Lˉ1; L: liposome without rosemary extract; LR 200, LR 600 and LR1000: rosemary extract liposome (LR) at 200, 600 and 1000 mg Lˉ1.

Total oxidation value

Table 3 shows the TOTOX values of the canola oil samples. Results indicates increased antioxidants in free and liposomal rosemary extracts. However, rosemary extract in liposomes showed stronger antioxidant properties than the free extract. Samples with rosemary extract liposomes at the concentration of 1000 and 600 mg Lˉ1 showed the lowest TOTOX value. So, there was no significant difference between these two levels in TOTOX value.

TOTOX changes in canola oil with various values free and encapsulated green tea extract during storage

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 1.02 ± 0.0A | 10.42 ± 0.01aB | 19.37 ± 0.01aC | 24.18 ± 0.02aD | 43.52 ± 0.05aE | 73.44 ± 0.03aF | 93.58 ± 0.01aG | 114.05 ± 0.03aH | 139.49 ± 0.06aI |

| ER 200 | 1.02 ± 0.02A | 9.22 ± 0.05abB | 16.39 ± 0.02bC | 22.16 ± 0.03bD | 39.88 ± 0.07cE | 63.50 ± 0.01cF | 84.56 ± 0.06cG | 104.52 ± 0.01cH | 130.01 ± 003cI |

| ER 600 | 1.02 ± 0.05A | 8.12 ± 0.03bcB | 13.95 ± 0.03bcC | 20.10 ± 0.07cD | 37.18 ± 0.01dE | 56.02 ± 0.04dF | 76.20 ± 0.04dG | 93.02 ± 0.02dH | 123.9 ± 0.02dI |

| ER 1000 | 1.02 ± 0.07A | 7.60 ± 0.01cB | 11.55 ± 0.06cC | 17.28 ± 0.02dD | 34.26 ± 0.03eE | 50.14 ± 0.02eE | 69.34 ± 0.01eG | 88.19 ± 0.02eH | 109.80 ± 0.04eI |

| L | 1.02 ± 0.01A | 9.97 ± 0.0aB | 20.12 ± 0.0aC | 23.42 ± 0.03abC | 41.46 ± 0.06bD | 71.96 ± 0.01bE | 91.22 ± 0.01bF | 110.71 ± 0.05bG | 134.11 ± 0.02bH |

| LR 200 | 1.02 ± 0.02A | 4.79 ± 0.03dB | 8.35 ± 0.03dC | 16.16 ± 0.05dD | 31.95 ± 0.02fE | 48.43 ± 0.05fF | 57.31 ± 0.03fG | 79.71 ± 0.03fH | 100.05 ± 0.05fI |

| LR 600 | 1.02 ± 0.03A | 2.64 ± 0.02eB | 7.12 ± 0.02deC | 13.19 ± 0.04efD | 17.53 ± 0.01hE | 45.25 ± 0.02gF | 52.31 ± 0.05gG | 73.49 ± 0.01hH | 82.08 ± 0.01gI |

| LR 1000 | 1.02 ± 0.04A | 2.20 ± 0.05eB | 5.66 ± 0.05eC | 12.08 ± 0.01fD | 15.87 ± 0.04iE | 30.95 ± 0.06iF | 47.84 ± 0.02hG | 65.91 ± 0.05iH | 82.01 ± 0.05gI |

| BHT 200 | 1.02 ± 0.07A | 3.56 ± 0.04deB | 8.44 ± 0.04dC | 14.38 ± 0.03eD | 19.85 ± 0.03gE | 35.33 ± 0.07hF | 58.04 ± 0.0fG | 75.96 ± 0.03gH | 100.34 ± 0.01fI |

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 1.02 ± 0.0A | 10.42 ± 0.01aB | 19.37 ± 0.01aC | 24.18 ± 0.02aD | 43.52 ± 0.05aE | 73.44 ± 0.03aF | 93.58 ± 0.01aG | 114.05 ± 0.03aH | 139.49 ± 0.06aI |

| ER 200 | 1.02 ± 0.02A | 9.22 ± 0.05abB | 16.39 ± 0.02bC | 22.16 ± 0.03bD | 39.88 ± 0.07cE | 63.50 ± 0.01cF | 84.56 ± 0.06cG | 104.52 ± 0.01cH | 130.01 ± 003cI |

| ER 600 | 1.02 ± 0.05A | 8.12 ± 0.03bcB | 13.95 ± 0.03bcC | 20.10 ± 0.07cD | 37.18 ± 0.01dE | 56.02 ± 0.04dF | 76.20 ± 0.04dG | 93.02 ± 0.02dH | 123.9 ± 0.02dI |

| ER 1000 | 1.02 ± 0.07A | 7.60 ± 0.01cB | 11.55 ± 0.06cC | 17.28 ± 0.02dD | 34.26 ± 0.03eE | 50.14 ± 0.02eE | 69.34 ± 0.01eG | 88.19 ± 0.02eH | 109.80 ± 0.04eI |

| L | 1.02 ± 0.01A | 9.97 ± 0.0aB | 20.12 ± 0.0aC | 23.42 ± 0.03abC | 41.46 ± 0.06bD | 71.96 ± 0.01bE | 91.22 ± 0.01bF | 110.71 ± 0.05bG | 134.11 ± 0.02bH |

| LR 200 | 1.02 ± 0.02A | 4.79 ± 0.03dB | 8.35 ± 0.03dC | 16.16 ± 0.05dD | 31.95 ± 0.02fE | 48.43 ± 0.05fF | 57.31 ± 0.03fG | 79.71 ± 0.03fH | 100.05 ± 0.05fI |

| LR 600 | 1.02 ± 0.03A | 2.64 ± 0.02eB | 7.12 ± 0.02deC | 13.19 ± 0.04efD | 17.53 ± 0.01hE | 45.25 ± 0.02gF | 52.31 ± 0.05gG | 73.49 ± 0.01hH | 82.08 ± 0.01gI |

| LR 1000 | 1.02 ± 0.04A | 2.20 ± 0.05eB | 5.66 ± 0.05eC | 12.08 ± 0.01fD | 15.87 ± 0.04iE | 30.95 ± 0.06iF | 47.84 ± 0.02hG | 65.91 ± 0.05iH | 82.01 ± 0.05gI |

| BHT 200 | 1.02 ± 0.07A | 3.56 ± 0.04deB | 8.44 ± 0.04dC | 14.38 ± 0.03eD | 19.85 ± 0.03gE | 35.33 ± 0.07hF | 58.04 ± 0.0fG | 75.96 ± 0.03gH | 100.34 ± 0.01fI |

(a-z): Within a column, different letters indicate significant differences (P < 0.05); (A–Z): Within a row, different letters indicate significant differences (P ≤ 0.05).

ER 200, ER 600 and ER1000: rosemary extract at 200, 600 and 1000 mg Lˉ1; L: liposome without rosemary extract; LR 200, LR 600 and LR1000: rosemary extract liposome (LR) at 200, 600 and 1000 mg Lˉ1.

TOTOX changes in canola oil with various values free and encapsulated green tea extract during storage

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 1.02 ± 0.0A | 10.42 ± 0.01aB | 19.37 ± 0.01aC | 24.18 ± 0.02aD | 43.52 ± 0.05aE | 73.44 ± 0.03aF | 93.58 ± 0.01aG | 114.05 ± 0.03aH | 139.49 ± 0.06aI |

| ER 200 | 1.02 ± 0.02A | 9.22 ± 0.05abB | 16.39 ± 0.02bC | 22.16 ± 0.03bD | 39.88 ± 0.07cE | 63.50 ± 0.01cF | 84.56 ± 0.06cG | 104.52 ± 0.01cH | 130.01 ± 003cI |

| ER 600 | 1.02 ± 0.05A | 8.12 ± 0.03bcB | 13.95 ± 0.03bcC | 20.10 ± 0.07cD | 37.18 ± 0.01dE | 56.02 ± 0.04dF | 76.20 ± 0.04dG | 93.02 ± 0.02dH | 123.9 ± 0.02dI |

| ER 1000 | 1.02 ± 0.07A | 7.60 ± 0.01cB | 11.55 ± 0.06cC | 17.28 ± 0.02dD | 34.26 ± 0.03eE | 50.14 ± 0.02eE | 69.34 ± 0.01eG | 88.19 ± 0.02eH | 109.80 ± 0.04eI |

| L | 1.02 ± 0.01A | 9.97 ± 0.0aB | 20.12 ± 0.0aC | 23.42 ± 0.03abC | 41.46 ± 0.06bD | 71.96 ± 0.01bE | 91.22 ± 0.01bF | 110.71 ± 0.05bG | 134.11 ± 0.02bH |

| LR 200 | 1.02 ± 0.02A | 4.79 ± 0.03dB | 8.35 ± 0.03dC | 16.16 ± 0.05dD | 31.95 ± 0.02fE | 48.43 ± 0.05fF | 57.31 ± 0.03fG | 79.71 ± 0.03fH | 100.05 ± 0.05fI |

| LR 600 | 1.02 ± 0.03A | 2.64 ± 0.02eB | 7.12 ± 0.02deC | 13.19 ± 0.04efD | 17.53 ± 0.01hE | 45.25 ± 0.02gF | 52.31 ± 0.05gG | 73.49 ± 0.01hH | 82.08 ± 0.01gI |

| LR 1000 | 1.02 ± 0.04A | 2.20 ± 0.05eB | 5.66 ± 0.05eC | 12.08 ± 0.01fD | 15.87 ± 0.04iE | 30.95 ± 0.06iF | 47.84 ± 0.02hG | 65.91 ± 0.05iH | 82.01 ± 0.05gI |

| BHT 200 | 1.02 ± 0.07A | 3.56 ± 0.04deB | 8.44 ± 0.04dC | 14.38 ± 0.03eD | 19.85 ± 0.03gE | 35.33 ± 0.07hF | 58.04 ± 0.0fG | 75.96 ± 0.03gH | 100.34 ± 0.01fI |

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 1.02 ± 0.0A | 10.42 ± 0.01aB | 19.37 ± 0.01aC | 24.18 ± 0.02aD | 43.52 ± 0.05aE | 73.44 ± 0.03aF | 93.58 ± 0.01aG | 114.05 ± 0.03aH | 139.49 ± 0.06aI |

| ER 200 | 1.02 ± 0.02A | 9.22 ± 0.05abB | 16.39 ± 0.02bC | 22.16 ± 0.03bD | 39.88 ± 0.07cE | 63.50 ± 0.01cF | 84.56 ± 0.06cG | 104.52 ± 0.01cH | 130.01 ± 003cI |

| ER 600 | 1.02 ± 0.05A | 8.12 ± 0.03bcB | 13.95 ± 0.03bcC | 20.10 ± 0.07cD | 37.18 ± 0.01dE | 56.02 ± 0.04dF | 76.20 ± 0.04dG | 93.02 ± 0.02dH | 123.9 ± 0.02dI |

| ER 1000 | 1.02 ± 0.07A | 7.60 ± 0.01cB | 11.55 ± 0.06cC | 17.28 ± 0.02dD | 34.26 ± 0.03eE | 50.14 ± 0.02eE | 69.34 ± 0.01eG | 88.19 ± 0.02eH | 109.80 ± 0.04eI |

| L | 1.02 ± 0.01A | 9.97 ± 0.0aB | 20.12 ± 0.0aC | 23.42 ± 0.03abC | 41.46 ± 0.06bD | 71.96 ± 0.01bE | 91.22 ± 0.01bF | 110.71 ± 0.05bG | 134.11 ± 0.02bH |

| LR 200 | 1.02 ± 0.02A | 4.79 ± 0.03dB | 8.35 ± 0.03dC | 16.16 ± 0.05dD | 31.95 ± 0.02fE | 48.43 ± 0.05fF | 57.31 ± 0.03fG | 79.71 ± 0.03fH | 100.05 ± 0.05fI |

| LR 600 | 1.02 ± 0.03A | 2.64 ± 0.02eB | 7.12 ± 0.02deC | 13.19 ± 0.04efD | 17.53 ± 0.01hE | 45.25 ± 0.02gF | 52.31 ± 0.05gG | 73.49 ± 0.01hH | 82.08 ± 0.01gI |

| LR 1000 | 1.02 ± 0.04A | 2.20 ± 0.05eB | 5.66 ± 0.05eC | 12.08 ± 0.01fD | 15.87 ± 0.04iE | 30.95 ± 0.06iF | 47.84 ± 0.02hG | 65.91 ± 0.05iH | 82.01 ± 0.05gI |

| BHT 200 | 1.02 ± 0.07A | 3.56 ± 0.04deB | 8.44 ± 0.04dC | 14.38 ± 0.03eD | 19.85 ± 0.03gE | 35.33 ± 0.07hF | 58.04 ± 0.0fG | 75.96 ± 0.03gH | 100.34 ± 0.01fI |

(a-z): Within a column, different letters indicate significant differences (P < 0.05); (A–Z): Within a row, different letters indicate significant differences (P ≤ 0.05).

ER 200, ER 600 and ER1000: rosemary extract at 200, 600 and 1000 mg Lˉ1; L: liposome without rosemary extract; LR 200, LR 600 and LR1000: rosemary extract liposome (LR) at 200, 600 and 1000 mg Lˉ1.

Thiobarbituric acid value

TBA reactive substance (TBARS) expresses oxidation products, such as malonaldehydes, which cause off-flavours in oil (Moczkowska et al., 2020). Table 4 shows changes in TBA value during 32 days of incubation. It was not unexpected that highest TBA value during the incubation period belongs to control samples. Samples containing rosemary extract liposome at concentrations of 1000, 600 and 200 mg Lˉ1, respectively, showed the lowest amount of TBA during storage. After that, the lowest TBA level belonged to the oil containing free rosemary extract at a concentration of 1000 mg Lˉ1.

TBARS values (mg malonaldehyde kgˉ1) in canola oil with various values free and encapsulated green tea extract during storage

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 4.0 ± 0.0A | 90.2 ± 7.10aB | 120.0 ± 9.8aC | 160.4 ± 10.5aD | 190.9 ± 20aE | 250.5 ± 20aF | 280.0 ± 20.2aG | 370.5 ± 25.2aH | 480.8 ± 36.7aI |

| ER 200 | 4.0 ± 0.0A | 42.2 ± 5.2bB | 91.5 ± 4.5bC | 154.3 ± 2.1cD | 183.4 ± 10.1bE | 322.2 ± 25.1cF | 372.6 ± 23.1bG | 411.5 ± 30.1cH | 488.3 ± 30.5cI |

| ER 600 | 4.0 ± 0.0A | 37.1 ± 7.3cB | 67.6 ± 6.1cC | 92.5 ± 2.1dD | 177.3 ± 9.5cE | 246.7 ± 20.5dF | 295.2 ± 10.5cG | 356.3 ± 30.4dH | 411.6 ± 20.7dI |

| ER 1000 | 4.0 ± 0.0A | 28.3 ± 6.1dB | 56.4 ± 5.5eC | 67.4 ± 7.2fD | 86.6 ± 9.5eE | 128.1 ± 23.1fF | 147.2 ± 27.1eG | 232.2 ± 21.6eH | 267.2 ± 24.1fI |

| L | 4.0 ± 0.0A | 92.0 ± 4.1aB | 120.0 ± 5.1aC | 160.5 ± 3.3bD | 190.2 ± 25.0aE | 240.4 ± 20.2bF | 280.2 ± 10.1aG | 350.3 ± 27.7bH | 440.1 ± 35.5bI |

| LR 200 | 4.0 ± 0.0A | 22.1 ± 7.5eB | 52.4 ± 10.5fC | 62.6 ± 6.5gD | 81.5 ± 7.5fE | 126.3 ± 23.5gF | 144.7 ± 20.1fG | 223.1 ± 25.3fH | 261.6 ± 21.6gI |

| LR 600 | 4.0 ± 0.0A | 17.2 ± 4.1fB | 44.3 ± 7.1gC | 55.1 ± 7.2hD | 75.3 ± 5.3gE | 119.5 ± 27.2hF | 141.1 ± 26.3gG | 212.5 ± 22.2gH | 257.1 ± 10.7hI |

| LR 1000 | 4.0 ± 0.0A | 11.3 ± 6.5gA | 37.7 ± 6.2hB | 52.2 ± 5.3iC | 72.1 ± 4.3hD | 112.4 ± 10.4iE | 136.2 ± 23.2hF | 184.6 ± 21.7hG | 248.2 ± 22.1iH |

| BHT 200 | 4.0 ± 0.0A | 30.0 ± 3.2dB | 58.2 ± 3.3dC | 70.8 ± 3.6eD | 90.7 ± 19.0dE | 130.2 ± 20eF | 150.4 ± 11.2dG | 230.5 ± 24.5eH | 270.9 ± 26.4eI |

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 4.0 ± 0.0A | 90.2 ± 7.10aB | 120.0 ± 9.8aC | 160.4 ± 10.5aD | 190.9 ± 20aE | 250.5 ± 20aF | 280.0 ± 20.2aG | 370.5 ± 25.2aH | 480.8 ± 36.7aI |

| ER 200 | 4.0 ± 0.0A | 42.2 ± 5.2bB | 91.5 ± 4.5bC | 154.3 ± 2.1cD | 183.4 ± 10.1bE | 322.2 ± 25.1cF | 372.6 ± 23.1bG | 411.5 ± 30.1cH | 488.3 ± 30.5cI |

| ER 600 | 4.0 ± 0.0A | 37.1 ± 7.3cB | 67.6 ± 6.1cC | 92.5 ± 2.1dD | 177.3 ± 9.5cE | 246.7 ± 20.5dF | 295.2 ± 10.5cG | 356.3 ± 30.4dH | 411.6 ± 20.7dI |

| ER 1000 | 4.0 ± 0.0A | 28.3 ± 6.1dB | 56.4 ± 5.5eC | 67.4 ± 7.2fD | 86.6 ± 9.5eE | 128.1 ± 23.1fF | 147.2 ± 27.1eG | 232.2 ± 21.6eH | 267.2 ± 24.1fI |

| L | 4.0 ± 0.0A | 92.0 ± 4.1aB | 120.0 ± 5.1aC | 160.5 ± 3.3bD | 190.2 ± 25.0aE | 240.4 ± 20.2bF | 280.2 ± 10.1aG | 350.3 ± 27.7bH | 440.1 ± 35.5bI |

| LR 200 | 4.0 ± 0.0A | 22.1 ± 7.5eB | 52.4 ± 10.5fC | 62.6 ± 6.5gD | 81.5 ± 7.5fE | 126.3 ± 23.5gF | 144.7 ± 20.1fG | 223.1 ± 25.3fH | 261.6 ± 21.6gI |

| LR 600 | 4.0 ± 0.0A | 17.2 ± 4.1fB | 44.3 ± 7.1gC | 55.1 ± 7.2hD | 75.3 ± 5.3gE | 119.5 ± 27.2hF | 141.1 ± 26.3gG | 212.5 ± 22.2gH | 257.1 ± 10.7hI |

| LR 1000 | 4.0 ± 0.0A | 11.3 ± 6.5gA | 37.7 ± 6.2hB | 52.2 ± 5.3iC | 72.1 ± 4.3hD | 112.4 ± 10.4iE | 136.2 ± 23.2hF | 184.6 ± 21.7hG | 248.2 ± 22.1iH |

| BHT 200 | 4.0 ± 0.0A | 30.0 ± 3.2dB | 58.2 ± 3.3dC | 70.8 ± 3.6eD | 90.7 ± 19.0dE | 130.2 ± 20eF | 150.4 ± 11.2dG | 230.5 ± 24.5eH | 270.9 ± 26.4eI |

(a-z): Within a column, different letters indicate significant differences (P ≤ 0.05); (A–Z): Within a row, different letters indicate significant differences (P < 0.05).

Abbreviations: ER 200, ER 600 and ER1000: rosemary extract at 200, 600 and 1000 mg Lˉ1; L: liposome without rosemary extract; LR 200, LR 600 and LR1000: rosemary extract liposome (LR) at 200, 600 and 1000 mg Lˉ1.

TBARS values (mg malonaldehyde kgˉ1) in canola oil with various values free and encapsulated green tea extract during storage

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 4.0 ± 0.0A | 90.2 ± 7.10aB | 120.0 ± 9.8aC | 160.4 ± 10.5aD | 190.9 ± 20aE | 250.5 ± 20aF | 280.0 ± 20.2aG | 370.5 ± 25.2aH | 480.8 ± 36.7aI |

| ER 200 | 4.0 ± 0.0A | 42.2 ± 5.2bB | 91.5 ± 4.5bC | 154.3 ± 2.1cD | 183.4 ± 10.1bE | 322.2 ± 25.1cF | 372.6 ± 23.1bG | 411.5 ± 30.1cH | 488.3 ± 30.5cI |

| ER 600 | 4.0 ± 0.0A | 37.1 ± 7.3cB | 67.6 ± 6.1cC | 92.5 ± 2.1dD | 177.3 ± 9.5cE | 246.7 ± 20.5dF | 295.2 ± 10.5cG | 356.3 ± 30.4dH | 411.6 ± 20.7dI |

| ER 1000 | 4.0 ± 0.0A | 28.3 ± 6.1dB | 56.4 ± 5.5eC | 67.4 ± 7.2fD | 86.6 ± 9.5eE | 128.1 ± 23.1fF | 147.2 ± 27.1eG | 232.2 ± 21.6eH | 267.2 ± 24.1fI |

| L | 4.0 ± 0.0A | 92.0 ± 4.1aB | 120.0 ± 5.1aC | 160.5 ± 3.3bD | 190.2 ± 25.0aE | 240.4 ± 20.2bF | 280.2 ± 10.1aG | 350.3 ± 27.7bH | 440.1 ± 35.5bI |

| LR 200 | 4.0 ± 0.0A | 22.1 ± 7.5eB | 52.4 ± 10.5fC | 62.6 ± 6.5gD | 81.5 ± 7.5fE | 126.3 ± 23.5gF | 144.7 ± 20.1fG | 223.1 ± 25.3fH | 261.6 ± 21.6gI |

| LR 600 | 4.0 ± 0.0A | 17.2 ± 4.1fB | 44.3 ± 7.1gC | 55.1 ± 7.2hD | 75.3 ± 5.3gE | 119.5 ± 27.2hF | 141.1 ± 26.3gG | 212.5 ± 22.2gH | 257.1 ± 10.7hI |

| LR 1000 | 4.0 ± 0.0A | 11.3 ± 6.5gA | 37.7 ± 6.2hB | 52.2 ± 5.3iC | 72.1 ± 4.3hD | 112.4 ± 10.4iE | 136.2 ± 23.2hF | 184.6 ± 21.7hG | 248.2 ± 22.1iH |

| BHT 200 | 4.0 ± 0.0A | 30.0 ± 3.2dB | 58.2 ± 3.3dC | 70.8 ± 3.6eD | 90.7 ± 19.0dE | 130.2 ± 20eF | 150.4 ± 11.2dG | 230.5 ± 24.5eH | 270.9 ± 26.4eI |

| Treatment . | Time (day) . | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 . | 4 . | 8 . | 12 . | 16 . | 20 . | 24 . | 28 . | 32 . | |

| Oil | 4.0 ± 0.0A | 90.2 ± 7.10aB | 120.0 ± 9.8aC | 160.4 ± 10.5aD | 190.9 ± 20aE | 250.5 ± 20aF | 280.0 ± 20.2aG | 370.5 ± 25.2aH | 480.8 ± 36.7aI |

| ER 200 | 4.0 ± 0.0A | 42.2 ± 5.2bB | 91.5 ± 4.5bC | 154.3 ± 2.1cD | 183.4 ± 10.1bE | 322.2 ± 25.1cF | 372.6 ± 23.1bG | 411.5 ± 30.1cH | 488.3 ± 30.5cI |

| ER 600 | 4.0 ± 0.0A | 37.1 ± 7.3cB | 67.6 ± 6.1cC | 92.5 ± 2.1dD | 177.3 ± 9.5cE | 246.7 ± 20.5dF | 295.2 ± 10.5cG | 356.3 ± 30.4dH | 411.6 ± 20.7dI |

| ER 1000 | 4.0 ± 0.0A | 28.3 ± 6.1dB | 56.4 ± 5.5eC | 67.4 ± 7.2fD | 86.6 ± 9.5eE | 128.1 ± 23.1fF | 147.2 ± 27.1eG | 232.2 ± 21.6eH | 267.2 ± 24.1fI |

| L | 4.0 ± 0.0A | 92.0 ± 4.1aB | 120.0 ± 5.1aC | 160.5 ± 3.3bD | 190.2 ± 25.0aE | 240.4 ± 20.2bF | 280.2 ± 10.1aG | 350.3 ± 27.7bH | 440.1 ± 35.5bI |

| LR 200 | 4.0 ± 0.0A | 22.1 ± 7.5eB | 52.4 ± 10.5fC | 62.6 ± 6.5gD | 81.5 ± 7.5fE | 126.3 ± 23.5gF | 144.7 ± 20.1fG | 223.1 ± 25.3fH | 261.6 ± 21.6gI |

| LR 600 | 4.0 ± 0.0A | 17.2 ± 4.1fB | 44.3 ± 7.1gC | 55.1 ± 7.2hD | 75.3 ± 5.3gE | 119.5 ± 27.2hF | 141.1 ± 26.3gG | 212.5 ± 22.2gH | 257.1 ± 10.7hI |

| LR 1000 | 4.0 ± 0.0A | 11.3 ± 6.5gA | 37.7 ± 6.2hB | 52.2 ± 5.3iC | 72.1 ± 4.3hD | 112.4 ± 10.4iE | 136.2 ± 23.2hF | 184.6 ± 21.7hG | 248.2 ± 22.1iH |

| BHT 200 | 4.0 ± 0.0A | 30.0 ± 3.2dB | 58.2 ± 3.3dC | 70.8 ± 3.6eD | 90.7 ± 19.0dE | 130.2 ± 20eF | 150.4 ± 11.2dG | 230.5 ± 24.5eH | 270.9 ± 26.4eI |

(a-z): Within a column, different letters indicate significant differences (P ≤ 0.05); (A–Z): Within a row, different letters indicate significant differences (P < 0.05).

Abbreviations: ER 200, ER 600 and ER1000: rosemary extract at 200, 600 and 1000 mg Lˉ1; L: liposome without rosemary extract; LR 200, LR 600 and LR1000: rosemary extract liposome (LR) at 200, 600 and 1000 mg Lˉ1.

According to the results, the amount of TBA in the samples with BHT antioxidants was lower than the oil samples containing free rosemary extract in concentrations of 200 and 600 mg Lˉ1. The amount of TBA increased rapidly after 4 days, similar to results reported by Chen et al. (2014). Jafari et al. (2022) detailed a diminished TBA in sunflower oil following expanded concentration of rosemary extract.

Conclusion

The effectiveness of free and liposomal rosemary extract on the oxidation process of canola oil was investigated in this research. The data indicated reduced the oxidation process by incorporation of rosemary extract in canola oil during 32 days of incubation. Liposomal rosemary extract in concentrations of 200, 600 and 1000 mg Lˉ1 had a better performance than the synthetic antioxidant BHT. The chemical structure of phenoxy radicals formed by phenolic compounds of rosemary extract, like carnosol and carnosic acid, reduces the speed of the propagation step in the oxidation process, which increases the oxidative stability of the oil.

Acknowledgements

All collaborators of this scientific work are in authors list.

Author contributions

shima jahanfar: Data curation (equal); investigation (equal); software (equal); writing – original draft (equal). Mehrdad Ghavami: Project administration (equal); resources (equal); writing – review and editing (equal). Kianoush Khosravi-Darani: Conceptualization (equal); funding acquisition (equal); methodology (equal); validation (equal); writing – review and editing (equal). Mahshid jahadi: Methodology (equal); software (equal); validation (equal); visualization (equal); writing – review and editing (equal). Hareem Mohsin: Validation (equal); visualization (equal); writing – review and editing (equal). Svetoslav Todorov: Conceptualization (equal); validation (equal); visualization (equal); writing – review and editing (equal). Abhishek Tripathi: Validation (equal); visualization (equal); writing – review and editing (equal).

Ethical approval

Ethics approval was not required for this research.

Peer review

The peer review history for this article is available at https://www.webofscience.com/api/gateway/wos/peer-review/10.1111/ijfs.16450.

Data availability statement

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy restrictions.

References

This reference has been used due to the investigation of antioxidant properties of rosemary extract on sunflower oil.

This reference was used due to the preparation of liposomes by thermal method, which was close to the preparation method of liposomes in our research work.

In this research, the ethanol extract of ginger was encapsulated and its antioxidant properties were investigated in oil, which was useful for our research that rosemary extract was extracted with ethanol and then encapsulated.

In this article, all the properties of rosemary extract, including particle size, zeta potential, which has a great effect on the encapsulation efficiency, are explained in detail with the relevant parameters.

This reference is a new reference that deals with the evaluation of oxidation products during the storage period of edible oils and it can be used as an authentic article since it was published in LWT journal.