-

PDF

- Split View

-

Views

-

Cite

Cite

Triana Kusumaningsih, Annisa Istiqomah, Maulidan Firdaus, Venty Suryanti, A green metrics approach toward antibacterial chitosan/starch-based films reinforced with garlic oil for extending the shelf-life of Capsicum annum, International Journal of Food Science and Technology, Volume 58, Issue 10, October 2023, Pages 5311–5318, https://doi.org/10.1111/ijfs.16638

Close - Share Icon Share

Abstract

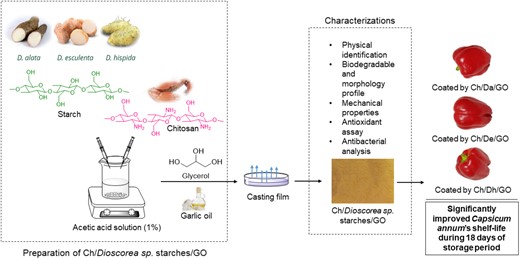

The study aimed to develop chitosan (Ch)/starch-based films for the preservation process of Capsicum annum, and further consider the green metrics approach for sustainability. Three types of starches derived from Dioscorea sp. were used: Dioscorea alata (Da), Dioscorea esculenta (De) and Dioscorea hispida (Dh). To further enhance the coating performance, garlic oil (GO) was incorporated, resulting in improvements in physical and mechanical properties, antioxidant and antibacterial activity. A comprehensive characterisation was conducted to assess the impact of GO on the Ch/starch environment. The presence of GO increased hydrophobicity, improved mechanical properties and thermal stability. Moreover, Ch/starch/GO films exhibited antioxidant and antibacterial activity compared to Ch/starch films. Finally, the application of the Ch/starch/GO on C. annum demonstrated an improvement in visual appearance, bacterial growth and extended its shelf life during storage. These findings highlight the potential of Ch/starch/GO as an effective approach for enhancing the properties and preservation of agricultural products.

Introduction

Plant-based foods are rich in beneficial nutrients that contribute to overall health and defend against infections (Kunnumakkara et al., 2021). Capsicum annum (bell pepper) is known for its nutrient content, including vitamins A, C and E, phenolic and flavonoid compounds, which exhibit antioxidant and antimicrobial properties. Recent research reveals that C. annum has potential health benefits, such as preventing atherosclerosis, cardiovascular disease, certain cancers and anti-ageing agent (Shotorbani et al., 2013; Kumar et al., 2021). However, postharvest treatment of C. annum is challenging due to its high respiration rate and susceptibility to environmental factors, which can affect its quality. Therefore, effective postharvest treatments are needed to address these issues.

According to The Food and Agriculture Organization, 1.3 billion tons of food is wasted due to spoilage food. Inadequate food packaging is a major contributor to the spoilage process through free radicals and pathogens (Ishangulyyev et al., 2019). Insufficient antioxidant and antibacterial properties of food packaging during shelf-life can be addressed by adding natural resources. Essential oils (EO) are commonly used as an additive agent in the production of food packaging production to improve biological activity. Garlic oil (GO) is commonly used as a natural flavour enhancer and rich in nutrient content. Moreover, GO has antioxidant and antibacterial activity due to its sulphur contents (Shah et al., 2021). In food packaging production, GO contributes to enhanced biological properties such as antibacterial, antifungal and antioxidant (Istiqomah et al., 2022a).

Chitosan (Ch) has gained significant attention due to its remarkable properties and diverse application, especially in food packaging sector (Moustafa et al., 2019). Dioscorea sp. starches are recognised for their composition and versatile applications. These starches possess unique physicochemical properties and valuable ingredients in food sector (Istiqomah et al., 2022a). Therefore, the exploration and utilisation of Dioscorea sp. starch hold promise for the advancement of food packaging industry. In recent years, Ch/starch coating has been extensively studied for food packaging due to its favourable properties. Furthermore, Ch/starch-based film categorised as promising candidate for the eco-friendly property, biocompatible and easily modified (Gopi et al., 2019; Pavoni et al., 2019).

The implementation of green chemistry principles is important for minimising the residual waste in the packaging production (Sohail et al., 2019). Sustainable food packaging should consider environmental, economic and social interests (Fadlallah et al., 2021). This study aims to develop a Ch/starch/GO film for coating C. annum and observing the shelf-life behaviour during 18 days of storage period. The film's properties were evaluated to determine its characteristic. The study also assessed the environmental impact during fabrication process using green metrics approach, including mass intensity, solvent intensity, reaction mass efficiency and E factor.

Experimental section

Materials

Chitosan (Ch) with medium molecular weight (20.0–50.0 kDa). Dioscorea alata (Da), Dioscorea hispida (Dh) and Dioscorea esculenta (De) was purchased from Yogyakarta Local Market. Glycerol and GO were acquired from Agung Jaya. Distilled water and acetic acid 100% were obtained from Sigma-Aldrich® Co, Singapore, Singapore. The bacterial strains were provided by Microbiology Laboratory, Faculty of Medicine, Sebelas Maret University, Indonesia.

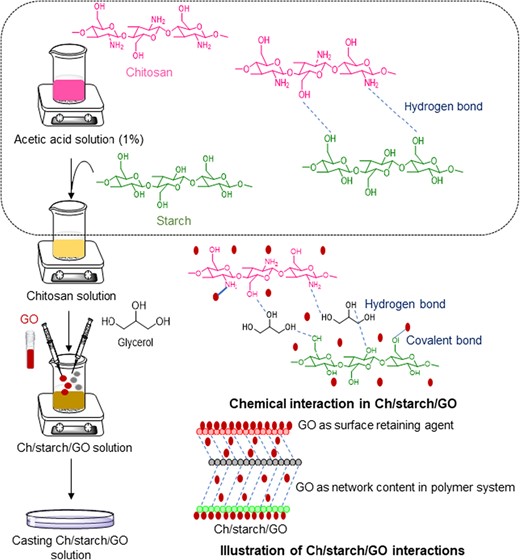

Preparation of Ch/starch film

The Ch/starch coating was prepared by casting and dehydration method (Istiqomah et al., 2022c). The general preparation of Ch/starch/GO is following Fig. 1. Ch (2% w/v) was dissolved in 100 mL of 1% (v/v) acetic acid. The Dioscorea sp. starch namely, Da (1% w/v), De (1.5% w/v) and Dh (1.5% w/v) was homogenised in Ch solution under heating conditions at its gelatinisation time and temperature. The gelatinisation time and temperature of each starch consisting of Da, De and Dh were reached at 12.87 min; 83.30 °C, 7.67 min; 78.85 °C and 7.07 min; 78.45 °C, respectively. The solution was cooled to ambient room temperature (28 °C), then 1.5% (v/v) glycerol and 0.5% (v/v) GO were added to the solution mixture (Tomadoni et al., 2019). Then, the current solution was homogenised through sonication method at 6000 r.p.m. for 2 min and leave it overnight. The mixture was poured on a Petri dish and dried using an oven at 30 °C for 24 h and leave it in the room temperature for the next 24 h.

Characterisation of Ch/starch-based film

Ch/starch-based films underwent various characterisation tests. The physical properties were assessed through water solubility testing and measurement of hydrophobicity through the contact angle (CA). Chemical analysis was performed using FTIR analysis. Mechanical properties were evaluated by observing parameters such as tensile strength, elongation at break and Young's modulus. Thermal properties were measured using the thermogravimetric analysis (TGA-DSC). Additionally, antioxidant analysis was conducted using the DPPH method, and antibacterial analysis was tested on four types of bacteria, including E. coli, S. typhi, S. aureus and S. epidermidis. To obtain a more comprehensive understanding, please refer to the Appendix S1.

Shelf life study

In the shelf life study on C. annum, sterilised fruits of similar size and weight were coated using a dipping method with a Ch/starch/GO solution. The fruit mass was monitored every 2 days, and the percentage of mass loss was calculated. Visual examination was performed at three-day intervals. Additionally, bacterial growth analysis was conducted using the total visible count (TVC) method. For a detailed description, kindly check the Appendix S1.

Green metrics assessment

The green metrics approach on the development of Ch/starch/GO films was determined by calculating several green aspects including mass intensity, water intensity, reaction mass efficiency and E factor. The determination of its following aspects was following eq. S4-S7.

Result and discussion

FTIR analysis

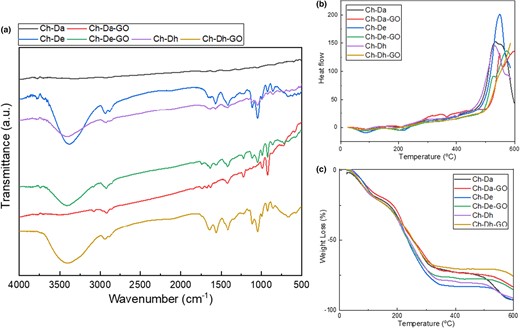

Figure 2a compares the collected spectra. Ch/starch films shows a wide peak of OH bond at 3295–3401 cm−1 due to Ch/starch interactions (Kaya et al., 2018a). The peak of CH stretch increases at 2927–2936 cm−1, amide I recorded at 1570–1582 cm−1, while amide III (1392–1410 cm−1) were enhanced by the effect of molecular interactions, especially from the original structure of Ch/starch chain (Kaya et al., 2018b). Ch/starch/GO spectrum exhibits a primary band at 3390–3416 cm−1, representing overlap of OH and NH stretches influenced by hydrogen bond. CH alkenes from GO are observed at 709–751 cm−1. The C-O stretching peak slightly shifts to a higher frequency due to polymer matrix interaction. Amide I, amide II and amide III are identified at 1635–1641 cm−1, 1562 cm−1 and 1414–1417 cm−1, respectively, with differences in hydrogen formation between NH2 and CH, OH groups from GO causing expansion and shift of amide II, and influencing amide III.

FTIR spectra (a), DSC (b) and TGA thermogram (c) of Ch/starch-based films.

Hydrophobicity analysis

The chemical substances in EO affect the hydrophobicity index of Ch/starch films (Shen & Kamdem, 2015). The physical properties of the films are displayed in Table 1. Contact angle (CA) reflects the hydrophobicity/hydrophilicity of the material surface, which indirectly affects the WS value. A CA value of more than 90° indicates a hydrophobic material, while a value lower than lower than 90° defines as hydrophilic (Yuan & Lee, 2013). The CA value of Ch/starch-based films lies in the range of 53.5–58.2°. These results were lower than Ch/starch/GO films (95.7–101.2°), mainly due to the hydrophobic backbone of the Ch chain. Moreover, the presence of GO reduces hydrogen bonds in the polymer environment (Fig. 2a), resulting in increasing the hydrophobic properties (Leceta et al., 2013).

| Ch-based films . | Parameters . | |||||

|---|---|---|---|---|---|---|

| T (mm) . | WS (%) . | CA (o) . | TS (MPa) . | EB (mm) . | YM (MPa) . | |

| Ch-Da | 0.22 | 20.87 | 53.50 | 5.65 | 3.57 | 8.10 |

| Ch-Da-GO | 0.37 | 10.11 | 95.70 | 12.96 | 3.99 | 21.10 |

| Ch-De | 0.23 | 23.78 | 58.20 | 2.50 | 2.70 | 2.68 |

| Ch-De-GO | 0.34 | 14.76 | 101.20 | 2.87 | 3.79 | 2.91 |

| Ch-Dh | 0.26 | 28.54 | 52.10 | 4.35 | 1.77 | 19.25 |

| Ch-Dh-GO | 0.43 | 11.26 | 98.50 | 6.67 | 2.90 | 20.36 |

| Ch-based films . | Parameters . | |||||

|---|---|---|---|---|---|---|

| T (mm) . | WS (%) . | CA (o) . | TS (MPa) . | EB (mm) . | YM (MPa) . | |

| Ch-Da | 0.22 | 20.87 | 53.50 | 5.65 | 3.57 | 8.10 |

| Ch-Da-GO | 0.37 | 10.11 | 95.70 | 12.96 | 3.99 | 21.10 |

| Ch-De | 0.23 | 23.78 | 58.20 | 2.50 | 2.70 | 2.68 |

| Ch-De-GO | 0.34 | 14.76 | 101.20 | 2.87 | 3.79 | 2.91 |

| Ch-Dh | 0.26 | 28.54 | 52.10 | 4.35 | 1.77 | 19.25 |

| Ch-Dh-GO | 0.43 | 11.26 | 98.50 | 6.67 | 2.90 | 20.36 |

CA, contact angle; EB, elongation at break; T, thickness; TS, tensile strength; WS, water solubility; YM, young modulus.

| Ch-based films . | Parameters . | |||||

|---|---|---|---|---|---|---|

| T (mm) . | WS (%) . | CA (o) . | TS (MPa) . | EB (mm) . | YM (MPa) . | |

| Ch-Da | 0.22 | 20.87 | 53.50 | 5.65 | 3.57 | 8.10 |

| Ch-Da-GO | 0.37 | 10.11 | 95.70 | 12.96 | 3.99 | 21.10 |

| Ch-De | 0.23 | 23.78 | 58.20 | 2.50 | 2.70 | 2.68 |

| Ch-De-GO | 0.34 | 14.76 | 101.20 | 2.87 | 3.79 | 2.91 |

| Ch-Dh | 0.26 | 28.54 | 52.10 | 4.35 | 1.77 | 19.25 |

| Ch-Dh-GO | 0.43 | 11.26 | 98.50 | 6.67 | 2.90 | 20.36 |

| Ch-based films . | Parameters . | |||||

|---|---|---|---|---|---|---|

| T (mm) . | WS (%) . | CA (o) . | TS (MPa) . | EB (mm) . | YM (MPa) . | |

| Ch-Da | 0.22 | 20.87 | 53.50 | 5.65 | 3.57 | 8.10 |

| Ch-Da-GO | 0.37 | 10.11 | 95.70 | 12.96 | 3.99 | 21.10 |

| Ch-De | 0.23 | 23.78 | 58.20 | 2.50 | 2.70 | 2.68 |

| Ch-De-GO | 0.34 | 14.76 | 101.20 | 2.87 | 3.79 | 2.91 |

| Ch-Dh | 0.26 | 28.54 | 52.10 | 4.35 | 1.77 | 19.25 |

| Ch-Dh-GO | 0.43 | 11.26 | 98.50 | 6.67 | 2.90 | 20.36 |

CA, contact angle; EB, elongation at break; T, thickness; TS, tensile strength; WS, water solubility; YM, young modulus.

Thermal analysis

The presence of GO in the coating affects the endothermic peaks, indicating a stable interaction on Ch/starch/GO films (Fig. 2b). This phenomenon is associated with lower water availability and partial gelatinisation of the starches (Ji et al., 2017). Ch/starch films exhibits a single endothermic peak around 540 °C–560 °C, while Ch/starch/GO exhibits double endothermic peaks at 550 °C–570 °C and 600 °C, respectively. The first peak is associated with water evaporation. The degradation stage of Ch/starch and Ch/starch/GO films is slightly shifted due to the difference in hydrogen bonding intensity and stable covalent bonding between GO and Ch/starch chain, resulting in reduced water mobility (Da Róz et al., 2011). GO and glycerol are considered to control the mobility in the polymer environment due to the chemical distribution of the starch chain into the Ch interlayer (Geng et al., 2015). Ch/starch/GO films exhibits a lower weight loss rate in the TGA graph (Fig. 2c), indicating lower moisture absorption and better thermal stability. However, the degradation process shows a similar pattern in three stages: the first stage at 50 °C–100 °C due to water and solvent evaporation, the second stage at 100 °C–200 °C due to glycerol degradation, Ch chain decomposition and evaporation of volatile substances in GO. The weight loss of Ch/starch/GO in the second stage is lower than Ch/starch, possibly due to stronger chemical bond formation between matrices in Ch/starch/GO. GO also increases chemical interactions on covalent bonds between its chemical substances with Ch/starch environment (Kadam et al., 2019; Zhang & Jiang, 2020). The final degradation occurs at 200 °C–300 °C, caused by depolymerisation of the Ch-chain and GO substances (Kaya et al., 2018a).

Mechanical properties

GO improves the mechanical properties of Ch/starch-based films (Table 1). Ch/starch films are theoretically expected to exhibit stable and strong mechanical properties due to their stiffness and elasticity. The presence of EO further strengthens the adhesion force in Ch/starch films by filling the 3D network. The mixing process initiate the protonation of the amino group at subcritical conditions, thus facilitating the hydrogen bonding with the starch chain (Angles & Dufresne, 2001; Babaee et al., 2015). Furthermore, cross-linking interactions and covalent bonds with the chemical substances in GO result in a stronger and firmer polymer structure. Moreover, cross-linking bonds reduce the free volume in the polymer structure and its molecular mobility. The EB (elongation at break) increases with the inclusion of GO, indicating increased discontinuity in the polysaccharide network after its incorporation (Valizadeh et al., 2019; Esmaeili et al., 2020; Rong et al., 2023).

Antioxidant activity

An active chemical substances in GO leads to physiological effects in various metabolic pathways on determining the antioxidant activity. As shown in Table 2, Ch/starch films has lower antioxidant activity compared to Ch/starch/GO films due to its stable macromolecular formation through amino residue and free radicals (Ruiz-Navajas et al., 2013). The Ch/starch/GO films experiences the protonation of -NH2 to -NH3+ during radical attacks (Yen et al., 2008). In addition, cross-linking by glycerol prevent the early explosive release of chemical substances from GO (Garavand et al., 2020; Istiqomah et al., 2022b). In addition, the different sources of starch contribute to variations in the antioxidant activity due to its physicochemical properties. Each starch contains unique bioactive compounds, which directly impact the biological activity. Additionally, differences in starch structures, such as branching and molecular weight, affect the release of these bioactive compounds (Istiqomah et al., 2022a).

| Materials . | Antioxidant activity (%) . | Inhibition zone (mm) . | |||

|---|---|---|---|---|---|

| E. coli . | S. typhi . | S. aureus . | S. epidermidis . | ||

| Ch-Da | 25.81 | 0 | 0 | 11.73 | 0 |

| Ch-Da-GO | 35.78 | 7.10 | 7.98 | 22.49 | 21.37 |

| Ch-De | 41.87 | 7.64 | 0 | 10.07 | 9.87 |

| Ch-De-GO | 42.88 | 13.23 | 8.78 | 18.02 | 20.25 |

| Ch-Dh | 28.75 | 7.43 | 7.08 | 16.67 | 12.43 |

| Ch-Dh-GO | 36.57 | 14.49 | 12.16 | 24.09 | 24.17 |

| Materials . | Antioxidant activity (%) . | Inhibition zone (mm) . | |||

|---|---|---|---|---|---|

| E. coli . | S. typhi . | S. aureus . | S. epidermidis . | ||

| Ch-Da | 25.81 | 0 | 0 | 11.73 | 0 |

| Ch-Da-GO | 35.78 | 7.10 | 7.98 | 22.49 | 21.37 |

| Ch-De | 41.87 | 7.64 | 0 | 10.07 | 9.87 |

| Ch-De-GO | 42.88 | 13.23 | 8.78 | 18.02 | 20.25 |

| Ch-Dh | 28.75 | 7.43 | 7.08 | 16.67 | 12.43 |

| Ch-Dh-GO | 36.57 | 14.49 | 12.16 | 24.09 | 24.17 |

| Materials . | Antioxidant activity (%) . | Inhibition zone (mm) . | |||

|---|---|---|---|---|---|

| E. coli . | S. typhi . | S. aureus . | S. epidermidis . | ||

| Ch-Da | 25.81 | 0 | 0 | 11.73 | 0 |

| Ch-Da-GO | 35.78 | 7.10 | 7.98 | 22.49 | 21.37 |

| Ch-De | 41.87 | 7.64 | 0 | 10.07 | 9.87 |

| Ch-De-GO | 42.88 | 13.23 | 8.78 | 18.02 | 20.25 |

| Ch-Dh | 28.75 | 7.43 | 7.08 | 16.67 | 12.43 |

| Ch-Dh-GO | 36.57 | 14.49 | 12.16 | 24.09 | 24.17 |

| Materials . | Antioxidant activity (%) . | Inhibition zone (mm) . | |||

|---|---|---|---|---|---|

| E. coli . | S. typhi . | S. aureus . | S. epidermidis . | ||

| Ch-Da | 25.81 | 0 | 0 | 11.73 | 0 |

| Ch-Da-GO | 35.78 | 7.10 | 7.98 | 22.49 | 21.37 |

| Ch-De | 41.87 | 7.64 | 0 | 10.07 | 9.87 |

| Ch-De-GO | 42.88 | 13.23 | 8.78 | 18.02 | 20.25 |

| Ch-Dh | 28.75 | 7.43 | 7.08 | 16.67 | 12.43 |

| Ch-Dh-GO | 36.57 | 14.49 | 12.16 | 24.09 | 24.17 |

Antibacterial activity

GO has been evaluated for its antibacterial properties against four types of bacteria (E. coli, S. typhi, S. aureus and S. epidermidis) with inhibition zones of 10.42 ± 3.57, 9.85 ± 1.22, 16.87 ± 1.01 and 18.82 ± 2.04 cm, respectively, indicating strong antibacterial activity. Ch/starch/GO coatings exhibit antibacterial activity against selected bacterial strains (Table 2). The inhibitory effect on Ch/starch-based films is attributed to the interaction between the Ch-chain and bacterial membranes, causing leakage of intracellular contents (Valizadeh et al., 2019). Ch/starch/GO films shows the highest inhibitory activity due to the penetration of hydrophobic material into bacterial phospholipid bilayers (Ojagh et al., 2010; Peng & Li, 2014). Additionally, GO also inhibits cellular respiration through enzyme influence. Previous research has shown successful use of GO as an antibacterial agent against other bacteria (Shah et al., 2021).

Shelf life study

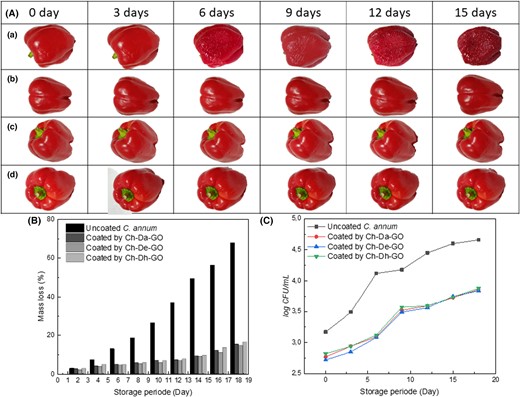

In the shelf-life study, surface spoilage, mass loss and TVC test are compared between uncoated and coated samples. Uncoated C. annum exhibits organoleptic changes including smell, appearance and texture, as well as mass loss and bacterial spoilage during the 18-day storage period. In contrast, coated C. annum exhibits stable organoleptic appearance and reduced mass loss. The coatings demonstrate antioxidant and antibacterial activity, effectively preventing free radicals and food-borne bacteria. As shown in Fig. 3, the mass loss study reveals that uncoated C. annum experiences a higher mass loss percentage (56.42% on the 16th day), indicating rapid senescence and decomposition due to external water and gas transfer. Coated pepper demonstrates improved mass loss profiles (15.37%, 14.72%, 16.47% on the last day for Ch-Da-GO, Ch-De-GO, Ch-Dh-GO, respectively), indicating enhanced water-barrier properties of Ch/starch/GO coating due to the formation of a cross-linked network, which blocks the transfer of environmental disturbances (Salama & Abdel Aziz, 2021).

(A) Visual examination of uncoated (a), coated by Ch-Da-GO (b), coated by Ch-De-GO (c), and coated by Ch-Dh-GO, (B) Mass loss study and (C) TVC test during storage period.

Ch/starch/GO coating inhibits bacterial growth in C. annum during the storage period, while uncoated C. annum experiences spoilage on the 6th day with surface spoilage observed on the last day. Coated C. annum demonstrates lower TVC (3.84–3.88 log CFU mL−1) compared to uncoated one (4.66 log CFU mL−1) during storage. The chemical substances in GO, with conjugated π-bond systems and electron donation properties, inhibit radical activities, contributing to radical-shielding protection (Mondal et al., 2019; Salama & Abdel Aziz, 2021).

Green metrics assessment

Raw materials

The green metrics assessment evaluates qualitative and quantitative aspects of materials and the fabrication process, including mass-based sustainability, social integrity and economic development (Mukherjee et al., 2020). In this study, renewable and biodegradable materials were used as raw materials. The coating production involved mechanical homogenisation, heat treatment for gelatinisation and chemical treatment with an acid solvent. The mass and water intensity were calculated to be 2.14–2.22 and 45.04–46.73, respectively, with a reaction mass efficiency of 42.80%–44.00%. The high solvent usage was due to the moderate solubility of Ch and starch, but optimising the material masses and reagent usage could improve the reaction mass efficiency and solubility (Table 3).

| Materials . | Mass intensity (kg kg−1) . | Solvent intensity (kg kg−1) . | Reaction mass efficiency (%) . | E-factor . |

|---|---|---|---|---|

| Ch-Da-GO | 2.14 | 46.73 | 42.80 | 1.34 |

| Ch-De-GO | 2.22 | 45.04 | 44.00 | 1.25 |

| Ch-Dh-GO | 2.18 | 45.87 | 43.60 | 1.29 |

| Materials . | Mass intensity (kg kg−1) . | Solvent intensity (kg kg−1) . | Reaction mass efficiency (%) . | E-factor . |

|---|---|---|---|---|

| Ch-Da-GO | 2.14 | 46.73 | 42.80 | 1.34 |

| Ch-De-GO | 2.22 | 45.04 | 44.00 | 1.25 |

| Ch-Dh-GO | 2.18 | 45.87 | 43.60 | 1.29 |

| Materials . | Mass intensity (kg kg−1) . | Solvent intensity (kg kg−1) . | Reaction mass efficiency (%) . | E-factor . |

|---|---|---|---|---|

| Ch-Da-GO | 2.14 | 46.73 | 42.80 | 1.34 |

| Ch-De-GO | 2.22 | 45.04 | 44.00 | 1.25 |

| Ch-Dh-GO | 2.18 | 45.87 | 43.60 | 1.29 |

| Materials . | Mass intensity (kg kg−1) . | Solvent intensity (kg kg−1) . | Reaction mass efficiency (%) . | E-factor . |

|---|---|---|---|---|

| Ch-Da-GO | 2.14 | 46.73 | 42.80 | 1.34 |

| Ch-De-GO | 2.22 | 45.04 | 44.00 | 1.25 |

| Ch-Dh-GO | 2.18 | 45.87 | 43.60 | 1.29 |

Emission residue

The production of Ch/starch/GO resulted in the discharge of non-harmful solvent and zero side products. The use of strong acid as a solvent or co-solvent was avoided in this manufacturing process. The environmental factor (E factor) was calculated to be 1.25–1.34, indicating minimal emissions. In this work, the raw materials were ensured to react with one another. However, the waste mixture on the side of the baker's glass could be easily removed with wash water, making it recyclable.

Disposal of waste

Ch/starch/GO coating can be applied as a one-cycle coating on vegetables or fruits for a limited storage period. Therefore, it can be easily disposed of through water leaching within a minute.

Toxicity potential

According to the European Chemicals Agency (ECHA), the raw materials used in this work are deemed safe for the human body and the environment. Ch, starch and GO are derived from natural resources and possess non-toxic characteristics, as they are biocompatible and biodegradable. Glycerol and acetic acid have also been proven to be food-grade materials. Therefore, the fabrication process should be undertaken with simple precautionary measures.

Affordability and social acceptance

A Ch/starch/GO solution (±500 mL) can effectively coat 18 C. annum fruits with weights ranging from 20 to 25 g. The optimised solution, costing less than $2 for 1 L of composite solution, demonstrates industrial-grade performance, making it an excellent and cost-effective coating option for vegetables and fruits. Considering the relevance of the social economy, food packaging based on natural resources is gaining attention due to concerns about environmental health and climate change. This eco-friendly food packaging has the potential to replace synthetic plastics and can gain social acceptance as a useful product for mitigating environmental impacts.

Conclusion

Ch/starch/GO film has shown immense potential as a sustainable solution for food packaging. The comprehensive characterisation conducted on this innovative coating has unequivocally demonstrated its outstanding performance across various parameters. Ch/starch/GO film exhibited a firm, denser, smoother and has hydrophobic surface. The incorporation of GO improved mechanical properties. The thermal stability of Ch/starch/GO film was enhanced and reduced mass loss. GO also imparted impressive antioxidant and antibacterial activities against E. coli, S. typhi, S. aureus and S. epidermidis, highlighting its potential for food preservation. Notably, the Ch/starch/GO showcased an impressive ability for coating the C. annum. During the storage period, Ch/starch/GO coating successfully inhibited bacterial growth and extended its shelf life 9 days longer compared to the uncoated ones. In the green metrics approach, the Ch/starch/GO demonstrates positive outcomes. The production process resulted in low emissions and minimal waste generation. Moreover, Ch/starch/GO coating is cost-effective, offering an affordable solution for food packaging. Its potential for mitigating environmental impacts and replace synthetic plastic contributes to its social acceptance as a valuable product in addressing concerns related to environmental health and climate change.

Acknowledgments

The authors are thankful to Directorate General Higher Education, Research and Technology, who provide financial support through Penelitian Dasar Unggulan Perguruan Tinggi Research Grant (469.1/UN27.22/PT.01.03/2022).

Author contributions

Triana Kusumaningsih: Conceptualization (equal); funding acquisition (equal); resources (equal); supervision (equal); writing – review and editing (equal). Annisa Istiqomah: Conceptualization (equal); data curation (equal); investigation (equal); methodology (equal); software (equal); validation (equal); writing – original draft (equal); writing – review and editing (equal). Maulidan Firdaus: Conceptualization (equal); data curation (equal); supervision (equal); validation (equal). Venty Suryanti: Supervision (equal); validation (equal).

Ethical statement

Ethics approval was not required for this research.

Peer review

The peer review history for this article is available at https://www.webofscience.com/api/gateway/wos/peer-review/10.1111/ijfs.16638.

Data availability statement

All data can be accessed in the manuscript and Appendix S1.

References

This research provide important information for our discussion.

This study provide comparative results for our study.

This research provide a sufficient background for our discussion.

This research provide important information for our discussion.