-

PDF

- Split View

-

Views

-

Cite

Cite

Mirosław Słowiński, Joanna Miazek, Krzysztof Dasiewicz, Aneta Cegiełka, An attempt to use a barley fibre preparation containing β-glucan in the production of functional canned meat, International Journal of Food Science and Technology, Volume 56, Issue 12, December 2021, Pages 6258–6267, https://doi.org/10.1111/ijfs.15335

Close - Share Icon Share

Abstract

Nutritional value and physical and sensory quality characteristics of medium-grounded model canned meat products containing barley fibre preparation Vitacel BG300 (0.0%, 3.0% and 6.0%) were assessed. The results showed that regardless of the type of thermal treatment (pasteurisation and sterilisation), the addition of barley fibre did not significantly (P > 0.05) alter the content of the main nutrients (protein, fat and chlorides) in the block of canned meat product. Increasing the dose of barley fibre from 3.0% to 6.0% significantly increased (P < 0.05) the thermal loss in both pasteurised and sterilised canned meat products. The colour of the blocks of both pasteurised and sterilised canned meat products with barley fibre was significantly (P < 0.05) darker, and the instrumental hardness differed from the corresponding control products. Despite the beneficial nutritional effect of the Vitacel BG300 barley fibre preparation, its use significantly deteriorated the sensory quality of canned meat products.

Introduction

Meat and meat products have traditionally been regarded as a source of easily digestible protein and fat, with the fatty acid profile of the meat depending on the animal species from which it was obtained (Laskowski et al., 2018). Currently, however, consumers also desire for other ingredients in meat products that would positively affect their health. One such ingredient, not present in traditional meat products, is dietary fibre, which is added to reformulated meat products in the form of various preparations (Karwowska et al., 2021).

Among fibre preparations, oat and barley fibre preparations derived from grains deserve special attention. This is because of the high content of β-glucan, which is a component of the water-soluble dietary fibre, in these grains (Elleuch et al., 2011; Hu et al., 2015). The content of β-glucan in barley and oat grains is 2.0−10.0 and 2.0−8.0 g per 100 g dry matter, respectively (Krupińska & Zegan, 2013). The source of β-glucan could also be fungi of the class Basidiomycetes and Saccharomyces (e.g. Saccharomyces cerevisiae). Its presence has also been reported in bamboo, algae, and even in the cell wall of some pathogenic bacteria (Jurczyńska et al., 2012). The source of origin of this compound determines the structure of the polymer chain, the frequency of occurrence and type of specific chemical bonds, and consequently its biological activity (Jurczyńska et al., 2012; Krupińska & Zegan, 2013; Hu et al., 2015). Physicochemical and technological properties of β-glucans, such as structure, molar mass, degree of chain branching, viscosity, water solubility and biological activity, depend not only on their source of origin but also on the conditions of their extraction (i.e. the method of extraction) as well as on the method of processing and storage of food produced with the addition of fibre preparation (Mathee & Appledorf, 1978; Gibiński, 2008; Ahmad et al., 2009; Lange, 2010).

The purpose of using dietary fibre preparations in the technology of meat products is quite complex. It, however, also involves increasing the nutritional value of various types of meat products (Biswas et al., 2011; Mehta et al., 2018; Zinina et al., 2019). To accomplish this, fibre preparations are added as bioactive ingredients to meat and fat raw materials during the manufacturing process, which results in a meat product that can be labelled with a health or nutrition claim (Regulation, 2006; Verma & Banerjee, 2010). Apart from providing the physiological and health benefits related to the incorporation of dietary fibre into meat products, various technological properties of fibre preparations are usually used simultaneously to modify the physicochemical characteristics of meat products (Huang et al., 2011; Hussein 2015; Apostu et al., 2017; Mehta et al., 2018; Vasquez Mejía et al., 2019; Zinina et al., 2019; Szpicer et al., 2020).

Because of the need to assess the possibility of enriching meat products with ß-glucan as described earlier, attempts have been made for several years to use oat and barley fibre preparations on an industrial scale (Huang et al., 2011; Hussein 2015; Vasquez Mejía et al., 2019; Szpicer et al., 2020). This component, in addition to having physiological properties typical of dietary fibre, also exhibits functional properties of viscous and gel-forming hydrocolloids. Solubility of oat and barley fibre in water and its specific rheological properties in the aqueous solution and in the gel state are determined by its molecular characteristics (structure, molecular weight and conformation) as well as temperature and concentration in solution (Delaney et al., 2003; Gibiński, 2008; Lange, 2010; Alvarez & Barbut, 2013; Hu et al., 2015).

Previous studies have shown that a good option is to use oat hydrolysates as fat replacers, as they can be used in the production of low-fat yogurt, mayonnaise, shortcrust pastries, or even homogenised frankfurter-type sausages or beef burgers without compromising their sensory and rheological qualities (Pinero et al., 2008; Alvarez & Barbut, 2013; Szpicer et al., 2020). Another possibility of the application of fibre preparations rich in β-glucan in meat products is to use them as components of coating dough (Lee & Inglett, 2007) or brine components (Vasquez Mejía et al., 2019). An interesting alternative is also the use of yeast β-glucans in meat batter reformulations in order to modify their technological and sensorial characteristics (Apostu et al., 2017).

On the basis of the above information regarding the functional properties of β-glucan-containing fibre preparations, it seemed appropriate to make an attempt to use this type of preparation for canned meat products. Canned meat products can be considered as convenient food products that are liked by consumers, which justifies the improvement of their nutritional value. This study aimed to evaluate the effect of the addition of a barley fibre preparation containing ß-glucan in the amount of 3.0% and 6.0% on the nutritional value, physical and sensory quality characteristics of medium-grounded pasteurised and sterilised model canned meat products.

Materials and methods

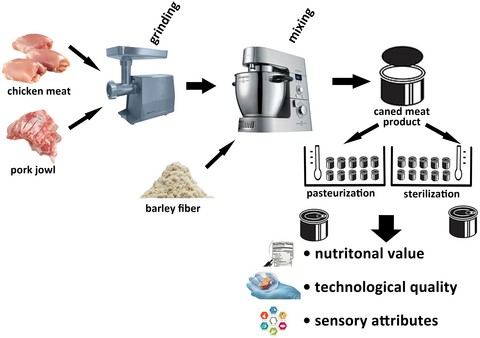

Production process of model canned meat products.

The study materials were model canned meat products. The raw materials for the production of meat products in cans were chilled (4 °C ± 1 °C) chicken thigh meat and pork jowl, and a barley fibre preparation.

Three series of experiments were conducted, during which three variants of batters for canned products were produced with the following composition: chicken thigh muscles 57.60%, pork jowl 10.20%, ice 30.50%, nitrite curing salt 1.20% (Promar PPH Sp. z o.o., Zawiercie, Poland), sodium isoascorbate 0.04% (Promar PPH Sp. z o.o.), polyphosphate preparation (Tari P31; BK Giulini GmbH, Ladenburg, Germany) 0.23% and seasoning mix (black pepper and herbal pepper) 0.23% (Kamis, McCormick Polska S.A., Stefanowo, Poland). One of the three meat batters did not contain the fibre preparation. The barley fibre preparation Vitacel BG300 (J. Rettenmeier & Söhne GmbH+Co. KG, Rosenberg, Germany) was added to the other two batters with the above composition in the amount of 3.0% or 6.0% by weight of the batter.

This research project is a part of a broader project on the application of food fibre preparations in the production of canned meat. One of the aims of this research project was to assess the possibility of producing canned meat product that would qualify for labelling with the nutritional claim ‘source of dietary fibre’ or ‘high content of dietary fibre’ based on the requirements of food law (Regulation, 2006). The influence of various fibre preparations on selected quality characteristics of canned meat products was reported by Słowiński et al., (2020, 2021). All fibre preparations assessed in this project, including the Vitacel BG300 barley fibre preparation, were added to the batters of canned meat products in the amount of 3.0% and 6.0% by weight of the batter.

Six treatments of model canned meat products were produced from three meat batters: CON-P—pasteurised product without the addition of the barley fibre; BG300-3-P—pasteurised product with the addition of 3.0% of the barley fibre; BG300-6-P—pasteurised product with the addition of 6.0% of the barley fibre; CON-S—sterilised product without the addition of the barley fibre; BG300-3-S—sterilised product with the addition of 3.0% of the barley fibre; and BG300-6-S—sterilised product with the addition of 6.0% of the barley fibre.

To produce medium-grounded meat batters, chicken thigh muscles and pork jowl were separately ground in a Mesko WN60 laboratory grinder (Mesko AGD Sp. z o.o., Skarżysko-Kamienna, Poland) equipped with a mesh cutting set with 8-mm-diameter holes for shredding chicken thigh muscles and 3-mm-diameter holes for pork jowls. Each of the grounded raw materials was mixed and weighed according to the assumed recipe composition. They were then mixed in a Kenwood KM070 laboratory mixer (Kenwood Ltd., Havant, UK) by using a frame mixer. During the mixing process, the individual ingredients were added in the following order:

chicken thigh muscles + nitrite curing salt + polyphosphate preparation + water (mixing time was approximately 1 min),

+ barley fibre preparation + sodium isoascorbate + seasoning mix + pork jowl (mixing time was approximately 4 min, final temperature of the batter was below 12 °C).

Meat batters were packed into metal cans (76 mm in diameter and 56 mm in height) in the amount of 190 g ± 0.1 g. The cans were closed with a ‘double overlap’ using a semi-automatic closing machine (Nov-Handy Novopacké, Wahlstedt, Germany). For each product treatment, 10 cans were prepared.

The pasteurisation process was performed in a water bath (100 °C ± 1 °C; Merazet S.A., Poznań, Poland) until the temperature of the geometric centre of the product reached 72 °C (the canned meat products were heated for approximately 50 min, counting the time from the moment the water in the bath reached boiling point). After pasteurisation, the canned meat products were cooled in an ice-water bath. The sterilisation process was performed in an autoclave (Jugema, Środa Wielkopolska, Poland). The canned meat products were placed in the autoclave preheated to 95 °C, and the sterilisation process was conducted at 121 °C ± 1 °C until the sterilisation value F = 3 was reached in the geometrical centre of the product. From this moment, the cooling process in the autoclave began. When the products were cool enough to be taken out of the autoclave after sterilisation, an additional cooling process was performed in the ice-water bath.

After removal from the ice-water bath, both pasteurised and sterilised canned products were dried with a paper towel and then placed in a cold room (4 °C ± 1 °C) and stored for 24 h.

Evaluation of quality characteristics of model canned meat products

After 24 h of storage, the canned meat products were subjected to quality assessment, which included determination of basic chemical composition. The method of near-infrared reflectance transmission using calibration on artificial neural networks in a FoodScan™ 2 Meat Analyser (Foss Analytical A/S, Hillerød, Denmark) was used to determine water, protein, fat, collagen and chloride content. The measurements were performed according to the Polish Standard (2010). Before measurements, each product was minced in a laboratory grinder (Mesko AGD Sp. z o. o., Skarżysko-Kamienna, Poland), and approximately 180 g of the sample was placed in a glass cuvette that was a part of the analyser. The measurement results were read on the monitor of a computer linked to the analyser. The FoodScan™ 2 Meat Analyser calibrations are described in the brochure ‘FOSS Application note AN5436 Rev. 4 FoodScan™ 2 Meat and Meat Products’ (Foss Analytical A/S; data not published). Overall independent test set accuracy expressed as Standard Error of Prediction (SEP) corrected for bias was 0.78% for fat, 0.72% for moisture, 0.62% for protein, 0.40% for collagen and 0.42% for salt (based on sodium). The linear correlations (expressed as RSQ) between the FoodScan™ 2 result and the reference result are as follows: 0.99 for fat, 0.99 for moisture, 0.97 for protein, 0.74 for collagen and 0.90 for salt (based on sodium). The total dietary fibre content in canned meat products was determined by the gravimetric-enzymatic method AOAC.(1994). Analyses for determining the total fibre content of meat products were performed in an external laboratory.

The pH was measured using a CP-401 pH meter (Elmetron, Zabrze, Poland) equipped with a combined glass-calomel electrode and a temperature compensation sensor and calibrated with pH 4 and pH 7 buffers. Prior to performing the pH measurement, 10 g of minced meat product and 20 mL of distilled water were placed in a glass beaker. All the ingredients were thoroughly mixed, and the mixture was then left undisturbed for 10 min. The electrode and the temperature compensation sensor were inserted into the solutions to be analysed, and the measurement result was read on the display of the pH meter. Water activity was measured using an AQUALAB 4TM apparatus (MeterFood, Pullman, WA, USA). The analysis was performed at 20.0 °C ± 1.0 °C. The samples for measurement were flat disks (approximately 5 mm in height and 20 mm in diameter) cut from the centre of the meat product block.

Thermal loss in canned meat products was determined by a weight method based on the leakage of mass from the canned meat product block during thermal treatment. For this purpose, the cans with meat products were opened on both sides, and the meat block was pushed out and weighed. The meat block was then cleaned by scraping the jelly and fat with a knife and weighed again. The result was expressed as a percentage in relation to the net weight of the canned meat batter. Colour parameters were measured in the CIEL*a*b* scale (Commission Internationale de l'Eclairage, 1986) by using a reflectance method and a Konica Minolta CR-200 spectrophotometer (Minolta Osaka, Japan; light source D65, observer angle 10°, measuring head hole of 8 mm), calibrated according to white standard (L* 99.18, a* - 0.07, b* - 0.05). To evaluate changes in the colour of canned meat products resulting from the addition of the tested barley fibre preparations and the applied thermal treatment, the so-called absolute colour difference (ΔE) was also used (International Commission on Illumination, 1986). The value of ΔE for the pasteurised (BG300-3-P and BG300-6-P) and sterilised (BG300-3-S and BG300-6-S) meat products was calculated in relation to the relevant control treatments, i.e. CON-P and CON-S, respectively. The value of ΔE gives the possibility to evaluate the differences in colour between two products as it is defined based on the perception of colours by the human eye. It is assumed that the value of the absolute difference in colour ΔE within the range of 0–2 indicates the inability to visually recognise the difference with the human visual sense, values between 2 and 3.5 allow an inexperienced observer to recognise the difference, values above 3.5 indicate a clear difference in colour, while values above 5 indicate that the observer has the impression of two different colours.

Prior to texture measurement, closed cans with meat products were conditioned at 20 °C for 4 h to align the temperature. Texture parameters of canned meat products were measured using a Zwicki 1120 texture analyser (Zwick GmbH & Co, Ulm, Germany). Texture Profile Analysis (TPA) was performed using a flat adapter, i.e. two parallel steel plates. The samples for texture measurements were cylinders (10 mm in diameter and 20 mm in height) cut from a block of meat product. The samples were compressed twice, and the head speed was 50 mm min−1. During the first cycle of compression, the sample was 30% deformed. Once initiated, the second cycle continued until this value decreased upon sample deformation. A testXpert software (v.12.0, 2006, Zwick GmbH & Co., Ulm, Germany) was used to calculate the values of the following parameters: cohesiveness, springiness, hardness and chewiness. Cohesiveness was calculated as the ratio between the work performed during the second compression and the work performed during the first compression; springiness was defined as the ratio between the second peak base and the first peak base; hardness was determined as the maximum force value (N) at the first sample compression; and chewiness (N) was calculated as the product of hardness, cohesiveness and springiness.

The chemical and physical analyses of canned meat products, except for colour measurements, were performed on three samples taken from three different cans for each variant of the product in each of the three production series. For each analysis, the mean value was considered as the result. For colour measurements, for each variant of the product in each production series, each measurement was performed five times on three samples taken from three different cans.

Assumptions for sensory evaluation were adopted according to Baryłko-Pikielna & Matuszewska (2009). Sensory evaluation of model canned meat products was conducted by a trained panel comprising eight persons of both sexes, in the age of 24 to 40 years, who were trained for the evaluated parameters. First, the canned meat products were subjected to conditioning at ambient temperature for 2 h, and product samples for sensory evaluation were then prepared. Approximately 20-mm-thick slices cut from the products were placed on white dishes and identified with random three-digit numbers. A 10-point scale was used by the sensory panel, where 0 indicated no acceptance at all and 10 indicated the highest level of product acceptance based on the following sensory quality characteristics: general appearance, colour on the cross-section, aroma, palatability, consistency and general desirability. The mean values were calculated based on individual results for each sensory descriptor.

The obtained results were statistically analysed by StatisticaTM v.12 software (StatSoft Inc., Tulsa, OK, USA). Prior to performing statistical tests, the Shapiro–Wilk test and the Leven test were used to examine the normality of data distribution and to determine the homogeneity of variance, respectively. One-way analysis of variance (one-way ANOVA) and Tukey’s HSD test were used to determine the significance of differences between the average values of quality characteristics of model canned meat products and to verify the significant differences between treatments. All calculations were performed at the significance level of α = 0.05.

Results and discussion

The barley fibre preparation Vitacel BG300 used in this study is made from barley grains. It contains a minimum of 54% dietary fibre, approximately 18% protein, approximately 2% fat and a maximum of 3% ash. The fibre fraction is composed of 19% water-insoluble fibre and 35% water-soluble fibre. A characteristic feature of this preparation is the content of at least 23% of β-glucan in dry matter, which is a component of the water-soluble fibre fraction. This preparation is light brown in colour with cereal taste and smell. According to the manufacturer’s declaration (Safety Data Sheet of Rettenmaier & Sohne GmbH+Co; data not published), the pH of a 10% solution of the preparation is between 4.5 and 6.5. Thus, this preparation differs significantly from other fibre preparations used in the meat industry, including wheat fibre, which is white in colour, is tasteless and odourless and contains at least 97% water-insoluble fibre in dry matter. However, because of the presence of β-glucan fraction in the Vitacel BG300 preparation, meat products made with its addition may have prebiotic features and thus have a beneficial effect on the health of people consuming them (Mehta et al., 2018).

Regardless of the type of thermal treatment used, the model canned meat products manufactured with the barley fibre preparation Vitacel BG300 did not differ significantly (P > 0.05) in terms of protein, fat and collagen content as compared to canned products without this fibre preparation (Table 1). However, for the 6.0% preparation addition (treatments: BG300-6-P and BG300-6-S), a significant (P < 0.05) decrease in water content was observed as compared to that for the relevant control treatments (CON-P and CON-S; Table 1). The model canned meat products had relatively low content of fat and chlorides. The fat content in the canned meat products was below 10%, and the chloride content did not exceed 2%, regardless of the amount of barley fibre added and the type of heat treatment applied. Thus, it can be assumed that the addition of this type of dietary fibre preparation to medium-grounded canned meat product does not cause significant changes in the content of basic chemical components that are particularly important from the nutritional point of view. Canned meat is a product whose nutritional value depends mainly on the type, quality and content of meat and fat components. For a ‘traditional’ canned meat product, the nutritional value depends mainly on the content and amino acid composition of the protein, which in turn depends on the content of myofibrillar proteins. The nutritional value of canned food can be increased by modifying the recipe composition, e.g. by adding nutritious ingredients (Słowiński et al., 2020). These ingredients include dietary fibre containing β-glucan. In a previous study on the quality of model homogenised sterilised canned meat made with the addition of wheat fibre preparations of various fibre lengths used in the amount of 3.0% or 6.0% of the weight of the batter, no effect of the type or amount of fibre was observed on the content of chemical components such as water, protein, fat, collagen and salt (Słowiński et al., 2020).

Basic chemical components determining the nutritional value of medium-grounded pasteurised and sterilised model canned meat products (mean ± standard deviation; n = 3)

| Quality characteristic . | Pasteurization . | Sterilization . | ||||

|---|---|---|---|---|---|---|

| CON-P . | BG300-3-P . | BG300-6-P . | CON-S . | BG300-3-S . | BG300-6-S . | |

| Water content (%) | 73.9 a ± 0.8 | 72.3 ab ± 1.2 | 69.9 b ± 0.5 | 74.7 A ± 0.5 | 73.2 AB ± 1.4 | 70.6 B ± 1.3 |

| Protein content (%) | 13.5 a ± 0.1 | 13.6 a ± 0.4 | 14.1 a ± 0.6 | 13.1 A ± 0.6 | 13.1 A ± 0.4 | 13.8 A ± 0.7 |

| Collagen content (%) | 1.5 a ± 0.3 | 1.8 a ± 0.4 | 1.7 a ± 0.3 | 1.8 A ± 0.2 | 1.9 A ± 0.3 | 1.9 A ± 0.2 |

| Fat content (%) | 8.8 a ± 0.6 | 9.1 a ± 1.1 | 9.7 a ± 0.7 | 8.6 A ± 1.0 | 8.2 A ± 1.9 | 9.0 A ± 1.2 |

| Chloride content (%) | 1.9 a ± 0.0 | 1.9 a ± 0.0 | 1.9 a ± 0.0 | 1.9 A ± 0.0 | 1.9 A ± 0.0 | 2.0 A ± 0.0 |

| Quality characteristic . | Pasteurization . | Sterilization . | ||||

|---|---|---|---|---|---|---|

| CON-P . | BG300-3-P . | BG300-6-P . | CON-S . | BG300-3-S . | BG300-6-S . | |

| Water content (%) | 73.9 a ± 0.8 | 72.3 ab ± 1.2 | 69.9 b ± 0.5 | 74.7 A ± 0.5 | 73.2 AB ± 1.4 | 70.6 B ± 1.3 |

| Protein content (%) | 13.5 a ± 0.1 | 13.6 a ± 0.4 | 14.1 a ± 0.6 | 13.1 A ± 0.6 | 13.1 A ± 0.4 | 13.8 A ± 0.7 |

| Collagen content (%) | 1.5 a ± 0.3 | 1.8 a ± 0.4 | 1.7 a ± 0.3 | 1.8 A ± 0.2 | 1.9 A ± 0.3 | 1.9 A ± 0.2 |

| Fat content (%) | 8.8 a ± 0.6 | 9.1 a ± 1.1 | 9.7 a ± 0.7 | 8.6 A ± 1.0 | 8.2 A ± 1.9 | 9.0 A ± 1.2 |

| Chloride content (%) | 1.9 a ± 0.0 | 1.9 a ± 0.0 | 1.9 a ± 0.0 | 1.9 A ± 0.0 | 1.9 A ± 0.0 | 2.0 A ± 0.0 |

Treatments: CON-P—pasteurised product without the addition of the barley fibre; BG300-3-P—pasteurised product with the addition of 3.0% of the barley fibre; BG300-6-P—pasteurised product with the addition of 6.0% of the barley fibre; CON-S—sterilised product without the addition of the barley fibre; BG300-3-S—sterilised product with the addition of 3.0% of the barley fibre; BG300-6-S—sterilised product with the addition of 6.0% of the barley fibre; a, b, c—means within the same row with different superscript letters differ significantly (P ≤ 0.05) among pasteurised treatments; A, B, C—means within the same row with different superscript letters differ significantly (P ≤ 0.05) among sterilised treatments

Basic chemical components determining the nutritional value of medium-grounded pasteurised and sterilised model canned meat products (mean ± standard deviation; n = 3)

| Quality characteristic . | Pasteurization . | Sterilization . | ||||

|---|---|---|---|---|---|---|

| CON-P . | BG300-3-P . | BG300-6-P . | CON-S . | BG300-3-S . | BG300-6-S . | |

| Water content (%) | 73.9 a ± 0.8 | 72.3 ab ± 1.2 | 69.9 b ± 0.5 | 74.7 A ± 0.5 | 73.2 AB ± 1.4 | 70.6 B ± 1.3 |

| Protein content (%) | 13.5 a ± 0.1 | 13.6 a ± 0.4 | 14.1 a ± 0.6 | 13.1 A ± 0.6 | 13.1 A ± 0.4 | 13.8 A ± 0.7 |

| Collagen content (%) | 1.5 a ± 0.3 | 1.8 a ± 0.4 | 1.7 a ± 0.3 | 1.8 A ± 0.2 | 1.9 A ± 0.3 | 1.9 A ± 0.2 |

| Fat content (%) | 8.8 a ± 0.6 | 9.1 a ± 1.1 | 9.7 a ± 0.7 | 8.6 A ± 1.0 | 8.2 A ± 1.9 | 9.0 A ± 1.2 |

| Chloride content (%) | 1.9 a ± 0.0 | 1.9 a ± 0.0 | 1.9 a ± 0.0 | 1.9 A ± 0.0 | 1.9 A ± 0.0 | 2.0 A ± 0.0 |

| Quality characteristic . | Pasteurization . | Sterilization . | ||||

|---|---|---|---|---|---|---|

| CON-P . | BG300-3-P . | BG300-6-P . | CON-S . | BG300-3-S . | BG300-6-S . | |

| Water content (%) | 73.9 a ± 0.8 | 72.3 ab ± 1.2 | 69.9 b ± 0.5 | 74.7 A ± 0.5 | 73.2 AB ± 1.4 | 70.6 B ± 1.3 |

| Protein content (%) | 13.5 a ± 0.1 | 13.6 a ± 0.4 | 14.1 a ± 0.6 | 13.1 A ± 0.6 | 13.1 A ± 0.4 | 13.8 A ± 0.7 |

| Collagen content (%) | 1.5 a ± 0.3 | 1.8 a ± 0.4 | 1.7 a ± 0.3 | 1.8 A ± 0.2 | 1.9 A ± 0.3 | 1.9 A ± 0.2 |

| Fat content (%) | 8.8 a ± 0.6 | 9.1 a ± 1.1 | 9.7 a ± 0.7 | 8.6 A ± 1.0 | 8.2 A ± 1.9 | 9.0 A ± 1.2 |

| Chloride content (%) | 1.9 a ± 0.0 | 1.9 a ± 0.0 | 1.9 a ± 0.0 | 1.9 A ± 0.0 | 1.9 A ± 0.0 | 2.0 A ± 0.0 |

Treatments: CON-P—pasteurised product without the addition of the barley fibre; BG300-3-P—pasteurised product with the addition of 3.0% of the barley fibre; BG300-6-P—pasteurised product with the addition of 6.0% of the barley fibre; CON-S—sterilised product without the addition of the barley fibre; BG300-3-S—sterilised product with the addition of 3.0% of the barley fibre; BG300-6-S—sterilised product with the addition of 6.0% of the barley fibre; a, b, c—means within the same row with different superscript letters differ significantly (P ≤ 0.05) among pasteurised treatments; A, B, C—means within the same row with different superscript letters differ significantly (P ≤ 0.05) among sterilised treatments

To determine the thermostability of the tested fibre preparation Vitacel BG300, the content of total dietary fibre was determined in homogenised batters with the addition of the fibre preparation in the amount of 6.0% before thermal processing and after pasteurisation or sterilisation. The results showed that the average content of dietary fibre in model canned meat products BG300-6-P and BG300-6-S was within the range of 2.39−2.42%, which was due to 50% content of fibre in the barley fibre preparation Vitacel BG300 (according to the information given in product specification). According to the food laws, food product should contain dietary fibre or β-glucan in an amount of not less than 3 g each in a portion consumed daily in order for it to be labelled with a nutritional claim on the packaging (Regulation, 2006). For the canned meat products tested in the present study, with 6 g of dietary fibre in 100 g of the canned meat product, the β-glucan content was not less than 0.56 g, which would not allow for a nutritional claim (approximately 600 g of canned food should be consumed per day). However, it can be assumed that this product would achieve this effect, i.e. provide the human body with 3 g or 6 g of β-glucan along with 100 g of food, when it is consumed together with other meat products enriched with β-glucan. Canned meat products, such as those produced in this study, can be considered as pro-health food because they contain an ingredient that is beneficial in terms of nutritional value and is not typically present in this type of product.

From the obtained results, it can also be assumed that regardless of the type of thermal treatment (pasteurisation or sterilisation), the content of dietary fibre in the model meat batters remained at the same level; thus, this component is resistant to degradation caused by high temperature (up to 121 °C). However, it should also be noted that heating may lead to many changes in the structure of compounds included in the dietary fibre fraction, both water-soluble and water-insoluble fractions, which may determine the change in their functional and physiological properties. Heat treatment cannot be completely eliminated from food processing, including meat. Many of the steps performed in food processing are essentially based on heating. Heat treatment of plant tissues changes their physical and chemical structure, affects cell wall properties and modifies fibre solubility (Mathee & Appledorf, 1978; Mc Dougall et al., 1996; Górecka, 2004; Caprita et al., 2011). Heat treatment of dietary fibre can modify both its chemical composition and physical properties (Chang & Moris, 1999; Wołoch & Pisulewski, 2002). In 1986, Siljeström reported that heating white wheat flour and wheat grains increased total dietary fibre. In another study, the author showed that water-insoluble fibre fractions changed to soluble forms during the process of heating food under elevated pressure and temperature (Elleuch et al., 2011). Water-soluble fibre content in food may also increase due to mechanical breaking of glycosidic bonds present in polysaccharides, resulting in the release of soluble forms of oligosaccharides and leading to an increase in water-soluble dietary fibre content (Esposito et al., 2005; Elleuch et al., 2011).

Barley fibre in the Vitacel BG300 preparation did not affect the pH or water activity of pasteurised and sterilised canned meat products as compared to their counterparts without fibre: CON-P and CON-S (Table 2). Compared to the control treatments CON-P and CON-S, medium-grounded canned meat products containing 6.0% barley fibre (BG300-6-P and BG300-6-S treatments) showed significantly (P < 0.05) higher thermal loss regardless of the type of thermal treatment. Moreover, a significant (P < 0.05) increase in thermal loss in model canned meat products was found in treatments containing 3.0% addition of barley fibre (BG300-3-P and BG300-3-S treatments) (Table 2).

Physical quality characteristics of medium-grounded pasteurised and sterilised model canned meat products (mean ± standard deviation; n = 3)

| Quality characteristic . | Pasteurization . | Sterilization . | ||||

|---|---|---|---|---|---|---|

| CON-P . | BG300-3-P . | BG300-6-P . | CON-S . | BG300-3-S . | BG300-6-S . | |

| pH | 6.55 a ± 0.01 | 6.52 a ± 0.01 | 6.49 a ± 0.02 | 6.57 A ± 0.01 | 6.47 A ± 0.02 | 6.46 A ± 0.02 |

| Water activity | 0.976 a ± 0.002 | 0.975 a ± 0.004 | 0.971 a ± 0.002 | 0.973 A ± 0.001 | 0.971 A ± 0.003 | 0.973 A ± 0.001 |

| Thermal loss (%) | 4.1 a ± 0.5 | 14.8 c ± 0.8 | 12.2 b ± 0.7 | 15.6 A ± 0.4 | 25.1 C ± 0.8 | 19.7 B ± 0.5 |

| L* | 67.32 b ± 0.95 | 65.70 a ± 0.08 | 65.28 a ± 0.66 | 66.89 B ± 0.44 | 63.84 A ± 0.54 | 63.62 A ± 0.17 |

| a* | 8.04 a ± 0.46 | 8.15 a ± 0.82 | 8.12 a ± 0.79 | 7.14 A ± 0.62 | 9.31 B ± 0.65 | 9.43 B ± 0.93 |

| b* | 5.50 a ± 0.19 | 8.20 b ± 0.50 | 11.83 c ± 0.96 | 6.75 A ± 0.36 | 11.86 B ± 0.28 | 14.74 C ± 0.99 |

| Cohesiveness | 0.58 b ± 0.02 | 0.48 a ± 0.01 | 0.48 a ± 0.03 | 0.39 A ± 0.04 | 0.40 A ± 0.02 | 0.42 A ± 0.03 |

| Springiness | 0.74 c ± 0.02 | 0.56 ab ± 0.06 | 0,65 bc ± 0,05 | 0,56 A ± 0,07 | 0.57 A ± 0.02 | 0.63 A ± 0.06 |

| Hardness (N) | 15.7 b ± 0.34 | 10.18 a ± 0.73 | 11.68 a ± 0.50 | 6.66 B ± 0.35 | 8.29 A ± 0.64 | 8.96 A ± 0.30 |

| Chewiness (N) | 6.85 b ± 0.25 | 2.75 a ± 0.42 | 3.59 a ± 0.28 | 1.33 A ± 0.61 | 2.01 A ± 0.43 | 2.40 A ± 0.33 |

| Quality characteristic . | Pasteurization . | Sterilization . | ||||

|---|---|---|---|---|---|---|

| CON-P . | BG300-3-P . | BG300-6-P . | CON-S . | BG300-3-S . | BG300-6-S . | |

| pH | 6.55 a ± 0.01 | 6.52 a ± 0.01 | 6.49 a ± 0.02 | 6.57 A ± 0.01 | 6.47 A ± 0.02 | 6.46 A ± 0.02 |

| Water activity | 0.976 a ± 0.002 | 0.975 a ± 0.004 | 0.971 a ± 0.002 | 0.973 A ± 0.001 | 0.971 A ± 0.003 | 0.973 A ± 0.001 |

| Thermal loss (%) | 4.1 a ± 0.5 | 14.8 c ± 0.8 | 12.2 b ± 0.7 | 15.6 A ± 0.4 | 25.1 C ± 0.8 | 19.7 B ± 0.5 |

| L* | 67.32 b ± 0.95 | 65.70 a ± 0.08 | 65.28 a ± 0.66 | 66.89 B ± 0.44 | 63.84 A ± 0.54 | 63.62 A ± 0.17 |

| a* | 8.04 a ± 0.46 | 8.15 a ± 0.82 | 8.12 a ± 0.79 | 7.14 A ± 0.62 | 9.31 B ± 0.65 | 9.43 B ± 0.93 |

| b* | 5.50 a ± 0.19 | 8.20 b ± 0.50 | 11.83 c ± 0.96 | 6.75 A ± 0.36 | 11.86 B ± 0.28 | 14.74 C ± 0.99 |

| Cohesiveness | 0.58 b ± 0.02 | 0.48 a ± 0.01 | 0.48 a ± 0.03 | 0.39 A ± 0.04 | 0.40 A ± 0.02 | 0.42 A ± 0.03 |

| Springiness | 0.74 c ± 0.02 | 0.56 ab ± 0.06 | 0,65 bc ± 0,05 | 0,56 A ± 0,07 | 0.57 A ± 0.02 | 0.63 A ± 0.06 |

| Hardness (N) | 15.7 b ± 0.34 | 10.18 a ± 0.73 | 11.68 a ± 0.50 | 6.66 B ± 0.35 | 8.29 A ± 0.64 | 8.96 A ± 0.30 |

| Chewiness (N) | 6.85 b ± 0.25 | 2.75 a ± 0.42 | 3.59 a ± 0.28 | 1.33 A ± 0.61 | 2.01 A ± 0.43 | 2.40 A ± 0.33 |

Treatments: CON-P—pasteurised product without the addition of the barley fibre; BG300-3-P—pasteurised product with the addition of 3.0% of the barley fibre; BG300-6-P—pasteurised product with the addition of 6.0% of the barley fibre; CON-S—sterilised product without the addition of the barley fibre; BG300-3-S—sterilised product with the addition of 3.0% of the barley fibre; BG300-6-S—sterilised product with the addition of 6.0% of the barley fibre; a, b, c—means within the same row with different superscript letters differ significantly (P ≤ 0.05) among pasteurised treatments; A, B, C—means within the same row with different superscript letters differ significantly (P ≤ 0.05) among sterilised treatments

Physical quality characteristics of medium-grounded pasteurised and sterilised model canned meat products (mean ± standard deviation; n = 3)

| Quality characteristic . | Pasteurization . | Sterilization . | ||||

|---|---|---|---|---|---|---|

| CON-P . | BG300-3-P . | BG300-6-P . | CON-S . | BG300-3-S . | BG300-6-S . | |

| pH | 6.55 a ± 0.01 | 6.52 a ± 0.01 | 6.49 a ± 0.02 | 6.57 A ± 0.01 | 6.47 A ± 0.02 | 6.46 A ± 0.02 |

| Water activity | 0.976 a ± 0.002 | 0.975 a ± 0.004 | 0.971 a ± 0.002 | 0.973 A ± 0.001 | 0.971 A ± 0.003 | 0.973 A ± 0.001 |

| Thermal loss (%) | 4.1 a ± 0.5 | 14.8 c ± 0.8 | 12.2 b ± 0.7 | 15.6 A ± 0.4 | 25.1 C ± 0.8 | 19.7 B ± 0.5 |

| L* | 67.32 b ± 0.95 | 65.70 a ± 0.08 | 65.28 a ± 0.66 | 66.89 B ± 0.44 | 63.84 A ± 0.54 | 63.62 A ± 0.17 |

| a* | 8.04 a ± 0.46 | 8.15 a ± 0.82 | 8.12 a ± 0.79 | 7.14 A ± 0.62 | 9.31 B ± 0.65 | 9.43 B ± 0.93 |

| b* | 5.50 a ± 0.19 | 8.20 b ± 0.50 | 11.83 c ± 0.96 | 6.75 A ± 0.36 | 11.86 B ± 0.28 | 14.74 C ± 0.99 |

| Cohesiveness | 0.58 b ± 0.02 | 0.48 a ± 0.01 | 0.48 a ± 0.03 | 0.39 A ± 0.04 | 0.40 A ± 0.02 | 0.42 A ± 0.03 |

| Springiness | 0.74 c ± 0.02 | 0.56 ab ± 0.06 | 0,65 bc ± 0,05 | 0,56 A ± 0,07 | 0.57 A ± 0.02 | 0.63 A ± 0.06 |

| Hardness (N) | 15.7 b ± 0.34 | 10.18 a ± 0.73 | 11.68 a ± 0.50 | 6.66 B ± 0.35 | 8.29 A ± 0.64 | 8.96 A ± 0.30 |

| Chewiness (N) | 6.85 b ± 0.25 | 2.75 a ± 0.42 | 3.59 a ± 0.28 | 1.33 A ± 0.61 | 2.01 A ± 0.43 | 2.40 A ± 0.33 |

| Quality characteristic . | Pasteurization . | Sterilization . | ||||

|---|---|---|---|---|---|---|

| CON-P . | BG300-3-P . | BG300-6-P . | CON-S . | BG300-3-S . | BG300-6-S . | |

| pH | 6.55 a ± 0.01 | 6.52 a ± 0.01 | 6.49 a ± 0.02 | 6.57 A ± 0.01 | 6.47 A ± 0.02 | 6.46 A ± 0.02 |

| Water activity | 0.976 a ± 0.002 | 0.975 a ± 0.004 | 0.971 a ± 0.002 | 0.973 A ± 0.001 | 0.971 A ± 0.003 | 0.973 A ± 0.001 |

| Thermal loss (%) | 4.1 a ± 0.5 | 14.8 c ± 0.8 | 12.2 b ± 0.7 | 15.6 A ± 0.4 | 25.1 C ± 0.8 | 19.7 B ± 0.5 |

| L* | 67.32 b ± 0.95 | 65.70 a ± 0.08 | 65.28 a ± 0.66 | 66.89 B ± 0.44 | 63.84 A ± 0.54 | 63.62 A ± 0.17 |

| a* | 8.04 a ± 0.46 | 8.15 a ± 0.82 | 8.12 a ± 0.79 | 7.14 A ± 0.62 | 9.31 B ± 0.65 | 9.43 B ± 0.93 |

| b* | 5.50 a ± 0.19 | 8.20 b ± 0.50 | 11.83 c ± 0.96 | 6.75 A ± 0.36 | 11.86 B ± 0.28 | 14.74 C ± 0.99 |

| Cohesiveness | 0.58 b ± 0.02 | 0.48 a ± 0.01 | 0.48 a ± 0.03 | 0.39 A ± 0.04 | 0.40 A ± 0.02 | 0.42 A ± 0.03 |

| Springiness | 0.74 c ± 0.02 | 0.56 ab ± 0.06 | 0,65 bc ± 0,05 | 0,56 A ± 0,07 | 0.57 A ± 0.02 | 0.63 A ± 0.06 |

| Hardness (N) | 15.7 b ± 0.34 | 10.18 a ± 0.73 | 11.68 a ± 0.50 | 6.66 B ± 0.35 | 8.29 A ± 0.64 | 8.96 A ± 0.30 |

| Chewiness (N) | 6.85 b ± 0.25 | 2.75 a ± 0.42 | 3.59 a ± 0.28 | 1.33 A ± 0.61 | 2.01 A ± 0.43 | 2.40 A ± 0.33 |

Treatments: CON-P—pasteurised product without the addition of the barley fibre; BG300-3-P—pasteurised product with the addition of 3.0% of the barley fibre; BG300-6-P—pasteurised product with the addition of 6.0% of the barley fibre; CON-S—sterilised product without the addition of the barley fibre; BG300-3-S—sterilised product with the addition of 3.0% of the barley fibre; BG300-6-S—sterilised product with the addition of 6.0% of the barley fibre; a, b, c—means within the same row with different superscript letters differ significantly (P ≤ 0.05) among pasteurised treatments; A, B, C—means within the same row with different superscript letters differ significantly (P ≤ 0.05) among sterilised treatments

The addition of barley fibre affected the colour of meat products, as assessed instrumentally (Table 2). Regardless of the amount of addition (3.0% and 6.0%), the incorporation of the barley fibre preparation Vitacel BG300 into canned meat products caused a significant (P < 0.05) darkening of the colour of the final products as compared to that of the relevant control treatments (CON-P and CON-S) and also significantly (P < 0.05) increased the mean value of the colour parameter b*. For both heat treatments, the mean value of yellowness (b*) increased gradually with the increase in the amount of the fibre preparation added to the meat batter. For the a* colour parameter, the mean value was significantly (P < 0.05) increased only in sterilised products with the addition of Vitacel BG300 (Table 2). The analysis of the absolute colour difference ΔE, which was calculated in relation to the relevant control treatments, showed that the impression of a different colour can be obtained when looking at the colour of sterilised canned meat products containing the addition of the barley fibre preparation Vitacel BG300 at the level of 3.0% and 6.0% (BG300-3-S and BG300-6-S, respectively) as well as the pasteurised canned meat product with the addition of 6% of this preparation (BG300-6-P). The ΔE value calculated for the sterilised canned products was 6.34 and 8.93, respectively, and that for the pasteurised one was 6.66. Therefore, considering the colour parameters described in the CIEL*a*b* scale and the absolute difference in colour ΔE calculated on their basis, it can be concluded that for the treatments with the addition of the Vitacel BG300 preparation (except for the BG300-3-P treatment), the differences observed were mainly due to the darkening of the blocks of products with the simultaneous increase in the proportion of yellow in the colour of the product. It should also be noted that a stronger reheating of the product through sterilisation and a higher addition level of the Vitacel BG300 preparation (6.0%) intensified the colour changes (ΔE > 5), leading to browning and darkening of the blocks of canned meat products containing this preparation, which was visible to the naked eye. This phenomenon might be caused by Maillard’s reactions, which are favoured by both increased temperature (e.g. during sterilisation) and the content of simple carbohydrates with the simultaneous presence of protein compounds.

The results obtained in our study confirm the findings of previous studies. The possible darkening and browning of meat products caused by the addition of oat β-glucan concentrate was demonstrated by Alvarez & Barbut (2013), who added Viscofiber® obtained from oats to model meat batters. Morin et al., (2002) found that the use of barley β-glucan concentrate in the production of low-fat breakfast sausages resulted in their darkening and an increase in the shear of yellowness (b*) and redness (a*) in the colour of the final product. Similar results were obtained by Petersson et al., (2014), who − based on the study of the addition of barley β-glucan concentrate to low-fat sausages and beef meatballs − observed significant colour changes accompanied by higher scores awarded in sensory evaluation. According to Vasquez Mejía et al., (2019), colour parameters of the whole muscle chicken breast were minimally affected by commercial β-glucan preparation. However, in that study, the β-glucan preparation was introduced into the meat with brine. The changes in the colour parameters of canned meat may show a different direction with a change in the fibre preparation used. For example, the addition of 6% wheat fibre preparations caused lightening of the colour of the model homogenised sterilised canned meat (Słowiński et al., 2020).

The use of the fibre preparation Vitacel BG 300 as a component of the medium-ground model canned meat product caused changes in texture, regardless of the amount of fibre preparation and the type of thermal treatment (Table 2). Analysis of the mean values of texture parameters measured in the TPA test showed that the changes in the texture of the meat blocks of canned food containing barley fibre were more pronounced in pasteurised products than in sterilised canned meat products. Although the sterilised products BG300-6-S and BG300-3-S showed significantly (P < 0.05) higher hardness and slightly (P > 0.05) higher chewiness than CON-S, the pasteurised products BG300-3-P and BG300-6-P exhibited significantly (P < 0.05) lower hardness, chewiness and cohesiveness than the control treatment CON-P. The results indicate a significant effect of temperature on the texture characteristics of medium-grounded canned meat products. The reduction in hardness of sausages with the addition of barley fibre was also indicated by Petersson et al., (2014). A significant decrease in hardness was also observed in model meat batters containing the addition of yeast β-glucan preparation, while the cohesiveness of the samples was maintained comparable to that of control batter (Apostu et al., 2017). According to Szpicer et al., (2020), replacing fat with oat β-glucan concentrate in beef burgers improved the texture of the product; this was concluded on the basis of an increase in the value of texture parameters (hardness, cohesiveness and springiness) as compared to those for burgers without fibre.

In this study, in both the evaluated groups of products, the canned meat products with the barley fibre preparation Vitacel BG300 scored lower in sensory evaluation than the relevant control treatments (Table 3). This may result from the fact that this preparation contains a significant proportion of simple and complex carbohydrates (including mainly starch) from barley grains and thus may contribute to the development of an unpleasant aftertaste in the final meat product, referred to by the panellists as typical for cereal products. The barley fibre preparation Vitacel BG300 is obtained from grains, and therefore, it has a more complex and diverse composition and heterogeneous structure. The application of this fibre preparation also resulted in a change in the colour of model canned meat products from light pink (typical for cured meat products) to light brown, which was perceived negatively by the panellists. This direction of colour change in canned meat products manufactured from poultry and pork had a negative impact on their sensory perception. Similar to the colour parameters measured instrumentally, it was also observed that because of higher temperature during sterilisation and higher addition level of the Vitacel BG300 fibre preparation (6.0%; BG300-6-P and BG300-6-S treatments), the changes in sensory quality characteristics intensified, thereby lowering the scores awarded to canned products containing this preparation. As described earlier, the underlying reasons for this phenomenon could be intensification of Maillard’s reaction. Deterioration in the sensory quality of low-fat pork and beef sausages was also found by Petersson et al., (2014), who investigated the possibility of using β-glucan derived from barley in the form of a concentrate (22% pure β-glucan). Pinero et al., (2008) recorded a different observation in their study on the effect of the addition of an oat preparation (Nutrim-10®, containing ca. 10% β-glucan) to beef patties with reduced fat content. The authors did not observe any significant differences in sensory attributes of the final product with oat fibre as compared to the control one.

Sensory quality characteristics (points) of medium-grounded pasteurised and sterilised model canned meat products (mean ± standard deviation; n = 3)

| Sensory quality characteristic . | Pasteurization . | Sterilization . | |||||

|---|---|---|---|---|---|---|---|

| CON-P . | BG300-3-P . | BG300-6-P . | CON-S . | BG300-3-S . | BG300-6-S . | ||

| General appearance | 5.6 b ± 0.33 | 3.5 a ± 0.13 | 2.9 a ± 0.50 | 7.4 B ± 0.25 | 3.7 A ± 0.38 | 3.7 A ± 0.40 | |

| Colour on the cross-section | 5.6 b ± 0.22 | 3.8 a ± 0.40 | 3.0 a ± 0.26 | 6.7 B ± 0.63 | 3.9 A ± 0.19 | 3.8 A ± 0.47 | |

| Aroma | 4.9 b ± 0.20 | 5.1 b ± 0.26 | 3.0 a ± 0.51 | 6.5 B ± 0.13 | 6.1 AB ± 0.83 | 5.4 A ± 0.33 | |

| Palatability | 5.0 b ± 0.10 | 3.7 a ± 0.95 | 3.4 a ± 0.33 | 6.2 B ± 0.32 | 4.8 A ± 0.82 | 3.5 A ± 0.92 | |

| Consistency | 6.1 b ± 0.25 | 4.0 a ± 0.76 | 4.2 a ± 0.26 | 5.7 B ± 0.10 | 5.0 AB ± 0.88 | 4.8 a ± 0.70 | |

| General desirability | 5.6 b ± 0.13 | 3.7 a ± 0.69 | 2.8 a ± 0.25 | 6.4 B ± 0.18 | 4.3 A ± 1.00 | 3.8 a ± 0.59 | |

| Sensory quality characteristic . | Pasteurization . | Sterilization . | |||||

|---|---|---|---|---|---|---|---|

| CON-P . | BG300-3-P . | BG300-6-P . | CON-S . | BG300-3-S . | BG300-6-S . | ||

| General appearance | 5.6 b ± 0.33 | 3.5 a ± 0.13 | 2.9 a ± 0.50 | 7.4 B ± 0.25 | 3.7 A ± 0.38 | 3.7 A ± 0.40 | |

| Colour on the cross-section | 5.6 b ± 0.22 | 3.8 a ± 0.40 | 3.0 a ± 0.26 | 6.7 B ± 0.63 | 3.9 A ± 0.19 | 3.8 A ± 0.47 | |

| Aroma | 4.9 b ± 0.20 | 5.1 b ± 0.26 | 3.0 a ± 0.51 | 6.5 B ± 0.13 | 6.1 AB ± 0.83 | 5.4 A ± 0.33 | |

| Palatability | 5.0 b ± 0.10 | 3.7 a ± 0.95 | 3.4 a ± 0.33 | 6.2 B ± 0.32 | 4.8 A ± 0.82 | 3.5 A ± 0.92 | |

| Consistency | 6.1 b ± 0.25 | 4.0 a ± 0.76 | 4.2 a ± 0.26 | 5.7 B ± 0.10 | 5.0 AB ± 0.88 | 4.8 a ± 0.70 | |

| General desirability | 5.6 b ± 0.13 | 3.7 a ± 0.69 | 2.8 a ± 0.25 | 6.4 B ± 0.18 | 4.3 A ± 1.00 | 3.8 a ± 0.59 | |

Treatments: CON-P—pasteurised product without the addition of the barley fibre; BG300-3-P—pasteurised product with the addition of 3.0% of the barley fibre; BG300-6-P—pasteurised product with the addition of 6.0% of the barley fibre; CON-S—sterilised product without the addition of the barley fibre; BG300-3-S—sterilised product with the addition of 3.0% of the barley fibre; BG300-6-S—sterilised product with the addition of 6.0% of the barley fibre; a, b, c—means within the same row with different superscript letters differ significantly (P ≤ 0.05) among pasteurised treatments; A, B, C—means within the same row with different superscript letters differ significantly (P ≤ 0.05) among sterilised treatments

Sensory quality characteristics (points) of medium-grounded pasteurised and sterilised model canned meat products (mean ± standard deviation; n = 3)

| Sensory quality characteristic . | Pasteurization . | Sterilization . | |||||

|---|---|---|---|---|---|---|---|

| CON-P . | BG300-3-P . | BG300-6-P . | CON-S . | BG300-3-S . | BG300-6-S . | ||

| General appearance | 5.6 b ± 0.33 | 3.5 a ± 0.13 | 2.9 a ± 0.50 | 7.4 B ± 0.25 | 3.7 A ± 0.38 | 3.7 A ± 0.40 | |

| Colour on the cross-section | 5.6 b ± 0.22 | 3.8 a ± 0.40 | 3.0 a ± 0.26 | 6.7 B ± 0.63 | 3.9 A ± 0.19 | 3.8 A ± 0.47 | |

| Aroma | 4.9 b ± 0.20 | 5.1 b ± 0.26 | 3.0 a ± 0.51 | 6.5 B ± 0.13 | 6.1 AB ± 0.83 | 5.4 A ± 0.33 | |

| Palatability | 5.0 b ± 0.10 | 3.7 a ± 0.95 | 3.4 a ± 0.33 | 6.2 B ± 0.32 | 4.8 A ± 0.82 | 3.5 A ± 0.92 | |

| Consistency | 6.1 b ± 0.25 | 4.0 a ± 0.76 | 4.2 a ± 0.26 | 5.7 B ± 0.10 | 5.0 AB ± 0.88 | 4.8 a ± 0.70 | |

| General desirability | 5.6 b ± 0.13 | 3.7 a ± 0.69 | 2.8 a ± 0.25 | 6.4 B ± 0.18 | 4.3 A ± 1.00 | 3.8 a ± 0.59 | |

| Sensory quality characteristic . | Pasteurization . | Sterilization . | |||||

|---|---|---|---|---|---|---|---|

| CON-P . | BG300-3-P . | BG300-6-P . | CON-S . | BG300-3-S . | BG300-6-S . | ||

| General appearance | 5.6 b ± 0.33 | 3.5 a ± 0.13 | 2.9 a ± 0.50 | 7.4 B ± 0.25 | 3.7 A ± 0.38 | 3.7 A ± 0.40 | |

| Colour on the cross-section | 5.6 b ± 0.22 | 3.8 a ± 0.40 | 3.0 a ± 0.26 | 6.7 B ± 0.63 | 3.9 A ± 0.19 | 3.8 A ± 0.47 | |

| Aroma | 4.9 b ± 0.20 | 5.1 b ± 0.26 | 3.0 a ± 0.51 | 6.5 B ± 0.13 | 6.1 AB ± 0.83 | 5.4 A ± 0.33 | |

| Palatability | 5.0 b ± 0.10 | 3.7 a ± 0.95 | 3.4 a ± 0.33 | 6.2 B ± 0.32 | 4.8 A ± 0.82 | 3.5 A ± 0.92 | |

| Consistency | 6.1 b ± 0.25 | 4.0 a ± 0.76 | 4.2 a ± 0.26 | 5.7 B ± 0.10 | 5.0 AB ± 0.88 | 4.8 a ± 0.70 | |

| General desirability | 5.6 b ± 0.13 | 3.7 a ± 0.69 | 2.8 a ± 0.25 | 6.4 B ± 0.18 | 4.3 A ± 1.00 | 3.8 a ± 0.59 | |

Treatments: CON-P—pasteurised product without the addition of the barley fibre; BG300-3-P—pasteurised product with the addition of 3.0% of the barley fibre; BG300-6-P—pasteurised product with the addition of 6.0% of the barley fibre; CON-S—sterilised product without the addition of the barley fibre; BG300-3-S—sterilised product with the addition of 3.0% of the barley fibre; BG300-6-S—sterilised product with the addition of 6.0% of the barley fibre; a, b, c—means within the same row with different superscript letters differ significantly (P ≤ 0.05) among pasteurised treatments; A, B, C—means within the same row with different superscript letters differ significantly (P ≤ 0.05) among sterilised treatments

The introduction of the fibre preparation to the recipe composition of canned meat product does not always lead to deterioration of the sensory quality. For the homogenised sterilised canned food made with two different wheat fibre preparations, significant (P < 0.05) differences were observed only in the assessment of tastiness between the product with 6% of the wheat fibre preparation with shorter fibres and the control product and the product containing 3% of the wheat fibre preparation with longer fibres (Słowiński et al., 2020).

Conclusion

The addition of the barley fibre preparation Vitacel BG300 to medium-grounded canned meat products, both pasteurised and sterilised, did not affect the content of basic nutrients. The enrichment of the meat product with dietary fibre could be considered as a nutritional benefit; however, the fibre content in the final product in an amount of less than 3 g per 100 g of product does not permit the use of the nutritional claim.

The addition of the Vitacel BG300 barley fibre preparation to medium-grounded canned meat products caused changes in physical quality characteristics. For both thermal treatments (pasteurisation and sterilisation), increasing the dose of fibre preparation from 3.0% to 6.0% led to an increase in thermal loss in model canned meat products. Compared to the relevant control products, the blocks of pasteurised and sterilised medium-grounded canned meat products containing 3.0% and 6.0% Vitacel BG300 showed a darker and brownish colour. The direction of changes in the texture of meat products in cans with barley fibre depended on the type of thermal treatment. Regardless of the amount of barley fibre added, the instrumental hardness of pasteurised products decreased, but it increased in sterilised products. In addition, both pasteurised and sterilised canned meat products had lower scores in the evaluation of the sensory quality characteristics than the relevant control products.

In conclusion, the obtained results indicate that the addition of the Vitacel BG300 barley fibre preparation to the recipe composition of a medium-grounded canned meat product seems to be technologically feasible. However, because of the introduction of a number of ingredients that change the sensory properties of canned meat products (mainly colour and taste), it was also concluded that this type of fibre preparation should not be used in products with the similar recipe composition (share of meat and fat raw materials) as done in this work. It can be assumed that better results might be obtained for the production of a pâté-type product, which is a product made of uncured meat with the addition of starchy raw materials. This is, however, beyond the scope of the present research.

Author contribution

Mirosław Słowiński: Conceptualization (equal); Data curation (equal); Methodology (equal); Writing-original draft (equal); Writing-review & editing (equal). Joanna Miazek: Conceptualization (equal); Data curation (equal); Investigation (equal); Methodology (equal); Writing-original draft (equal); Writing-review & editing (equal). Krzysztof Dasiewicz: Formal analysis (equal); Visualization (equal); Writing-original draft (equal); Writing-review & editing (equal). Aneta Cegiełka: Investigation (equal); Visualization (equal); Writing-original draft (equal); Writing-review & editing (equal).

Conflict of interest

The authors declare that there is no conflict of interest.

Ethics approval

Ethics approval was not required for this research.

Peer review

The peer review history for this article is available at https://publons.com/publon/10.1111/ijfs.15335.

Data availability statement

Research data are not shared.

References

This work has been selected because it shows the results of research on the influence of various types of dietary fibre on the quality characteristics of meat batters with a reduced amount of fat. The study showed that the addition of inulin powder resulted in better emulsion stability, while the addition of mixtures of inulin gel and β-glucan improved the textural parameters of low-fat emulsions.

This research suggests that it is possible to use yeast preparations containing β-glucan to reformulate meat products. When added to meat batters, yeast β-glucans improved some technological properties of batters, apart from increasing the nutritional value. It was also concluded that yeast β-glucan could be used for developing meat products targeted for children and elders due to the decrease in the hardness of emulsified meat products.

Comission Internationale de l’Eclairage (CIE). (1986). Colorimetry: Official Recommendations of the International Commission on Illumination. Vienna, Austria: 2nd Edition, Publication CIE No. 15.2.

This article was considered in order to understand the structure and physiological properties of cereal β-glucan, which is a very valuable functional ingredient. The authors explained that the structure, rheological properties and physiological properties of β-glucan are determined by processing technology and extraction methods. Therefore, the growing interest in β-glucan as a food ingredient should be accompanied by the desire to learn about the properties of preparations containing this ingredient.

Regulation, (

In this article, the authors reviewed strategies to improve the functional value of meat products through the introduction of dietary fibre. The raw materials for manufacturing fibre preparations and the technological properties of fibres in meat products are briefly characterised, and examples of meat products containing fibre as an ingredient of natural origin were given. It was also emphasised that the addition of dietary fibre in meat products contributes to the fabrication of products, which enhances physiological functions.