-

PDF

- Split View

-

Views

-

Cite

Cite

Raheel Suleman, Teng Hui, Zhenyu Wang, Huan Liu, Dequan Zhang, Comparative analysis of charcoal grilling, infrared grilling and superheated steam roasting on the colour, textural quality and heterocyclic aromatic amines of lamb patties, International Journal of Food Science and Technology, Volume 55, Issue 3, March 2020, Pages 1057–1068, https://doi.org/10.1111/ijfs.14388

Close - Share Icon Share

Abstract

The colour, textural profile and heterocyclic aromatic amines content of lamb patties cooked by charcoal grilling, infrared grilling and superheated steam roasting were investigated. The results of colour showed that lightness and yellowness values were highest in the superheated steam and lowest in charcoal grilled patties. The texture characteristics observed in the superheated steam, and infrared patties were much better. Water loss was highest in charcoal grilled meat. Charcoal grilling produced a significantly (P < 0.05) much higher amount of total HAAs, ranging from 171.26 ng g−1 to 555.29 ng g−1 (polar) and from 200.77 ng g−1 to 426.07 ng g−1 (non-polar) HAAs, than infrared (39.21 ng g−1 −181.37 ng g−1) and (52.84 ng g−1 −148.59 ng g−1) and superheated steam roasting (from 8.67 ng g−1 to 30.66 ng g−1 and from 23.61 ng g−1 to 89.66 ng g−1) for both types of HAAs in lamb patties. Colour, texture and HAAs were significantly influenced by time and by the temperature used for each cooking method.

Introduction

Roasted or grilled meat products are popular all around the world due to the particular smoky or roasted aroma or flavour. Different processing methods, including grilling, roasting, microwave oven cooking, deep frying, conventional oven cooking and boiling, are applied to meat to improve taste, aroma and other sensory characteristics(Juárez et al., 2010; Alina et al., 2012). Each cooking method affects the colour pigments (myoglobin), which are directly related to heating time and temperature. The colour of meat degrades at the higher heating temperature. Similarly, the texture gets more tough/hard depending upon the heating mechanism and the temperature applied to meat while cooking (Abdulhameed et al., 2016). The consumption of lamb meat in different forms such as grilled and roasted is central to various cuisines in China, New Zealand and Australia, and its popularity is increasing globally due to the high level of important nutrients such as iron, zinc, selenium, fatty acids and vitamins (Cabrera & Saadoun, 2014; Mao et al., 2016). There are numerous ways of cooking lamb meat and these cooking methods add taste and improve its physical appearance, but it is important to ensure that these cooking methods keep lamb meat products safe and nutritious for consumers.

Cooking methods (grilling, barbecue, roasting, etc.) also induce the formation of some harmful compounds called heterocyclic aromatic amines (HAAs) in meat products that are directly exposed to the heat. These HAAs have the potential to cause cancer and can be a risk to consumers (Jinap et al., 2013). Different factors might influence the formation of HAAs, such as cooking time, temperature, method, equipment, water content and fats in meat. They are formed through the Maillard reaction between creatine/creatinine, free amino acids and sugars at temperatures between 150 °C and 250 °C (Jaegerstad & Skog, 2005). The International Agency for Research on Cancer (IARC) has defined 2-amino-1-methyl-6-phenylimidazo[4,5-b]pyridine (PhIP), 2-amino-3,4-dimethyl-3H-imidazo[4,5-f]quinoline (MeIQ), 2-amino-9H-pyrido[2,3-b]indole (AαC), 2-amino-3-methyl-9H-pyrido[2,3-b]indole (MeAαC) and 2-amino-3,8-dimethylimidazo[4,5-f]quinoxaline (MeIQx) as possible (2B) human carcinogens, and 2-amino-3-methyl-3H-imidazo[4,5-f]quinoline (IQ) as a probable (2A) human carcinogen (IARC, 1993).

Charcoal grilling is a common method of cooking meat at restaurants and domestically, but previous studies have shown that barbecue or grilled meat has more HAAs than microwaved or steamed meat (Viegas et al., 2012). Many cooking methods have been developed in modern food processing that provide an alternative many thermal processing methods with better efficiency and better food qualities. One of the modern methods is superheated steam roasting. The basic principle for the formation of superheated steam is the addition of sensible heat to the water, which leads to an increase in its temperature above the boiling point or saturation temperature at a given pressure and improves the penetration of heat into the meat products without affecting meat quality traits (Somjai et al., 2009).

Similarly, using infrared radiation (IR-processing) in ovens has been an effective technology to prevent overheating, oxidation, low yield and high energy cost, which are prevalent in conventional hot air ovens (Rahimi et al., 2018). Infrared is based on the electromagnetic spectrum, and the wavelength used for infrared applications is in range of 0.5 to 1000 μm, which can be absorbed by the food compounds (water molecules and ions), resulting in a rise in a temperature. Infrared application has other benefits such as reduced nutrients decomposition and uniform and faster heating (Rastogi, 2012). These cooking methods have better effects on meat and meat products. The present study was aimed to investigate the effect of these new cooking methods (infrared and superheated steam roasting) compared with traditional charcoal grilling on the HAAs in lamb patties and to show how each cooking method affects the physico-chemical and sensorial traits (colour and texture) of the lamb patties.

Material and methods

Chemicals and Reagents

The HAA standards 2-amino-9H-pyrido[2,3-b]indole (AαC), 2-amino-3-methyl-9H-pyrido[2,3-b]indole (MeAαC), 1-methyl-9H-pyrido[3,4-b]indole (Harman), 9H-pyrido[3,4-b]indole (Norharman), 2-amino-6-methyldipyrido[1,2-a:3′,2′-d]imidazole (Glu-P-1), 2-amino-1,6-dimethylfuro[3,2-e]imidazo[4,5-b]pyridine (IFP), 3-amino-1,4-dimethyl-5H-pyrido[4,3-b]indole (TrP-P-1), 3-amino-1-methyl-5H-pyrido[4,3-b]indole (TrP-P-2), 2-amino-3-methylimidazo[4,5-f] quinoline (IQ), 2-amino-3,4-dimethylimidazo[4,5-f] (MeIQ), 2-amino-1-methylimidazo[4,5-b] quinoline (IQ[4,5-b]), 2-amino-1-methyl-6-phenylimidazo[4,5-b]pyridine (PhIP), 2-amino-1-methylimidazo[4,5-f]quinoline (ISO-IQ), 2-amino-1,6-dimethylimidazo[4,5-b]pyridine (DMIP), 2-amino-5-phenylpyridine (Phe-P-1), 2-amino-3-methyl-3H-imidazo[4,5-f]quinoxaline (IQx), 2-amino-3,8-dimethylimidazo[4,5-f]quinoxaline (8-MeIQx), 2-amino-3,4,8-trimethylimidazo[4,5-f]quinoxaline (4,8-DiMeIQx) and 2-amino-3,7,8-trimethylimidazo[4,5-f]quinoxaline (7,8-DiMeIQx) were purchased from Toronto Research Chemicals (Canada). The purity of all the standards was greater than 99.9%. HAAs extraction and purification reagents included Quechers extraction packets containing 4 g magnesium sulphate and 1 g ammonium acetate. The primary and secondary amine (PSA), encapped C-18EC (extraction column) and MgSO4 together in 15 mL centrifuge tubes were procured from Agilent Technologies (USA). The chemicals for proximate analysis (diethyl ether, concentrated sulphuric acid, copper sulphate, potassium sulphate, boric acid, sodium hydroxide, methyl red and ethyl alcohol) and for antioxidants activity analysis 2, 2 diphenyl-1-picrylhydrazyl (DPPH), butylated hydroxy toluene (BHT), ammonium acetate and acetonitrile were procured from Sigma Aldrich Co. USA with ˃99% purity. The chemicals and reagents were obtained in the packaged form and were kept at required temperature until they were used for the analysis.

Preparation of lamb meat patties

Fresh lamb shoulder oyster cut muscles, 30 in total from Bayannur sheep 8-month old (Inner Mongolia, P.R China), were procured from Inner Mongolia Grassland Hongbao Food Co. Ltd in P.R. China. After sheep were slaughtered, the carcasses were chilled at 4 °C for 24 h, and the oyster cut muscles were sliced and were stored at −80 °C until they were used. The lamb meat patties were prepared by removing the fat from the oyster cut muscles, and then, the muscle was ground using a grinder with 5 mm blades. Fifty grams of fresh ground lamb oyster cut muscles was used to make a patty using a petri dish (6 cm × 1.5 cm) to ensure uniformity.

Cooking of patties

In total 45 patties were prepared and divided into 15 patties for each cooking treatment, using three patties for each cooking time interval as replicates. The three patties at each cooking time were cooked together as replicates, starting from the time to achieve a core temperature of 72 °C, then another three patties were cooked as replicates for next cooking time interval, using charcoal fire grilling at a temperature of 450–500 °C (measured by laser thermometer, Fluke, USA). For charcoal grilling, patties were grilled for 10 min total (5 min each side) to achieve 72 °C, which was considered as 0 min. Then the patties were for an additional 1, 2, 3 and 4 min. For infrared grilling, similarly from 15 patties, 3 patties were grilled at same time for each cooking interval as replicates. The time to achieve a core temperature of 72 °C at 240 °C using an electric oven (Midea, China) was 17 min (0 min) for infrared grilled meat, and grilling continued to 21 min, as 0 min (17 min), 18 min (1 min), 19 min (2 min), 20 min (3 min) and 21 min (4 min) for each patty to be infrared grilled. A similar protocol as infrared was followed for superheated steam cooking of patties. The internal temperature of each patty was measured by a digital data logger (Hangzhou Co. LTD China) with an accessary digital contact thermometer probe inserted into the geometric centre of each ground lamb patty. After cooking, the lamb patties were cooled at room temperature for 1–2 h, were packed in plastic ziplock bags and were stored at −20 °C until use.

Proximate analysis and cooking loss

The moisture, fat and protein contents of the samples were determined according to the literature (Oz & Zikirov, 2015). Cooking loss was calculated as the differences in weights of the patties before and after cooking. The equation for calculating the cooking loss in cooked samples is given below;

Colour analysis

The lamb patties after cooking were placed in paper plates for cooling at room temperature 26 °C for 10–15 minutes, and then, colour analysis was done of all cooked patties. The colour of the flat surface in the centre for each sample was determined as described by Choi et al. (2016) using a colorimeter (Minolta Chroma meter CR-210, Minolta Ltd., Japan) with 8 mm diameter measuring aperture size, illuminant D65, 10° standard observer and CIE L*, a*, b* colour score, calibrated with a white plate, L* = +97.83, a* = −0.43 and b* = +1.98. Seven measurements for each of three replicates were obtained. Lightness (CIE L*- value), redness (CIE a*- value) and yellowness (CIE b*- value) values were recorded.

Texture profile analysis

The lamb patties after cooking were placed in paper plates for cooling at room temperature 26 °C for 10–15 minutes, and then, colour analysis was done of all cooked patties. Then, the texture of lamb patties was analysed by following the method described by Zeng et al. (2017) with some modifications. A texture analyser (TA-XT plus, Stable Micro System, Surrey, UK) fitted with a cylindrical probe (P/50, 50-mm stainless cylinder) was used. At room temperature, the lamb patties were cut into small cubes (1 cm × 1 cm × 1 cm). Each cube was subjected to a two-cycle compression test to determine the texture characteristic parameters of hardness, cohesiveness, gumminess, chewiness and resilience. The settings for texture measurement were as follows: pre-test speed, 3.0 mm s−1; test speed, 2.0 mm s−1; post-test speed, 3.0 mm s−1; strain, 50%; and time, 5.0 s. Determinations were performed in triplicate.

Preparation, extraction and quantification of heterocyclic aromatic amines (HAAs) in cooked meat samples

The heterocyclic amines in the cooked patties were determined by the Quechers Method of Hsiao et al. (2017). The standards mixture solutions of different concentrations were prepared from stock solutions with a final concentrations of 5, 10, 25, 50, 100, 300 and 500 ppb in methanol to have calibration curves and limit of detection and limit of quantification LODs and LOQs determined through UPLC-MS/MS. The LOQs, LODs and recovery % of UPLC-MS/MS has been given in Table S1.

For HAA analysis, using UPLC-MS/MS, a homogenous meat sample was accurately weighed (2 g in 50 mL plastic centrifuge tube). Then, one ceramic homogeneous stone and 10 mL deionized water were added to same centrifuge tube. Afterwards, the centrifuge tube was given oscillations back and forth mechanically for 10 min. After this step, 10 mL acetonitrile solution containing 1% acetic acid was added to that tube and was oscillated again for 10 min. After oscillations, an extraction powder package containing 4 g of anhydrous magnesium sulphate and 1 g of anhydrous sodium acetate was added to the tube. The tube was manually shaken for 1 min to mix the extraction package with the solvent. Afterwards, the centrifuge tube was centrifuged at 4 °C, at 3200 g speed for 10 min in centrifuge machine (Himac, HITACHI Co, Japan). After centrifugation, 6 mL of supernatant was taken and was added to a purification tube (containing 900 mg of anhydrous magnesium sulphate, 300 mg of PSA and 300 mg C18EC). This tube was shaken manually for 1 min. After it was mixed, solution was centrifuged at a speed of 3200 g for 5 min. Then, 1 mL of clear supernatant was taken and dried using nitrogen freeze drying. To the freeze-dried sample, 0.2 mL of methanol was added, and the solution was mixed evenly with a vortex machine (Vortex genie-2, Scientific industries USA). Then, the solution was filtered with 0.22 μm PVDF membrane (Sigma Aldrich Co. USA), and finally, it was injected to the UPLC-MS/MS for analysis.

Statistics

The data were expressed as the means ± standard errors. All the treatments were analysed statistically using one way ANOVA and significant differences among the treatments and within treatments were found using the Duncan multiple range tests through SPSS version 19.0 (SPSS, Inc., Chicago, IL., U.S.A.). P < 0.05 was considered statistically significantly different. Principal component analysis (PCA) was performed using the Origin Pro software (v.2018).

Results and discussion

Water, fat and protein content

The results of the proximate analysis are shown in Table 1. The water in the charcoal grilling was lost at higher rate from 0 min to 4 min compared with the infrared and the superheated steam roasting at the same cooking intervals. The water in the charcoal grilled patties decreased significantly (P < 0.05) and varied from 68.35% to 43.58%, while the protein and fat increased at every interval from 30.70% to 40.82% and from 3.63% to 6%, respectively. The infrared cooking method decreased the water content in lamb patties but less so than charcoal grilling. The water content declined significantly (P < 0.05) from 69.35% to 56.58% at all the time intervals. The protein and fat increased from 38.73% to 37.83% and from 3.08% to 5.17%, respectively, in the lamb patties. We observed that superheated steam roasted lamb patties had higher water content than samples cooked by other methods, but the water content decreased significantly (P < 0.05) at all cooking intervals from 70.25% to 59.25%, while protein and fat contents increased but were lower in content than in the other two methods. The protein increased from 28.06% to 35.50%, and the fat content increased from 3.01% to 5.08% (P < 0.05) respectively.

| Cooking method . | Parameter . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Charcoal grilling | Water | 68.35 ± 0.73Ba | 57.06 ± 0.37Cb | 49.29 ± 0.34Cc | 45.87 ± 0.48Cd | 43.58 ± 0.38Ce |

| Protein | 30.70 ± 0.28Ad | 31.72 ± 0.32Ad | 33.96 ± 0.72Ac | 37.50 ± 0.37Ab | 40.82 ± 0.59Aa | |

| Fat | 3.63 ± 0.15Ac | 4.74 ± 0.14Ab | 5.65 ± 0.05Aa | 5.84 ± 0.06Aa | 6.00 ± 0.10Aa | |

| Infrared grilling | Water | 69.35 ± 0.28ABa | 66.73 ± 0.53Bb | 63.62 ± 0.65Bc | 60.20 ± 0.55Bd | 56.58 ± 0.38Be |

| Protein | 28.73 ± 0.33Be | 30.08 ± 0.59Ad | 33.87 ± 0.57Ac | 36.04 ± 0.50Bb | 37.83 ± 0.54Ba | |

| Fat | 3.08 ± 0.12Bd | 3.97 ± 0.09Bc | 4.52 ± 0.17Bb | 4.84 ± 0.06Bab | 5.17 ± 0.07Ba | |

| Superheated steam roasting | Water | 70.25 ± 0.34Aa | 68.40 ± 0.35Ab | 66.95 ± 0.59Ac | 63.20 ± 0.29Ad | 59.25 ± 0.52Ae |

| Protein | 28.06 ± 0.05Be | 30.15 ± 0.42Ad | 32.53 ± 0.32Ac | 34.38 ± 0.28Cb | 35.50 ± 0.31Ca | |

| Fat | 3.01 ± 0.09Bd | 3.97 ± 0.09Bc | 4.15 ± 0.04Cbc | 4.27 ± 0.06Cb | 5.08 ± 0.03Ba | |

| Cooking method . | Parameter . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Charcoal grilling | Water | 68.35 ± 0.73Ba | 57.06 ± 0.37Cb | 49.29 ± 0.34Cc | 45.87 ± 0.48Cd | 43.58 ± 0.38Ce |

| Protein | 30.70 ± 0.28Ad | 31.72 ± 0.32Ad | 33.96 ± 0.72Ac | 37.50 ± 0.37Ab | 40.82 ± 0.59Aa | |

| Fat | 3.63 ± 0.15Ac | 4.74 ± 0.14Ab | 5.65 ± 0.05Aa | 5.84 ± 0.06Aa | 6.00 ± 0.10Aa | |

| Infrared grilling | Water | 69.35 ± 0.28ABa | 66.73 ± 0.53Bb | 63.62 ± 0.65Bc | 60.20 ± 0.55Bd | 56.58 ± 0.38Be |

| Protein | 28.73 ± 0.33Be | 30.08 ± 0.59Ad | 33.87 ± 0.57Ac | 36.04 ± 0.50Bb | 37.83 ± 0.54Ba | |

| Fat | 3.08 ± 0.12Bd | 3.97 ± 0.09Bc | 4.52 ± 0.17Bb | 4.84 ± 0.06Bab | 5.17 ± 0.07Ba | |

| Superheated steam roasting | Water | 70.25 ± 0.34Aa | 68.40 ± 0.35Ab | 66.95 ± 0.59Ac | 63.20 ± 0.29Ad | 59.25 ± 0.52Ae |

| Protein | 28.06 ± 0.05Be | 30.15 ± 0.42Ad | 32.53 ± 0.32Ac | 34.38 ± 0.28Cb | 35.50 ± 0.31Ca | |

| Fat | 3.01 ± 0.09Bd | 3.97 ± 0.09Bc | 4.15 ± 0.04Cbc | 4.27 ± 0.06Cb | 5.08 ± 0.03Ba | |

Results are given as Means ± Standard error with small letters (a, b and c) show significant difference (P < 0.05) in rows among the different time intervals in three cooking methods while capital letters (A, B and C) show the significant difference (P < 0.05) in columns among the cooking methods on same time intervals.

| Cooking method . | Parameter . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Charcoal grilling | Water | 68.35 ± 0.73Ba | 57.06 ± 0.37Cb | 49.29 ± 0.34Cc | 45.87 ± 0.48Cd | 43.58 ± 0.38Ce |

| Protein | 30.70 ± 0.28Ad | 31.72 ± 0.32Ad | 33.96 ± 0.72Ac | 37.50 ± 0.37Ab | 40.82 ± 0.59Aa | |

| Fat | 3.63 ± 0.15Ac | 4.74 ± 0.14Ab | 5.65 ± 0.05Aa | 5.84 ± 0.06Aa | 6.00 ± 0.10Aa | |

| Infrared grilling | Water | 69.35 ± 0.28ABa | 66.73 ± 0.53Bb | 63.62 ± 0.65Bc | 60.20 ± 0.55Bd | 56.58 ± 0.38Be |

| Protein | 28.73 ± 0.33Be | 30.08 ± 0.59Ad | 33.87 ± 0.57Ac | 36.04 ± 0.50Bb | 37.83 ± 0.54Ba | |

| Fat | 3.08 ± 0.12Bd | 3.97 ± 0.09Bc | 4.52 ± 0.17Bb | 4.84 ± 0.06Bab | 5.17 ± 0.07Ba | |

| Superheated steam roasting | Water | 70.25 ± 0.34Aa | 68.40 ± 0.35Ab | 66.95 ± 0.59Ac | 63.20 ± 0.29Ad | 59.25 ± 0.52Ae |

| Protein | 28.06 ± 0.05Be | 30.15 ± 0.42Ad | 32.53 ± 0.32Ac | 34.38 ± 0.28Cb | 35.50 ± 0.31Ca | |

| Fat | 3.01 ± 0.09Bd | 3.97 ± 0.09Bc | 4.15 ± 0.04Cbc | 4.27 ± 0.06Cb | 5.08 ± 0.03Ba | |

| Cooking method . | Parameter . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Charcoal grilling | Water | 68.35 ± 0.73Ba | 57.06 ± 0.37Cb | 49.29 ± 0.34Cc | 45.87 ± 0.48Cd | 43.58 ± 0.38Ce |

| Protein | 30.70 ± 0.28Ad | 31.72 ± 0.32Ad | 33.96 ± 0.72Ac | 37.50 ± 0.37Ab | 40.82 ± 0.59Aa | |

| Fat | 3.63 ± 0.15Ac | 4.74 ± 0.14Ab | 5.65 ± 0.05Aa | 5.84 ± 0.06Aa | 6.00 ± 0.10Aa | |

| Infrared grilling | Water | 69.35 ± 0.28ABa | 66.73 ± 0.53Bb | 63.62 ± 0.65Bc | 60.20 ± 0.55Bd | 56.58 ± 0.38Be |

| Protein | 28.73 ± 0.33Be | 30.08 ± 0.59Ad | 33.87 ± 0.57Ac | 36.04 ± 0.50Bb | 37.83 ± 0.54Ba | |

| Fat | 3.08 ± 0.12Bd | 3.97 ± 0.09Bc | 4.52 ± 0.17Bb | 4.84 ± 0.06Bab | 5.17 ± 0.07Ba | |

| Superheated steam roasting | Water | 70.25 ± 0.34Aa | 68.40 ± 0.35Ab | 66.95 ± 0.59Ac | 63.20 ± 0.29Ad | 59.25 ± 0.52Ae |

| Protein | 28.06 ± 0.05Be | 30.15 ± 0.42Ad | 32.53 ± 0.32Ac | 34.38 ± 0.28Cb | 35.50 ± 0.31Ca | |

| Fat | 3.01 ± 0.09Bd | 3.97 ± 0.09Bc | 4.15 ± 0.04Cbc | 4.27 ± 0.06Cb | 5.08 ± 0.03Ba | |

Results are given as Means ± Standard error with small letters (a, b and c) show significant difference (P < 0.05) in rows among the different time intervals in three cooking methods while capital letters (A, B and C) show the significant difference (P < 0.05) in columns among the cooking methods on same time intervals.

Cooking loss

The cooking losses are shown in Fig. 1. The results showed that cooking losses in the charcoal grilled lamb patties were higher than those in infrared grilled and the superheated steam roasted lamb patties. There was a significant difference (P < 0.05) at 0 and 4 min of charcoal grilling as the cooking loss was 37.87% at 0 min and 58.28% at 4 min, while in the infrared grilled patties, the cooking loss at initial time was 31.24% and increased to 47.66% in the last 4 min, and the superheated steam roasted lamb patties had the least cooking losses with 24.83%, initially which increased to 45.31% at 4 min. We observed that at 4 min, there was no significance in the cooking losses between superheated and infrared grilling, but charcoal grilling still had higher cooking loss. The probable reason for higher cooking loss in charcoal grilling is that this method exposes the patties to direct flame or charcoal fire, which makes the meat more dried due to higher loss of water. There was less water loss and, hence, less cooking loss in the superheated steam and infrared grilling due to indirect heating.

Cooking losses in the lamb patties cooked by three cooking methods. Capital letters (A, B and C) show the significant difference (P < 0.05) in the three cooking methods while the small letters (a, b and c) show the significant difference (P < 0.05) at different cooking intervals within the same cooking method.

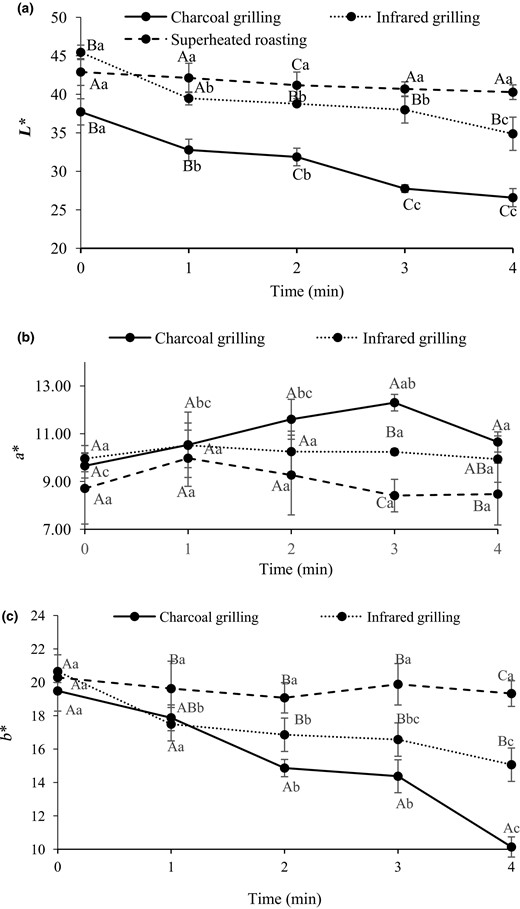

Colour

In Fig. 2 (a), the lightness of the charcoal grilled patties decreased significantly with the increase in time. In a previous study on chicken meat, it was seen that L* and a* values were decreased, and b* values were increased. A dry heat method such as grilling results in dark colour with a decrease in L* value (Oz & Celik, 2015). The infrared grilled lamb patties also showed the same decline, which was lesser than for charcoal grilling. In a previous study of Turp et al. (2016), on meat balls of beef, infrared grilling of meat balls for 12 min with the lowest distance application of infrared caused a darker colour (lower L* value) on both the external and the internal surface of the meatballs. Superheated steam roasted lamb patties had the lowest decrease in lightness value from 0 to 4 min, and there was no significant difference (P ˃ 0.05) among the time intervals. However, the highest value of lightness at the last cooking time was observed in superheated steam compared with infrared and charcoal grilled patties. In a study by Kumar et al. (2006), the colour parameters L*, a* and b* decreased in the superheated steam cooking at all temperatures and times. The decrease in the colour parameters might be due to the Maillard reaction, which is affected and by the chemical environment and by the composition of the product. In Fig. 2 (b), the a* values in charcoal grilled patties increased significantly from the initial 0 min to 3 min (P < 0.05), but there was a decline at last min of cooking (4 min). In the case of infrared grilled patties, a* values increased until 2 min. In case of superheated steam patties, a* values increased from 0 min to 2 min but then decreased significantly (P < 0.05) at 3 min then at 4 min there was a slight increase in the values. In Fig. 2 (c), the yellowness values were observed in the patties. The b* values generally decreased significantly (P < 0.05) in all the patties cooked by charcoal and infrared grilling methods, but not in those cooked by superheated steam, where there was no significant difference at any of the time intervals of cooking.

(a) Lightness value (L*) of the lamb patties cooked by the three cooking methods. (b) Redness value (a*) of the lamb patties cooked by the three cooking methods. (c) Yellowness value (b*) of the lamb patties cooked by the three cooking methods. Different small letters (a, b and c) indicate the significant difference (P < 0.05) between different time intervals of same cooking methods while capital letters (A, B and C) show the significance difference (P < 0.05) between different cooking methods on same time of cooking.

Texture profile

The results of texture analysis are shown in Table 2. The results showed that hardness in the charcoal grilled lamb patties increased with increasing the cooking time (P < 0.05). According to the study of (Tornberg, 2005), cooking at higher temperatures may cause structural variations and denaturation of proteins due to higher heat flux. In a previous study by Pandey et al. (2014), the hardness of deep fried mutton kebabs was found to be lower than that of grilled kebabs. Heat-induced changes are time and temperature dependent, and the net effect of this toughening or tenderization relies on upon cooking conditions (Pathare & Roskilly, 2016). The opposite trend was observed for the infrared grilled cooking on patties, as the hardness was decreased significantly at all cooking intervals, while the springiness was increased except at 2 min. In a study by Turp et al. (2016), it was seen that the application of infrared cooking with different times at 4, 8 and 12 min significantly affected only the hardness and chewiness in beef by lowering the hardness with an increase in the cooking time, and we observed the similar trend. The superheated steam roasting significantly increased hardness in the lamb patties at all cooking intervals significantly (P < 0.05). The gumminess and the chewiness were decreased significantly (P < 0.05) in the superheated steam samples with increased cooking time from 0 to 4 min. In a study by Abdulhameed et al. (2016) on chicken sausage, hardness was decreased with both time and temperature. The drop in the hardness value could be due to the softening of connective tissue caused by the conversion of collagen to gelatin, which improved meat tenderness (Dhanapal et al., 2012). However, the superheated steam roasting had lower hardness values than the charcoal grilled samples. Springiness, gumminess and chewiness decreased significantly (P˃0.05) with the cooking time using superheated steam.

Texture profile analysis of lamb patties cooked with three different methods

| Parameter . | Cooking methods . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Hardness (g) | Charcoal grilled | 8974.35 ± 1.26Be | 12194.01 ± 1.58Ad | 13117.74 ± 1.89Ac | 24515.13 ± 1.16Ab | 27208.48 ± 1.96Aa |

| Infrared grilled | 9876.34 ± 2.25Ab | 8825.97 ± 1.18Cc | 7354.81 ± 2.20Cd | 7233.85 ± 2.10Ce | 11546.66 ± 1.70Ca | |

| Superheated steam roasted | 8076.59 ± 1.80Ce | 9542.41 ± 0.88Bd | 10211.25 ± 1.56Bc | 11395.02 ± 1.01Bb | 11842.02 ± 1.62Ba | |

| Springiness | Charcoal grilled | 0.74 ± 0.01Bb | 0.83 ± 0.02Aa | 0.82 ± 0.02Aa | 0.84 ± 0.01Aa | 0.83 ± 0.02Aa |

| Infrared grilled | 0.81 ± 0.01Abc | 0.86 ± 0.01Aab | 0.78 ± 0.01Ac | 0.86 ± 0.02Aab | 0.89 ± 0.01Aa | |

| Superheated steam roasted | 0.84 ± 0.01Aab | 0.81 ± 0.01Aab | 0.81 ± 0.02Aab | 0.79 ± 0.02Ab | 0.87 ± 0.02Aa | |

| Cohesiveness | Charcoal grilled | 0.51 ± 0.02Aa | 0.53 ± 0.01Aa | 0.58 ± 0.08Aa | 0.56 ± 0.01Aa | 0.55 ± 0.02Aa |

| Infrared grilled | 0.39 ± 0.02Cbc | 0.39 ± 0.01Cbc | 0.38 ± 0.01Bc | 0.44 ± 0.01Ba | 0.43 ± 0.01Bab | |

| Superheated steam roasted | 0.42 ± 0.01Ba | 0.41 ± 0.01Ba | 0.43 ± 0.01ABa | 0.43 ± 0.02Ba | 0.43 ± 0.01Ba | |

| Gumminess (g) | Charcoal grilled | 5250.47 ± 2.41Ae | 6567.80 ± 1.34Ad | 7555.76 ± 1.93Ac | 12975.69 ± 1.74Aa | 9394.93 ± 0.68Ab |

| Infrared grilled | 3957.55 ± 1.78Cb | 3678.71 ± 0.82Cd | 2794.62 ± 0.68Ce | 3792.35 ± 0.67Bc | 5473.23 ± 2.22Ba | |

| Superheated steam roasted | 4895.27 ± 1.39Ba | 3926.55 ± 2.07Bb | 3782.98 ± 1.12Bc | 3487.33 ± 1.97Cd | 3477.20 ± 1.70Ce | |

| Chewiness (g) | Charcoal grilled | 3256.30 ± 1.22Be | 4786.55 ± 2.20Ad | 5741.49 ± 1.84Ac | 11587.02 ± 2.46Aa | 7547.40 ± 2.63Ab |

| Infrared grilled | 3195.86 ± 2.00Cb | 3001.09 ± 2.82Cc | 2286.38 ± 2.11Ce | 2891.62 ± 2.43Cd | 5031.37 ± 2.45Ba | |

| Superheated steam roasted | 4201.86 ± 0.96Aa | 3866.44 ± 1.58Bb | 3723.80 ± 0.82Bc | 3143.73 ± 1.09Bd | 2783.61 ± 1.06Ce | |

| Parameter . | Cooking methods . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Hardness (g) | Charcoal grilled | 8974.35 ± 1.26Be | 12194.01 ± 1.58Ad | 13117.74 ± 1.89Ac | 24515.13 ± 1.16Ab | 27208.48 ± 1.96Aa |

| Infrared grilled | 9876.34 ± 2.25Ab | 8825.97 ± 1.18Cc | 7354.81 ± 2.20Cd | 7233.85 ± 2.10Ce | 11546.66 ± 1.70Ca | |

| Superheated steam roasted | 8076.59 ± 1.80Ce | 9542.41 ± 0.88Bd | 10211.25 ± 1.56Bc | 11395.02 ± 1.01Bb | 11842.02 ± 1.62Ba | |

| Springiness | Charcoal grilled | 0.74 ± 0.01Bb | 0.83 ± 0.02Aa | 0.82 ± 0.02Aa | 0.84 ± 0.01Aa | 0.83 ± 0.02Aa |

| Infrared grilled | 0.81 ± 0.01Abc | 0.86 ± 0.01Aab | 0.78 ± 0.01Ac | 0.86 ± 0.02Aab | 0.89 ± 0.01Aa | |

| Superheated steam roasted | 0.84 ± 0.01Aab | 0.81 ± 0.01Aab | 0.81 ± 0.02Aab | 0.79 ± 0.02Ab | 0.87 ± 0.02Aa | |

| Cohesiveness | Charcoal grilled | 0.51 ± 0.02Aa | 0.53 ± 0.01Aa | 0.58 ± 0.08Aa | 0.56 ± 0.01Aa | 0.55 ± 0.02Aa |

| Infrared grilled | 0.39 ± 0.02Cbc | 0.39 ± 0.01Cbc | 0.38 ± 0.01Bc | 0.44 ± 0.01Ba | 0.43 ± 0.01Bab | |

| Superheated steam roasted | 0.42 ± 0.01Ba | 0.41 ± 0.01Ba | 0.43 ± 0.01ABa | 0.43 ± 0.02Ba | 0.43 ± 0.01Ba | |

| Gumminess (g) | Charcoal grilled | 5250.47 ± 2.41Ae | 6567.80 ± 1.34Ad | 7555.76 ± 1.93Ac | 12975.69 ± 1.74Aa | 9394.93 ± 0.68Ab |

| Infrared grilled | 3957.55 ± 1.78Cb | 3678.71 ± 0.82Cd | 2794.62 ± 0.68Ce | 3792.35 ± 0.67Bc | 5473.23 ± 2.22Ba | |

| Superheated steam roasted | 4895.27 ± 1.39Ba | 3926.55 ± 2.07Bb | 3782.98 ± 1.12Bc | 3487.33 ± 1.97Cd | 3477.20 ± 1.70Ce | |

| Chewiness (g) | Charcoal grilled | 3256.30 ± 1.22Be | 4786.55 ± 2.20Ad | 5741.49 ± 1.84Ac | 11587.02 ± 2.46Aa | 7547.40 ± 2.63Ab |

| Infrared grilled | 3195.86 ± 2.00Cb | 3001.09 ± 2.82Cc | 2286.38 ± 2.11Ce | 2891.62 ± 2.43Cd | 5031.37 ± 2.45Ba | |

| Superheated steam roasted | 4201.86 ± 0.96Aa | 3866.44 ± 1.58Bb | 3723.80 ± 0.82Bc | 3143.73 ± 1.09Bd | 2783.61 ± 1.06Ce | |

Results are given as Means ± Standard error with the significant difference (P < 0.05) in the rows at each time interval of cooking within the same cooking method while (A, B and C) show the significant difference (P < 0.05) in the columns between the different cooking.

Texture profile analysis of lamb patties cooked with three different methods

| Parameter . | Cooking methods . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Hardness (g) | Charcoal grilled | 8974.35 ± 1.26Be | 12194.01 ± 1.58Ad | 13117.74 ± 1.89Ac | 24515.13 ± 1.16Ab | 27208.48 ± 1.96Aa |

| Infrared grilled | 9876.34 ± 2.25Ab | 8825.97 ± 1.18Cc | 7354.81 ± 2.20Cd | 7233.85 ± 2.10Ce | 11546.66 ± 1.70Ca | |

| Superheated steam roasted | 8076.59 ± 1.80Ce | 9542.41 ± 0.88Bd | 10211.25 ± 1.56Bc | 11395.02 ± 1.01Bb | 11842.02 ± 1.62Ba | |

| Springiness | Charcoal grilled | 0.74 ± 0.01Bb | 0.83 ± 0.02Aa | 0.82 ± 0.02Aa | 0.84 ± 0.01Aa | 0.83 ± 0.02Aa |

| Infrared grilled | 0.81 ± 0.01Abc | 0.86 ± 0.01Aab | 0.78 ± 0.01Ac | 0.86 ± 0.02Aab | 0.89 ± 0.01Aa | |

| Superheated steam roasted | 0.84 ± 0.01Aab | 0.81 ± 0.01Aab | 0.81 ± 0.02Aab | 0.79 ± 0.02Ab | 0.87 ± 0.02Aa | |

| Cohesiveness | Charcoal grilled | 0.51 ± 0.02Aa | 0.53 ± 0.01Aa | 0.58 ± 0.08Aa | 0.56 ± 0.01Aa | 0.55 ± 0.02Aa |

| Infrared grilled | 0.39 ± 0.02Cbc | 0.39 ± 0.01Cbc | 0.38 ± 0.01Bc | 0.44 ± 0.01Ba | 0.43 ± 0.01Bab | |

| Superheated steam roasted | 0.42 ± 0.01Ba | 0.41 ± 0.01Ba | 0.43 ± 0.01ABa | 0.43 ± 0.02Ba | 0.43 ± 0.01Ba | |

| Gumminess (g) | Charcoal grilled | 5250.47 ± 2.41Ae | 6567.80 ± 1.34Ad | 7555.76 ± 1.93Ac | 12975.69 ± 1.74Aa | 9394.93 ± 0.68Ab |

| Infrared grilled | 3957.55 ± 1.78Cb | 3678.71 ± 0.82Cd | 2794.62 ± 0.68Ce | 3792.35 ± 0.67Bc | 5473.23 ± 2.22Ba | |

| Superheated steam roasted | 4895.27 ± 1.39Ba | 3926.55 ± 2.07Bb | 3782.98 ± 1.12Bc | 3487.33 ± 1.97Cd | 3477.20 ± 1.70Ce | |

| Chewiness (g) | Charcoal grilled | 3256.30 ± 1.22Be | 4786.55 ± 2.20Ad | 5741.49 ± 1.84Ac | 11587.02 ± 2.46Aa | 7547.40 ± 2.63Ab |

| Infrared grilled | 3195.86 ± 2.00Cb | 3001.09 ± 2.82Cc | 2286.38 ± 2.11Ce | 2891.62 ± 2.43Cd | 5031.37 ± 2.45Ba | |

| Superheated steam roasted | 4201.86 ± 0.96Aa | 3866.44 ± 1.58Bb | 3723.80 ± 0.82Bc | 3143.73 ± 1.09Bd | 2783.61 ± 1.06Ce | |

| Parameter . | Cooking methods . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Hardness (g) | Charcoal grilled | 8974.35 ± 1.26Be | 12194.01 ± 1.58Ad | 13117.74 ± 1.89Ac | 24515.13 ± 1.16Ab | 27208.48 ± 1.96Aa |

| Infrared grilled | 9876.34 ± 2.25Ab | 8825.97 ± 1.18Cc | 7354.81 ± 2.20Cd | 7233.85 ± 2.10Ce | 11546.66 ± 1.70Ca | |

| Superheated steam roasted | 8076.59 ± 1.80Ce | 9542.41 ± 0.88Bd | 10211.25 ± 1.56Bc | 11395.02 ± 1.01Bb | 11842.02 ± 1.62Ba | |

| Springiness | Charcoal grilled | 0.74 ± 0.01Bb | 0.83 ± 0.02Aa | 0.82 ± 0.02Aa | 0.84 ± 0.01Aa | 0.83 ± 0.02Aa |

| Infrared grilled | 0.81 ± 0.01Abc | 0.86 ± 0.01Aab | 0.78 ± 0.01Ac | 0.86 ± 0.02Aab | 0.89 ± 0.01Aa | |

| Superheated steam roasted | 0.84 ± 0.01Aab | 0.81 ± 0.01Aab | 0.81 ± 0.02Aab | 0.79 ± 0.02Ab | 0.87 ± 0.02Aa | |

| Cohesiveness | Charcoal grilled | 0.51 ± 0.02Aa | 0.53 ± 0.01Aa | 0.58 ± 0.08Aa | 0.56 ± 0.01Aa | 0.55 ± 0.02Aa |

| Infrared grilled | 0.39 ± 0.02Cbc | 0.39 ± 0.01Cbc | 0.38 ± 0.01Bc | 0.44 ± 0.01Ba | 0.43 ± 0.01Bab | |

| Superheated steam roasted | 0.42 ± 0.01Ba | 0.41 ± 0.01Ba | 0.43 ± 0.01ABa | 0.43 ± 0.02Ba | 0.43 ± 0.01Ba | |

| Gumminess (g) | Charcoal grilled | 5250.47 ± 2.41Ae | 6567.80 ± 1.34Ad | 7555.76 ± 1.93Ac | 12975.69 ± 1.74Aa | 9394.93 ± 0.68Ab |

| Infrared grilled | 3957.55 ± 1.78Cb | 3678.71 ± 0.82Cd | 2794.62 ± 0.68Ce | 3792.35 ± 0.67Bc | 5473.23 ± 2.22Ba | |

| Superheated steam roasted | 4895.27 ± 1.39Ba | 3926.55 ± 2.07Bb | 3782.98 ± 1.12Bc | 3487.33 ± 1.97Cd | 3477.20 ± 1.70Ce | |

| Chewiness (g) | Charcoal grilled | 3256.30 ± 1.22Be | 4786.55 ± 2.20Ad | 5741.49 ± 1.84Ac | 11587.02 ± 2.46Aa | 7547.40 ± 2.63Ab |

| Infrared grilled | 3195.86 ± 2.00Cb | 3001.09 ± 2.82Cc | 2286.38 ± 2.11Ce | 2891.62 ± 2.43Cd | 5031.37 ± 2.45Ba | |

| Superheated steam roasted | 4201.86 ± 0.96Aa | 3866.44 ± 1.58Bb | 3723.80 ± 0.82Bc | 3143.73 ± 1.09Bd | 2783.61 ± 1.06Ce | |

Results are given as Means ± Standard error with the significant difference (P < 0.05) in the rows at each time interval of cooking within the same cooking method while (A, B and C) show the significant difference (P < 0.05) in the columns between the different cooking.

Polar HAAs

The results of polar HAAs are shown in Table 3. Each cooking method had a significant effect on the content of polar HAAs. The polar HAAs in charcoal grilled lamb patties were higher in content due to high-temperature cooking, and as the time from core temperature to 4 min increased, there was an increased trend in HAAs content. The total content ranged from 171.26 to 555.29 ng g−1, as shown in Fig. 3 (a). According to Viegas et al. (2012), the charcoal grilling of beef produced many HAAs such as MeIQx, PhIP, TrP-1 and AαC and MeAαC. In a previous study, by Oz & Cakmak (2016), IQ was determined at a higher amount samples cooked on wire barbecue. In our study, we found that IQ was produced in higher content than the other HAAs. Moreover, to elaborate the formation of HAAs in charcoal grilled meat a figure showing the formation pathways of different kinds of HAAs in grilled/roasted meat is shown in Fig. 4. Infrared grilled patties had a significantly (P < 0.05) lower content of polar HAAs, and the overall quantity was also lower than those in charcoal grilled patties as shown in Table 3 and Fig. 3 (a). Superheated steam roasted patties had also lower content of all polar HAAs than the charcoal grilled patties. Previous studies of Kondjoyan et al. (2010) on beef longissimus muscle, which was subjected to superheated steam at 170 and 200 °C, showed that the content of the polar HAAs IQx, MeIQx, PhIP and 4,8-DiMeIQx after 5 min of cooking increased from 2.5 fold to 8.0 fold, respectively. However, we observed that superheated steam was efficient to reduce the content of many HAAs.

| Cooking method . | HAAs ng g−1 . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Charcoal grilling | DMIP | 127.24 ± 0.60Ae | 270.57 ± 1.12Ad | 276.87 ± 0.66Ac | 389.06 ± 1.71Ab | 405.22 ± 0.78Aa |

| PhIP | 20.83 ± 0.90Ae | 32.14 ± 0.45Ad | 55.41 ± 0.65Ac | 63.72 ± 0.93Ab | 73.32 ± 1.43Aa | |

| IQ | 0.08 ± 0.01Be | 0.13 ± 0.02Bd | 0.21 ± 0.01Bc | 0.34 ± 0.03Bb | 0.41 ± 0.01Ba | |

| IQx | 14.72 ± 0.50Ad | 16.08 ± 0.76Ad | 19.64 ± 0.21Ac | 24.27 ± 0.75Ab | 41.42 ± 0.91Aa | |

| 4,8-DiMeIQx | 1.45 ± 0.02Ad | 3.99 ± 0.06Ac | 6.90 ± 0.08Ab | 9.99 ± 0.56Aa | 10.30 ± 0.13Aa | |

| 7,8-DiMeIQx | 0.43 ± 0.01Be | 0.62 ± 0.05Ad | 0.80 ± 0.01Ac | 1.23 ± 0.04Ab | 1.65 ± 0.07Aa | |

| IQ(4,5-b) | 1.32 ± 0.01Ae | 1.79 ± 0.01Ad | 2.53 ± 0.05Ac | 4.14 ± 0.21Ab | 6.37 ± 0.11Aa | |

| 8-MeIQx | 4.27 ± 0.02Ad | 6.98 ± 0.18Ac | 10.52 ± 0.34Ab | 11.56 ± 0.45Ab | 12.84 ± 0.62Aa | |

| ISO-IQ | 0.88 ± 0.03Ae | 1.40 ± 0.01Ad | 1.95 ± 0.05Ac | 2.26 ± 0.11Ab | 4.05 ± 0.07Aa | |

| Infrared grilling | DMIP | 28.81 ± 0.84Be | 36.71 ± 0.81Bd | 89.35 ± 0.42Bc | 121.70 ± 0.75Bb | 139.02 ± 0.82Ba |

| PhIP | 2.40 ± 0.37Bd | 2.99 ± 0.13Bcd | 4.08 ± 0.20Bc | 5.95 ± 0.49Bb | 10.31 ± 0.83Ba | |

| IQx | 3.94 ± 0.17Bc | 6.22 ± 1.19Bbc | 8.97 ± 1.86Bb | 15.52 ± 0.84Ba | 16.96 ± 0.57Ba | |

| IQ(4,5-b) | 0.25 ± 0.05Cd | 0.69 ± 0.11Cc | 1.03 ± 0.07Bb | 1.29 ± 0.06Bab | 1.56 ± 0.15Ba | |

| 4,8-DiMeIQx | 0.14 ± 0.01Bc | 0.22 ± 0.01Bc | 0.46 ± 0.07Bb | 0.66 ± 0.09Bb | 1.17 ± 0.11Ba | |

| 7,8-DiMeIQx | 0.66 ± 0.01Ad | 0.70 ± 0.01Ac | 0.71 ± 0.02Bbc | 0.72 ± 0.02Bb | 0.80 ± 0.01Ba | |

| MeIQ | 2.85 ± 0.33d | 4.28 ± 0.39 cd | 5.86 ± 0.53bc | 7.72 ± 0.32b | 11.66 ± 1.24a | |

| Superheated steam roasting | DMIP | 3.79 ± 0.09Cc | 4.84 ± 0.66Cbc | 5.98 ± 0.13Cb | 6.24 ± 0.07Cb | 15.72 ± 0.76Ca |

| PhIP | 1.24 ± 0.06Ce | 2.58 ± 0.05Bd | 3.18 ± 0.09Bc | 3.88 ± 0.01Bb | 6.38 ± 0.05Ca | |

| IQ | 0.80 ± 0.05Ad | 1.27 ± 0.01Ac | 1.45 ± 0.05Ab | 1.56 ± 0.03Ab | 1.93 ± 0.05Aa | |

| IQx | 1.35 ± 0.02Cd | 1.37 ± 0.01Cd | 1.69 ± 0.05Cc | 2.04 ± 0.08Cb | 2.33 ± 0.10Ca | |

| IQ(4,5-b) | 0.79 ± 0.13Bb | 1.38 ± 0.12Ba | 1.19 ± 0.12Ba | 1.38 ± 0.12Ba | 1.44 ± 0.01Ba | |

| 8-MeIQx | 0.19 ± 0.01Be | 0.33 ± 0.02Bd | 0.47 ± 0.03Bc | 0.75 ± 0.02Bb | 1.63 ± 0.01Ba | |

| ISO-IQ | 0.50 ± 0.01Bd | 0.77 ± 0.04Bc | 0.86 ± 0.02Bb | 1.14 ± 0.05Ba | 1.24 ± 0.03Ba | |

| Cooking method . | HAAs ng g−1 . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Charcoal grilling | DMIP | 127.24 ± 0.60Ae | 270.57 ± 1.12Ad | 276.87 ± 0.66Ac | 389.06 ± 1.71Ab | 405.22 ± 0.78Aa |

| PhIP | 20.83 ± 0.90Ae | 32.14 ± 0.45Ad | 55.41 ± 0.65Ac | 63.72 ± 0.93Ab | 73.32 ± 1.43Aa | |

| IQ | 0.08 ± 0.01Be | 0.13 ± 0.02Bd | 0.21 ± 0.01Bc | 0.34 ± 0.03Bb | 0.41 ± 0.01Ba | |

| IQx | 14.72 ± 0.50Ad | 16.08 ± 0.76Ad | 19.64 ± 0.21Ac | 24.27 ± 0.75Ab | 41.42 ± 0.91Aa | |

| 4,8-DiMeIQx | 1.45 ± 0.02Ad | 3.99 ± 0.06Ac | 6.90 ± 0.08Ab | 9.99 ± 0.56Aa | 10.30 ± 0.13Aa | |

| 7,8-DiMeIQx | 0.43 ± 0.01Be | 0.62 ± 0.05Ad | 0.80 ± 0.01Ac | 1.23 ± 0.04Ab | 1.65 ± 0.07Aa | |

| IQ(4,5-b) | 1.32 ± 0.01Ae | 1.79 ± 0.01Ad | 2.53 ± 0.05Ac | 4.14 ± 0.21Ab | 6.37 ± 0.11Aa | |

| 8-MeIQx | 4.27 ± 0.02Ad | 6.98 ± 0.18Ac | 10.52 ± 0.34Ab | 11.56 ± 0.45Ab | 12.84 ± 0.62Aa | |

| ISO-IQ | 0.88 ± 0.03Ae | 1.40 ± 0.01Ad | 1.95 ± 0.05Ac | 2.26 ± 0.11Ab | 4.05 ± 0.07Aa | |

| Infrared grilling | DMIP | 28.81 ± 0.84Be | 36.71 ± 0.81Bd | 89.35 ± 0.42Bc | 121.70 ± 0.75Bb | 139.02 ± 0.82Ba |

| PhIP | 2.40 ± 0.37Bd | 2.99 ± 0.13Bcd | 4.08 ± 0.20Bc | 5.95 ± 0.49Bb | 10.31 ± 0.83Ba | |

| IQx | 3.94 ± 0.17Bc | 6.22 ± 1.19Bbc | 8.97 ± 1.86Bb | 15.52 ± 0.84Ba | 16.96 ± 0.57Ba | |

| IQ(4,5-b) | 0.25 ± 0.05Cd | 0.69 ± 0.11Cc | 1.03 ± 0.07Bb | 1.29 ± 0.06Bab | 1.56 ± 0.15Ba | |

| 4,8-DiMeIQx | 0.14 ± 0.01Bc | 0.22 ± 0.01Bc | 0.46 ± 0.07Bb | 0.66 ± 0.09Bb | 1.17 ± 0.11Ba | |

| 7,8-DiMeIQx | 0.66 ± 0.01Ad | 0.70 ± 0.01Ac | 0.71 ± 0.02Bbc | 0.72 ± 0.02Bb | 0.80 ± 0.01Ba | |

| MeIQ | 2.85 ± 0.33d | 4.28 ± 0.39 cd | 5.86 ± 0.53bc | 7.72 ± 0.32b | 11.66 ± 1.24a | |

| Superheated steam roasting | DMIP | 3.79 ± 0.09Cc | 4.84 ± 0.66Cbc | 5.98 ± 0.13Cb | 6.24 ± 0.07Cb | 15.72 ± 0.76Ca |

| PhIP | 1.24 ± 0.06Ce | 2.58 ± 0.05Bd | 3.18 ± 0.09Bc | 3.88 ± 0.01Bb | 6.38 ± 0.05Ca | |

| IQ | 0.80 ± 0.05Ad | 1.27 ± 0.01Ac | 1.45 ± 0.05Ab | 1.56 ± 0.03Ab | 1.93 ± 0.05Aa | |

| IQx | 1.35 ± 0.02Cd | 1.37 ± 0.01Cd | 1.69 ± 0.05Cc | 2.04 ± 0.08Cb | 2.33 ± 0.10Ca | |

| IQ(4,5-b) | 0.79 ± 0.13Bb | 1.38 ± 0.12Ba | 1.19 ± 0.12Ba | 1.38 ± 0.12Ba | 1.44 ± 0.01Ba | |

| 8-MeIQx | 0.19 ± 0.01Be | 0.33 ± 0.02Bd | 0.47 ± 0.03Bc | 0.75 ± 0.02Bb | 1.63 ± 0.01Ba | |

| ISO-IQ | 0.50 ± 0.01Bd | 0.77 ± 0.04Bc | 0.86 ± 0.02Bb | 1.14 ± 0.05Ba | 1.24 ± 0.03Ba | |

Results are given as Means ± Standard error with significant difference (P < 0.05) in the rows between time intervals for each cooking method while capital letters (A, B and C) show the significant difference (P < 0.05) in columns between the cooking methods. MeIQ was detected only in the infrared grilled samples so no capital letters appear on the values to show the significance with other cooking methods.

| Cooking method . | HAAs ng g−1 . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Charcoal grilling | DMIP | 127.24 ± 0.60Ae | 270.57 ± 1.12Ad | 276.87 ± 0.66Ac | 389.06 ± 1.71Ab | 405.22 ± 0.78Aa |

| PhIP | 20.83 ± 0.90Ae | 32.14 ± 0.45Ad | 55.41 ± 0.65Ac | 63.72 ± 0.93Ab | 73.32 ± 1.43Aa | |

| IQ | 0.08 ± 0.01Be | 0.13 ± 0.02Bd | 0.21 ± 0.01Bc | 0.34 ± 0.03Bb | 0.41 ± 0.01Ba | |

| IQx | 14.72 ± 0.50Ad | 16.08 ± 0.76Ad | 19.64 ± 0.21Ac | 24.27 ± 0.75Ab | 41.42 ± 0.91Aa | |

| 4,8-DiMeIQx | 1.45 ± 0.02Ad | 3.99 ± 0.06Ac | 6.90 ± 0.08Ab | 9.99 ± 0.56Aa | 10.30 ± 0.13Aa | |

| 7,8-DiMeIQx | 0.43 ± 0.01Be | 0.62 ± 0.05Ad | 0.80 ± 0.01Ac | 1.23 ± 0.04Ab | 1.65 ± 0.07Aa | |

| IQ(4,5-b) | 1.32 ± 0.01Ae | 1.79 ± 0.01Ad | 2.53 ± 0.05Ac | 4.14 ± 0.21Ab | 6.37 ± 0.11Aa | |

| 8-MeIQx | 4.27 ± 0.02Ad | 6.98 ± 0.18Ac | 10.52 ± 0.34Ab | 11.56 ± 0.45Ab | 12.84 ± 0.62Aa | |

| ISO-IQ | 0.88 ± 0.03Ae | 1.40 ± 0.01Ad | 1.95 ± 0.05Ac | 2.26 ± 0.11Ab | 4.05 ± 0.07Aa | |

| Infrared grilling | DMIP | 28.81 ± 0.84Be | 36.71 ± 0.81Bd | 89.35 ± 0.42Bc | 121.70 ± 0.75Bb | 139.02 ± 0.82Ba |

| PhIP | 2.40 ± 0.37Bd | 2.99 ± 0.13Bcd | 4.08 ± 0.20Bc | 5.95 ± 0.49Bb | 10.31 ± 0.83Ba | |

| IQx | 3.94 ± 0.17Bc | 6.22 ± 1.19Bbc | 8.97 ± 1.86Bb | 15.52 ± 0.84Ba | 16.96 ± 0.57Ba | |

| IQ(4,5-b) | 0.25 ± 0.05Cd | 0.69 ± 0.11Cc | 1.03 ± 0.07Bb | 1.29 ± 0.06Bab | 1.56 ± 0.15Ba | |

| 4,8-DiMeIQx | 0.14 ± 0.01Bc | 0.22 ± 0.01Bc | 0.46 ± 0.07Bb | 0.66 ± 0.09Bb | 1.17 ± 0.11Ba | |

| 7,8-DiMeIQx | 0.66 ± 0.01Ad | 0.70 ± 0.01Ac | 0.71 ± 0.02Bbc | 0.72 ± 0.02Bb | 0.80 ± 0.01Ba | |

| MeIQ | 2.85 ± 0.33d | 4.28 ± 0.39 cd | 5.86 ± 0.53bc | 7.72 ± 0.32b | 11.66 ± 1.24a | |

| Superheated steam roasting | DMIP | 3.79 ± 0.09Cc | 4.84 ± 0.66Cbc | 5.98 ± 0.13Cb | 6.24 ± 0.07Cb | 15.72 ± 0.76Ca |

| PhIP | 1.24 ± 0.06Ce | 2.58 ± 0.05Bd | 3.18 ± 0.09Bc | 3.88 ± 0.01Bb | 6.38 ± 0.05Ca | |

| IQ | 0.80 ± 0.05Ad | 1.27 ± 0.01Ac | 1.45 ± 0.05Ab | 1.56 ± 0.03Ab | 1.93 ± 0.05Aa | |

| IQx | 1.35 ± 0.02Cd | 1.37 ± 0.01Cd | 1.69 ± 0.05Cc | 2.04 ± 0.08Cb | 2.33 ± 0.10Ca | |

| IQ(4,5-b) | 0.79 ± 0.13Bb | 1.38 ± 0.12Ba | 1.19 ± 0.12Ba | 1.38 ± 0.12Ba | 1.44 ± 0.01Ba | |

| 8-MeIQx | 0.19 ± 0.01Be | 0.33 ± 0.02Bd | 0.47 ± 0.03Bc | 0.75 ± 0.02Bb | 1.63 ± 0.01Ba | |

| ISO-IQ | 0.50 ± 0.01Bd | 0.77 ± 0.04Bc | 0.86 ± 0.02Bb | 1.14 ± 0.05Ba | 1.24 ± 0.03Ba | |

| Cooking method . | HAAs ng g−1 . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Charcoal grilling | DMIP | 127.24 ± 0.60Ae | 270.57 ± 1.12Ad | 276.87 ± 0.66Ac | 389.06 ± 1.71Ab | 405.22 ± 0.78Aa |

| PhIP | 20.83 ± 0.90Ae | 32.14 ± 0.45Ad | 55.41 ± 0.65Ac | 63.72 ± 0.93Ab | 73.32 ± 1.43Aa | |

| IQ | 0.08 ± 0.01Be | 0.13 ± 0.02Bd | 0.21 ± 0.01Bc | 0.34 ± 0.03Bb | 0.41 ± 0.01Ba | |

| IQx | 14.72 ± 0.50Ad | 16.08 ± 0.76Ad | 19.64 ± 0.21Ac | 24.27 ± 0.75Ab | 41.42 ± 0.91Aa | |

| 4,8-DiMeIQx | 1.45 ± 0.02Ad | 3.99 ± 0.06Ac | 6.90 ± 0.08Ab | 9.99 ± 0.56Aa | 10.30 ± 0.13Aa | |

| 7,8-DiMeIQx | 0.43 ± 0.01Be | 0.62 ± 0.05Ad | 0.80 ± 0.01Ac | 1.23 ± 0.04Ab | 1.65 ± 0.07Aa | |

| IQ(4,5-b) | 1.32 ± 0.01Ae | 1.79 ± 0.01Ad | 2.53 ± 0.05Ac | 4.14 ± 0.21Ab | 6.37 ± 0.11Aa | |

| 8-MeIQx | 4.27 ± 0.02Ad | 6.98 ± 0.18Ac | 10.52 ± 0.34Ab | 11.56 ± 0.45Ab | 12.84 ± 0.62Aa | |

| ISO-IQ | 0.88 ± 0.03Ae | 1.40 ± 0.01Ad | 1.95 ± 0.05Ac | 2.26 ± 0.11Ab | 4.05 ± 0.07Aa | |

| Infrared grilling | DMIP | 28.81 ± 0.84Be | 36.71 ± 0.81Bd | 89.35 ± 0.42Bc | 121.70 ± 0.75Bb | 139.02 ± 0.82Ba |

| PhIP | 2.40 ± 0.37Bd | 2.99 ± 0.13Bcd | 4.08 ± 0.20Bc | 5.95 ± 0.49Bb | 10.31 ± 0.83Ba | |

| IQx | 3.94 ± 0.17Bc | 6.22 ± 1.19Bbc | 8.97 ± 1.86Bb | 15.52 ± 0.84Ba | 16.96 ± 0.57Ba | |

| IQ(4,5-b) | 0.25 ± 0.05Cd | 0.69 ± 0.11Cc | 1.03 ± 0.07Bb | 1.29 ± 0.06Bab | 1.56 ± 0.15Ba | |

| 4,8-DiMeIQx | 0.14 ± 0.01Bc | 0.22 ± 0.01Bc | 0.46 ± 0.07Bb | 0.66 ± 0.09Bb | 1.17 ± 0.11Ba | |

| 7,8-DiMeIQx | 0.66 ± 0.01Ad | 0.70 ± 0.01Ac | 0.71 ± 0.02Bbc | 0.72 ± 0.02Bb | 0.80 ± 0.01Ba | |

| MeIQ | 2.85 ± 0.33d | 4.28 ± 0.39 cd | 5.86 ± 0.53bc | 7.72 ± 0.32b | 11.66 ± 1.24a | |

| Superheated steam roasting | DMIP | 3.79 ± 0.09Cc | 4.84 ± 0.66Cbc | 5.98 ± 0.13Cb | 6.24 ± 0.07Cb | 15.72 ± 0.76Ca |

| PhIP | 1.24 ± 0.06Ce | 2.58 ± 0.05Bd | 3.18 ± 0.09Bc | 3.88 ± 0.01Bb | 6.38 ± 0.05Ca | |

| IQ | 0.80 ± 0.05Ad | 1.27 ± 0.01Ac | 1.45 ± 0.05Ab | 1.56 ± 0.03Ab | 1.93 ± 0.05Aa | |

| IQx | 1.35 ± 0.02Cd | 1.37 ± 0.01Cd | 1.69 ± 0.05Cc | 2.04 ± 0.08Cb | 2.33 ± 0.10Ca | |

| IQ(4,5-b) | 0.79 ± 0.13Bb | 1.38 ± 0.12Ba | 1.19 ± 0.12Ba | 1.38 ± 0.12Ba | 1.44 ± 0.01Ba | |

| 8-MeIQx | 0.19 ± 0.01Be | 0.33 ± 0.02Bd | 0.47 ± 0.03Bc | 0.75 ± 0.02Bb | 1.63 ± 0.01Ba | |

| ISO-IQ | 0.50 ± 0.01Bd | 0.77 ± 0.04Bc | 0.86 ± 0.02Bb | 1.14 ± 0.05Ba | 1.24 ± 0.03Ba | |

Results are given as Means ± Standard error with significant difference (P < 0.05) in the rows between time intervals for each cooking method while capital letters (A, B and C) show the significant difference (P < 0.05) in columns between the cooking methods. MeIQ was detected only in the infrared grilled samples so no capital letters appear on the values to show the significance with other cooking methods.

(a) At 0 min (core temperature-time), total polar HAAs content ng g−1 dry matter basis in lamb patties cooked with three different cooking methods. (b) At 0 min, total non-polar HAAs content ng g−1 dry matter basis in lamb patties cooked with three different cooking methods. The small letters (a, b and c) show the significant difference (P < 0.05) at all times of cooking within the cooking method while the capital letters (A, B and C) show the significant difference (P < 0.05) among the cooking methods.

![Formation pathways of different kinds of HAAs (Kizil et al., 2011; Gibis, 2016; Reartes et al., 2016) produced in charcoal grilled or roasted meat. (a) IQx or IQ compounds. (b) PhIP compound. (c) β-carbolines (Norharman) compound. [Colour figure can be viewed at wileyonlinelibrary.com]](https://oup.silverchair-cdn.com/oup/backfile/Content_public/Journal/ijfst/55/3/10.1111_ijfs.14388/1/m_ijfs14388-fig-0004-m.jpeg?Expires=1750346997&Signature=eGkFvZvGbC3Zeug~zSi1sGpdi8nXNrH08aILX2VZTqbEeJkFJ8HGyuWGU8nheJDlEl-iGh-RGMsT~2rX9CReAWQLzbSg5vLckkSNV43RKWXtxNj4fCt-CHcLVWllcAcEwCHMvtyl-ICoZvkNwTW~T~lPnNl44iK3HOdk-0873fxSM8GhZrrTGTZojIqPVJVXWGYH94uXaSoKQOp0lN5siaDT2c~omsyA6gPHF0Mjgt3zLFdLOP9XcIyythZPbpCw8TZkGP4J-9BNJhDRq7-LuhagOQU2ahKn0l2av1hK986I56pTfivRjuX7ssWbtVSnS9~gFOSJxDSOevVdKyTWrA__&Key-Pair-Id=APKAIE5G5CRDK6RD3PGA)

Formation pathways of different kinds of HAAs (Kizil et al., 2011; Gibis, 2016; Reartes et al., 2016) produced in charcoal grilled or roasted meat. (a) IQx or IQ compounds. (b) PhIP compound. (c) β-carbolines (Norharman) compound. [Colour figure can be viewed at wileyonlinelibrary.com]

Non-polar HAAs

The results of non-polar HAAs in Table 4 showed that charcoal fire grilling produced a higher content of non-polar HAAs in a similar pattern to that observed earlier for the polar HAAs. According to a study by Guo et al. (2014), the formation of different HAAs in cooked lamb depends on the cooking time and the cooking method and on the presence of Harman and Norharman with concentration ranges of 0.38–7.23 ng g−1 and 0.73–6.17 ng g−1, respectively, but not on the presence of TrP-P-1 and TrP-P-2. We observed the same trend of occurrence in our lamb patties with the presence of Harman and Norharman, but TrP-P-1 and TrP-P-2 were not detected in our patties. We observed that AαC was formed in our lamb patties similar to results of (Knize et al., 1997) and stated that flames of charcoal fire produced the AαC in beef grilled over charcoal fire. The content of non-polar HAAs, including Harman, Norharman, AαC and Glu-P-1, increased significantly (P ˃ 0.05) from 88.59 to 95.18 ng g−1, from 98.68 to 312.45 ng g−1, from 12.66 ng g−1 to 16.88 ng g−1 and from 0.84 to 1.55 ng g−1, respectively, while the total content was increased significantly (P ˃ 0.05) from 200.77 to 426.07 ng g−1 at the last minute of cooking. The infrared grilling produced a lesser content of non-polar HAAs with Harman, Norharman, Glu-P-1 and Glu-P-2 with 3.74–18.21, 46.90–116.50, 0.26–0.81 and 1.93–13.07 ng g−1, respectively.

| Cooking method . | HAAs . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Charcoal grilling | Harman | 88.59 ± 0.30Ac | 87.98 ± 0.99Ac | 91.52 ± 0.41Ab | 93.11 ± 0.11Ab | 95.18 ± 0.48Aa |

| Norharman | 98.68 ± 0.76Ad | 159.46 ± 1.60Ac | 162.45 ± 0.25Ac | 307.06 ± 1.28Ab | 312.45 ± 1.02Aa | |

| AαC | 12.66 ± 0.26d | 13.69 ± 0.31 cd | 14.86 ± 0.54bc | 15.43 ± 0.33b | 16.88 ± 0.54a | |

| Glu-P-1 | 0.84 ± 0.42Aa | 0.98 ± 0.05Aa | 0.98 ± 0.02Aa | 1.34 ± 0.26Aa | 1.55 ± 0.13Aa | |

| Infrared grilling | Harman | 3.74 ± 0.60Bc | 5.49 ± 0.48Bc | 10.33 ± 0.97Bb | 15.88 ± 0.44Ba | 18.21 ± 1.01Ba |

| Norharman | 46.90 ± 0.85Be | 81.44 ± 0.40Bd | 89.21 ± 0.47Bc | 91.98 ± 0.63Bb | 116.50 ± 0.86Ba | |

| Glu-P-1 | 0.26 ± 0.03Ac | 0.35 ± 0.04Bc | 0.37 ± 0.08Bc | 0.56 ± 0.01Bb | 0.81 ± 0.05Ba | |

| Glu-P-2 | 1.93 ± 0.30Bd | 3.85 ± 0.46Bd | 6.63 ± 1.03Bc | 10.07 ± 0.43Bb | 13.07 ± 0.76Ba | |

| Superheated steam roasting | Harman | 1.63 ± 0.03Ce | 1.97 ± 0.04Cd | 2.59 ± 0.01Cc | 3.14 ± 0.06Cb | 3.52 ± 0.07Ca |

| Norharman | 6.21 ± 0.05Ce | 7.99 ± 0.03Cd | 9.09 ± 0.20Cc | 10.74 ± 0.20Cb | 11.83 ± 0.05Ca | |

| Glu-P-2 | 15.60 ± 0.60Ae | 30.08 ± 0.69Ad | 49.60 ± 0.30Ac | 59.32 ± 0.58Ab | 66.98 ± 1.25Aa | |

| MeAαC | 0.16 ± 0.01c | 0.14 ± 0.01c | 0.72 ± 0.55c | 5.97 ± 0.54b | 7.32 ± 0.75a | |

| Cooking method . | HAAs . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Charcoal grilling | Harman | 88.59 ± 0.30Ac | 87.98 ± 0.99Ac | 91.52 ± 0.41Ab | 93.11 ± 0.11Ab | 95.18 ± 0.48Aa |

| Norharman | 98.68 ± 0.76Ad | 159.46 ± 1.60Ac | 162.45 ± 0.25Ac | 307.06 ± 1.28Ab | 312.45 ± 1.02Aa | |

| AαC | 12.66 ± 0.26d | 13.69 ± 0.31 cd | 14.86 ± 0.54bc | 15.43 ± 0.33b | 16.88 ± 0.54a | |

| Glu-P-1 | 0.84 ± 0.42Aa | 0.98 ± 0.05Aa | 0.98 ± 0.02Aa | 1.34 ± 0.26Aa | 1.55 ± 0.13Aa | |

| Infrared grilling | Harman | 3.74 ± 0.60Bc | 5.49 ± 0.48Bc | 10.33 ± 0.97Bb | 15.88 ± 0.44Ba | 18.21 ± 1.01Ba |

| Norharman | 46.90 ± 0.85Be | 81.44 ± 0.40Bd | 89.21 ± 0.47Bc | 91.98 ± 0.63Bb | 116.50 ± 0.86Ba | |

| Glu-P-1 | 0.26 ± 0.03Ac | 0.35 ± 0.04Bc | 0.37 ± 0.08Bc | 0.56 ± 0.01Bb | 0.81 ± 0.05Ba | |

| Glu-P-2 | 1.93 ± 0.30Bd | 3.85 ± 0.46Bd | 6.63 ± 1.03Bc | 10.07 ± 0.43Bb | 13.07 ± 0.76Ba | |

| Superheated steam roasting | Harman | 1.63 ± 0.03Ce | 1.97 ± 0.04Cd | 2.59 ± 0.01Cc | 3.14 ± 0.06Cb | 3.52 ± 0.07Ca |

| Norharman | 6.21 ± 0.05Ce | 7.99 ± 0.03Cd | 9.09 ± 0.20Cc | 10.74 ± 0.20Cb | 11.83 ± 0.05Ca | |

| Glu-P-2 | 15.60 ± 0.60Ae | 30.08 ± 0.69Ad | 49.60 ± 0.30Ac | 59.32 ± 0.58Ab | 66.98 ± 1.25Aa | |

| MeAαC | 0.16 ± 0.01c | 0.14 ± 0.01c | 0.72 ± 0.55c | 5.97 ± 0.54b | 7.32 ± 0.75a | |

Results are given as Means ± Standard error with significant difference (P < 0.05) in the rows for each time interval of individual cooking method while capital letters (A, B and C) show the significant difference (P < 0.05) between cooking methods in the columns. AαC and MeAαC were detected individually in only each one method of cooking so no significant difference could be found therefore no capital letters appear on their values.

| Cooking method . | HAAs . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Charcoal grilling | Harman | 88.59 ± 0.30Ac | 87.98 ± 0.99Ac | 91.52 ± 0.41Ab | 93.11 ± 0.11Ab | 95.18 ± 0.48Aa |

| Norharman | 98.68 ± 0.76Ad | 159.46 ± 1.60Ac | 162.45 ± 0.25Ac | 307.06 ± 1.28Ab | 312.45 ± 1.02Aa | |

| AαC | 12.66 ± 0.26d | 13.69 ± 0.31 cd | 14.86 ± 0.54bc | 15.43 ± 0.33b | 16.88 ± 0.54a | |

| Glu-P-1 | 0.84 ± 0.42Aa | 0.98 ± 0.05Aa | 0.98 ± 0.02Aa | 1.34 ± 0.26Aa | 1.55 ± 0.13Aa | |

| Infrared grilling | Harman | 3.74 ± 0.60Bc | 5.49 ± 0.48Bc | 10.33 ± 0.97Bb | 15.88 ± 0.44Ba | 18.21 ± 1.01Ba |

| Norharman | 46.90 ± 0.85Be | 81.44 ± 0.40Bd | 89.21 ± 0.47Bc | 91.98 ± 0.63Bb | 116.50 ± 0.86Ba | |

| Glu-P-1 | 0.26 ± 0.03Ac | 0.35 ± 0.04Bc | 0.37 ± 0.08Bc | 0.56 ± 0.01Bb | 0.81 ± 0.05Ba | |

| Glu-P-2 | 1.93 ± 0.30Bd | 3.85 ± 0.46Bd | 6.63 ± 1.03Bc | 10.07 ± 0.43Bb | 13.07 ± 0.76Ba | |

| Superheated steam roasting | Harman | 1.63 ± 0.03Ce | 1.97 ± 0.04Cd | 2.59 ± 0.01Cc | 3.14 ± 0.06Cb | 3.52 ± 0.07Ca |

| Norharman | 6.21 ± 0.05Ce | 7.99 ± 0.03Cd | 9.09 ± 0.20Cc | 10.74 ± 0.20Cb | 11.83 ± 0.05Ca | |

| Glu-P-2 | 15.60 ± 0.60Ae | 30.08 ± 0.69Ad | 49.60 ± 0.30Ac | 59.32 ± 0.58Ab | 66.98 ± 1.25Aa | |

| MeAαC | 0.16 ± 0.01c | 0.14 ± 0.01c | 0.72 ± 0.55c | 5.97 ± 0.54b | 7.32 ± 0.75a | |

| Cooking method . | HAAs . | Time (min) . | ||||

|---|---|---|---|---|---|---|

| 0 . | 1 . | 2 . | 3 . | 4 . | ||

| Charcoal grilling | Harman | 88.59 ± 0.30Ac | 87.98 ± 0.99Ac | 91.52 ± 0.41Ab | 93.11 ± 0.11Ab | 95.18 ± 0.48Aa |

| Norharman | 98.68 ± 0.76Ad | 159.46 ± 1.60Ac | 162.45 ± 0.25Ac | 307.06 ± 1.28Ab | 312.45 ± 1.02Aa | |

| AαC | 12.66 ± 0.26d | 13.69 ± 0.31 cd | 14.86 ± 0.54bc | 15.43 ± 0.33b | 16.88 ± 0.54a | |

| Glu-P-1 | 0.84 ± 0.42Aa | 0.98 ± 0.05Aa | 0.98 ± 0.02Aa | 1.34 ± 0.26Aa | 1.55 ± 0.13Aa | |

| Infrared grilling | Harman | 3.74 ± 0.60Bc | 5.49 ± 0.48Bc | 10.33 ± 0.97Bb | 15.88 ± 0.44Ba | 18.21 ± 1.01Ba |

| Norharman | 46.90 ± 0.85Be | 81.44 ± 0.40Bd | 89.21 ± 0.47Bc | 91.98 ± 0.63Bb | 116.50 ± 0.86Ba | |

| Glu-P-1 | 0.26 ± 0.03Ac | 0.35 ± 0.04Bc | 0.37 ± 0.08Bc | 0.56 ± 0.01Bb | 0.81 ± 0.05Ba | |

| Glu-P-2 | 1.93 ± 0.30Bd | 3.85 ± 0.46Bd | 6.63 ± 1.03Bc | 10.07 ± 0.43Bb | 13.07 ± 0.76Ba | |

| Superheated steam roasting | Harman | 1.63 ± 0.03Ce | 1.97 ± 0.04Cd | 2.59 ± 0.01Cc | 3.14 ± 0.06Cb | 3.52 ± 0.07Ca |

| Norharman | 6.21 ± 0.05Ce | 7.99 ± 0.03Cd | 9.09 ± 0.20Cc | 10.74 ± 0.20Cb | 11.83 ± 0.05Ca | |

| Glu-P-2 | 15.60 ± 0.60Ae | 30.08 ± 0.69Ad | 49.60 ± 0.30Ac | 59.32 ± 0.58Ab | 66.98 ± 1.25Aa | |

| MeAαC | 0.16 ± 0.01c | 0.14 ± 0.01c | 0.72 ± 0.55c | 5.97 ± 0.54b | 7.32 ± 0.75a | |

Results are given as Means ± Standard error with significant difference (P < 0.05) in the rows for each time interval of individual cooking method while capital letters (A, B and C) show the significant difference (P < 0.05) between cooking methods in the columns. AαC and MeAαC were detected individually in only each one method of cooking so no significant difference could be found therefore no capital letters appear on their values.

In Fig. 3 (b), the total content of non-polar HAAs in the infrared grilled lamb patties was 52.84 ng g−1 at 0 min, which was increased to 148.59 ng g−1 at 4 min in the lamb patties. The non-polar HAAs content in superheated steam patties was the lowest with 23.61 ng g−1 at the initial time where core temperature was achieved and 89.66 ng g−1 at 4 min of cooking in the lamb patties. We observed that the quantities of the non-polar HAAs were not too high, as previously studied by (Ahn & Grün, 2005; Ni et al., 2008). We also observed that non-polar HAAs were lower in superheated steam roasted lamb patties. The results showed that charcoal fire grilling produced higher contents of the polar and non-polar HAAs in the lamb meat patties, while the infrared method produced comparatively produced lower contents of both kinds of HAAs in the lamb patties. The results might differ due to different times in achieving the core temperature and due to differences in the cooking methods. There was a significant difference (P < 0.05) in the results of the three cooking methods.

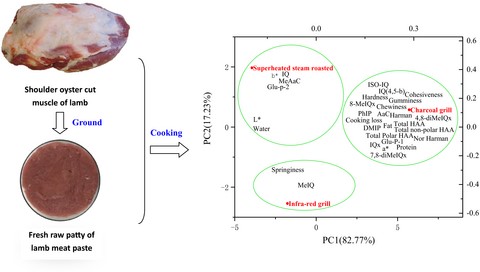

Principal component analysis

Principal component analysis PCA was applied to the data matrix and the two principal components (PCs) were extracted, explaining up to 100% of the total variance, which was 82.77% as shown by PC1 and 17.23% as shown by PC2, as shown in Fig. 5.

![Principal component analysis score biplots of charcoal grilling, infrared grilling and superheated steam roasting on the lamb patties. [Colour figure can be viewed at wileyonlinelibrary.com]](https://oup.silverchair-cdn.com/oup/backfile/Content_public/Journal/ijfst/55/3/10.1111_ijfs.14388/1/m_ijfs14388-fig-0005-m.jpeg?Expires=1750346997&Signature=dNJswJqtP2ZhMkW4q~8JQcvfEkuaH11Uej10nT7WtdHza7NhrJwetC~jT1jdhhCpv9vMq3Ys9hwCRi3migGZlCi7IL8YVkzHu3CJH5xfUROmHmlaf97Y-hPrzt3zcKGDCCrigFkfghr2Ia9MtL8eZrXrq-8H4BtEeTNsHYqQZ32vemamG-RwQM1H0pX99jDwN2bImhFWReKW3aznaYtfIe1GpiXVB1UGpaY9yjE4or44DegiFE16zfj5OY5d11cciDvtTVnA75hbLjYZbsHPhHkcqmLBkEaHFqFFMQmJlA4OVvf7EhSUI56-katt1Q5aMxjJi3E1FkZwbopUpb2wgQ__&Key-Pair-Id=APKAIE5G5CRDK6RD3PGA)

Principal component analysis score biplots of charcoal grilling, infrared grilling and superheated steam roasting on the lamb patties. [Colour figure can be viewed at wileyonlinelibrary.com]

A complete separation between the three treatments was obtained. It was suggested that the cooking methods had a significant effect on the colour and texture properties of lamb patties, and most importantly, both the heating sources and heating transfer had a crucial role on HAA formation. Charcoal grilling had a positive effect on the formation of red colour; however, it did give rise to serious cooking loss, hardness and more generation of HAA, such as DMIP, IQx, IQ(4,5-b), ISO-IQ, 8-MeIQx, 7,8-diMeIQx, 4,8-diMeIQx, PhIP, Nor-Harman, Harman, AαC and Glu-P-1. It was obvious that the other two cooking methods showed a significant effect on reducing HAA formation. Comparatively, superheated steam roasting led to higher IQ, MeAαC and Glu-P-2, and it made for higher lightness values to higher water content. On the other hand, infrared grilling only caused higher MeIQ, and it contributed to higher springiness. These two cooking methods potentially showed beneficial effects for practical production applications.

Conclusion

The study concluded that highest water loss was observed in the charcoal grilled lamb patties. The protein and fat content was also highest in the charcoal grilled patties than infrared and superheated steam roasted patties. Moreover, the colour degradation was seen in every cooking method but the charcoal grilling produced the highest values of dark colour of patties. The texture profile was observed to be better in both infrared grilling and the superheated steam roasted patties. Higher temperature cooking such as charcoal grilling was responsible for the highest formation of non-polar HAAs such as Harman and Norharman while among polar HAAs DMIP and PhIP were highest in content than the infrared and superheated steam roasting. Therefore, we can say that both methods infrared and superheated steam roasting had proved to be much better cooking method in terms of reduction of HAAs, better colour stability and better textural profile. This technology can be utilised by industries that are processing lamb meat products.

Acknowledgments

This work has been financially supported by National Key R&D Programme of China (2016YFD0401505, 2018YFD0400101), China Agriculture Research System (CARS-38), Modern Agricultural Talent Support Programme-Outstanding Talents and Innovative Team of Agricultural Scientific Research (2016-2020) and National Agricultural Science and Technology Innovation Programme (meat science and nutrition). The authors appreciated to Caoyuanhongbao Food Co., Ltd for their helpful support in sampling.

Conflict of interest

The authors declare that they have no conflict of interest.

Data availability statement

Research data are not shared.

Ethical guidelines

Ethics approval was not required for this research.