-

PDF

- Split View

-

Views

-

Cite

Cite

Muhammad Waqar Arshad, Muhammad Moazzam, Muhammad Mustafa Raziq, Waqas Ahmed, Linking the willingness of smallholder dairy farmers to adopt minimum food safety and quality standards to the country's export potential, International Journal of Food Science and Technology, Volume 58, Issue 10, October 2023, Pages 5557–5567, https://doi.org/10.1111/ijfs.16539

Close - Share Icon Share

Abstract

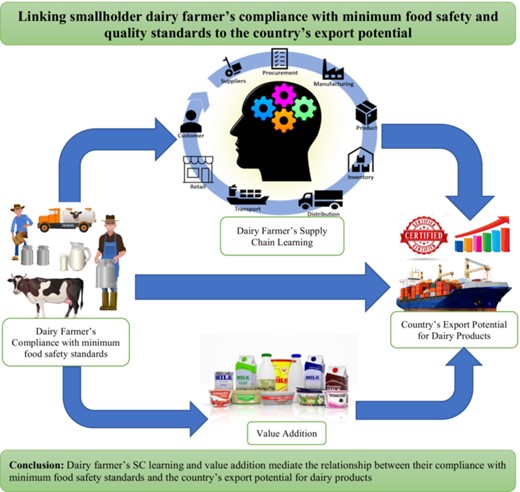

Food safety is a crucial aspect of human well-being, covered under the second sustainable development goal (SDG). Sustainable food supply chains must ensure compliance with food safety standards from farm to fork. Consumers in developed countries are becoming ever more demanding regarding ‘producers’ compliance with food safety and quality standards. Most food products ending up in high-end markets come from developing countries, predominantly agricultural economies characterised by fragmented and smallholder farmers. Owing to enhanced agricultural exports, developing countries are struggling to implement or improve food safety standards. This study examines the link between the willingness of smallholder dairy farmers to adopt minimum food safety standards and the country's ability to export agri-food products. Moreover, it investigates the role of farmer's supply chain learning and level of value addition in this relationship. A cross-section of 260 smallholder dairy farmers was surveyed from four districts of the Punjab province in Pakistan through purposive sampling. The data were collected using a questionnaire using a 5-point Likert scale to gauge ‘farmers’ responses. The data were analysed using structural equation modelling (SEM) and confirmatory factor analysis (CFA). We found significant mediation of supply chain learning and value addition between compliance with minimum food safety standards and the country's export potential. This study contributes to the body of knowledge on food safety by testing its relationship with a country's export potential and the factors affecting this relationship. Moreover, it provides food for thought for policymakers in food safety.

Introduction

The contemporary dairy industry is a dynamic and multifaceted system that faces a myriad of challenges in meeting the global demand for high-quality dairy products. The participation of smallholder dairy farmers is crucial in meeting this demand. Yet, their compliance with minimum food safety and quality standards poses a formidable obstacle to their integration into export markets. Governments impose minimum food safety standards to meet SDGs, satisfy the demands of high-end consumers and gain access to international markets (Do et al., 2019, 2022; Barbancho-Maya & López-Toro, 2022; Yadav et al., 2023). Among food products, milk and milk products are the most perishable and need specialised handling and cold chain infrastructure at each stage of the milk supply chain. Consumers' belief and trust in the quality and safety of dairy products play a vital role (Zhang et al., 2022). A substantial proportion of the food commodities sourced find their way into exclusive markets from developing countries characterised by economies primarily centred around agriculture. Dairy farming in developing countries is mainly a fragmented and smallholder enterprise (Msalya, 2017). Ensuring compliance with food safety standards is a collective responsibility of every stakeholder in the dairy supply chain, including farmers, industry, consumers and governments. Nevertheless, the dairy farm, serving as the primary point of production, poses the most significant obstacle in global dairy supply chains.

Owing to the wide variety and volume of food products produced and traded globally, a more significant effort is needed from regulatory agencies to oversee compliance with minimum food safety and quality standards. Moreover, it brings difficult for the supply chain stakeholders, particularly the farmers, to comply with these complex standards. While evaluating the level of adoption of minimum food safety practices by dairy farmers Korale-Gedara et al. (2023) reported that mandatory training and financial assistance helped smallholder dairy farmers produce safer milk.

The past literature on smallholder farmers highlight various challenges and barriers in adopting minimum food safety and quality standards and their impact on export potential. Holzapfel & Hampel-Milagrosa (2020) found that the poorest segment of smallholder farmers has not benefited from donor interventions, and most smallholder farmers serve domestic markets or lower-value export markets, where private standards are not required. Moreover, the high cost of adopting quality and food safety systems is one of the most critical barriers to adoption (Barbancho-Maya & López-Toro, 2022). One primary challenge smallholder dairy farmer face is the lack of access to adequate resources and infrastructure, such as modern equipment, proper storage facilities and transportation networks which can result in compromised hygiene practices, thus affecting the safety and quality of the milk produced.

Food safety practices are complex and challenging to implement in developing countries, mainly due to the predominance of smallholder farms, with dairy farming as secondary employment (Mangla et al., 2021). In most of the developing countries, agricultural products contribute a major share to the exports and overall GDP. Poor compliance with minimum food safety standards at the farm level is a bottleneck in exploiting the country's true export potential. Moreover, factors including dairy farmer's knowledge of global supply chain activities and level of value addition affect the relationship between the level of compliance with minimum food safety standards and the country's export potential (Shen et al., 2019; Kayikci et al., 2022).

This study addresses a critical gap in the literature by examining the relationship between smallholder dairy farmers' compliance with minimum food safety standards and the country's export potential. This research is among the first to focus specifically on the role of smallholder dairy farmers in developing countries, who form the backbone of the dairy sector. This research pioneers a comprehensive examination of the intricate connections between the adherence of smallholder dairy farmers to essential food safety and quality standards and the subsequent implications for the nation's export potential.

Such a novel perspective fills a significant gap in the existing literature. It offers valuable guidance for policymakers, stakeholders and practitioners in developing and enhancing sustainable and economically viable dairy sectors within the country's export-oriented endeavours. It also contributes to the body of literature by examining the mediating role of supply chain learning and value addition in the relationship between compliance with minimum food safety and quality standards and a country's export potential. The proposed framework has been built on the notion that if a government implements minimum food safety and quality standards at the dairy farm level, the dairy farmer's knowledge of supply chain operations, along with value addition, will lead to the enhanced export potential of that country and hence helping farmers in increasing their income and eradicating poverty (Zhuang et al., 2020; Shafique et al., 2021).

Literature review

The decision to engage in a particular behaviour depends on an individual's willingness. The theory of planned behaviour (TPB), as proposed by Ajzen (1988), is widely used in social psychological studies for describing people's behaviours in a variety of domains (Gao et al., 2017). The most valuable resource that a business or farm can manage has emerged as knowledge and learning. Adding value to dairy farming by using modern farming techniques, willingness and farmers' knowledge are now crucial in smallholder dairy farming. Therefore, TPB addresses these concerns related to the willingness of farmers to comply with minimum food safety and quality standards and supply chain learning.

Previous research indicates that the adherence to minimum food safety and quality standards and their impact on export potential present numerous challenges and obstacles for farmers. As highlighted by Holzapfel & Hampel-Milagrosa (2020), most small-scale farmers primarily cater to local or low-value export markets, where adherence to private standards is not deemed necessary. Moreover, the poorest segment of small-scale farmers has not experienced significant benefits from interventions by external donors. AccordinBarbancho-Maya & López-Toro (2022) identified that the high cost associated with implementing quality and food safety systems within organisations as the primary barrier to adoption.

Contaminated milk could serve as a vector for infections like E. coli. Bacteria, viruses, parasite agents and chemical residues are among the culprits for foodborne diseases that significantly impact consumers' health and nutrition status (Amenu et al., 2019). Due to the substantial costs involved, the food safety standards impact how competitive a firm's export strategy is. Hence, policymakers need to increase the effectiveness and efficacy of government and private sector measures (Yadav et al., 2021). In developing countries, Yadav et al. (2021) weak implementation of food safety management systems, low compliance with minimum food safety regulations, poor milk quality and food safety concerns are severe challenges to dairy supply chains (Amenu et al., 2019).

Another thing that comes between the policy and practice is the farmer's willingness associated with the behaviour and attitudes of smallholder farmers, explained by the theory of planned behaviour. According to Ledo et al. (2019), their attitudes and lack of understanding affect their adherence to minimum food safety regulations and milk quality standards. Therefore, we can hypothesise as follows:

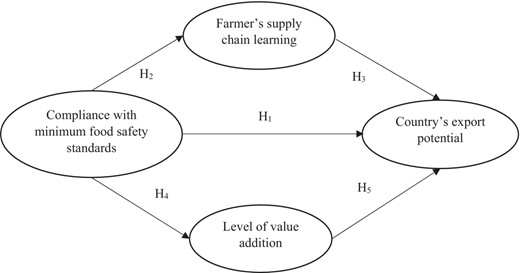

A positive relationship exists between farmer's willingness to comply with minimum food safety and quality standards and the country's export potential (EP).

Small-scale dairy farmers poor attitudes and lack of knowledge affect how they adhere to rules governing the safety of their products and the quality of their milk (Ledo et al., 2019). Improved knowledge, training and optimistic attitudes have been associated with more hygienic milk handling procedures at the farm level, according to empirical research (Lindahl et al., 2018). Government-supported legislative frameworks can facilitate open market trends, farmer training and development programmes, fostering partnerships and investment in infrastructure development (Mangla et al., 2021). Dongol et al. (2017) emphasise that awareness regarding adherence to food safety regulations and dairy quality standards is essential for preventing food infections.

Farmers must adopt practical methods for milk quality and safety from a financial, technical, and cultural standpoint (Hermans et al., 2017). According to Yadav et al. (2021), intentions are described as the rationale for adopting FSS or the opportunities that drive the introduction of specific frameworks, and certifications related to FSS initiatives are usually driven by various factors that vary between countries and product lines. Unfortunately, much research shows that farmers do not use preventive measures while carrying out daily farm practices (Damalas & Koutroubas, 2016). The literature has not discussed the relationship between supply chain learning and farmer's willingness to comply with minimum safety and quality standards. Therefore, we can hypothesise.

A positive relationship exists between the farmer's attitude towards compliance with minimum food safety and quality standards and supply chain learning.

Based on the dynamic ‘capability’ perspective, it is suggested that absorptive capacity is a significant source of superior business performance. Notably, a farmer with a high absorptive ability is more likely to apply new knowledge discovered from external sources (such as customers, suppliers, competitors and other channel partners) to find commercial possibilities in the market. Supply chain learning fosters the interconnectedness required to disseminate knowledge across internal functions, considerably improving the quality of learning methods. Sharing data among internal systems is a vital integrative technique for SC knowledge (Shen et al., 2019). Businesses devote more resources to information exchange to enhance their operational and production processes (Lei et al., 2020). Therefore, further empirical studies are needed to examine the data-sharing process and SC learning between upstream and downstream supply chain partners and help increase the export potential for different value-added products, resulting in valuable foreign remittance. So, the hypothesis is formulated as follows,

Supply chain learning has a positive relationship with export potential.

In most developing countries, agriculture provides work for a large percentage of the population, raising the standard of living for smallholder farmers. This sector is significantly contributing towards achieving SDGs at all levels by 2030, which include eradicating poverty (Jha et al., 2016). One of the diversifications utilised to improve quick investment recovery and increase farmer income is value addition (Salvioni et al., 2020). The food value chain is complicated because so many stages are involved in its value creation, such as every stage from the very beginning stage to the stage that adds value and last to the stage where the product is brought to the market (Le et al., 2022). Through the development of value and innovation, a product is transformed from its initial form to one that is more valuable (Oyewole & Eforuoku, 2019). According to the theory of planned behaviour, farmers' willingness plays a vital role in creating value in additional in-process products and services. Hence, the following hypothesis can be formulated:

A positive relationship exists between compliance with minimum food safety and quality standards and value addition (VA).

The market for agricultural exports from third-world countries did not expand significantly because practically all of it still travels to the European Union in its basic form with little to no value addition. However, there is room for improvement and a need for it in exporting different agricultural goods and their value-added products (Mani et al., 2018). For instance, a few of these nations have created a comprehensive food safety value chain that complies with high international standards (Mani & Kabiraj, 2019). The lack of appropriate processing units and other preservation facilities has also hampered value-adding, ultimately impacting on the farm sector's ability to export. Moreover, this works against the government's goal of boosting fresh milk consumption and lowering reliance on imports, which is frequently a significant limitation in terms of developing countries' need for foreign reserves (Korale-Gedara et al., 2023). Due to limited a access to financial resources, inadequate rural connections, insecure land titles and the lack of suitable water and energy supplies eventually increase the cost of processing and value addition. These are essential components of value addition, and their scarcity in rural regions prevents the enhancement of value addition in agricultural products, which undermines the wealth of farmers and other participants in the supply chain. So, the following hypothesis can be formulated as.

Value addition (VA) has a positive relationship with export potential (EP).

According to the resource-based view, supply chain learning can be regarded as a resource or a capability related to a farmer's attitude and behaviour. It may play the role of a bridge in the relationship between compliance with minimum safety and quality standards and export potential (Guo et al., 2020). It is because supply chain partners may provide different ideas, information and resources that are critical for a farmer's supply chain learning and compliance with the minimum food safety and quality standards. When farmers possess robust supply chain learning, compliance with minimum food safety and quality standards may be promoted through supply chain learning and hence have a positive impact on the export potential. Therefore, this research argues that smallholder farmers can successfully comply with minimum food safety standards through the mediating role of supply chain learning, thus stating the following hypothesis.

Supply chain learning mediates the relationship between compliance with minimum food quality and safety standards and export potential.

External factors influence the willingness of smallholder farmers in the form of supply chain learning, which increases farmers' ability and commitment to comply with minimum food safety and quality standards. The power of farmers to comply with basic minimum food safety and quality standards and supply chain learning are crucial instruments for boosting ‘farmers’ willingness, which finally increases the ability of smallholders farmers to increase value-adding activities of milk at the farm level, hence increasing the potential for exports (Zahra et al., 2006; Salvato & Rerup, 2011). According to Ren et al. (2018), as an external force, supply chain learning makes sure that farmers' actions are in line with the strategic objectives that aim to increase ‘farmers’ willingness at the farm production level, playing a significant role in the increase in production and their export potential at the farm production level (Chaudhary et al., 2019). Therefore, the following hypotheses can be formulated:

Value addition (VA) mediates the relationship compliance with minimum food safety and quality standards and export potential (EP).

Limited literature tests the relationship between compliance with minimum food safety and quality standards, supply chain learning (SCL) and value addition and their impact on the export potential of the farmer's dairy sector in an emerging economy. Few studies, for example Korale-Gedara et al. (2023) discuss factors affecting minimum food safety and quality standards and antecedents of and consequences for implementing minimum food safety and quality standards. However, limited literature exists regarding the link between dairy farmers' willingness for compliance with minimum food safety and quality standards and the country's overall export potential viz a viz the other variables affecting this relationship. Therefore, we propose a conceptual framework (Fig. 1) that tests the said variables' contribution to this relationship to address this research gap.

The proposed study addresses the research gap regarding compliance with minimum food safety and quality standards and its influence on export potential while supply chain learning and value addition act as mediators. Moreover, the knowledge that farmers acquire from suppliers and customers, and other sources, use that knowledge for value addition in the product in the dairy sector of Pakistan. This research addresses this gap by examining the mediating role of value addition (VA) and supply chain learning (SCL).

Methodology

This study uses the positivist research philosophy and quantitative/objective approach to test the relationship between various constructs (Saunders et al., 2019). The population of the study is smallholder dairy farmers in Pakistan. A sample size of 260 smallholder dairy farmers was drawn through purposive sampling technique. Out of these 260 respondents, 65 were selected from each of the four districts in Pakistan, namely Khanewal, Lodhran, Muzaffargarh and Layyah. These districts are located in the Indus Valley where most of the country's dairy herds are raised. To establish the adequacy of the sample size, G*power analysis was used, which is highly suggested in the PLS literature to calculate the appropriate sample size (Faul et al., 2007; Hair Jr et al., 2014; Soper, 2019). Using a statistical power of 80% and a medium-sized f2 effect of 0.15, with four predictors, the G*Power analysis revealed that a minimum of 129 participants is required which is less than 260. Cross-sectional data were collected through the interviewer-completed structured questionnaires.

Measures of variables

A 5-point Likert scale, Strongly Disagree = 1, Disagree = 2, Neither Agree nor Disagree = 3, Agree = 4, Strongly Agree = 5 was used to gauge the responses. To gauge farmer's willingness to comply with minimum food safety and quality standards, a 10-item scale (Shea et al., 2014) was used, that is ‘I am committed to implementing minimum dairy quality and safety standards’. ‘I am determined to implement minimum dairy quality and safety standards’. Similarly, to measure supply chain learning, a 15-item scale (Haq, 2021) was used, for example, two of these statements, “I acquire substantial production information from most of the customers” and “I have systematic checks to ensure that the knowledge from most customers is used”. For value addition, a 23-item scale (Singh & Shabani, 2017) was used. This scale consists of items and statements related to farmers value addition practices done at farm level, that is proper feeding and medical care of dairy animals, related to feeding, grading and providing good living environment for dairy animals. For export potential, a 19-item scale (Harris, 2016; Larder et al., 2018) was used. This scale consists of items and statements related to hygiene, breeding, calf management, disease control, risk management, spoilage and contamination, development of toxins, procedures to demonstrate how it is ensured that samples are representative, and statements like ‘sampling does not contaminate the dairy product’, ‘the sampling and testing plans for product safety parameters outlining the test, methods, sampling frequency, product safety limits and action if limits are exceeded’. Structural equation modelling (SEM) was used to examine the structural relationships between the chosen variables. As recommended by Hair Jr et al. (2021), third-generation SEM, known as partial least squares (PLS), was used to measure the association between the constructs.

The procedural and statistical remedies were applied to control the common method bias (Tehseen et al., 2017). Each construct's convergent validity (AVE) is above the minimum threshold value of 0.5. Similarly, the composite reliability (CR) is above 0.6 for each construct. Henseler et al. (2015) put forward the utilisation of the heterotrait–monotrait ratio (HTMT) for evaluating the correlations in Table 1 to establish the discriminant validity. Henseler et al. (2015) have established the threshold for determining discriminant validity through the heterotrait–monotrait ratio (HTMT) as a value of 0.90, alongside a confidence interval of less than 1 for HTMT.

| . | CWMFSQS . | EXP POT . | SCL . | VAD . |

|---|---|---|---|---|

| CWMFSQS | - | |||

| EXP POT | 0.737 | - | ||

| SCL | 0.751 | 0.828 | - | |

| VAD | 0.838 | 0.763 | 0.693 | - |

| . | CWMFSQS . | EXP POT . | SCL . | VAD . |

|---|---|---|---|---|

| CWMFSQS | - | |||

| EXP POT | 0.737 | - | ||

| SCL | 0.751 | 0.828 | - | |

| VAD | 0.838 | 0.763 | 0.693 | - |

| . | CWMFSQS . | EXP POT . | SCL . | VAD . |

|---|---|---|---|---|

| CWMFSQS | - | |||

| EXP POT | 0.737 | - | ||

| SCL | 0.751 | 0.828 | - | |

| VAD | 0.838 | 0.763 | 0.693 | - |

| . | CWMFSQS . | EXP POT . | SCL . | VAD . |

|---|---|---|---|---|

| CWMFSQS | - | |||

| EXP POT | 0.737 | - | ||

| SCL | 0.751 | 0.828 | - | |

| VAD | 0.838 | 0.763 | 0.693 | - |

Results

Demographics

The demographic profile of the respondents, presented in Table 2, indicates that 61% had no education at all, 29.50% had formal education of 1–10 years, 3.8% had 11–12 years of education, 3.4% had 13–16 years of education, and only 2.4% had 16 years or above education among 260 dairy farmers.

| . | N . | Percentage . | Cumulative percentage . |

|---|---|---|---|

| Education | |||

| No formal education | 161 | 61.0 | 61.0 |

| 1–10 years | 76 | 29.5 | 90.5 |

| 11–12 years | 9 | 3.8 | 94.3 |

| 13–16 years | 9 | 3.4 | 97.7 |

| Above 16 years | 5 | 2.3 | 100 |

| Experience | |||

| Less than 5 years | 27 | 10.6 | 10.6 |

| 6–10 years | 82 | 31.4 | 42.0 |

| 11–15 years | 83 | 31.8 | 73.8 |

| 16–20 years | 42 | 16.2 | 90.0 |

| Above 20 years | 29 | 10.0 | 100 |

| Income | |||

| PKR 20000–40000 | 10 | 4.2 | 4.2 |

| PKR 40001–60000 | 55 | 21.2 | 25.4 |

| PKR 60001–80000 | 121 | 46.2 | 71.6 |

| PKR 80001–100000 | 62 | 23.5 | 95.1 |

| Above PKR 100000 | 12 | 4.9 | 100 |

| . | N . | Percentage . | Cumulative percentage . |

|---|---|---|---|

| Education | |||

| No formal education | 161 | 61.0 | 61.0 |

| 1–10 years | 76 | 29.5 | 90.5 |

| 11–12 years | 9 | 3.8 | 94.3 |

| 13–16 years | 9 | 3.4 | 97.7 |

| Above 16 years | 5 | 2.3 | 100 |

| Experience | |||

| Less than 5 years | 27 | 10.6 | 10.6 |

| 6–10 years | 82 | 31.4 | 42.0 |

| 11–15 years | 83 | 31.8 | 73.8 |

| 16–20 years | 42 | 16.2 | 90.0 |

| Above 20 years | 29 | 10.0 | 100 |

| Income | |||

| PKR 20000–40000 | 10 | 4.2 | 4.2 |

| PKR 40001–60000 | 55 | 21.2 | 25.4 |

| PKR 60001–80000 | 121 | 46.2 | 71.6 |

| PKR 80001–100000 | 62 | 23.5 | 95.1 |

| Above PKR 100000 | 12 | 4.9 | 100 |

| . | N . | Percentage . | Cumulative percentage . |

|---|---|---|---|

| Education | |||

| No formal education | 161 | 61.0 | 61.0 |

| 1–10 years | 76 | 29.5 | 90.5 |

| 11–12 years | 9 | 3.8 | 94.3 |

| 13–16 years | 9 | 3.4 | 97.7 |

| Above 16 years | 5 | 2.3 | 100 |

| Experience | |||

| Less than 5 years | 27 | 10.6 | 10.6 |

| 6–10 years | 82 | 31.4 | 42.0 |

| 11–15 years | 83 | 31.8 | 73.8 |

| 16–20 years | 42 | 16.2 | 90.0 |

| Above 20 years | 29 | 10.0 | 100 |

| Income | |||

| PKR 20000–40000 | 10 | 4.2 | 4.2 |

| PKR 40001–60000 | 55 | 21.2 | 25.4 |

| PKR 60001–80000 | 121 | 46.2 | 71.6 |

| PKR 80001–100000 | 62 | 23.5 | 95.1 |

| Above PKR 100000 | 12 | 4.9 | 100 |

| . | N . | Percentage . | Cumulative percentage . |

|---|---|---|---|

| Education | |||

| No formal education | 161 | 61.0 | 61.0 |

| 1–10 years | 76 | 29.5 | 90.5 |

| 11–12 years | 9 | 3.8 | 94.3 |

| 13–16 years | 9 | 3.4 | 97.7 |

| Above 16 years | 5 | 2.3 | 100 |

| Experience | |||

| Less than 5 years | 27 | 10.6 | 10.6 |

| 6–10 years | 82 | 31.4 | 42.0 |

| 11–15 years | 83 | 31.8 | 73.8 |

| 16–20 years | 42 | 16.2 | 90.0 |

| Above 20 years | 29 | 10.0 | 100 |

| Income | |||

| PKR 20000–40000 | 10 | 4.2 | 4.2 |

| PKR 40001–60000 | 55 | 21.2 | 25.4 |

| PKR 60001–80000 | 121 | 46.2 | 71.6 |

| PKR 80001–100000 | 62 | 23.5 | 95.1 |

| Above PKR 100000 | 12 | 4.9 | 100 |

Demographics show that most of the farmers have no formal education or less than 10 years of education. The reason is that in Pakistan, the literacy rate in rural areas is very low because of the low trend towards formal education. Because of this, farmers learning of the supply chain is also low. Most farmers have farm experience of more than 5 years and 11–15 years because most of these smallholder dairy farmers are doing it as a family business. Most farmers have an income between 60 000 and 80 000 Rs, it is because these farmers only sell milk which is more than their family use. Few have less income ranging from 20 000 to 40 000 and 40 000 Rs. There are various reasons for generating less income. One of the major reasons is having lack of knowledge regarding modern dairy practices and the lack of financial resources.

Data screening and missing value treatment

There are four primary causes for missing data (Saunders et al., 2019). First, the respondent's data were not required, possibly because of the survey's filter question. Second, the respondent declined to respond to the query (a non-response). Third, the respondent was unable to provide an answer or an opinion. This might be seen as either conveying an answer or missing data, depending on the situation. Fourth, the respondent might have accidentally omitted a question, or their response might not have been clear. Additionally, it is possible that leaving a survey question partially blank implies a response; in these circumstances, the data are not categorised as missing. The data contained no missing values.

Measurement model

The results show that the overall variance is within an acceptable range, indicating that there is no common method bias. The PLS-SEM path, proposed by Henseler et al. (2009) was evaluated and results were produced using a two-step procedure. The measurement of the structural model comes after the first stage, which involves evaluating the measurement model. Table 3 presents composite reliability scores for export potential (0.901), value addition (0.929), supply chain learning (0.958) and compliance with minimum food safety and quality standards (0.930) are all within the acceptable range and exhibit high internal consistency (Hair Jr et al., 2021).

| . | M . | SD . | CR . | 1 . | 2 . | 3 . | 4 . |

|---|---|---|---|---|---|---|---|

| Compliance with minimum food safety & quality standards | 4.40 | .602 | 0.930 | 0.831 | |||

| Supply chain learning | 4.21 | .797 | 0.958 | *** | 0.779 | ||

| Value addition | 3.90 | .613 | 0.929 | ** | ** | 0.828 | |

| Export potential | 4.08 | .081 | 0.901 | * | * | * | 0.777 |

| . | M . | SD . | CR . | 1 . | 2 . | 3 . | 4 . |

|---|---|---|---|---|---|---|---|

| Compliance with minimum food safety & quality standards | 4.40 | .602 | 0.930 | 0.831 | |||

| Supply chain learning | 4.21 | .797 | 0.958 | *** | 0.779 | ||

| Value addition | 3.90 | .613 | 0.929 | ** | ** | 0.828 | |

| Export potential | 4.08 | .081 | 0.901 | * | * | * | 0.777 |

AVE, diagonal values of average variance extracted; CR, composite reliability. *P < 0.05. **P < 0.01. ***P < 0.001.

| . | M . | SD . | CR . | 1 . | 2 . | 3 . | 4 . |

|---|---|---|---|---|---|---|---|

| Compliance with minimum food safety & quality standards | 4.40 | .602 | 0.930 | 0.831 | |||

| Supply chain learning | 4.21 | .797 | 0.958 | *** | 0.779 | ||

| Value addition | 3.90 | .613 | 0.929 | ** | ** | 0.828 | |

| Export potential | 4.08 | .081 | 0.901 | * | * | * | 0.777 |

| . | M . | SD . | CR . | 1 . | 2 . | 3 . | 4 . |

|---|---|---|---|---|---|---|---|

| Compliance with minimum food safety & quality standards | 4.40 | .602 | 0.930 | 0.831 | |||

| Supply chain learning | 4.21 | .797 | 0.958 | *** | 0.779 | ||

| Value addition | 3.90 | .613 | 0.929 | ** | ** | 0.828 | |

| Export potential | 4.08 | .081 | 0.901 | * | * | * | 0.777 |

AVE, diagonal values of average variance extracted; CR, composite reliability. *P < 0.05. **P < 0.01. ***P < 0.001.

The discriminant validity is adequate because the square root of AVE is greater than the relationship between the latent variable (Fornell & Larcker, 1981). Confirmatory factory analysis was performed on all the factor loadings and those with values below 0.50 threshold point were eliminated. Resultantly, the factor loadings ranging from 0.610 to 0.953, as shown in Table 4 were kept (Hair Jr et al., 2021).

| Constructs . | Factor loadings . | Constructs . | Factor loadings . |

|---|---|---|---|

| Compliance with minimum food safety & quality standards | (α = 0.910) | VAD9 | *** |

| CWMFSQS 1 | 0.878 | VAD10 | *** |

| CWMFSQS 2 | 0.819 | VAD11 | *** |

| CWMFSQS 3 | 0.805 | VAD12 | *** |

| CWMFSQS 4 | 0.846 | VAD13 | *** |

| CWMFSQS 5 | 0.832 | VAD14 | 0.825 |

| CWMFSQS 6 | *** | VAD15 | 0.773 |

| CWMFSQS 7 | *** | VAD16 | 0.832 |

| CWMFSQS 8 | *** | VAD17 | 0.851 |

| CWMFSQS 9 | *** | VAD18 | 0.844 |

| CWMFSQS 10 | 0.801 | VAD19 | *** |

| Supply chain learning | (α = 0.953) | VAD20 | *** |

| SCL1 | 0.800 | VAD21 | *** |

| SCL2 | 0.725 | VAD22 | *** |

| SCL3 | 0.752 | VAD23 | *** |

| SCL4 | 0.765 | Export potential | (α = 0.869) |

| SCL5 | 0.722 | EP1 | *** |

| SCL6 | 0.817 | EP2 | *** |

| SCL7 | 0.804 | EP3 | *** |

| SCL8 | 0.768 | EP4 | *** |

| SCL9 | 0.759 | EP5 | *** |

| SCL10 | 0.753 | EP6 | *** |

| SCL11 | 0.824 | EP7 | *** |

| SCL12 | 0.814 | EP8 | *** |

| SCL13 | 0.818 | EP9 | 0.736 |

| SCL14 | 0.761 | EP10 | 0.747 |

| SCL15 | 0.786 | EP11 | *** |

| Value addition | (α = 0.908) | EP12 | *** |

| VAD1 | *** | EP13 | 0.740 |

| VAD2 | *** | EP14 | 0.844 |

| VAD3 | *** | EP15 | 0.807 |

| VAD4 | *** | EP16 | *** |

| VAD5 | *** | EP17 | *** |

| VAD6 | *** | EP18 | *** |

| VAD7 | 0.747 | EP19 | 0.783 |

| VAD8 | *** |

| Constructs . | Factor loadings . | Constructs . | Factor loadings . |

|---|---|---|---|

| Compliance with minimum food safety & quality standards | (α = 0.910) | VAD9 | *** |

| CWMFSQS 1 | 0.878 | VAD10 | *** |

| CWMFSQS 2 | 0.819 | VAD11 | *** |

| CWMFSQS 3 | 0.805 | VAD12 | *** |

| CWMFSQS 4 | 0.846 | VAD13 | *** |

| CWMFSQS 5 | 0.832 | VAD14 | 0.825 |

| CWMFSQS 6 | *** | VAD15 | 0.773 |

| CWMFSQS 7 | *** | VAD16 | 0.832 |

| CWMFSQS 8 | *** | VAD17 | 0.851 |

| CWMFSQS 9 | *** | VAD18 | 0.844 |

| CWMFSQS 10 | 0.801 | VAD19 | *** |

| Supply chain learning | (α = 0.953) | VAD20 | *** |

| SCL1 | 0.800 | VAD21 | *** |

| SCL2 | 0.725 | VAD22 | *** |

| SCL3 | 0.752 | VAD23 | *** |

| SCL4 | 0.765 | Export potential | (α = 0.869) |

| SCL5 | 0.722 | EP1 | *** |

| SCL6 | 0.817 | EP2 | *** |

| SCL7 | 0.804 | EP3 | *** |

| SCL8 | 0.768 | EP4 | *** |

| SCL9 | 0.759 | EP5 | *** |

| SCL10 | 0.753 | EP6 | *** |

| SCL11 | 0.824 | EP7 | *** |

| SCL12 | 0.814 | EP8 | *** |

| SCL13 | 0.818 | EP9 | 0.736 |

| SCL14 | 0.761 | EP10 | 0.747 |

| SCL15 | 0.786 | EP11 | *** |

| Value addition | (α = 0.908) | EP12 | *** |

| VAD1 | *** | EP13 | 0.740 |

| VAD2 | *** | EP14 | 0.844 |

| VAD3 | *** | EP15 | 0.807 |

| VAD4 | *** | EP16 | *** |

| VAD5 | *** | EP17 | *** |

| VAD6 | *** | EP18 | *** |

| VAD7 | 0.747 | EP19 | 0.783 |

| VAD8 | *** |

α, Cronbach's alpha.

Item deleted during factor analysis.

| Constructs . | Factor loadings . | Constructs . | Factor loadings . |

|---|---|---|---|

| Compliance with minimum food safety & quality standards | (α = 0.910) | VAD9 | *** |

| CWMFSQS 1 | 0.878 | VAD10 | *** |

| CWMFSQS 2 | 0.819 | VAD11 | *** |

| CWMFSQS 3 | 0.805 | VAD12 | *** |

| CWMFSQS 4 | 0.846 | VAD13 | *** |

| CWMFSQS 5 | 0.832 | VAD14 | 0.825 |

| CWMFSQS 6 | *** | VAD15 | 0.773 |

| CWMFSQS 7 | *** | VAD16 | 0.832 |

| CWMFSQS 8 | *** | VAD17 | 0.851 |

| CWMFSQS 9 | *** | VAD18 | 0.844 |

| CWMFSQS 10 | 0.801 | VAD19 | *** |

| Supply chain learning | (α = 0.953) | VAD20 | *** |

| SCL1 | 0.800 | VAD21 | *** |

| SCL2 | 0.725 | VAD22 | *** |

| SCL3 | 0.752 | VAD23 | *** |

| SCL4 | 0.765 | Export potential | (α = 0.869) |

| SCL5 | 0.722 | EP1 | *** |

| SCL6 | 0.817 | EP2 | *** |

| SCL7 | 0.804 | EP3 | *** |

| SCL8 | 0.768 | EP4 | *** |

| SCL9 | 0.759 | EP5 | *** |

| SCL10 | 0.753 | EP6 | *** |

| SCL11 | 0.824 | EP7 | *** |

| SCL12 | 0.814 | EP8 | *** |

| SCL13 | 0.818 | EP9 | 0.736 |

| SCL14 | 0.761 | EP10 | 0.747 |

| SCL15 | 0.786 | EP11 | *** |

| Value addition | (α = 0.908) | EP12 | *** |

| VAD1 | *** | EP13 | 0.740 |

| VAD2 | *** | EP14 | 0.844 |

| VAD3 | *** | EP15 | 0.807 |

| VAD4 | *** | EP16 | *** |

| VAD5 | *** | EP17 | *** |

| VAD6 | *** | EP18 | *** |

| VAD7 | 0.747 | EP19 | 0.783 |

| VAD8 | *** |

| Constructs . | Factor loadings . | Constructs . | Factor loadings . |

|---|---|---|---|

| Compliance with minimum food safety & quality standards | (α = 0.910) | VAD9 | *** |

| CWMFSQS 1 | 0.878 | VAD10 | *** |

| CWMFSQS 2 | 0.819 | VAD11 | *** |

| CWMFSQS 3 | 0.805 | VAD12 | *** |

| CWMFSQS 4 | 0.846 | VAD13 | *** |

| CWMFSQS 5 | 0.832 | VAD14 | 0.825 |

| CWMFSQS 6 | *** | VAD15 | 0.773 |

| CWMFSQS 7 | *** | VAD16 | 0.832 |

| CWMFSQS 8 | *** | VAD17 | 0.851 |

| CWMFSQS 9 | *** | VAD18 | 0.844 |

| CWMFSQS 10 | 0.801 | VAD19 | *** |

| Supply chain learning | (α = 0.953) | VAD20 | *** |

| SCL1 | 0.800 | VAD21 | *** |

| SCL2 | 0.725 | VAD22 | *** |

| SCL3 | 0.752 | VAD23 | *** |

| SCL4 | 0.765 | Export potential | (α = 0.869) |

| SCL5 | 0.722 | EP1 | *** |

| SCL6 | 0.817 | EP2 | *** |

| SCL7 | 0.804 | EP3 | *** |

| SCL8 | 0.768 | EP4 | *** |

| SCL9 | 0.759 | EP5 | *** |

| SCL10 | 0.753 | EP6 | *** |

| SCL11 | 0.824 | EP7 | *** |

| SCL12 | 0.814 | EP8 | *** |

| SCL13 | 0.818 | EP9 | 0.736 |

| SCL14 | 0.761 | EP10 | 0.747 |

| SCL15 | 0.786 | EP11 | *** |

| Value addition | (α = 0.908) | EP12 | *** |

| VAD1 | *** | EP13 | 0.740 |

| VAD2 | *** | EP14 | 0.844 |

| VAD3 | *** | EP15 | 0.807 |

| VAD4 | *** | EP16 | *** |

| VAD5 | *** | EP17 | *** |

| VAD6 | *** | EP18 | *** |

| VAD7 | 0.747 | EP19 | 0.783 |

| VAD8 | *** |

α, Cronbach's alpha.

Item deleted during factor analysis.

The structural elements of both the linear relationship model as well as the mediation analysis model have undergone in-depth examinations. There have been tests of five direct association possibilities. Only one of the five investigated direct association hypotheses could not be validated based on the required significance level and t-values (Table 5). These outcomes were obtained via bootstrapping using 260 cases/observations and 5000 sample iterations.

| Direct relationships . | B . | SD . | T-stats . | P-value . | Decision . | R2 . |

|---|---|---|---|---|---|---|

| CWMFSQS → EP | 0.037 | 0.066 | 0.566 | 0.571 | Not confirmed | |

| CWMFSQS →SCL | 0.751 | 0.049 | 15.406 | 0.000*** | Confirmed | 0.564 |

| SCL → EP | 0.644 | 0.062 | 10.344 | 0.000*** | Confirmed | 0.718 |

| CWMFSQS → VA | 0.805 | 0.049 | 16.307 | 0.000*** | Confirmed | 0.647 |

| VA → EP | 0.230 | 0.061 | 5.841 | 0.000*** | Confirmed |

| Direct relationships . | B . | SD . | T-stats . | P-value . | Decision . | R2 . |

|---|---|---|---|---|---|---|

| CWMFSQS → EP | 0.037 | 0.066 | 0.566 | 0.571 | Not confirmed | |

| CWMFSQS →SCL | 0.751 | 0.049 | 15.406 | 0.000*** | Confirmed | 0.564 |

| SCL → EP | 0.644 | 0.062 | 10.344 | 0.000*** | Confirmed | 0.718 |

| CWMFSQS → VA | 0.805 | 0.049 | 16.307 | 0.000*** | Confirmed | 0.647 |

| VA → EP | 0.230 | 0.061 | 5.841 | 0.000*** | Confirmed |

B, beta value; CWMSQS, compliance with minimum food safety and quality standards; EP, export potential; SCL, supply chain learning; VA, value addition.

P < 0.001.

| Direct relationships . | B . | SD . | T-stats . | P-value . | Decision . | R2 . |

|---|---|---|---|---|---|---|

| CWMFSQS → EP | 0.037 | 0.066 | 0.566 | 0.571 | Not confirmed | |

| CWMFSQS →SCL | 0.751 | 0.049 | 15.406 | 0.000*** | Confirmed | 0.564 |

| SCL → EP | 0.644 | 0.062 | 10.344 | 0.000*** | Confirmed | 0.718 |

| CWMFSQS → VA | 0.805 | 0.049 | 16.307 | 0.000*** | Confirmed | 0.647 |

| VA → EP | 0.230 | 0.061 | 5.841 | 0.000*** | Confirmed |

| Direct relationships . | B . | SD . | T-stats . | P-value . | Decision . | R2 . |

|---|---|---|---|---|---|---|

| CWMFSQS → EP | 0.037 | 0.066 | 0.566 | 0.571 | Not confirmed | |

| CWMFSQS →SCL | 0.751 | 0.049 | 15.406 | 0.000*** | Confirmed | 0.564 |

| SCL → EP | 0.644 | 0.062 | 10.344 | 0.000*** | Confirmed | 0.718 |

| CWMFSQS → VA | 0.805 | 0.049 | 16.307 | 0.000*** | Confirmed | 0.647 |

| VA → EP | 0.230 | 0.061 | 5.841 | 0.000*** | Confirmed |

B, beta value; CWMSQS, compliance with minimum food safety and quality standards; EP, export potential; SCL, supply chain learning; VA, value addition.

P < 0.001.

The results of value addition and supply chain learning as mediators are shown in Table 6. The study found that the association between compliance with minimum food safety and quality standards and export potential is fully mediated by value addition (β = 0.185, t = 3.615, P 0.00). Additionally, supply chain learning (β =0.484, t = 9.683, P 0.00) showed full mediation between compliance to minimum food safety and quality standards and export potential.

| . | β . | SD . | T-Stat . | P-value . | Mediation . |

|---|---|---|---|---|---|

| Compliance with minimum food safety & quality standards → supply chain learning → export potential | 0.484 | 0.050 | 9.683 | 0.000 | Full mediation |

| Compliance with minimum food safety & quality standards → value addition → export potential | 0.185 | 0.051 | 3.615 | 0.000 | Full mediation |

| . | β . | SD . | T-Stat . | P-value . | Mediation . |

|---|---|---|---|---|---|

| Compliance with minimum food safety & quality standards → supply chain learning → export potential | 0.484 | 0.050 | 9.683 | 0.000 | Full mediation |

| Compliance with minimum food safety & quality standards → value addition → export potential | 0.185 | 0.051 | 3.615 | 0.000 | Full mediation |

B, beta value.

| . | β . | SD . | T-Stat . | P-value . | Mediation . |

|---|---|---|---|---|---|

| Compliance with minimum food safety & quality standards → supply chain learning → export potential | 0.484 | 0.050 | 9.683 | 0.000 | Full mediation |

| Compliance with minimum food safety & quality standards → value addition → export potential | 0.185 | 0.051 | 3.615 | 0.000 | Full mediation |

| . | β . | SD . | T-Stat . | P-value . | Mediation . |

|---|---|---|---|---|---|

| Compliance with minimum food safety & quality standards → supply chain learning → export potential | 0.484 | 0.050 | 9.683 | 0.000 | Full mediation |

| Compliance with minimum food safety & quality standards → value addition → export potential | 0.185 | 0.051 | 3.615 | 0.000 | Full mediation |

B, beta value.

The measurement model (Fig. 2) indicated the mediating roles of supply chain learning and value addition in the relationship between compliance with minimum food safety and quality standards and export potential with factor loadings. According to the findings, loadings below the 0.50 level were dropped. The remaining loadings, which in Table 3 ranged from 0.610 to 0.953, were kept (Hair Jr et al., 2021).

Discussion

The results demonstrate the direct and indirect impact of smallholder dairy farmers' willingness to comply with minimum food safety standards on a country's export potential while testing the mediating role of supply chain learning and value addition. Hypothesis 1 predicted that farmer's attitude towards compliance with minimum food safety and quality standards is not related to export potential (β = 0.037, t = 0.566, P > 0.05). This study supports the findings of Nguyen & Jolly (2020) who reported that farmers perceive the implementation of food safety standards as a financial burden, as they perceive minimal benefits associated with compliance. This perception could potentially discourage farmers from adhering to these standards.

According to Hypothesis 2, compliance with minimum food safety and quality standards has a positive impact on supply chain learning (β = 0.644, t = 15 406, P > 0.05). The results of this study also provide credence to the idea put up by Nyokabi et al. (2021) that farmers' knowledge, behavioural traits and subsequently learning play a crucial part in adhering to the standards for food safety and quality. According to Hypothesis 3, Supply chain learning is positively related to export potential (β = 0.644, t = 10.344, P < 0.00). Table 6 illustrates the influence of the variables on export potential in the dairy sector of Pakistan (dependent variable). Table 6 displays the findings of supply chain learning and value addition as mediators (Preacher & Hayes, 2008). The study discovered that value addition (β = 0.185, t = 3.615, P < 0.00) fully mediates the relationship between compliance with minimum food safety and quality standards and export potential. Moreover, supply chain learning (β = 0.484, t = 9.683, P < 0.00) also showed full mediation between compliance with minimum food safety and quality standards and export potential. As a result of Hypotheses 2 and 3, Hypothesis 6 was also accepted.

According to Hypothesis 4, there is a positive relationship between willingness to comply with minimum food safety and quality standards and value addition. Hypothesis 4 showed a positive relationship between compliance with minimum food safety and quality standards and value addition (β = 0.805, t = 16.307, P < 0.00). Value addition is one of the diversification strategies used to enhance speedy investment recovery and boost farmer income (Salvioni et al., 2020). The findings of this study confirm that for value addition, there should be the willingness of farmers to comply with minimum food safety and quality standards. Value addition will certainly help small farmers in speedy investment recovery, increasing the farmer's income and hence helping them in poverty alleviation. The lack of implementation of minimum food safety and quality laws also plays a major role in this regard. However, farmers' ability to innovate and plan the addition of value to their products is severely constrained by the market environment, enabling services, processing technologies, infrastructure, and institutional, economic and socio-demographic issues (Gashaw et al., 2018). According to Hypothesis 5, value addition has a positive relationship with export potential (β = 0.230, t = 5.841, P < 0.00). Value-added products have great export potential because they are becoming more and more significant in the global market. By adding value, farmers and small companies could increase their revenue.

Hypotheses 4, 5 and 7 confirm the mediation role of value addition which can be supported by the findings of Chaudhary et al. (2019) that smallholder dairy farmers, with their increased willingness to comply with minimum food safety and quality standards, are better able to learn new practices for adding value to milk produced at the farm level, because of their enhanced knowledge through sharing of valuable knowledge with suppliers and customers. This study addresses a critical gap in the literature by examining the relationship between smallholder dairy farmers compliance with minimum food safety standards and the country's export potential. The component regarding supply chain learning (SCL) and value addition investigates the role of supply chain learning and value addition in enhancing the export potential of smallholder dairy farmers. It also focuses on identifying and addressing the capacity gaps that smallholder dairy farmers face in meeting MFSQS, implementing SCL practices and enhancing value addition. Targeted interventions, such as training programmes, extension services and the provision of relevant information, have been proposed to build farmers' capacity and improve their compliance with food safety and quality standards. It also measures the overall impact of the above components on the export potential of smallholder dairy farmers in an emerging economy.

Conclusion, policy and managerial implications, limitations and future research

Governments enforce minimum food safety and quality standards to ensure the well-being of their citizens, enhance the export potential of their agricultural products and improve the return on investment for farmers. The findings of this study indicated that compliance with minimum food safety and quality standards has a significant indirect effect on a country's export potential, given the value addition and supply chain learning in the mediating role. Dairy farmers use the knowledge they learn from peers, suppliers, customers and other sources to perform their operations better and add value to their produce. This article contributes to the body of knowledge by examining the mediating role of supply chain learning and value addition in the relationship between farmers' willingness to comply with minimum food safety and quality standards and a country's export potential. Based on the absorptive capacitive view, our findings highlight that compliance with minimum safety and quality standards, along with a concerted effort for enhancing dairy farmers supply chain learning and value addition, can contribute positively to improving a country's export potential and hence helping farmers in eradicating poverty.

This study provides food for thought for the policymakers in food safety and human well-being. In Pakistan, the government has failed in developing, and more importantly imposing a contemporary food safety policy. For this purpose, the concerned regulating department at federal level along with Pakistan Standards and Quality Control Authority (PSQCA) can benchmark the existing standards with best-in-class real benchmark from any advanced country to identify the weakness and corresponding best practices to develop a worldclass food safety policy. The minimum standards should be high enough that an agri-food product produced anywhere in the country should meet international market requirements. The policy implementation needs continuous improvement through a stringent monitoring system and training of smallholder farmers in capacity building. From a managerial perspective, compliance with minimum food safety and quality standards stems from the state-of-the-art knowledge about supply chain stakeholders such as farm input suppliers, dairy farming best practices, competitors and customer requirement. Moreover, they must realise that their innovative behaviour can positively impact the value addition and ultimately to the country's export potential.

The present study exclusively addresses the concerns about food safety within farming, thus constraining its scope. Several prospective avenues for future research emerge, encompassing an investigation into the minimum food safety standards and their compliance within the manufacturing sphere or across the entire supply chain, thereby identifying impediments associated with food policies. Additionally, further research may involve formulating a comprehensive policy framework for implementing minimum food safety and quality standards, accompanied by establishing capacity-building initiatives targeting small-scale farmers. Future studies could pursue an evaluation of the economic ramifications linked to compliance of food safety and quality standards by smallholder farmers. Considering future research directions, exploring the role played by market connections, value chains and certification systems in facilitating smallholder dairy farmers' adherence to food safety and quality standards and their integration into global supply chains holds promise.

Conflict of interest

The authors do not have any conflict of interest to declare.

Ethical approval

Ethical approval was not required for this research.

Author contributions

Muhammad Waqar Arshad: Conceptualization (lead); data curation (lead); formal analysis (lead); methodology (lead); visualization (lead); writing – original draft (lead). Muhammad Moazzam: Conceptualization (supporting); formal analysis (supporting); methodology (supporting); supervision (lead); visualization (supporting); writing – review and editing (supporting). Muhammad Mustafa Raziq: Conceptualization (supporting); formal analysis (supporting); methodology (supporting); supervision (supporting); visualization (supporting); writing – review and editing (supporting). Waqas Ahmed: Supervision (supporting); visualization (supporting); writing – review and editing (supporting).

Peer review

The peer review history for this article is available at https://www.webofscience.com/api/gateway/wos/peer-review/10.1111/ijfs.16539.

Data availability statement

The data that support the findings of this study are available on request from the corresponding author.

References

Food safety and quality systems is a complex and multi-facet domain. Barbancho-Maya and López-Toro (2022) identified determinants of quality and food safety systems adoption in the agri-food sector. This article increased our knowledge of the subject as well as provided us with a relevant and comprehensive literature on the subject which was helpful in selecting appropriate set of constructs and related variables.

Do et al. (2022) provide valuable insights into various strategies adopted by exporters of agricultural products and how they relate to compliance with food safety standards and export potential. It supports our study in identifying the research gap, building conceptual framework and measurement instruments particularly for procurement, production, and marketing perspectives of supply chain learning.

The smallholder dairy farmers' knowledge of the supply chain activities performed by suppliers, competitors (other farmers), and customers makes the overall environment characterizing the supply chain stakeholder's decision making. Haq (2021) highlights that supply chain learning plays very important role in organizational decision making which ultimately contributes to the overall performance.

Value addition is a key driver of export potential in food supply chains. It is an indicator of food safety and quality at dairy farm level. Within the confines of this scholarly inquiry, Singh and Shabani (2017) thoroughly explore value-adding methodologies prevalent throughout the intricate food supply chain operating within the Indian food industry. This study was benefitted in the process of developing measurement instrument on value addition.

The systematic literature review on food safety standards adoption and its impact on firms' export performance conducted by Yadav, Dutta, and Kumar (2021) is closed related to and provides the basis for our study. It provides the theoretical foundations of the relationship between adherence to food safety standards and the potential for exporting goods. Moreover, it helped us review the further literature and classify variables under appropriate constructs.