-

PDF

- Split View

-

Views

-

Cite

Cite

Peixia Chen, Jing Hong, Chong Liu, Xueling Zheng, Xiaohui Tian, Jiaying Shang, Saeed Hamid Saeed Omer, Suitability of corn flour in steamed bread matrices of corn-wheat composite flour: a thermal, rheological and nutritional approach, International Journal of Food Science and Technology, Volume 58, Issue 10, October 2023, Pages 5346–5356, https://doi.org/10.1111/ijfs.16649

Close - Share Icon Share

Abstract

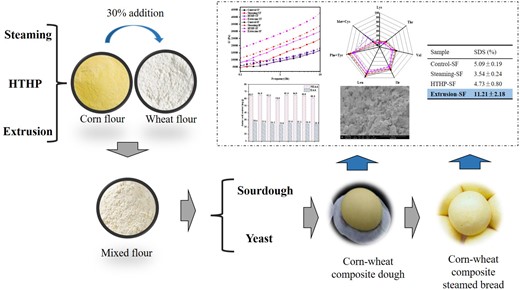

This study investigated the thermal, rheological, morphological, and nutritional properties of corn-wheat composite steamed bread (CWCSB) with different heat treatment methods (steaming, high temperature and high pressure, extrusion) and fermentation methods (yeast and sourdough). The results indicated that sourdough fermentation (SF) improved the textural properties and protein digestibility of CWCSB compared to yeast fermentation (YF). All heat treatments enhanced the elastic behaviour of the dough, with the extrusion method showing a higher G′ value. Both extrusion and steaming treatments resulted in reduced hardness, viscosity, and chewiness of the CWCSB. Due to the flash evaporation effect, a denser dough structure was formed by extrusion, thus reducing enzyme accessibility and resulting in an increased content of slowly digestible starch from 5.09% to 11.21%. In conclusion, extrusion combined with SF could be used as a potential method to improve the suitability of corn flour in steamed bread of corn-wheat composite flour.

Introduction

Due to dietary and health issues, the incorporation of other whole grains with fine wheat flour has gained attention as a means to enhance food nutrition. Corn, a highly productive grain, is commonly used in feed production, but accounts for a smaller portion of total food consumption (Zhou et al., 2023). When used as a whole grain flour, corn flour has more crude fibre, minerals, and vitamins than wheat flour (Kaushal et al., 2023). Therefore, the development and research of corn flour products are critical to the advancement of the corn food industry and human health (Nuss & Tanumihardjo, 2010). Due to the different components and structures of protein between corn and wheat, it is difficult to construct a gluten network in corn flour during processing, resulting in low viscoelasticity of dough and reduced softness of its products (Erickson et al., 2012). Consequently, the above defects limit the application of corn flour to its final products.

To enhance the suitability of corn flour in corn-wheat composite steamed bread (CWCSB), researchers have documented the impacts of physical, chemical, and biological alteration of corn flour on the rheological properties and digestibility of products (Miyazaki & Morita, 2005; Mariotti et al., 2009; Román et al., 2015; Zhang et al., 2016). Physical modification is a cost-effective and environmentally friendly technique that allows for large-scale application. Microwave treatment promoted the formation of amylose lipid complexes and the reorganisation of crystalline, thus leading to a decreased digestion rate (Román et al., 2015). Zhang et al. (2016) concluded that extrusion treatment reduced the viscosity of corn flour and increased its resistant starch (RS) content by 19.0%. Miyazaki & Morita (2005) demonstrated that heat-moisture treatment of corn starch decreased the elasticity of dough as well as the specific volume and softness of bread. The preparation method of steamed bread includes yeast fermentation (YF) and sourdough fermentation (SF), and several studies have reported the use of SF to improve the quality of bread with pure corn flour. In addition, SF has been reported to improve the quality of pure corn flour bread by increasing volume, decreasing elasticity, and softening the texture (Falade et al., 2015).

However, few studies focused on the combination of fermentation and heat treatment of corn flour in the application of CWCSB. In our previous research, we observed that fermentation and cooking methods significantly influenced both the dough and steamed bread quality (Gao et al., 2022). Thus, it can be speculated that the combination of physical modification and fermentation could be a new approach to potentially improving the compatibility of corn flour in CWCSB.

In this study, 30% of wheat flour was replaced by native, steaming, high temperature and high pressure (HTHP), and extrusion-modified corn flour, respectively. And the CWCSB was prepared by YF and SF. The pasting, rheological, morphological, textural profile analysis, amino acid composition, protein, and starch digestibility properties of CWCSB were all investigated and analysed. This work provides a theoretical reference for enhancing corn flour's suitability compared to wheat flour and has a beneficial impact on the promotion of corn flour as a staple food.

Materials and methods

Materials

Corn flour (moisture of 8.61%; ash of 1.17%, db; protein of 8.49%, db) was obtained from the Henan Fuyunwang Happy Farm Ecological Food Co., LTD. (Pingdingshan, China). Wheat flour (moisture of 13.33%; ash of 0.51%, db; protein of 11.19%, db) was provided by Zhengzhou Tiandiren Flour Industry Co., LTD. (Zhengzhou, China) Commercial dry yeast was purchased from Angel Yeast Co., LTD. (Yichang, China) All chemicals used in this study were of analytical grade.

Preparation of corn-wheat composite flour, dough and steamed bread

Three heat treatment methods, steaming, HTHP, and extrusion, were performed on corn flour as described by Gao et al. (2022) with modifications. Steaming is prepared by putting corn flour into a conical bottle sealed in a steamer for 30 min. Corn flour was packaged in the same manner and placed in a sterilised pot at 121 °C and 0.5 MPa for 30 min, labelled as HTHP. Extrusion treatment refers to the adjustment of the 20% water content of corn flour with extrusion temperature of 155 °C. Then all the matrices will be transferred to an oven for 2 h at 60 °C. After that, samples will be passed through an 80-mesh sieve. Corn flour without any treatment was used as the control. The modified corn flour was mixed with wheat flour in a ratio of 3:7 (w w−1) to produce corn-wheat composite flour.

The corn-wheat composite dough was fermented by yeast and sourdough. The method of yeast-fermented dough: corn-wheat flour (100%) was mixed with dry yeast (1%, w w−1) and water (46%, w w−1) in a dough mixer for 5 min. The dough was pressed 5 times with a tablet press, divided into several doughs of about 100 g, and finally kneaded into a smooth dough by hand. Preparation of sourdough fermented dough: corn-wheat flour (100%) was mixed with dry yeast (1%, w w−1) and water (50%, w w−1) in a dough mixer for 5 min at 35 °C and fermented at humidity of 85% for 12 h to produce a sourdough starter. Corn-wheat flour (100%) was mixed with sourdough starter (50%, w w−1) and water (41.7%, w w−1) in the dough mixer for 5 min. The following steps were the same as for yeast fermented dough. Finally, all dough samples are required to rest at 35 °C for 30 min. The dough, after resting, is placed in a steamer and steamed for 20 min to obtain CWCSB.

After heat treatments of control (unprocessed), steaming, HTHP, and extrusion, the CWCSB fermented by yeast and sourdough was expressed as Control-YF, Steaming-YF, HTHP-YF, Extrusion-YF, Control-SF, Steaming-SF, HTHP-SF, and Extrusion-SF, respectively.

Pasting properties of corn-wheat composite flour

The pasting properties of corn-wheat composite flour samples were determined using a Rapid Visco Analyser (RVA-4; Newport Scientific, Warriewood, Australia). Approximately 25 mL of distilled water and about 3.5 g of corn-wheat flour sample (adjusted to a 14% wet basis) were added to the RVA container. The sample was heated from 50 to 95 °C at a rate of 9 °C min−1 within 5 min, maintained at 95 °C for 3 min, and then cooled to 50 °C. The rotation speed was set at 160 rpm.

Rheological properties of corn-wheat composite dough

The rheological properties of dough and gluten after fermentation were measured by a rheometer (RS6000, Thermo Fisher Haake, Germany). The rheometer is equipped with a titanium alloy plate. According to the method described by Li et al. (2021), the instrument parameters are set as follows: diameter, 35 mm; interlayer distance, 2 mm; strain, 0.5%; frequency scanning range, 0.1–10 Hz; test temperature, 35 °C.

Morphological properties of corn-wheat composite dough

The surface image of the dough after fermentation was taken by a camera (AF-S, Nikon, China). The experiment was performed as described by Hong et al. (2020). The dough after fermentation was freeze-dried using the lyophiliser (LGJ-10C, Sihuan Scientific, Beijing, China). Several tiny pieces of about 1 × 1 × 0.5 cm were placed on the surface of the stub, and a thin layer of gold was applied to the surface. The samples were then observed using a scanning electron microscope (S-3400 N, HITACHI, Japan) at an accelerating voltage of 10.0 kV.

Height diameter ratio, specific volume, and textural profile analysis

Following the method of Gao et al. (2018), the height (H) and diameter (D) of dough or steamed bread are measured by a vernier calliper, and H/D is the height-diameter ratio. The ratio of the volume to the mass of steamed bread is the specific volume (SV, mL g−1).

The steamed bread samples were uniformly cut into 15 -mm slices by a microtome, and three steamed bread slices were selected and measured using a TA-XT Plus texture analyser (Stable Micro System, Godalming, UK). With reference to Wu et al. (2012), instrument parameters were as follows: pre-test speed, 3.0 mm s−1; test speed, 1.0 mm s−1; post-test speed, 1.0 mm s−1; compressive deformation, 50%; secondary compression interval time, 3 s; trigger force, 5 g.

Amino acid composition and amino acid score of corn-wheat composite steamed bread

The amino acid composition of CWCSB was evaluated by an amino acid analyser (S-433(D), Sykam, Munich, Germany). In accordance with the modified FAO/WHO 2007 recommendations of the amino acid content model and the score of optimal human protein (WHO/FAO/UNU, 2007), the different amino acids, amino acid score, essential amino acids (EAA) and non-essential amino acids (NEAA) in CWCSB were assessed.

In vitro digestibility of corn-wheat composite steamed bread

Protein digestibility

The in vitro protein digestibility was carried out with reference to the method of Gao et al. (2022). N indicates the digestible protein content of steamed bread prepared using different heat treatments and fermentation methods. The in vitro protein digestibility was calculated by eq. (1):

Starch digestibility

In vitro starch digestibility including rapidly digestible starch (RDS), slow digestible starch (SDS) and resistant starch (RS) content was measured as described by Englyst et al. (1992). The glucose content (G0, G20, and G120) after 0, 20, and 120 min of enzymatic hydrolysis was calculated, respectively. The residual residue was previously deeply hydrolysed with potassium hydroxide (7 M) and amyloglucosidase (50 AGU mL−1) to determine the total glucose concentration (TG). The conversion factor between the amounts of glucose and starch was 0.9. The values obtained for G0, G20, G120, and TG were used to calculate RDS, SDS, and RS as follows.

Statistical analysis

Analytical determinations for samples were made in triplicate, and standard deviations were reported. SPSS version 22.0 was used to evaluate statistical significance (P < 0.05). And statistical comparisons were performed by single-factor analysis of variance (ANOVA) and Duncan's method. Origin 2018 software was used for plotting and fitting data.

Results and discussion

Pasting properties of corn-wheat composite dough

The pasting properties of corn-wheat composite flour with a supplement of 30% corn flour treated by different methods are shown in Table 1. The pasting properties of corn-wheat composite flour after heat treatment were significantly different from those of control (P < 0.05). The peak viscosity, trough viscosity, final viscosity, and setback value of corn-wheat composite flour were shown as: steaming > HTHP > control > extrusion. The breakdown value of modified corn-wheat composite flour was lower than that of control (441 cP), demonstrating that heat treatment enhanced the thermal stability of starch granules in corn flour. The final viscosity has profound implications for predicting the viscosity of processed products. The final viscosity of corn-wheat composite flour under HTHP (1771 cP) was similar to that of control (1584 cP). The final viscosity of corn-wheat flour was increased by 30.7% and decreased by 30.2% as treated by steaming and extrusion.

| Sample . | Peak viscosity (cP) . | Trough viscosity (cP) . | Breakdown value (cP) . | Final viscosity (cP) . | Setback value (cP) . |

|---|---|---|---|---|---|

| Control | 1253.0 ± 4.2c | 812.0 ± 4.2c | 441.0 ± 8.5a | 1584.0 ± 7.1c | 772.0 ± 2.8c |

| Steaming | 1566.5 ± 101.1a | 1181.5 ± 85.6a | 385.0 ± 15.6b | 2071.0 ± 58.0a | 889.5 ± 27.6a |

| HTHP | 1350.0 ± 1.4b | 914.5 ± 5.0b | 435.5 ± 3.5a | 1771.0 ± 1.4b | 856.5 ± 3.5b |

| Extrusion | 811.5 ± 7.8d | 628.5 ± 6.4d | 183.0 ± 1.4c | 1106.5 ± 7.7d | 478.0 ± 1.4d |

| Sample . | Peak viscosity (cP) . | Trough viscosity (cP) . | Breakdown value (cP) . | Final viscosity (cP) . | Setback value (cP) . |

|---|---|---|---|---|---|

| Control | 1253.0 ± 4.2c | 812.0 ± 4.2c | 441.0 ± 8.5a | 1584.0 ± 7.1c | 772.0 ± 2.8c |

| Steaming | 1566.5 ± 101.1a | 1181.5 ± 85.6a | 385.0 ± 15.6b | 2071.0 ± 58.0a | 889.5 ± 27.6a |

| HTHP | 1350.0 ± 1.4b | 914.5 ± 5.0b | 435.5 ± 3.5a | 1771.0 ± 1.4b | 856.5 ± 3.5b |

| Extrusion | 811.5 ± 7.8d | 628.5 ± 6.4d | 183.0 ± 1.4c | 1106.5 ± 7.7d | 478.0 ± 1.4d |

Control, native corn-wheat composite flour with the 30% addition of corn flour.

Results were presented as mean ± standard deviation. Different letters in the same column show significant differences (P < 0.05, n = 3).

HTHP, high temperature and high pressure.

| Sample . | Peak viscosity (cP) . | Trough viscosity (cP) . | Breakdown value (cP) . | Final viscosity (cP) . | Setback value (cP) . |

|---|---|---|---|---|---|

| Control | 1253.0 ± 4.2c | 812.0 ± 4.2c | 441.0 ± 8.5a | 1584.0 ± 7.1c | 772.0 ± 2.8c |

| Steaming | 1566.5 ± 101.1a | 1181.5 ± 85.6a | 385.0 ± 15.6b | 2071.0 ± 58.0a | 889.5 ± 27.6a |

| HTHP | 1350.0 ± 1.4b | 914.5 ± 5.0b | 435.5 ± 3.5a | 1771.0 ± 1.4b | 856.5 ± 3.5b |

| Extrusion | 811.5 ± 7.8d | 628.5 ± 6.4d | 183.0 ± 1.4c | 1106.5 ± 7.7d | 478.0 ± 1.4d |

| Sample . | Peak viscosity (cP) . | Trough viscosity (cP) . | Breakdown value (cP) . | Final viscosity (cP) . | Setback value (cP) . |

|---|---|---|---|---|---|

| Control | 1253.0 ± 4.2c | 812.0 ± 4.2c | 441.0 ± 8.5a | 1584.0 ± 7.1c | 772.0 ± 2.8c |

| Steaming | 1566.5 ± 101.1a | 1181.5 ± 85.6a | 385.0 ± 15.6b | 2071.0 ± 58.0a | 889.5 ± 27.6a |

| HTHP | 1350.0 ± 1.4b | 914.5 ± 5.0b | 435.5 ± 3.5a | 1771.0 ± 1.4b | 856.5 ± 3.5b |

| Extrusion | 811.5 ± 7.8d | 628.5 ± 6.4d | 183.0 ± 1.4c | 1106.5 ± 7.7d | 478.0 ± 1.4d |

Control, native corn-wheat composite flour with the 30% addition of corn flour.

Results were presented as mean ± standard deviation. Different letters in the same column show significant differences (P < 0.05, n = 3).

HTHP, high temperature and high pressure.

Extrusion decreased all pasting viscosities, which was consistent with other studies (Wang et al., 2022a). Probably due to flash evaporation destroying the crystal structure of starch, the instantaneous drop of pressure causes a certain amount of water to evaporate, leading to the weakening of the hydrogen bond association of amylopectin (Zhang et al., 2016; Lang et al., 2023). It may also be attributed to the formation of complex between starch and non-starch components (protein, lipid, and polysaccharide) of corn flour during extrusion, which limits the penetration of water molecules and the swelling capability of starch, thus reducing the viscosity (Tang et al., 2019; Yang et al., 2021). During the steaming process, water molecules in the steam are cross-linked with starch by hydrogen bonds, increasing viscosity (Donmez et al., 2021). This phenomenon was also confirmed by the moisture content of corn flour after heat treatment (steaming, 9.24%; extrusion, 6.14%). Due to the low moisture content of the extrusion treatment, gelatinisation was inhibited, thus limiting its water absorption and swelling of starch granules (Zhang et al., 2016).

Rheological properties of corn-wheat composite dough

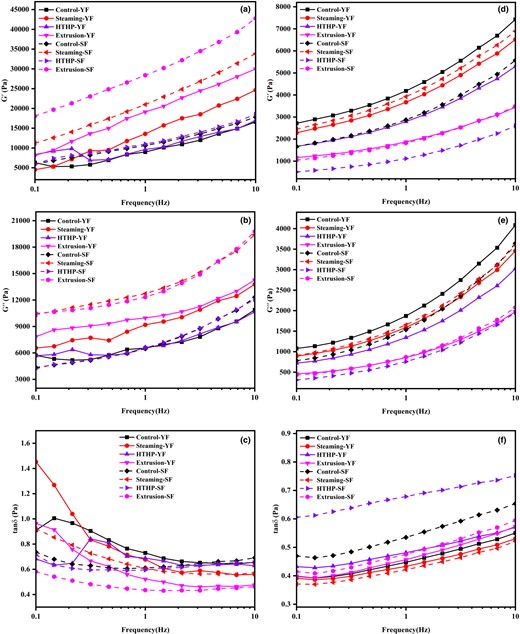

The rheological properties of dough were considered to have a significant correlation with product quality. Elastic modulus (G′) measures the elasticity of dough, reflecting the energy stored in the material after the end of the oscillation, while viscous modulus (G″) represents the viscosity of dough, indicating the energy lost during the oscillation process (Ewoldt et al., 2008). In Fig. 1a,b, the G′ and G″ of the dough showed a rising trend at 0.1–10 Hz. During the frequency sweep process, both moduli of dough with treatment of steaming and extrusion were higher than control (Fig. 1a,b), while the fermented dough by sourdough was much higher. This may be attributed to the increase in deformable protein and gelatinisation of corn flour treated by steaming and extrusion, which increases water binding sites in dough, leading to higher hydration of protein and starch granules (Millar et al., 2019; Hong et al., 2022). In addition, more interactions may exist between the components of heat-treated corn flour (fibre, starch, and protein) and raw wheat flour, enhancing the stability and rheological properties of dough (Zou et al., 2023). The dough with HTHP treated corn flour showed similar viscoelasticity (G′ and G″). When compared with the control, which shows the same as mentioned in the above pasting properties. On the other hand, HTHP probably caused less damage to corn flour. The loss factor (tanδ) is calculated by the ratio of G″ to G′. The tanδ value reflects the overall viscoelasticity of the dough. The tanδ value of extrusion treatment was the lowest (Fig. 1c), indicating an advantage of elasticity over viscosity. At 0–10 Hz, the tanδ value of SF was lower than that of YF, and the degree of change in SF with frequency was relatively small. This indicates that extrusion treatment and SF effectively improved the elastic properties and resisted the deformation ability of corn-wheat composite dough.

Rheological properties of corn-wheat composite dough and gluten after fermentation. After heat treatment by control (unprocessed), steaming, HTHP, and extrusion, the corn-wheat composite steamed bread fermented by yeast and sourdough was expressed as Control-YF, Steaming-YF, HTHP-YF, Extrusion-YF, Control-SF, Steaming-SF, HTHP-SF, and Extrusion-SF, respectively. (a–c) represent the elastic modulus (G′), viscous modulus (G″), and loss factor (tanδ) of the dough after fermentation. (d–f) represent the elastic modulus (G′), viscous modulus (G″), and loss factor (tanδ) of the gluten after fermentation.

To further determine the effect of fermentation methods on gluten in dough, the rheological properties of gluten in fermented dough were supplemented with modified corn flour (Fig. 1d–f). With the increase in frequency (0.1–10 Hz), G′, G″ and tanδ values all showed an uptrend, especially G′ values, which were always greater than G″ (tanδ <1). The viscoelasticity of gluten is mainly due to the formation of a protein network structure. After heat treatment, the elasticity and viscosity of the gluten decreased (Fig. 1d,e), which may be due to the destruction of disulfide bonds, surface hydrophobicity, and other interactions by heat treatment, resulting in a decrease in the structural stability of gluten (Mann et al., 2014). Various heat treatments induced distinct effects on the viscoelastic properties of gluten. After being treated by HTHP and SF, the G′ and G″ values of gluten were the lowest. However, the tanδ value of HTHP-SF is significantly higher than that of HTHP-YF, with tanδ values of 0.48 and 0.68 at 1 Hz, respectively. The difference in tanδ values between other treatments was small, indicating that the combination of SF and HTHP treatment has a greater impact on gluten. The tanδ values were generally lower in corn-wheat gluten prepared by SF than YF, but the rheological properties were similar between the two fermentation methods after steaming treatment, indicating that the metabolites (ethanol, succinic acid, and glutathione) during SF played a role in softening gluten and improving dough viscoelasticity (Gao et al., 2022).

Morphological properties of corn-wheat composite dough

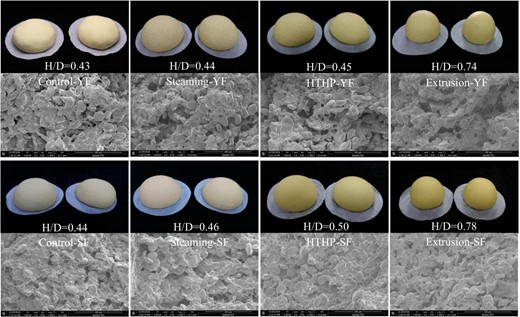

Figure 2 presents the appearance and internal microstructure as observed by camera and SEM. The height-diameter ratio (H/D) of dough treated by extrusion was 0.74 (yeast) and 0.78 (sourdough), respectively. The starch was firmly wrapped in the gluten matrix in extrusion samples, exhibiting a denser microstructure (Fig. 2). However, the control, steaming, and HTHP-treated dough exhibited an apparent collapse in appearance, and no significant change in the H/D value of the dough was detected in the three modified methods, as the inner compactness of the dough. The reason for the high H/D values of the extrusion treatment may be the destructive effect of the extrusion treatment. This corresponds to a decrease in the elastic behaviour of gluten (Fig. 1c). In addition, it can be observed that the colour of dough treated by different modification methods is inconsistent (extrusion > HTHP > steaming > control), which is related to the temperature, time, and humidity of the modification processing. The pigment substances in corn flour are mainly zeaxanthin and cryptoflavin, and heat treatment will lead to degradation and diffusion of these substances (Harakotr et al., 2014). And natural pigments have low stability and are easily dissolved in water molecules, and hot steam will accelerate the decomposition of pigment substances (Kanha et al., 2022). Therefore, the sample without heat treatment (control) has less pigment diffusion. Probably due to the high humidity of the steaming treatment, some pigments are dissolved in steam and degraded, so less pigment is retained in corn flour. However, the humidity of HTHP and extrusion treatment is low, and pigment substances are diffused to the surface of corn flour, only a small amount of which is taken away by water vapour.

Images of appearance and internal microstructure of corn-wheat composite dough after fermentation. Scanning electron microscope images of corn-wheat composite dough at ×1500 magnification to illustrate the micro-structure. After heat treatment by control (unprocessed), steaming, HTHP, and extrusion, the corn-wheat composite steamed bread fermented by yeast and sourdough was expressed as Control-YF, Steaming-YF, HTHP-YF, Extrusion-YF, Control-SF, Steaming-SF, HTHP-SF, and Extrusion-SF, respectively.

The H/D of SF dough was higher than that of YF dough treated with the same heat method, with a smooth appearance, and a compact and uniform internal structure. This may be due to sourdough containing other bacteria (lactic acid bacteria, acetic acid bacteria, etc.), resulting in a decrease in pH, thus softening the gluten network and weakening the yeast's ability to produce gas (Meng et al., 2020; Wang et al., 2022b). The loose structure of YF was observed by SEM, which may be due to the strong gas production capacity of yeast, the increase in height and diameter at the same time, and ultimately a small H/D.

Height to diameter ratio, specific volume, and texture profile analysis of corn-wheat composite steamed bread

The information on the high diameter ratio (H/D), specific volume (SV), and texture profile analysis (TPA) of CWCSB are shown in Table 2. The H/D of extruded composite steamed bread was 0.69 (yeast) and 0.70 (sourdough), which was significantly higher than that of the other three heat treatment methods. The result is consistent with the high H/D of the morphological properties of the dough (Fig. 2). The SV of steamed bread fermented by yeast after extrusion decreased by 15.0%, but no significant reduction (P < 0.05) was found in the product fermented by sourdough. These results indicated that SF improved the problem of high hardness and non-looseness in composite dough caused by extrusion treatment.

Height to diameter ratio, specific volume, and textural profile analysis of corn-wheat composite steamed bread

| Sample . | H/D . | SV (mL g−1) . | Hardness (g) . | Elasticity . | Gumminess . | Chewiness . |

|---|---|---|---|---|---|---|

| Control-YF | 0.46 ± 0.00bc | 1.67 ± 0.01a | 6556.33 ± 32.56b | 0.85 ± 0.03c | 4422.80 ± 98.79c | 3741.74 ± 114.72c |

| Steaming-YF | 0.44 ± 0.00cd | 1.64 ± 0.03a | 4605.69 ± 75.85e | 0.89 ± 0.01b | 3587.47 ± 39.82f | 3185.86 ± 30.56e |

| HTHP-YF | 0.47 ± 0.01b | 1.66 ± 0.03a | 7087.35 ± 76.04a | 0.93 ± 0.01a | 5106.09 ± 38.96a | 4724.04 ± 23.19a |

| Extrusion-YF | 0.69 ± 0.02a | 1.42 ± 0.02b | 5308.52 ± 71.19c | 0.93 ± 0.01a | 4148.57 ± 54.34d | 3849.58 ± 2.87c |

| Control-SF | 0.42 ± 0.01d | 1.67 ± 0.04a | 5418.73 ± 94.31c | 0.94 ± 0.01a | 4079.82 ± 84.32d | 3846.68 ± 106.78c |

| Steaming-SF | 0.44 ± 0.03cd | 1.55 ± 0.18a | 4465.05 ± 77.84f | 0.92 ± 0.01a | 3246.66 ± 47.36g | 2991.49 ± 13.71f |

| HTHP-SF | 0.48 ± 0.00b | 1.67 ± 0.04a | 6574.56 ± 97.14b | 0.93 ± 0.02a | 4704.21 ± 80.76b | 4356.38 ± 157.48b |

| Extrusion-SF | 0.70 ± 0.01a | 1.64 ± 0.07a | 5017.29 ± 40.13d | 0.92 ± 0.01a | 3868.03 ± 57.50e | 3547.97 ± 34.99d |

| Sample . | H/D . | SV (mL g−1) . | Hardness (g) . | Elasticity . | Gumminess . | Chewiness . |

|---|---|---|---|---|---|---|

| Control-YF | 0.46 ± 0.00bc | 1.67 ± 0.01a | 6556.33 ± 32.56b | 0.85 ± 0.03c | 4422.80 ± 98.79c | 3741.74 ± 114.72c |

| Steaming-YF | 0.44 ± 0.00cd | 1.64 ± 0.03a | 4605.69 ± 75.85e | 0.89 ± 0.01b | 3587.47 ± 39.82f | 3185.86 ± 30.56e |

| HTHP-YF | 0.47 ± 0.01b | 1.66 ± 0.03a | 7087.35 ± 76.04a | 0.93 ± 0.01a | 5106.09 ± 38.96a | 4724.04 ± 23.19a |

| Extrusion-YF | 0.69 ± 0.02a | 1.42 ± 0.02b | 5308.52 ± 71.19c | 0.93 ± 0.01a | 4148.57 ± 54.34d | 3849.58 ± 2.87c |

| Control-SF | 0.42 ± 0.01d | 1.67 ± 0.04a | 5418.73 ± 94.31c | 0.94 ± 0.01a | 4079.82 ± 84.32d | 3846.68 ± 106.78c |

| Steaming-SF | 0.44 ± 0.03cd | 1.55 ± 0.18a | 4465.05 ± 77.84f | 0.92 ± 0.01a | 3246.66 ± 47.36g | 2991.49 ± 13.71f |

| HTHP-SF | 0.48 ± 0.00b | 1.67 ± 0.04a | 6574.56 ± 97.14b | 0.93 ± 0.02a | 4704.21 ± 80.76b | 4356.38 ± 157.48b |

| Extrusion-SF | 0.70 ± 0.01a | 1.64 ± 0.07a | 5017.29 ± 40.13d | 0.92 ± 0.01a | 3868.03 ± 57.50e | 3547.97 ± 34.99d |

After heat treatment by control (unprocessed), steaming, HTHP and extrusion, the corn-wheat composite steamed bread fermented by yeast and sourdough were expressed as Control-YF, Steaming-YF, HTHP-YF, Extrusion-YF, Control-SF, Steaming-SF, HTHP-SF and Extrusion-SF, respectively.

Results were presented as mean ± standard deviation. Different letters in the same column in the table show significant differences (P < 0.05, n = 3).

H/D, height diameter ratio; SV, specific volume.

Height to diameter ratio, specific volume, and textural profile analysis of corn-wheat composite steamed bread

| Sample . | H/D . | SV (mL g−1) . | Hardness (g) . | Elasticity . | Gumminess . | Chewiness . |

|---|---|---|---|---|---|---|

| Control-YF | 0.46 ± 0.00bc | 1.67 ± 0.01a | 6556.33 ± 32.56b | 0.85 ± 0.03c | 4422.80 ± 98.79c | 3741.74 ± 114.72c |

| Steaming-YF | 0.44 ± 0.00cd | 1.64 ± 0.03a | 4605.69 ± 75.85e | 0.89 ± 0.01b | 3587.47 ± 39.82f | 3185.86 ± 30.56e |

| HTHP-YF | 0.47 ± 0.01b | 1.66 ± 0.03a | 7087.35 ± 76.04a | 0.93 ± 0.01a | 5106.09 ± 38.96a | 4724.04 ± 23.19a |

| Extrusion-YF | 0.69 ± 0.02a | 1.42 ± 0.02b | 5308.52 ± 71.19c | 0.93 ± 0.01a | 4148.57 ± 54.34d | 3849.58 ± 2.87c |

| Control-SF | 0.42 ± 0.01d | 1.67 ± 0.04a | 5418.73 ± 94.31c | 0.94 ± 0.01a | 4079.82 ± 84.32d | 3846.68 ± 106.78c |

| Steaming-SF | 0.44 ± 0.03cd | 1.55 ± 0.18a | 4465.05 ± 77.84f | 0.92 ± 0.01a | 3246.66 ± 47.36g | 2991.49 ± 13.71f |

| HTHP-SF | 0.48 ± 0.00b | 1.67 ± 0.04a | 6574.56 ± 97.14b | 0.93 ± 0.02a | 4704.21 ± 80.76b | 4356.38 ± 157.48b |

| Extrusion-SF | 0.70 ± 0.01a | 1.64 ± 0.07a | 5017.29 ± 40.13d | 0.92 ± 0.01a | 3868.03 ± 57.50e | 3547.97 ± 34.99d |

| Sample . | H/D . | SV (mL g−1) . | Hardness (g) . | Elasticity . | Gumminess . | Chewiness . |

|---|---|---|---|---|---|---|

| Control-YF | 0.46 ± 0.00bc | 1.67 ± 0.01a | 6556.33 ± 32.56b | 0.85 ± 0.03c | 4422.80 ± 98.79c | 3741.74 ± 114.72c |

| Steaming-YF | 0.44 ± 0.00cd | 1.64 ± 0.03a | 4605.69 ± 75.85e | 0.89 ± 0.01b | 3587.47 ± 39.82f | 3185.86 ± 30.56e |

| HTHP-YF | 0.47 ± 0.01b | 1.66 ± 0.03a | 7087.35 ± 76.04a | 0.93 ± 0.01a | 5106.09 ± 38.96a | 4724.04 ± 23.19a |

| Extrusion-YF | 0.69 ± 0.02a | 1.42 ± 0.02b | 5308.52 ± 71.19c | 0.93 ± 0.01a | 4148.57 ± 54.34d | 3849.58 ± 2.87c |

| Control-SF | 0.42 ± 0.01d | 1.67 ± 0.04a | 5418.73 ± 94.31c | 0.94 ± 0.01a | 4079.82 ± 84.32d | 3846.68 ± 106.78c |

| Steaming-SF | 0.44 ± 0.03cd | 1.55 ± 0.18a | 4465.05 ± 77.84f | 0.92 ± 0.01a | 3246.66 ± 47.36g | 2991.49 ± 13.71f |

| HTHP-SF | 0.48 ± 0.00b | 1.67 ± 0.04a | 6574.56 ± 97.14b | 0.93 ± 0.02a | 4704.21 ± 80.76b | 4356.38 ± 157.48b |

| Extrusion-SF | 0.70 ± 0.01a | 1.64 ± 0.07a | 5017.29 ± 40.13d | 0.92 ± 0.01a | 3868.03 ± 57.50e | 3547.97 ± 34.99d |

After heat treatment by control (unprocessed), steaming, HTHP and extrusion, the corn-wheat composite steamed bread fermented by yeast and sourdough were expressed as Control-YF, Steaming-YF, HTHP-YF, Extrusion-YF, Control-SF, Steaming-SF, HTHP-SF and Extrusion-SF, respectively.

Results were presented as mean ± standard deviation. Different letters in the same column in the table show significant differences (P < 0.05, n = 3).

H/D, height diameter ratio; SV, specific volume.

Better quality steamed bread typically has low viscosity, chewiness, and viscosity but great elasticity (Li et al., 2021). The elasticity of Steaming-YF was slightly elevated in this study compared with Control-YF, and there was no significant difference in the elasticity of steamed bread treated by other methods (P < 0.05). By adding corn flour modified by steaming, the hardness, viscosity, and chewiness of steamed bread fermented by yeast and sourdough decreased by 29.8%, 18.9%, 14.9%, and 17.5%, 20.4%, 22.2%, respectively, which effectively improved the texture quality of CWCSB. Similarly, the texture of CWCSB was also improved by extrusion, but the improvement effect was lower than that of steaming. In contrast, HTHP treatment increased the hardness, viscosity, and chewiness of CWCSB. This is related to the low G′ value and high tanδ value of gluten in rheology properties (Fig. 1d,f). The hardness, viscosity, and chewiness of CWCSB are always lower in SF than by YF under most of the same modification methods. This is attributed to the softening effect of sourdough on dough and gluten (Meng et al., 2020; Wang et al., 2022a). In summary, steamed bread processed by steaming combined with SF could obtain better textural quality.

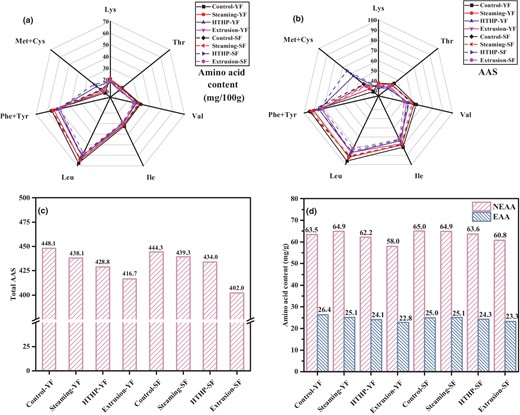

Amino acid composition and amino acid score of corn-wheat composite steamed bread

The amino acid composition and amino acid score (AAS) of all steamed bread samples are shown in Fig. 3a–d. According to the revised FAO/WHO standards (Esan et al., 2018), the recommended levels of lysine, threonine, valine, isoleucine, leucine, Phe + Tyr, and Met + Cys are 55.0, 40.0, 50.0, 40.0, 70.0, 60.0, and 35.0 mg 100 g−1, respectively. Limiting amino acids plays an important role in the nutritional value of proteins. In cereal foods, lysine is often referred to as the first limiting amino acid because it has a positive nutritional role in promoting body development and enhancing immunity, but its content is very low and easy to destroy during processing. The first restricted amino acids of Control-YF and Control-SF are Met + Cys and Lys, respectively (Fig. 3a). When steamed bread was prepared by YF, the first limiting amino acid of steaming modification was still Met + Cys, and AAS increased by 14.8% (Fig. 3b). However, the first limiting amino acid of HTHP and extrusion was Lys, and AAS decreased from 37.2 to 32.9 (yeast) and 33.8 (sourdough), respectively. For SF, the first limiting amino acid of samples treated with steaming, HTHP, and extrusion modification was Lys, and there was a slight increase in AAS at Lys.

Amino acid composition and amino acid score of corn-wheat composite steamed bread. (a–c) show different amino acid contents, amino acid scores, and total amino acid scores of corn-wheat composite steamed bread after different treatments. (d) shows different non-essential amino acids (NEAA) and essential amino acids (EAA) in corn-wheat composite steamed bread after different treatments. After heat treatment by control (unprocessed), steaming, HTHP, and extrusion, the corn-wheat composite steamed bread fermented by yeast and sourdough were expressed as Control-YF, Steaming-YF, HTHP-YF, Extrusion-YF, Control-SF, Steaming-SF, HTHP-SF, and Extrusion-SF, respectively.

The total amino acid score (TAAS) was obtained by summing different AAS values and is presented in Fig. 3c. The order of TAAS in all samples is: Control-YF (448.1) > Control-SF (444.3) > Seaming-SF (439.3) > Steaming-YF (438.1) > HTHP-SF (434.0) > HTHP-YF (428.8) > Extrusion-YF (416.7) > Extrusion-SF (402.0).

Amino acids needed by the human body include EAA and NEAA. EAA refers to amino acids that cannot be synthesised by humans or animals themselves, and the speed and quantity of synthesis cannot meet the normal physiological needs of the body, which can only be obtained by ingesting food (Hou & Wu, 2018). Figure 3d reflects the results of EAA and NEAA in steamed bread under different modification treatments and preparation methods. The TAA and EAA contents of steamed bread prepared by the three treatments were in the following order: steaming > HTHP > extrusion. The degree of amino acid damage in corn flour by different processing methods can be reflected (Meade et al., 2005). Mostly, the TAA, EAA, and NEAA content of steamed bread prepared by SF was slightly higher than that by YF, which may be due to the degradation of gluten proteins happened at a longer time during SF to generate peptides and amino acids for small molecules (Gobbetti et al., 2014).

The results demonstrated that the addition of steamed corn flour and SF can maintain a higher total AAS, and supplement the content of restricted amino acids in CWCSB, showing a high nutritional quality.

In vitro digestibility of corn-wheat composite steamed bread

As a staple food product of steamed bread, digestible properties of protein and starch are essential. The protein digestion properties, RDS, SDS, and RS contents of CWCSB with different modifications and fermentation preparation methods are shown in Table 3. The digestible protein of CWCSB fermented by sourdough was significantly higher than that fermented by yeast. It is generally believed that small molecules of amino acids are more easily digested and absorbed by the human body (Xu et al., 2021). Rheological properties also confirmed that the gluten degradation in SF was more severe, producing more small molecular proteins, and that the enzyme was easier to act on the protein (Gao et al., 2022). This result corresponds to the higher amino acid content of CWCSB prepared by SF. Extrusion-YF reduced the protein digestibility by 5.72%, which may be due to the aggregation and denaturation of the protein, making it difficult to bind to proteases and difficult to digest and hydrolyse, resulting in a decrease in digestibility. Extrusion-SF showed the opposite result, with a 3.4% increase in protein digestibility. HTHP improved the protein digestibility of CWCSB by 3.3% (yeast) and 5.6% (sourdough). This may be due to the relatively loose internal structure of the dough after high temperature and high pressure (Fig. 2), which increases the digestion site of the enzyme.

Protein and starch digestion properties of corn-wheat composite steamed bread

| Sample . | Protein digestibility (%) . | RDS (%) . | SDS (%) . | RS (%) . |

|---|---|---|---|---|

| Control-YF | 9.61 ± 0.20d | 24.28 ± 0.17d | 9.07 ± 0.46b | 4.96 ± 0.41bc |

| Steaming-YF | 9.69 ± 0.03d | 26.57 ± 0.34c | 6.90 ± 1.31c | 6.00 ± 1.03ab |

| HTHP-YF | 9.93 ± 0.09cd | 30.13 ± 0.03a | 5.42 ± 0.14cd | 4.78 ± 0.15bc |

| Extrusion-YF | 9.06 ± 0.35e | 30.49 ± 0.63a | 6.84 ± 1.33c | 4.03 ± 0.87c |

| Control-SF | 10.23 ± 0.06c | 28.62 ± 0.23b | 5.09 ± 0.19cd | 6.37 ± 0.28a |

| Steaming-SF | 10.35 ± 0.09b | 28.73 ± 0.74b | 3.54 ± 0.24d | 6.16 ± 0.95ab |

| HTHP-SF | 10.80 ± 0.27a | 28.65 ± 0.11b | 4.73 ± 0.80d | 6.64 ± 0.94a |

| Extrusion-SF | 10.58 ± 0.37ab | 27.92 ± 1.51b | 11.21 ± 2.18a | 4.87 ± 0.70bc |

| Sample . | Protein digestibility (%) . | RDS (%) . | SDS (%) . | RS (%) . |

|---|---|---|---|---|

| Control-YF | 9.61 ± 0.20d | 24.28 ± 0.17d | 9.07 ± 0.46b | 4.96 ± 0.41bc |

| Steaming-YF | 9.69 ± 0.03d | 26.57 ± 0.34c | 6.90 ± 1.31c | 6.00 ± 1.03ab |

| HTHP-YF | 9.93 ± 0.09cd | 30.13 ± 0.03a | 5.42 ± 0.14cd | 4.78 ± 0.15bc |

| Extrusion-YF | 9.06 ± 0.35e | 30.49 ± 0.63a | 6.84 ± 1.33c | 4.03 ± 0.87c |

| Control-SF | 10.23 ± 0.06c | 28.62 ± 0.23b | 5.09 ± 0.19cd | 6.37 ± 0.28a |

| Steaming-SF | 10.35 ± 0.09b | 28.73 ± 0.74b | 3.54 ± 0.24d | 6.16 ± 0.95ab |

| HTHP-SF | 10.80 ± 0.27a | 28.65 ± 0.11b | 4.73 ± 0.80d | 6.64 ± 0.94a |

| Extrusion-SF | 10.58 ± 0.37ab | 27.92 ± 1.51b | 11.21 ± 2.18a | 4.87 ± 0.70bc |

After heat treatment by control (unprocessed), steaming, HTHP, and extrusion, the corn-wheat composite steamed bread fermented by yeast and sourdough were expressed as Control-YF, Steaming-YF, HTHP-YF, Extrusion-YF, Control-SF, Steaming-SF, HTHP-SF, and Extrusion-SF, respectively; RDS, rapidly digestible starch; SDS, slowly digestible starch; RS, resistant starch.

Results were presented as mean ± standard deviation. Different letters in the same column in the table show significant differences (P < 0.05, n = 3).

Protein and starch digestion properties of corn-wheat composite steamed bread

| Sample . | Protein digestibility (%) . | RDS (%) . | SDS (%) . | RS (%) . |

|---|---|---|---|---|

| Control-YF | 9.61 ± 0.20d | 24.28 ± 0.17d | 9.07 ± 0.46b | 4.96 ± 0.41bc |

| Steaming-YF | 9.69 ± 0.03d | 26.57 ± 0.34c | 6.90 ± 1.31c | 6.00 ± 1.03ab |

| HTHP-YF | 9.93 ± 0.09cd | 30.13 ± 0.03a | 5.42 ± 0.14cd | 4.78 ± 0.15bc |

| Extrusion-YF | 9.06 ± 0.35e | 30.49 ± 0.63a | 6.84 ± 1.33c | 4.03 ± 0.87c |

| Control-SF | 10.23 ± 0.06c | 28.62 ± 0.23b | 5.09 ± 0.19cd | 6.37 ± 0.28a |

| Steaming-SF | 10.35 ± 0.09b | 28.73 ± 0.74b | 3.54 ± 0.24d | 6.16 ± 0.95ab |

| HTHP-SF | 10.80 ± 0.27a | 28.65 ± 0.11b | 4.73 ± 0.80d | 6.64 ± 0.94a |

| Extrusion-SF | 10.58 ± 0.37ab | 27.92 ± 1.51b | 11.21 ± 2.18a | 4.87 ± 0.70bc |

| Sample . | Protein digestibility (%) . | RDS (%) . | SDS (%) . | RS (%) . |

|---|---|---|---|---|

| Control-YF | 9.61 ± 0.20d | 24.28 ± 0.17d | 9.07 ± 0.46b | 4.96 ± 0.41bc |

| Steaming-YF | 9.69 ± 0.03d | 26.57 ± 0.34c | 6.90 ± 1.31c | 6.00 ± 1.03ab |

| HTHP-YF | 9.93 ± 0.09cd | 30.13 ± 0.03a | 5.42 ± 0.14cd | 4.78 ± 0.15bc |

| Extrusion-YF | 9.06 ± 0.35e | 30.49 ± 0.63a | 6.84 ± 1.33c | 4.03 ± 0.87c |

| Control-SF | 10.23 ± 0.06c | 28.62 ± 0.23b | 5.09 ± 0.19cd | 6.37 ± 0.28a |

| Steaming-SF | 10.35 ± 0.09b | 28.73 ± 0.74b | 3.54 ± 0.24d | 6.16 ± 0.95ab |

| HTHP-SF | 10.80 ± 0.27a | 28.65 ± 0.11b | 4.73 ± 0.80d | 6.64 ± 0.94a |

| Extrusion-SF | 10.58 ± 0.37ab | 27.92 ± 1.51b | 11.21 ± 2.18a | 4.87 ± 0.70bc |

After heat treatment by control (unprocessed), steaming, HTHP, and extrusion, the corn-wheat composite steamed bread fermented by yeast and sourdough were expressed as Control-YF, Steaming-YF, HTHP-YF, Extrusion-YF, Control-SF, Steaming-SF, HTHP-SF, and Extrusion-SF, respectively; RDS, rapidly digestible starch; SDS, slowly digestible starch; RS, resistant starch.

Results were presented as mean ± standard deviation. Different letters in the same column in the table show significant differences (P < 0.05, n = 3).

Heat treatment and YF increased the RDS content. However, there was no significant difference (P < 0.05) in RDS with different modification methods of SF. SDS and RS refer to starch that is digested slowly or cannot be hydrolysed by amylase in the small intestine and can effectively suppress the increase in postprandial blood glucose levels (Jiang et al., 2020). In most cases, compared with the control, the SDS content of CWCSB with different modified corn flour was decreased, while the SDS content of steamed bread with Extrusion-SF increased from 5.09% to 11.21%. And the RS content of the steaming-YF and HTHP-SF samples increased by 21.0% and 4.2%, respectively. This is related to the denser structure observed by SEM (Fig. 2). In addition, extrusion is considered a type of heat-moisture treatment. After heat-moisture treatment, interactions occur between starch and proteins, lipids, and fibres, hindering the accessibility of digestive enzymes and increasing RS and SDS (Kong et al., 2018). Although the extrusion treatment increased the SDS content of steamed bread in different degrees, the RS content decreased by 18.8% (yeast) and 23.5% (sourdough), respectively, indicating that the inhibition effect of extrusion on digestive enzymes was limited and that more RDS changed into SDS, while less RS was formed. This is different from some current results (Zhang et al., 2016; Zou et al., 2023). These studies showed that more RS was produced after extrusion treatment. The reason for inconsistent results might be the degradation of starch granules by fermentation and the increase in enzyme accessibility.

Conclusions

This study investigated the suitability of corn flour in corn-wheat composite dough and CWCSB. The morphological, rheological, and nutritional properties of CWCSB were preliminarily discussed. SF achieved better nutritional characteristics, manifested by higher AAS, protein digestibility, and RS content. The suitability of different heat-treated corn flours for CWCSB matrices was different. When CWCSB was fermented by SF, the steaming method reduced the hardness, viscosity and chewability of the steamed bread by 17.5%, 20.4%, and 22.2%, respectively. All modified treatments enhanced the elastic behaviour of the composite dough. HTHP can improve Met + Cys scores from 43.5 to 64.8. Moreover, extrusion treatment increased the SDS content from 5.09% to 11.21% in CWCSB, which may provide valuable information for the development of composite steamed bread with a lower glycaemic index. The results showed that extrusion combined with SF could be a potential and effective approach to improving the adaptability of corn flour in CWCSB.

Acknowledgments

This work was supported by the fund of the Key Laboratory of Henan Province, Henan University of Technology (NO. GO202215), the Natural Science Foundation of Henan Province (NO. 232300421264), the Fundamental Research Funds for the Key Science and Technology Project of Henan Province (222102110298), and the Special Fund of the National Wheat Industry Technology System of China (No. CARS-03).

Author contributions

Peixia Chen: Formal analysis (equal); investigation (equal); writing – original draft (equal). Jing Hong: Conceptualization (equal); methodology (equal); writing – review and editing (equal). Chong Liu: Supervision (equal). Xueling Zheng: Supervision (equal). Xiaohui Tian: Formal analysis (equal). Jiaying Shang: Visualization (equal). Saeed Hamid Saeed Omer: Visualization (equal).

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

Ethics approval was not required for this research.

Data availability statement

Research data are not shared.

References

Annotated references

Gao, Q., Liu, C., Zheng, X. (2018). Effect of heat treatment of rye flour on rye-wheat steamed bread quality. International Journal of Food Science & Technology, 53, 1109–1119.

Reason of citation: The article described the method of determining the height-diameter ratio and specific volume of dough and steamed bread clearly, and it is helpful to evaluate the quality properties of CWCSB.

Tang, M., Wang, L., Cheng, X., Wu, Y., Ouyang, J. (2019). Non-starch constituents influence the in vitro digestibility of naked oat (Avena nuda L.) starch. Food Chemistry, 297, 124953.

Yang, Y., Jiao, A., Zhao, S., Liu, Q., Fu, X., Jin, Z. (2021). Effect of removal of endogenous non-starch components on the structural, physicochemical properties, and in vitro digestibility of highland barley starch. Food Hydrocolloids, 117, 106698.

Reason of citation: Both above articles elucidated the influence of non-starch components on starch gelatinisation properties, which was consistent with the results of our article and provided effective support for the argument.

Zou, X., Wang, X., Zhang, M., Peng, P., Ma, Q., Hu, X. (2023). Pre-baking-steaming of oat induces stronger macromolecular interactions and more resistant starch in oat-buckwheat noodle. Food Chemistry, 400, 134045.

Reason of citation: The article was helpful to explain the reason for the increase of dough stability after adding heat-treated corn flour.