-

PDF

- Split View

-

Views

-

Cite

Cite

John Gwamba, Johanita Kruger, John R N Taylor, Influence of grain quality characteristics and basic processing technologies on the mineral and antinutrient contents of iron and zinc biofortified open-pollinated variety and hybrid-type pearl millet, International Journal of Food Science and Technology, Volume 55, Issue 4, April 2020, Pages 1547–1558, https://doi.org/10.1111/ijfs.14375

Close - Share Icon Share

Abstract

The present study aimed at determining whether mineral biofortified pearl millets will continue to maintain significantly higher iron and zinc contents after processing, and the effects of decortication, steeping/fermentation and parboiling on mineral, phytate and total phenolic contents in eight varieties of pearl millets (two biofortified hybrids, Dhanashakti and ICMH 1201, five improved varieties with high iron content and one traditional variety) were also investigated. The hybrids showed higher iron and zinc contents after processing compared to the improved varieties, for example, 17–51% and 10–26% higher iron and zinc contents, respectively, after steeping/fermentation followed by decortication compared to the best varieties. Phytate:mineral ratios also indicated that iron bioavailability was higher in the hybrids after processing, several times above the critical 1:1 ratio. Across all the types, iron content after processing was positively correlated (P ≤ 0.05) with high kernel weight, large kernels, and high fat content, and zinc content was positively correlated with high fat content. These kernel characteristics should aid in the selection of high iron and zinc pearl millet types.

Introduction

Iron and zinc are deficient in the diets of many people in developing countries, especially in Africa. Data from nine African countries indicate iron deficiencies of 15–51% among women of childbearing age and 11–64% among children under 5 years of age (Mwangi et al., 2017). Concerning zinc, based on the availability in national food supplies and the prevalence of stunting, it has been estimated that zinc intake of about 25% of the population in sub-Saharan Africa was inadequate during the period 2003–2007 (Wessells & Brown, 2012).

Pearl millet is a major cereal staple in Africa, notably in the more arid parts, where it is processed into a wide variety of products (Taylor, 2016). It accounts for one-third of the cereal crops in the Sahel region (Sahara Desert margin) (FAOSTAT, 2016). Overall, the nutrient content of pearl millet grain is appreciable, being a major source of starch, protein, lipids and B vitamins and a significant source of essential minerals like K, P, Mg, Ca, Fe and Zn in descending content (Taylor, 2016). However, like all cereals, pearl millet is high in phytate, approx. 700–1100 mg/100 g, and is also relatively high in polyphenols, approx. 500–800 mg ferulic acid equiv./100 g (Krishnan & Meera, 2017). Phytate binds to divalent mineral ions in general and polyphenols to iron in particular and inhibit their uptake and absorption by the body (Fairweather-Tait & Hurrell, 1996). In pearl millet, phytate and polyphenols have generally been found to be associated with reduced iron and zinc bioaccessibility (Krishnan & Meera, 2017).

As a consequence, processing methods such as decortication, soaking, lactic acid fermentation, sprouting and thermal treatment have been investigated with the aim of improving the mineral nutritive value of pearl millet (Lestienne et al., 2005; Hama et al., 2011, 2012; Jha et al., 2015). Additionally, there is intense ongoing research in several countries, which is coordinated by ICRISAT, the International Crops Research Institute for the Semi-Arid Tropics, to select and develop pearl millet types, including hybrids, with enhanced iron and zinc contents using conventional breeding-type biofortification (Rai et al., 2013; Kumar Are et al., 2019). However, in view of the presence of phytate and polyphenol-type antinutrients in the outer layers of the pearl millet grain and the fact that iron and zinc are also generally concentrated in the outer layers of the kernel (Minnis-Ndimba et al., 2015), a key question is whether these biofortified pearl millets will still deliver significantly enhanced levels of iron and zinc after being processed into foods. To date, this important aspect has received very limited attention. Hama et al. (2012) compared the effects of progressive decortication (so-called dehulling) of pearl millet grains on the estimated iron and zinc bioavailability of two biofortified varieties with a traditional variety. They concluded that after grain decortication, there was no improvement in iron bioavailability but a potential improvement in zinc bioavailability was observed.

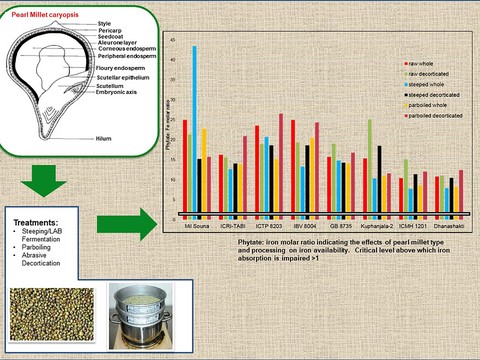

The objectives of this study were therefore twofold: (i) To determine and compare the effects of the several commonly used basic grain processing technologies—abrasive decortication, steeping/fermentation and parboiling—on the contents of essential minerals (focusing on iron and zinc), phytate, and phenolic antinutrient compounds of biofortified pearl millet varieties and hybrids, and (ii) to determine whether there were any associations between essential mineral content in processed pearl millet and particular grain quality characteristics.

Materials and methods

Pearl millet varieties

Eight different varieties of pearl millets were used in this study. These comprised six open-pollinated varieties: Mil Souna, a traditional variety from Senegal, and five improved varieties with enhanced agronomic characteristics and high content of iron, TP 8203, ICRI-TABI, GB 8735 and IBV 8004 (kindly provided by the Institute for Agricultural Research (ISRA) and the Food Technology Institute (ITA) in Senegal) and Kuphanjala-2 (also known as Okashana-2) (kindly provided by ICRISAT, Zimbabwe). The study also included two mineral biofortified hybrids that have been specifically bred for high iron and zinc contents (Govindaraj et al., 2015), ICMH 1201 and Dhanashakti (kindly provided by ICRISAT, India).

Grain processing

The grains were cleaned by aspiration using compressed air. Visible foreign material was removed by hand. The cleaned whole grain was processed using three different procedures:

Abrasive decortication was performed for 5 minutes using a tangential abrasive dehulling device (TADD) (Venables Machine Works, Saskatoon, Canada), according to the method described by Gomez et al. (1997). The specific decortication time was selected by experimentation as it abraded off up to 22% of the kernel weight, which corresponds to most of the outside layers. Medium-sized pearl millet kernels comprise an average of 24.9% by weight of germ and bran (Abdelrahman et al., 1984).

Steeping was followed by abrasive decortication. Whole grain (50 g) was steeped for 8 h at 30 °C with a particulate matter-free supernatant (25 mL) obtained from a successful static mixed culture lactic acid bacteria fermentation of sorghum flour (ratio of flour to water 1:1.25 (w/w)), of pH 3.7. During steeping, the grain absorbed the entire liquid. After steeping, the grain was dried at 35 °C for 24 h in a forced draught oven.

Parboiling was followed by abrasive decortication. Whole grain (50 g) was spread on a 1400-μm mesh opening sieve and then stacked on another sieve on top of the open pan. The second sieve was included to help ensure that water did not splash on the grains. Parboiling was carried out for 20 min using rapidly generated steam. After parboiling, the grain was dried as described above.

Milling

The processed grain was milled into flour using an IKA MF 10 air-cooled, laboratory mill (Staufen, Germany) fitted with a 500 μm diam. screen opening and stored at 10 °C for up to one month prior to chemical analyses.

Analyses

Thousand kernel weight

Thousand kernel weight (TKW) was determined by counting and weighing 1000 sound kernels of a representative sample in triplicate (Chiremba et al., 2011).

Kernel size

This was determined by sieving sound grains through screen opening sizes of 2.36 and 1.70 mm, according to Gomez et al. (1997), using a vibratory sieve shaker. The test was performed in duplicate. The fractions were divided into three groups: large, >2.36 mm; intermediate, 1.70–2.36 mm; and small, <1.70 mm.

Grain hardness estimated by % dehulling loss

This was determined on sound raw grain using the TADD as described above. The percentage of kernel removed after 5 min of decortication was calculated as dehulling loss:

Proximate analyses

Moisture by air-oven method, crude fat by Soxhlet extraction and crude protein (N × 6.25) by Dumas combustion were determined by using AACC standard methods 44–15A, 30–25 and 46–30, respectively (AACC, 2000). Crude fibre was determined by a filter bag technique using an Ankom 2000 automated fibre analyser (Macedon, NY, USA).

Mineral contents

Individual minerals were quantified using approved methods of the AOAC International (2002). Acid digestion was carried out in a heating block according to the method 935.13. Accurately weighed samples (0.5 g) were digested using a 5:2 (v/v) ratio of 65% nitric acid and 70% perchloric acid at 240 °C. Iron, zinc and magnesium were analysed by atomic absorption spectrophotometry using method 999.10. Calcium was determined using method 935.13 by titration with KMnO4. For phosphorus, a colorimetric method involving reaction with molydovanadate reagent was used, according to method 965.17.

Phytate

Phytate content was determined using the extraction and assay procedure of Frühbeck et al. (1995). Dowex1-anion-exchange resin-AG 1 × 4 (4% cross-linkage, chloride form, 100–200 mesh) (74–149 μm) (Sigma-Aldrich, Johannesburg, South Africa) in glass barrel Econo-columns, 7 × 5 mm, was used for purification of the extracts. The standard sodium phytate (P-8810, Sigma-Aldrich) and purified extracts were reacted with Wade reagent (ferric chloride and sulphosalicylic acid), and then absorbance was measured at 500 nm. The phytate contents were used to calculate the phytate to iron molar ratios (Hurrell, 2004) and phytate to zinc molar ratios (Ma et al., 2007).

Total phenolics

Total phenolic compounds were determined using a Folin-Ciocalteu assay, as described by Waterman & Mole (1994), using 0.103 mol L−1 HCl in methanol as the extractant at a volume to flour weight ratio of 40:1 (Price et al., 1978). Catechin (C-1788, Sigma-Aldrich) was used as a standard, and the total phenolic content was expressed as mg catechin equiv./100 g.

Statistical analyses

All experiments were performed at least twice. Data were analysed using one-way and multifactorial analysis of variance (ANOVA) using Statistica v10 (Tulsa, USA) software. Pearson correlations were performed using Microsoft Excel XLSTAT software (Addinsoft, New York, USA).

Results and discussion

Grain physical characteristics and chemical composition

The two biofortified pearl millet hybrids differed in grain physical characteristics from the traditional and the improved high-iron pearl millet varieties. Their kernels were heavier (TKW > 13 g), generally of larger size (>50% larger than 2.36 mm) and generally harder (<12% dehulling loss; Table 1). In contrast, Mil Souna, the traditional Senegalese pearl millet variety, had the lowest TKW, smallest kernel size (<2% larger than 2.36 mm) and was the softest (22% dehulling loss). These data indicate that the biofortified hybrids would be better suited to mechanical decortication than the traditional varieties on account of their high kernel weight and low dehulling loss (Chiremba et al., 2011).

Physical characteristics and general chemical composition of the pearl millet types

| Type . | Thousand kernel weight (g) . | Grain size (% >2.36 mm) . | Grain hardness (estimated by % dehulling loss by weight after 5 min of decortication) . | Protein (g/100 g db) . | Fat (g/100 g db) . | Crude fibre (g/100 g db) . |

|---|---|---|---|---|---|---|

| Traditional variety | ||||||

| Mil Souna | 6.9a ± 0.2 | 1.2a ± 0.0 | 22.0d ± 0.5 | 11.6 cd ± 0.1 | 4.52b ± 0.03 | 1.48b ± 0.02 |

| Improved varieties | ||||||

| ICRI-TABI | 8.1b ± 0.1 | 2.5a ± 0.1 | 16.7b ± 0.1 | 10.2a ± 0.2 | 5.00c ± 0.00 | 2.24c ± 0.07 |

| ICTP 8203 | 9.5c ± 0.3 | 12.0b ± 0.6 | 15.8b ± 0.3 | 11.3c ± 0.2 | 4.48b ± 0.18 | 1.54b ± 0.07 |

| IBV 8004 | 9.5c ± 0.2 | 10.4b ± 0.2 | 11.8a ± 0.0 | 13.5f ± 0.1 | 5.40e ± 0.07 | 1.48b ± 0.02 |

| GB 8735 | 11.5d ± 0.2 | 35.6c ± 0.3 | 20.6c ± 0.3 | 10.6ab ± 0.1 | 4.17a ± 0.11 | 2.94d ± 0.07 |

| Kuphanjala-2 | 12.9e ± 0.1 | 58.1e ± 0.3 | 11.5a ± 0.0 | 12.4e ± 0.0 | 5.29d ± 0.07 | 2.24c ± 0.07 |

| Hybrids | ||||||

| ICMH 1201 | 13.6f ± 0.1 | 51.8d ± 1.0 | 11.9a ± 0.2 | 12.3e ± 0.1 | 5.50e ± 0.14 | 1.23a ± 0.05 |

| Dhanashakti | 14.7g ± 0.2 | 78.8f ± 0.6 | 11.2a ± 0.1 | 13.4f ± 0.1 | 6.50e ± 0.28 | 1.49b ± 0.03 |

| Type . | Thousand kernel weight (g) . | Grain size (% >2.36 mm) . | Grain hardness (estimated by % dehulling loss by weight after 5 min of decortication) . | Protein (g/100 g db) . | Fat (g/100 g db) . | Crude fibre (g/100 g db) . |

|---|---|---|---|---|---|---|

| Traditional variety | ||||||

| Mil Souna | 6.9a ± 0.2 | 1.2a ± 0.0 | 22.0d ± 0.5 | 11.6 cd ± 0.1 | 4.52b ± 0.03 | 1.48b ± 0.02 |

| Improved varieties | ||||||

| ICRI-TABI | 8.1b ± 0.1 | 2.5a ± 0.1 | 16.7b ± 0.1 | 10.2a ± 0.2 | 5.00c ± 0.00 | 2.24c ± 0.07 |

| ICTP 8203 | 9.5c ± 0.3 | 12.0b ± 0.6 | 15.8b ± 0.3 | 11.3c ± 0.2 | 4.48b ± 0.18 | 1.54b ± 0.07 |

| IBV 8004 | 9.5c ± 0.2 | 10.4b ± 0.2 | 11.8a ± 0.0 | 13.5f ± 0.1 | 5.40e ± 0.07 | 1.48b ± 0.02 |

| GB 8735 | 11.5d ± 0.2 | 35.6c ± 0.3 | 20.6c ± 0.3 | 10.6ab ± 0.1 | 4.17a ± 0.11 | 2.94d ± 0.07 |

| Kuphanjala-2 | 12.9e ± 0.1 | 58.1e ± 0.3 | 11.5a ± 0.0 | 12.4e ± 0.0 | 5.29d ± 0.07 | 2.24c ± 0.07 |

| Hybrids | ||||||

| ICMH 1201 | 13.6f ± 0.1 | 51.8d ± 1.0 | 11.9a ± 0.2 | 12.3e ± 0.1 | 5.50e ± 0.14 | 1.23a ± 0.05 |

| Dhanashakti | 14.7g ± 0.2 | 78.8f ± 0.6 | 11.2a ± 0.1 | 13.4f ± 0.1 | 6.50e ± 0.28 | 1.49b ± 0.03 |

Values expressed as means of two independent samples analysed in duplicate (n = 2) ± 1 SD.

Values with different superscripts differ significantly (P ≤ 0.001).

Physical characteristics and general chemical composition of the pearl millet types

| Type . | Thousand kernel weight (g) . | Grain size (% >2.36 mm) . | Grain hardness (estimated by % dehulling loss by weight after 5 min of decortication) . | Protein (g/100 g db) . | Fat (g/100 g db) . | Crude fibre (g/100 g db) . |

|---|---|---|---|---|---|---|

| Traditional variety | ||||||

| Mil Souna | 6.9a ± 0.2 | 1.2a ± 0.0 | 22.0d ± 0.5 | 11.6 cd ± 0.1 | 4.52b ± 0.03 | 1.48b ± 0.02 |

| Improved varieties | ||||||

| ICRI-TABI | 8.1b ± 0.1 | 2.5a ± 0.1 | 16.7b ± 0.1 | 10.2a ± 0.2 | 5.00c ± 0.00 | 2.24c ± 0.07 |

| ICTP 8203 | 9.5c ± 0.3 | 12.0b ± 0.6 | 15.8b ± 0.3 | 11.3c ± 0.2 | 4.48b ± 0.18 | 1.54b ± 0.07 |

| IBV 8004 | 9.5c ± 0.2 | 10.4b ± 0.2 | 11.8a ± 0.0 | 13.5f ± 0.1 | 5.40e ± 0.07 | 1.48b ± 0.02 |

| GB 8735 | 11.5d ± 0.2 | 35.6c ± 0.3 | 20.6c ± 0.3 | 10.6ab ± 0.1 | 4.17a ± 0.11 | 2.94d ± 0.07 |

| Kuphanjala-2 | 12.9e ± 0.1 | 58.1e ± 0.3 | 11.5a ± 0.0 | 12.4e ± 0.0 | 5.29d ± 0.07 | 2.24c ± 0.07 |

| Hybrids | ||||||

| ICMH 1201 | 13.6f ± 0.1 | 51.8d ± 1.0 | 11.9a ± 0.2 | 12.3e ± 0.1 | 5.50e ± 0.14 | 1.23a ± 0.05 |

| Dhanashakti | 14.7g ± 0.2 | 78.8f ± 0.6 | 11.2a ± 0.1 | 13.4f ± 0.1 | 6.50e ± 0.28 | 1.49b ± 0.03 |

| Type . | Thousand kernel weight (g) . | Grain size (% >2.36 mm) . | Grain hardness (estimated by % dehulling loss by weight after 5 min of decortication) . | Protein (g/100 g db) . | Fat (g/100 g db) . | Crude fibre (g/100 g db) . |

|---|---|---|---|---|---|---|

| Traditional variety | ||||||

| Mil Souna | 6.9a ± 0.2 | 1.2a ± 0.0 | 22.0d ± 0.5 | 11.6 cd ± 0.1 | 4.52b ± 0.03 | 1.48b ± 0.02 |

| Improved varieties | ||||||

| ICRI-TABI | 8.1b ± 0.1 | 2.5a ± 0.1 | 16.7b ± 0.1 | 10.2a ± 0.2 | 5.00c ± 0.00 | 2.24c ± 0.07 |

| ICTP 8203 | 9.5c ± 0.3 | 12.0b ± 0.6 | 15.8b ± 0.3 | 11.3c ± 0.2 | 4.48b ± 0.18 | 1.54b ± 0.07 |

| IBV 8004 | 9.5c ± 0.2 | 10.4b ± 0.2 | 11.8a ± 0.0 | 13.5f ± 0.1 | 5.40e ± 0.07 | 1.48b ± 0.02 |

| GB 8735 | 11.5d ± 0.2 | 35.6c ± 0.3 | 20.6c ± 0.3 | 10.6ab ± 0.1 | 4.17a ± 0.11 | 2.94d ± 0.07 |

| Kuphanjala-2 | 12.9e ± 0.1 | 58.1e ± 0.3 | 11.5a ± 0.0 | 12.4e ± 0.0 | 5.29d ± 0.07 | 2.24c ± 0.07 |

| Hybrids | ||||||

| ICMH 1201 | 13.6f ± 0.1 | 51.8d ± 1.0 | 11.9a ± 0.2 | 12.3e ± 0.1 | 5.50e ± 0.14 | 1.23a ± 0.05 |

| Dhanashakti | 14.7g ± 0.2 | 78.8f ± 0.6 | 11.2a ± 0.1 | 13.4f ± 0.1 | 6.50e ± 0.28 | 1.49b ± 0.03 |

Values expressed as means of two independent samples analysed in duplicate (n = 2) ± 1 SD.

Values with different superscripts differ significantly (P ≤ 0.001).

The biofortified hybrids also differed somewhat in chemical composition from the open-pollinated varieties, as they were generally higher in protein (>12%) and fat (≥5.5%) contents. In contrast, they had generally lower crude fibre (branny-type cellulose, pentosan and lignin components) contents (<1.5%). However, the overall protein and fat contents of all the pearl millet types were within the ranges reported in other studies (Lestienne et al., 2007; Hama et al., 2011).

Concerning mineral composition, the two biofortified hybrids had the highest iron contents, approximately three times higher than the traditional variety, which had the lowest iron content (2). The improved varieties showed intermediate content of this mineral. The iron contents of improved varieties ICRI-TABI and GB 8735 were, however, much lower than those reported by Hama et al. (2012) for these two varieties, 4.31 and 5.63 mg/100 g vs. 7.29 and 6.73, respectively. The value for ICRI-TABI was similar to that reported by Bashir et al. (2014) (3.92 mg/100 g), which was the mean value across four cultivation environments in the same season. These differences can be accounted for by the fact that cultivation environment as well as genotype was found to significantly affect (P < 0.01) the mineral content of pearl millet varieties (Bashir et al., 2014).

Effects of pearl millet type, abrasive decortication, steeping/fermentation in back-slopped liquor and parboiling on iron, zinc, calcium, phosphorus and magnesium contents (mg/100 g db)

| Type . | Raw grain . | Steeped/fermented grain . | Parboiled grain . | Means and effect of type (T) . | |||

|---|---|---|---|---|---|---|---|

| Whole . | Decorticated . | Whole . | Decorticated . | Whole . | Decorticated . | ||

| Iron | |||||||

| Traditional variety | |||||||

| Mil Souna | 3.04bcde ± 0.15 | 3.23defgh ± 0.08 | 1.33a ± 0.04(−56) | 3.48fgh ± 0.08(+14)[+161] | 2.84bcd ± 0.11 | 3.59gh ± 0.07(+18)[+26] | 2.92A ± 0.79 |

| Improved varieties | |||||||

| ICRI-TABI | 4.31ij ± 0.08 | 3.09bcdef ± 0.08(−28) | 5.10mn ± 0.24(+18) | 2.74bc ± 0.08(−36)[ −46] | 4.96lmn ± 0.07(+15) | 2.73b ± 0.08(−37)[ −45] | 3.82B ± 1.05 |

| ICTP 8203 | 4.50ijk ± 0.15 | 3.33efgh ± 0.08(−26) | 5.01mn ± 0.01(+11) | 3.30efgh ± 0.07(−27)[ −34] | 5.06mn ± 0.22(+12) | 2.70b ± 0.15(−40)[ −47] | 3.98B ± 0.96 |

| IBV 8004 | 4.72jklm ± 0.08 | 3.64h ± 0.08(−23) | 5.22no ± 0.00(+11) | 3.66h ± 0.14(−22)[ −30] | 4.92klmn ± 0.02 | 3.18cdefg ± 0.07(−33)[ −35] | 4.22C ± 0.80 |

| GB 8735 | 5.63opq ± 0.07 | 3.37efgh ± 0.15(−40) | 5.77pq ± 0.07 | 4.44ij ± 0.14(−21)[ −23] | 5.83q ± 0.08 | 3.65 h ± 0.15(−35)[ −37] | 4.78D ± 1.06 |

| Kuphanjala-2 | 7.51s ± 0.07 | 4.22i ± 0.07(−44) | 8.21t ± 0.07(+9) | 4.28ij ± 0.15(−43)[ −48] | 9.59vw ± 0.07(+28) | 4.53ijkl ± 0.00(−40)[ −53] | 6.39E ± 2.23 |

| Hybrids | |||||||

| ICMH 1201 | 8.84u ± 0.30 | 5.26no ± 0.08(−40) | 8.28t ± 0.35(−6) | 5.18n ± 0.01(−41)[ −37] | 8.15t ± 0.09(−9) | 5.34nop ± 0.30(−40)[ −35] | 6.84F ± 1.68 |

| Dhanashakti | 9.55vw ± 0.01 | 7.18s ± 0.08(−25) | 9.25uv ± 0.08 | 6.70r ± 0.08(−30)[ −28] | 9.80w ± 0.03 | 6.31r ± 0.00(−34)[ −36] | 8.13G ± 1.50 |

| Means and effect of processing (P) | 6.01C ± 2.27 | 4.17B ± 1.36 (−31) | 6.02C ± 2.45 | 4.22B ± 1.21(−30)[ −30] | 6.39D ± 2.42(+6) | 4.00A ± 1.25(−33)[ −37] | PxT P ≤ 0.001 |

| Zinc | |||||||

| Traditional variety | |||||||

| Mil Souna | 3.37ijklmn ± 0.08 | 3.40jklmn ± 0.00 | 3.76opqr ± 0.08(+12) | 2.73abc ± 0.08(−18)[ −27] | 3.66nopq ± 0.07 | 4.18tu ± 0.00(+24)[+14] | 3.52B ± 0.46 |

| Improved varieties | |||||||

| ICRI-TABI | 3.17fghijk ± 0.00 | 2.66ab ± 0.08(−16) | 3.38jklmn ± 0.08 | 3.71opq ± 0.07(+17)[+10] | 3.25ghijkl ± 0.07 | 2.79bcd ± 0.00(−12)[ −14] | 3.16A ± 0.37 |

| ICTP 8203 | 3.18fghijk ± 0.00 | 3.06defghi ± 0.00 | 3.47klmno ± 0.07 | 2.76abcd ± 0.07(−13)[ −20] | 3.30hijklm ± 0.15 | 2.80bcde ± 0.15(−11)[ −15] | 3.09A ± 0.28 |

| IBV 8004 | 4.12stu ± 0.00 | 3.75opqr ± 0.08(−9) | 4.26u ± 0.15 | 3.88qrst ± 0.01[−9] | 3.85pqrs ± 0.01 | 3.66nopq ± 0.00(−11) | 3.92C ± 0.22 |

| GB 8735 | 3.61mnopq ± 0.00 | 2.88bcdef ± 0.08(−20) | 3.72opq ± 0.07 | 3.52lmno ± 0.08 | 3.64nopq ± 0.00 | 3.54lmnop ± 0.00 | 3.48B ± 0.29 |

| Kuphanjala−2 | 2.95bcdefg ± 0.08 | 2.47a ± 0.08(−16) | 3.11efghij ± 0.00 | 2.94bcdefg ± 0.08[−5] | 3.00cdefgh ± 0.00 | 3.72l ± 0.38(+26)[+24] | 3.03A ± 0.40 |

| Hybrids | |||||||

| ICMH 1201 | 4.36u ± 0.00 | 4.12stu ± 0.00 | 4.22u ± 0.09 | 4.26u ± 0.22 | 4.21u ± 0.07 | 4.06rstu ± 0.00 | 4.21D ± 0.13 |

| Dhanashakti | 4.83v ± 0.07 | 4.97v ± 0.00 | 4.81v ± 0.00 | 4.88v ± 0.08 | 5.06v ± 0.06 | 4.76v ± 0.08 | 4.88E ± 0.12 |

| Means and effect of processing (P) | 3.70C ± 0.65 | 3.41A ± 0.81(−8) | 3.84D ± 0.54(+4) | 3.59B ± 0.74(−3)[ −7] | 3.75CD ± 0.63 | 3.69BC ± 0.66 | PxT P ≤ 0.001 |

| Calcium | |||||||

| Traditional variety | |||||||

| Mil Souna | 8.12m ± 0.23 | 1.81bcde ± 0.23(−78) | 19.37s ± 0.43(+139) | 0.64abc ± 0.00(−92)[ −97] | 19.90st ± 0.66(+145) | 4.99hij ± 0.23(−39)[ −75] | 9.14C ± 8.15 |

| Improved varieties | |||||||

| ICRI-TABI | 4.75hij ± 0.23 | 7.49lm ± 0.46(+58) | 12.89no ± 0.02(+171) | 1.18abcd ± 0.30(−75)[ −91] | 14.56p ± 0.22(+207) | 0.00a(−100)[ −100] | 6.81B ± 5.72 |

| ICTP 8203 | 3.95ghi ± 0.47 | 0.00a(−100) | 15.04pq ± 0.03(+281) | 0.00a(−100)[ −100] | 16.46qr ± 0.24(+317) | 0.00a(−100)[−100] | 5.91A ± 7.43 |

| IBV 8004 | 13.72op ± 0.54 | 6.03jkl ± 0.24(−56) | 23.80u ± 0.21(+76) | 3.72fgh ± 0.24(−73)[ −84] | 21.48t ± 0.84(+57) | 2.58defg ± 0.00(−81)[ −88] | 11.89D ± 8.80 |

| GB 8735 | 5.58ijk ± 0.46 | 0.00a [−100] | 16.35qr ± 0.24(+193) | 0.00a(−100)[−100] | 17.17m ± 0.69(+208) | 0.00a(−100)[−100] | 6.52AB ± 7.85 |

| Kuphanjala-2 | 7.51lm ± 0.71 | 1.48abcde ± 0.23(−80) | 20.61st ± 0.48(+174) | 3.53fgh ± 0.45(−53)[ −83] | 15.11pq ± 0.45(+101) | 6.80klm ± 0.46(−9)[ −55] | 9.17C ± 6.96 |

| Hybrids | |||||||

| ICMH 1201 | 11.79n ± 0.01 | 3.09efg ± 0.23(−74) | 28.74w ± 1.56(+144) | 0.65abc ± 0.00(−94)[ −98] | 25.99v ± 1.56(+120) | 1.60abcde ± 0.00(−86)[ −94] | 11.98D ± 12.02 |

| Dhanashakti | 8.30m ± 0.22 | 2.27cdef ± 0.00(−73) | 19.42s ± 0.22(+134) | 0.32ab ± 0.00(−96)[ −98] | 23.33u ± 0.97(+181) | 1.44abcde ± 0.23(−83)[ −94] | 9.18C ± 9.46 |

| Means and effect of processing (P) | 7.96D ± 3.28 | 2.77C ± 2.62(−65) | 19.52E ± 4.90(+145) | 1.25A ± 1.47(−84)[ −94] | 19.25E ± 4.02(+142) | 2.18B ± 2.44(−73)[ −89] | PxT P ≤ 0.001 |

| Phosphorus | |||||||

| Traditional variety | |||||||

| Mil Souna | 296ghijklm ± 4 | 238abcdef ± 17(−20) | 288fghijkl ± 3 | 225abcd ± 7(−24)[ −22] | 268cdefghij ± 0 | 253cdefg ± 16 | 261B ± 28 |

| Improved varieties | |||||||

| ICRI-TABI | 287fghijkl ± 1 | 216abc ± 2(−25) | 263cdefghi ± 1 | 194ab ± 0(−32)[ −26] | 251cdefg ± 0 | 186a ± 8(−35)[−26] | 233A ± 39 |

| ICTP 8203 | 343mnopq ± 1 | 293ghijklm ± 2 | 323klmnop ± 0 | 238abcdef ± 7(−31)[ −26] | 281efghijkl ± 1(−18) | 195ab ± 26(−43)[ −48] | 279B ± 53 |

| IBV 8004 | 404rs ± 9 | 229abcde ± 167(−43) | 363opqr ± 1 | 316jklmno ± 3(−22)[ −13] | 311ijklmno ± 2(−23) | 262cdefghi ± 10(−35) | 314C ± 79 |

| GB 8735 | 355nopqr ± 1 | 196ab ± 4(−45) | 292ghijklm ± 1(−18) | 265cdefghij ± 3(−25) | 288fghijkl ± 0(−19) | 221abc ± 18(−38)[ −23] | 269B ± 54 |

| Kuphanjala-2 | 416s ± 10 | 281efghijkl ± 29(−32) | 389qrs ± 2 | 327klmnop ± 2(−21) | 374pqrs ± 2 | 307hijklmn ± 1(−26)[ −18] | 349D ± 51 |

| Hybrids | |||||||

| ICMH 1201 | 358nopqr ± 4 | 282fghijkl ± 3(−21) | 276defghijk ± 5(−23) | 246bcdefg ± 5(−31) | 255cdefgh ± 0(−29) | 260cdefghi ± 8(−27) | 279B ± 39 |

| Dhanashakti | 370pqrs ± 7 | 333lmnop ± 3 | 308ijklmn ± 2(−17) | 282fghijkl ± 1(−24) | 323klmnop ± 4 | 230abcde ± 39(−38)[ −29] | 308C ± 47 |

| Means and effect of processing (P) | 354E ± 44 | 258B ± 63(−27) | 313D ± 42(−12) | 262B ± 44(−26)[ −16] | 294C ± 40(−17) | 239A ± 41(−32)[ −19] | PxT P ≤ 0.05 |

| Magnesium | |||||||

| Traditional variety | |||||||

| Mil Souna | 113lm ± 4 | 93hi ± 1(−18) | 140tuvw ± 0(+24) | 81def ± 2(−28)[ −42] | 131qrs ± 8(+16) | 107kl ± 2(−5)[ −18] | 111D ± 21 |

| Improved varieties | |||||||

| ICRI−TABI | 103jk ± 0 | 74cd ± 1(−28) | 127pqr ± 1(+23) | 67bc ± 1(−35)[ −47] | 114lmn ± 0(+11) | 61ab ± 1(−41)[ −46] | 91A ± 26 |

| ICTP 8203 | 114lm ± 4 | 95hij ± 0(−17) | 142uvw ± 1(+25) | 79de ± 2(−31)[ −44] | 120mnop ± 1 | 66bc ± 2(−42)[ −45] | 103C ± 27 |

| IBV 8004 | 146w ± 3 | 123opq ± 1(−16) | 169x ± 1(+16) | 113lm ± 3(−23)[ −33] | 138stuv ± 2 | 89fgh ± 2(−39)[ −36] | 130G ± 27 |

| GB 8735 | 118mno ± 2 | 55a ± 0(−53) | 127pqr ± 2(+8) | 91ghi ± 3(−23)[−28] | 122nop ± 1 | 77de ± 2(−35)[−37] | 98B ± 27 |

| Kuphanjala-2 | 139stuvw ± 2 | 89fgh ± 3(−36) | 165x ± 4(+19) | 102jk ± 3(−27)[−38] | 143vw ± 1 | 106kl ± 2(−24)[−26] | 124F ± 28 |

| Hybrids | |||||||

| ICMH 1201 | 134rstu ± 2 | 101jk ± 0(−25) | 138stuv ± 0 | 96hij ± 1(−28)[ −30] | 122nop ± 1(−9) | 96hij ± 1(−38)[−21] | 114E ± 19 |

| Dhanashakti | 132rst ± 4 | 116mno ± 3(−12) | 141uvw ± 2(+7) | 99ijk ± 2(−25)[ −30] | 139tuvw ± 0 | 84efg ± 1(−36)[ −40] | 118E ± 22 |

| Means and effect of processing (P) | 125C ± 15 | 93B ± 21(−26) | 144E ± 15(+15) | 91B ± 14(−27)[−37] | 129D ± 10(+3) | 86A ± 17(−31)[−33] | PxT P ≤ 0.001 |

| Type . | Raw grain . | Steeped/fermented grain . | Parboiled grain . | Means and effect of type (T) . | |||

|---|---|---|---|---|---|---|---|

| Whole . | Decorticated . | Whole . | Decorticated . | Whole . | Decorticated . | ||

| Iron | |||||||

| Traditional variety | |||||||

| Mil Souna | 3.04bcde ± 0.15 | 3.23defgh ± 0.08 | 1.33a ± 0.04(−56) | 3.48fgh ± 0.08(+14)[+161] | 2.84bcd ± 0.11 | 3.59gh ± 0.07(+18)[+26] | 2.92A ± 0.79 |

| Improved varieties | |||||||

| ICRI-TABI | 4.31ij ± 0.08 | 3.09bcdef ± 0.08(−28) | 5.10mn ± 0.24(+18) | 2.74bc ± 0.08(−36)[ −46] | 4.96lmn ± 0.07(+15) | 2.73b ± 0.08(−37)[ −45] | 3.82B ± 1.05 |

| ICTP 8203 | 4.50ijk ± 0.15 | 3.33efgh ± 0.08(−26) | 5.01mn ± 0.01(+11) | 3.30efgh ± 0.07(−27)[ −34] | 5.06mn ± 0.22(+12) | 2.70b ± 0.15(−40)[ −47] | 3.98B ± 0.96 |

| IBV 8004 | 4.72jklm ± 0.08 | 3.64h ± 0.08(−23) | 5.22no ± 0.00(+11) | 3.66h ± 0.14(−22)[ −30] | 4.92klmn ± 0.02 | 3.18cdefg ± 0.07(−33)[ −35] | 4.22C ± 0.80 |

| GB 8735 | 5.63opq ± 0.07 | 3.37efgh ± 0.15(−40) | 5.77pq ± 0.07 | 4.44ij ± 0.14(−21)[ −23] | 5.83q ± 0.08 | 3.65 h ± 0.15(−35)[ −37] | 4.78D ± 1.06 |

| Kuphanjala-2 | 7.51s ± 0.07 | 4.22i ± 0.07(−44) | 8.21t ± 0.07(+9) | 4.28ij ± 0.15(−43)[ −48] | 9.59vw ± 0.07(+28) | 4.53ijkl ± 0.00(−40)[ −53] | 6.39E ± 2.23 |

| Hybrids | |||||||

| ICMH 1201 | 8.84u ± 0.30 | 5.26no ± 0.08(−40) | 8.28t ± 0.35(−6) | 5.18n ± 0.01(−41)[ −37] | 8.15t ± 0.09(−9) | 5.34nop ± 0.30(−40)[ −35] | 6.84F ± 1.68 |

| Dhanashakti | 9.55vw ± 0.01 | 7.18s ± 0.08(−25) | 9.25uv ± 0.08 | 6.70r ± 0.08(−30)[ −28] | 9.80w ± 0.03 | 6.31r ± 0.00(−34)[ −36] | 8.13G ± 1.50 |

| Means and effect of processing (P) | 6.01C ± 2.27 | 4.17B ± 1.36 (−31) | 6.02C ± 2.45 | 4.22B ± 1.21(−30)[ −30] | 6.39D ± 2.42(+6) | 4.00A ± 1.25(−33)[ −37] | PxT P ≤ 0.001 |

| Zinc | |||||||

| Traditional variety | |||||||

| Mil Souna | 3.37ijklmn ± 0.08 | 3.40jklmn ± 0.00 | 3.76opqr ± 0.08(+12) | 2.73abc ± 0.08(−18)[ −27] | 3.66nopq ± 0.07 | 4.18tu ± 0.00(+24)[+14] | 3.52B ± 0.46 |

| Improved varieties | |||||||

| ICRI-TABI | 3.17fghijk ± 0.00 | 2.66ab ± 0.08(−16) | 3.38jklmn ± 0.08 | 3.71opq ± 0.07(+17)[+10] | 3.25ghijkl ± 0.07 | 2.79bcd ± 0.00(−12)[ −14] | 3.16A ± 0.37 |

| ICTP 8203 | 3.18fghijk ± 0.00 | 3.06defghi ± 0.00 | 3.47klmno ± 0.07 | 2.76abcd ± 0.07(−13)[ −20] | 3.30hijklm ± 0.15 | 2.80bcde ± 0.15(−11)[ −15] | 3.09A ± 0.28 |

| IBV 8004 | 4.12stu ± 0.00 | 3.75opqr ± 0.08(−9) | 4.26u ± 0.15 | 3.88qrst ± 0.01[−9] | 3.85pqrs ± 0.01 | 3.66nopq ± 0.00(−11) | 3.92C ± 0.22 |

| GB 8735 | 3.61mnopq ± 0.00 | 2.88bcdef ± 0.08(−20) | 3.72opq ± 0.07 | 3.52lmno ± 0.08 | 3.64nopq ± 0.00 | 3.54lmnop ± 0.00 | 3.48B ± 0.29 |

| Kuphanjala−2 | 2.95bcdefg ± 0.08 | 2.47a ± 0.08(−16) | 3.11efghij ± 0.00 | 2.94bcdefg ± 0.08[−5] | 3.00cdefgh ± 0.00 | 3.72l ± 0.38(+26)[+24] | 3.03A ± 0.40 |

| Hybrids | |||||||

| ICMH 1201 | 4.36u ± 0.00 | 4.12stu ± 0.00 | 4.22u ± 0.09 | 4.26u ± 0.22 | 4.21u ± 0.07 | 4.06rstu ± 0.00 | 4.21D ± 0.13 |

| Dhanashakti | 4.83v ± 0.07 | 4.97v ± 0.00 | 4.81v ± 0.00 | 4.88v ± 0.08 | 5.06v ± 0.06 | 4.76v ± 0.08 | 4.88E ± 0.12 |

| Means and effect of processing (P) | 3.70C ± 0.65 | 3.41A ± 0.81(−8) | 3.84D ± 0.54(+4) | 3.59B ± 0.74(−3)[ −7] | 3.75CD ± 0.63 | 3.69BC ± 0.66 | PxT P ≤ 0.001 |

| Calcium | |||||||

| Traditional variety | |||||||

| Mil Souna | 8.12m ± 0.23 | 1.81bcde ± 0.23(−78) | 19.37s ± 0.43(+139) | 0.64abc ± 0.00(−92)[ −97] | 19.90st ± 0.66(+145) | 4.99hij ± 0.23(−39)[ −75] | 9.14C ± 8.15 |

| Improved varieties | |||||||

| ICRI-TABI | 4.75hij ± 0.23 | 7.49lm ± 0.46(+58) | 12.89no ± 0.02(+171) | 1.18abcd ± 0.30(−75)[ −91] | 14.56p ± 0.22(+207) | 0.00a(−100)[ −100] | 6.81B ± 5.72 |

| ICTP 8203 | 3.95ghi ± 0.47 | 0.00a(−100) | 15.04pq ± 0.03(+281) | 0.00a(−100)[ −100] | 16.46qr ± 0.24(+317) | 0.00a(−100)[−100] | 5.91A ± 7.43 |

| IBV 8004 | 13.72op ± 0.54 | 6.03jkl ± 0.24(−56) | 23.80u ± 0.21(+76) | 3.72fgh ± 0.24(−73)[ −84] | 21.48t ± 0.84(+57) | 2.58defg ± 0.00(−81)[ −88] | 11.89D ± 8.80 |

| GB 8735 | 5.58ijk ± 0.46 | 0.00a [−100] | 16.35qr ± 0.24(+193) | 0.00a(−100)[−100] | 17.17m ± 0.69(+208) | 0.00a(−100)[−100] | 6.52AB ± 7.85 |

| Kuphanjala-2 | 7.51lm ± 0.71 | 1.48abcde ± 0.23(−80) | 20.61st ± 0.48(+174) | 3.53fgh ± 0.45(−53)[ −83] | 15.11pq ± 0.45(+101) | 6.80klm ± 0.46(−9)[ −55] | 9.17C ± 6.96 |

| Hybrids | |||||||

| ICMH 1201 | 11.79n ± 0.01 | 3.09efg ± 0.23(−74) | 28.74w ± 1.56(+144) | 0.65abc ± 0.00(−94)[ −98] | 25.99v ± 1.56(+120) | 1.60abcde ± 0.00(−86)[ −94] | 11.98D ± 12.02 |

| Dhanashakti | 8.30m ± 0.22 | 2.27cdef ± 0.00(−73) | 19.42s ± 0.22(+134) | 0.32ab ± 0.00(−96)[ −98] | 23.33u ± 0.97(+181) | 1.44abcde ± 0.23(−83)[ −94] | 9.18C ± 9.46 |

| Means and effect of processing (P) | 7.96D ± 3.28 | 2.77C ± 2.62(−65) | 19.52E ± 4.90(+145) | 1.25A ± 1.47(−84)[ −94] | 19.25E ± 4.02(+142) | 2.18B ± 2.44(−73)[ −89] | PxT P ≤ 0.001 |

| Phosphorus | |||||||

| Traditional variety | |||||||

| Mil Souna | 296ghijklm ± 4 | 238abcdef ± 17(−20) | 288fghijkl ± 3 | 225abcd ± 7(−24)[ −22] | 268cdefghij ± 0 | 253cdefg ± 16 | 261B ± 28 |

| Improved varieties | |||||||

| ICRI-TABI | 287fghijkl ± 1 | 216abc ± 2(−25) | 263cdefghi ± 1 | 194ab ± 0(−32)[ −26] | 251cdefg ± 0 | 186a ± 8(−35)[−26] | 233A ± 39 |

| ICTP 8203 | 343mnopq ± 1 | 293ghijklm ± 2 | 323klmnop ± 0 | 238abcdef ± 7(−31)[ −26] | 281efghijkl ± 1(−18) | 195ab ± 26(−43)[ −48] | 279B ± 53 |

| IBV 8004 | 404rs ± 9 | 229abcde ± 167(−43) | 363opqr ± 1 | 316jklmno ± 3(−22)[ −13] | 311ijklmno ± 2(−23) | 262cdefghi ± 10(−35) | 314C ± 79 |

| GB 8735 | 355nopqr ± 1 | 196ab ± 4(−45) | 292ghijklm ± 1(−18) | 265cdefghij ± 3(−25) | 288fghijkl ± 0(−19) | 221abc ± 18(−38)[ −23] | 269B ± 54 |

| Kuphanjala-2 | 416s ± 10 | 281efghijkl ± 29(−32) | 389qrs ± 2 | 327klmnop ± 2(−21) | 374pqrs ± 2 | 307hijklmn ± 1(−26)[ −18] | 349D ± 51 |

| Hybrids | |||||||

| ICMH 1201 | 358nopqr ± 4 | 282fghijkl ± 3(−21) | 276defghijk ± 5(−23) | 246bcdefg ± 5(−31) | 255cdefgh ± 0(−29) | 260cdefghi ± 8(−27) | 279B ± 39 |

| Dhanashakti | 370pqrs ± 7 | 333lmnop ± 3 | 308ijklmn ± 2(−17) | 282fghijkl ± 1(−24) | 323klmnop ± 4 | 230abcde ± 39(−38)[ −29] | 308C ± 47 |

| Means and effect of processing (P) | 354E ± 44 | 258B ± 63(−27) | 313D ± 42(−12) | 262B ± 44(−26)[ −16] | 294C ± 40(−17) | 239A ± 41(−32)[ −19] | PxT P ≤ 0.05 |

| Magnesium | |||||||

| Traditional variety | |||||||

| Mil Souna | 113lm ± 4 | 93hi ± 1(−18) | 140tuvw ± 0(+24) | 81def ± 2(−28)[ −42] | 131qrs ± 8(+16) | 107kl ± 2(−5)[ −18] | 111D ± 21 |

| Improved varieties | |||||||

| ICRI−TABI | 103jk ± 0 | 74cd ± 1(−28) | 127pqr ± 1(+23) | 67bc ± 1(−35)[ −47] | 114lmn ± 0(+11) | 61ab ± 1(−41)[ −46] | 91A ± 26 |

| ICTP 8203 | 114lm ± 4 | 95hij ± 0(−17) | 142uvw ± 1(+25) | 79de ± 2(−31)[ −44] | 120mnop ± 1 | 66bc ± 2(−42)[ −45] | 103C ± 27 |

| IBV 8004 | 146w ± 3 | 123opq ± 1(−16) | 169x ± 1(+16) | 113lm ± 3(−23)[ −33] | 138stuv ± 2 | 89fgh ± 2(−39)[ −36] | 130G ± 27 |

| GB 8735 | 118mno ± 2 | 55a ± 0(−53) | 127pqr ± 2(+8) | 91ghi ± 3(−23)[−28] | 122nop ± 1 | 77de ± 2(−35)[−37] | 98B ± 27 |

| Kuphanjala-2 | 139stuvw ± 2 | 89fgh ± 3(−36) | 165x ± 4(+19) | 102jk ± 3(−27)[−38] | 143vw ± 1 | 106kl ± 2(−24)[−26] | 124F ± 28 |

| Hybrids | |||||||

| ICMH 1201 | 134rstu ± 2 | 101jk ± 0(−25) | 138stuv ± 0 | 96hij ± 1(−28)[ −30] | 122nop ± 1(−9) | 96hij ± 1(−38)[−21] | 114E ± 19 |

| Dhanashakti | 132rst ± 4 | 116mno ± 3(−12) | 141uvw ± 2(+7) | 99ijk ± 2(−25)[ −30] | 139tuvw ± 0 | 84efg ± 1(−36)[ −40] | 118E ± 22 |

| Means and effect of processing (P) | 125C ± 15 | 93B ± 21(−26) | 144E ± 15(+15) | 91B ± 14(−27)[−37] | 129D ± 10(+3) | 86A ± 17(−31)[−33] | PxT P ≤ 0.001 |

Means of analysis of two independent samples (n = 2) ± 1 SD.

abcValues with different superscripts differ significantly (P ≤ 0.001) for iron, zinc, calcium, magnesium and differ significantly (P ≤ 0.05) for phosphorus.

ABCLeast significant mean values from main effects factorial Anova with different superscripts in the same row/column, differ significantly (P ≤ 0.001) for iron, zinc, calcium, magnesium and differ significantly (P ≤ 0.05) for phosphorus.

() Values in brackets are the differences (% change where significant – P ≤ 0.001) in the mineral content of processed whole-grain (steeped or parboiled) and decorticated raw and processed grain (steeped or parboiled) compared to the raw whole-grain pearl millet.

[] Values in square brackets are the differences (% change where significant – P ≤ 0.001) in the mineral content of decorticated processed grain (steeped or parboiled) compared to whole-grain processed (steeped or parboiled) pearl millet.

Effects of pearl millet type, abrasive decortication, steeping/fermentation in back-slopped liquor and parboiling on iron, zinc, calcium, phosphorus and magnesium contents (mg/100 g db)

| Type . | Raw grain . | Steeped/fermented grain . | Parboiled grain . | Means and effect of type (T) . | |||

|---|---|---|---|---|---|---|---|

| Whole . | Decorticated . | Whole . | Decorticated . | Whole . | Decorticated . | ||

| Iron | |||||||

| Traditional variety | |||||||

| Mil Souna | 3.04bcde ± 0.15 | 3.23defgh ± 0.08 | 1.33a ± 0.04(−56) | 3.48fgh ± 0.08(+14)[+161] | 2.84bcd ± 0.11 | 3.59gh ± 0.07(+18)[+26] | 2.92A ± 0.79 |

| Improved varieties | |||||||

| ICRI-TABI | 4.31ij ± 0.08 | 3.09bcdef ± 0.08(−28) | 5.10mn ± 0.24(+18) | 2.74bc ± 0.08(−36)[ −46] | 4.96lmn ± 0.07(+15) | 2.73b ± 0.08(−37)[ −45] | 3.82B ± 1.05 |

| ICTP 8203 | 4.50ijk ± 0.15 | 3.33efgh ± 0.08(−26) | 5.01mn ± 0.01(+11) | 3.30efgh ± 0.07(−27)[ −34] | 5.06mn ± 0.22(+12) | 2.70b ± 0.15(−40)[ −47] | 3.98B ± 0.96 |

| IBV 8004 | 4.72jklm ± 0.08 | 3.64h ± 0.08(−23) | 5.22no ± 0.00(+11) | 3.66h ± 0.14(−22)[ −30] | 4.92klmn ± 0.02 | 3.18cdefg ± 0.07(−33)[ −35] | 4.22C ± 0.80 |

| GB 8735 | 5.63opq ± 0.07 | 3.37efgh ± 0.15(−40) | 5.77pq ± 0.07 | 4.44ij ± 0.14(−21)[ −23] | 5.83q ± 0.08 | 3.65 h ± 0.15(−35)[ −37] | 4.78D ± 1.06 |

| Kuphanjala-2 | 7.51s ± 0.07 | 4.22i ± 0.07(−44) | 8.21t ± 0.07(+9) | 4.28ij ± 0.15(−43)[ −48] | 9.59vw ± 0.07(+28) | 4.53ijkl ± 0.00(−40)[ −53] | 6.39E ± 2.23 |

| Hybrids | |||||||

| ICMH 1201 | 8.84u ± 0.30 | 5.26no ± 0.08(−40) | 8.28t ± 0.35(−6) | 5.18n ± 0.01(−41)[ −37] | 8.15t ± 0.09(−9) | 5.34nop ± 0.30(−40)[ −35] | 6.84F ± 1.68 |

| Dhanashakti | 9.55vw ± 0.01 | 7.18s ± 0.08(−25) | 9.25uv ± 0.08 | 6.70r ± 0.08(−30)[ −28] | 9.80w ± 0.03 | 6.31r ± 0.00(−34)[ −36] | 8.13G ± 1.50 |

| Means and effect of processing (P) | 6.01C ± 2.27 | 4.17B ± 1.36 (−31) | 6.02C ± 2.45 | 4.22B ± 1.21(−30)[ −30] | 6.39D ± 2.42(+6) | 4.00A ± 1.25(−33)[ −37] | PxT P ≤ 0.001 |

| Zinc | |||||||

| Traditional variety | |||||||

| Mil Souna | 3.37ijklmn ± 0.08 | 3.40jklmn ± 0.00 | 3.76opqr ± 0.08(+12) | 2.73abc ± 0.08(−18)[ −27] | 3.66nopq ± 0.07 | 4.18tu ± 0.00(+24)[+14] | 3.52B ± 0.46 |

| Improved varieties | |||||||

| ICRI-TABI | 3.17fghijk ± 0.00 | 2.66ab ± 0.08(−16) | 3.38jklmn ± 0.08 | 3.71opq ± 0.07(+17)[+10] | 3.25ghijkl ± 0.07 | 2.79bcd ± 0.00(−12)[ −14] | 3.16A ± 0.37 |

| ICTP 8203 | 3.18fghijk ± 0.00 | 3.06defghi ± 0.00 | 3.47klmno ± 0.07 | 2.76abcd ± 0.07(−13)[ −20] | 3.30hijklm ± 0.15 | 2.80bcde ± 0.15(−11)[ −15] | 3.09A ± 0.28 |

| IBV 8004 | 4.12stu ± 0.00 | 3.75opqr ± 0.08(−9) | 4.26u ± 0.15 | 3.88qrst ± 0.01[−9] | 3.85pqrs ± 0.01 | 3.66nopq ± 0.00(−11) | 3.92C ± 0.22 |

| GB 8735 | 3.61mnopq ± 0.00 | 2.88bcdef ± 0.08(−20) | 3.72opq ± 0.07 | 3.52lmno ± 0.08 | 3.64nopq ± 0.00 | 3.54lmnop ± 0.00 | 3.48B ± 0.29 |

| Kuphanjala−2 | 2.95bcdefg ± 0.08 | 2.47a ± 0.08(−16) | 3.11efghij ± 0.00 | 2.94bcdefg ± 0.08[−5] | 3.00cdefgh ± 0.00 | 3.72l ± 0.38(+26)[+24] | 3.03A ± 0.40 |

| Hybrids | |||||||

| ICMH 1201 | 4.36u ± 0.00 | 4.12stu ± 0.00 | 4.22u ± 0.09 | 4.26u ± 0.22 | 4.21u ± 0.07 | 4.06rstu ± 0.00 | 4.21D ± 0.13 |

| Dhanashakti | 4.83v ± 0.07 | 4.97v ± 0.00 | 4.81v ± 0.00 | 4.88v ± 0.08 | 5.06v ± 0.06 | 4.76v ± 0.08 | 4.88E ± 0.12 |

| Means and effect of processing (P) | 3.70C ± 0.65 | 3.41A ± 0.81(−8) | 3.84D ± 0.54(+4) | 3.59B ± 0.74(−3)[ −7] | 3.75CD ± 0.63 | 3.69BC ± 0.66 | PxT P ≤ 0.001 |

| Calcium | |||||||

| Traditional variety | |||||||

| Mil Souna | 8.12m ± 0.23 | 1.81bcde ± 0.23(−78) | 19.37s ± 0.43(+139) | 0.64abc ± 0.00(−92)[ −97] | 19.90st ± 0.66(+145) | 4.99hij ± 0.23(−39)[ −75] | 9.14C ± 8.15 |

| Improved varieties | |||||||

| ICRI-TABI | 4.75hij ± 0.23 | 7.49lm ± 0.46(+58) | 12.89no ± 0.02(+171) | 1.18abcd ± 0.30(−75)[ −91] | 14.56p ± 0.22(+207) | 0.00a(−100)[ −100] | 6.81B ± 5.72 |

| ICTP 8203 | 3.95ghi ± 0.47 | 0.00a(−100) | 15.04pq ± 0.03(+281) | 0.00a(−100)[ −100] | 16.46qr ± 0.24(+317) | 0.00a(−100)[−100] | 5.91A ± 7.43 |

| IBV 8004 | 13.72op ± 0.54 | 6.03jkl ± 0.24(−56) | 23.80u ± 0.21(+76) | 3.72fgh ± 0.24(−73)[ −84] | 21.48t ± 0.84(+57) | 2.58defg ± 0.00(−81)[ −88] | 11.89D ± 8.80 |

| GB 8735 | 5.58ijk ± 0.46 | 0.00a [−100] | 16.35qr ± 0.24(+193) | 0.00a(−100)[−100] | 17.17m ± 0.69(+208) | 0.00a(−100)[−100] | 6.52AB ± 7.85 |

| Kuphanjala-2 | 7.51lm ± 0.71 | 1.48abcde ± 0.23(−80) | 20.61st ± 0.48(+174) | 3.53fgh ± 0.45(−53)[ −83] | 15.11pq ± 0.45(+101) | 6.80klm ± 0.46(−9)[ −55] | 9.17C ± 6.96 |

| Hybrids | |||||||

| ICMH 1201 | 11.79n ± 0.01 | 3.09efg ± 0.23(−74) | 28.74w ± 1.56(+144) | 0.65abc ± 0.00(−94)[ −98] | 25.99v ± 1.56(+120) | 1.60abcde ± 0.00(−86)[ −94] | 11.98D ± 12.02 |

| Dhanashakti | 8.30m ± 0.22 | 2.27cdef ± 0.00(−73) | 19.42s ± 0.22(+134) | 0.32ab ± 0.00(−96)[ −98] | 23.33u ± 0.97(+181) | 1.44abcde ± 0.23(−83)[ −94] | 9.18C ± 9.46 |

| Means and effect of processing (P) | 7.96D ± 3.28 | 2.77C ± 2.62(−65) | 19.52E ± 4.90(+145) | 1.25A ± 1.47(−84)[ −94] | 19.25E ± 4.02(+142) | 2.18B ± 2.44(−73)[ −89] | PxT P ≤ 0.001 |

| Phosphorus | |||||||

| Traditional variety | |||||||

| Mil Souna | 296ghijklm ± 4 | 238abcdef ± 17(−20) | 288fghijkl ± 3 | 225abcd ± 7(−24)[ −22] | 268cdefghij ± 0 | 253cdefg ± 16 | 261B ± 28 |

| Improved varieties | |||||||

| ICRI-TABI | 287fghijkl ± 1 | 216abc ± 2(−25) | 263cdefghi ± 1 | 194ab ± 0(−32)[ −26] | 251cdefg ± 0 | 186a ± 8(−35)[−26] | 233A ± 39 |

| ICTP 8203 | 343mnopq ± 1 | 293ghijklm ± 2 | 323klmnop ± 0 | 238abcdef ± 7(−31)[ −26] | 281efghijkl ± 1(−18) | 195ab ± 26(−43)[ −48] | 279B ± 53 |

| IBV 8004 | 404rs ± 9 | 229abcde ± 167(−43) | 363opqr ± 1 | 316jklmno ± 3(−22)[ −13] | 311ijklmno ± 2(−23) | 262cdefghi ± 10(−35) | 314C ± 79 |

| GB 8735 | 355nopqr ± 1 | 196ab ± 4(−45) | 292ghijklm ± 1(−18) | 265cdefghij ± 3(−25) | 288fghijkl ± 0(−19) | 221abc ± 18(−38)[ −23] | 269B ± 54 |

| Kuphanjala-2 | 416s ± 10 | 281efghijkl ± 29(−32) | 389qrs ± 2 | 327klmnop ± 2(−21) | 374pqrs ± 2 | 307hijklmn ± 1(−26)[ −18] | 349D ± 51 |

| Hybrids | |||||||

| ICMH 1201 | 358nopqr ± 4 | 282fghijkl ± 3(−21) | 276defghijk ± 5(−23) | 246bcdefg ± 5(−31) | 255cdefgh ± 0(−29) | 260cdefghi ± 8(−27) | 279B ± 39 |

| Dhanashakti | 370pqrs ± 7 | 333lmnop ± 3 | 308ijklmn ± 2(−17) | 282fghijkl ± 1(−24) | 323klmnop ± 4 | 230abcde ± 39(−38)[ −29] | 308C ± 47 |

| Means and effect of processing (P) | 354E ± 44 | 258B ± 63(−27) | 313D ± 42(−12) | 262B ± 44(−26)[ −16] | 294C ± 40(−17) | 239A ± 41(−32)[ −19] | PxT P ≤ 0.05 |

| Magnesium | |||||||

| Traditional variety | |||||||

| Mil Souna | 113lm ± 4 | 93hi ± 1(−18) | 140tuvw ± 0(+24) | 81def ± 2(−28)[ −42] | 131qrs ± 8(+16) | 107kl ± 2(−5)[ −18] | 111D ± 21 |

| Improved varieties | |||||||

| ICRI−TABI | 103jk ± 0 | 74cd ± 1(−28) | 127pqr ± 1(+23) | 67bc ± 1(−35)[ −47] | 114lmn ± 0(+11) | 61ab ± 1(−41)[ −46] | 91A ± 26 |

| ICTP 8203 | 114lm ± 4 | 95hij ± 0(−17) | 142uvw ± 1(+25) | 79de ± 2(−31)[ −44] | 120mnop ± 1 | 66bc ± 2(−42)[ −45] | 103C ± 27 |

| IBV 8004 | 146w ± 3 | 123opq ± 1(−16) | 169x ± 1(+16) | 113lm ± 3(−23)[ −33] | 138stuv ± 2 | 89fgh ± 2(−39)[ −36] | 130G ± 27 |

| GB 8735 | 118mno ± 2 | 55a ± 0(−53) | 127pqr ± 2(+8) | 91ghi ± 3(−23)[−28] | 122nop ± 1 | 77de ± 2(−35)[−37] | 98B ± 27 |

| Kuphanjala-2 | 139stuvw ± 2 | 89fgh ± 3(−36) | 165x ± 4(+19) | 102jk ± 3(−27)[−38] | 143vw ± 1 | 106kl ± 2(−24)[−26] | 124F ± 28 |

| Hybrids | |||||||

| ICMH 1201 | 134rstu ± 2 | 101jk ± 0(−25) | 138stuv ± 0 | 96hij ± 1(−28)[ −30] | 122nop ± 1(−9) | 96hij ± 1(−38)[−21] | 114E ± 19 |

| Dhanashakti | 132rst ± 4 | 116mno ± 3(−12) | 141uvw ± 2(+7) | 99ijk ± 2(−25)[ −30] | 139tuvw ± 0 | 84efg ± 1(−36)[ −40] | 118E ± 22 |

| Means and effect of processing (P) | 125C ± 15 | 93B ± 21(−26) | 144E ± 15(+15) | 91B ± 14(−27)[−37] | 129D ± 10(+3) | 86A ± 17(−31)[−33] | PxT P ≤ 0.001 |

| Type . | Raw grain . | Steeped/fermented grain . | Parboiled grain . | Means and effect of type (T) . | |||

|---|---|---|---|---|---|---|---|

| Whole . | Decorticated . | Whole . | Decorticated . | Whole . | Decorticated . | ||

| Iron | |||||||

| Traditional variety | |||||||

| Mil Souna | 3.04bcde ± 0.15 | 3.23defgh ± 0.08 | 1.33a ± 0.04(−56) | 3.48fgh ± 0.08(+14)[+161] | 2.84bcd ± 0.11 | 3.59gh ± 0.07(+18)[+26] | 2.92A ± 0.79 |

| Improved varieties | |||||||

| ICRI-TABI | 4.31ij ± 0.08 | 3.09bcdef ± 0.08(−28) | 5.10mn ± 0.24(+18) | 2.74bc ± 0.08(−36)[ −46] | 4.96lmn ± 0.07(+15) | 2.73b ± 0.08(−37)[ −45] | 3.82B ± 1.05 |

| ICTP 8203 | 4.50ijk ± 0.15 | 3.33efgh ± 0.08(−26) | 5.01mn ± 0.01(+11) | 3.30efgh ± 0.07(−27)[ −34] | 5.06mn ± 0.22(+12) | 2.70b ± 0.15(−40)[ −47] | 3.98B ± 0.96 |

| IBV 8004 | 4.72jklm ± 0.08 | 3.64h ± 0.08(−23) | 5.22no ± 0.00(+11) | 3.66h ± 0.14(−22)[ −30] | 4.92klmn ± 0.02 | 3.18cdefg ± 0.07(−33)[ −35] | 4.22C ± 0.80 |

| GB 8735 | 5.63opq ± 0.07 | 3.37efgh ± 0.15(−40) | 5.77pq ± 0.07 | 4.44ij ± 0.14(−21)[ −23] | 5.83q ± 0.08 | 3.65 h ± 0.15(−35)[ −37] | 4.78D ± 1.06 |

| Kuphanjala-2 | 7.51s ± 0.07 | 4.22i ± 0.07(−44) | 8.21t ± 0.07(+9) | 4.28ij ± 0.15(−43)[ −48] | 9.59vw ± 0.07(+28) | 4.53ijkl ± 0.00(−40)[ −53] | 6.39E ± 2.23 |

| Hybrids | |||||||

| ICMH 1201 | 8.84u ± 0.30 | 5.26no ± 0.08(−40) | 8.28t ± 0.35(−6) | 5.18n ± 0.01(−41)[ −37] | 8.15t ± 0.09(−9) | 5.34nop ± 0.30(−40)[ −35] | 6.84F ± 1.68 |

| Dhanashakti | 9.55vw ± 0.01 | 7.18s ± 0.08(−25) | 9.25uv ± 0.08 | 6.70r ± 0.08(−30)[ −28] | 9.80w ± 0.03 | 6.31r ± 0.00(−34)[ −36] | 8.13G ± 1.50 |

| Means and effect of processing (P) | 6.01C ± 2.27 | 4.17B ± 1.36 (−31) | 6.02C ± 2.45 | 4.22B ± 1.21(−30)[ −30] | 6.39D ± 2.42(+6) | 4.00A ± 1.25(−33)[ −37] | PxT P ≤ 0.001 |

| Zinc | |||||||

| Traditional variety | |||||||

| Mil Souna | 3.37ijklmn ± 0.08 | 3.40jklmn ± 0.00 | 3.76opqr ± 0.08(+12) | 2.73abc ± 0.08(−18)[ −27] | 3.66nopq ± 0.07 | 4.18tu ± 0.00(+24)[+14] | 3.52B ± 0.46 |

| Improved varieties | |||||||

| ICRI-TABI | 3.17fghijk ± 0.00 | 2.66ab ± 0.08(−16) | 3.38jklmn ± 0.08 | 3.71opq ± 0.07(+17)[+10] | 3.25ghijkl ± 0.07 | 2.79bcd ± 0.00(−12)[ −14] | 3.16A ± 0.37 |

| ICTP 8203 | 3.18fghijk ± 0.00 | 3.06defghi ± 0.00 | 3.47klmno ± 0.07 | 2.76abcd ± 0.07(−13)[ −20] | 3.30hijklm ± 0.15 | 2.80bcde ± 0.15(−11)[ −15] | 3.09A ± 0.28 |

| IBV 8004 | 4.12stu ± 0.00 | 3.75opqr ± 0.08(−9) | 4.26u ± 0.15 | 3.88qrst ± 0.01[−9] | 3.85pqrs ± 0.01 | 3.66nopq ± 0.00(−11) | 3.92C ± 0.22 |

| GB 8735 | 3.61mnopq ± 0.00 | 2.88bcdef ± 0.08(−20) | 3.72opq ± 0.07 | 3.52lmno ± 0.08 | 3.64nopq ± 0.00 | 3.54lmnop ± 0.00 | 3.48B ± 0.29 |

| Kuphanjala−2 | 2.95bcdefg ± 0.08 | 2.47a ± 0.08(−16) | 3.11efghij ± 0.00 | 2.94bcdefg ± 0.08[−5] | 3.00cdefgh ± 0.00 | 3.72l ± 0.38(+26)[+24] | 3.03A ± 0.40 |

| Hybrids | |||||||

| ICMH 1201 | 4.36u ± 0.00 | 4.12stu ± 0.00 | 4.22u ± 0.09 | 4.26u ± 0.22 | 4.21u ± 0.07 | 4.06rstu ± 0.00 | 4.21D ± 0.13 |

| Dhanashakti | 4.83v ± 0.07 | 4.97v ± 0.00 | 4.81v ± 0.00 | 4.88v ± 0.08 | 5.06v ± 0.06 | 4.76v ± 0.08 | 4.88E ± 0.12 |

| Means and effect of processing (P) | 3.70C ± 0.65 | 3.41A ± 0.81(−8) | 3.84D ± 0.54(+4) | 3.59B ± 0.74(−3)[ −7] | 3.75CD ± 0.63 | 3.69BC ± 0.66 | PxT P ≤ 0.001 |

| Calcium | |||||||

| Traditional variety | |||||||

| Mil Souna | 8.12m ± 0.23 | 1.81bcde ± 0.23(−78) | 19.37s ± 0.43(+139) | 0.64abc ± 0.00(−92)[ −97] | 19.90st ± 0.66(+145) | 4.99hij ± 0.23(−39)[ −75] | 9.14C ± 8.15 |

| Improved varieties | |||||||

| ICRI-TABI | 4.75hij ± 0.23 | 7.49lm ± 0.46(+58) | 12.89no ± 0.02(+171) | 1.18abcd ± 0.30(−75)[ −91] | 14.56p ± 0.22(+207) | 0.00a(−100)[ −100] | 6.81B ± 5.72 |

| ICTP 8203 | 3.95ghi ± 0.47 | 0.00a(−100) | 15.04pq ± 0.03(+281) | 0.00a(−100)[ −100] | 16.46qr ± 0.24(+317) | 0.00a(−100)[−100] | 5.91A ± 7.43 |

| IBV 8004 | 13.72op ± 0.54 | 6.03jkl ± 0.24(−56) | 23.80u ± 0.21(+76) | 3.72fgh ± 0.24(−73)[ −84] | 21.48t ± 0.84(+57) | 2.58defg ± 0.00(−81)[ −88] | 11.89D ± 8.80 |

| GB 8735 | 5.58ijk ± 0.46 | 0.00a [−100] | 16.35qr ± 0.24(+193) | 0.00a(−100)[−100] | 17.17m ± 0.69(+208) | 0.00a(−100)[−100] | 6.52AB ± 7.85 |

| Kuphanjala-2 | 7.51lm ± 0.71 | 1.48abcde ± 0.23(−80) | 20.61st ± 0.48(+174) | 3.53fgh ± 0.45(−53)[ −83] | 15.11pq ± 0.45(+101) | 6.80klm ± 0.46(−9)[ −55] | 9.17C ± 6.96 |

| Hybrids | |||||||

| ICMH 1201 | 11.79n ± 0.01 | 3.09efg ± 0.23(−74) | 28.74w ± 1.56(+144) | 0.65abc ± 0.00(−94)[ −98] | 25.99v ± 1.56(+120) | 1.60abcde ± 0.00(−86)[ −94] | 11.98D ± 12.02 |

| Dhanashakti | 8.30m ± 0.22 | 2.27cdef ± 0.00(−73) | 19.42s ± 0.22(+134) | 0.32ab ± 0.00(−96)[ −98] | 23.33u ± 0.97(+181) | 1.44abcde ± 0.23(−83)[ −94] | 9.18C ± 9.46 |

| Means and effect of processing (P) | 7.96D ± 3.28 | 2.77C ± 2.62(−65) | 19.52E ± 4.90(+145) | 1.25A ± 1.47(−84)[ −94] | 19.25E ± 4.02(+142) | 2.18B ± 2.44(−73)[ −89] | PxT P ≤ 0.001 |

| Phosphorus | |||||||

| Traditional variety | |||||||

| Mil Souna | 296ghijklm ± 4 | 238abcdef ± 17(−20) | 288fghijkl ± 3 | 225abcd ± 7(−24)[ −22] | 268cdefghij ± 0 | 253cdefg ± 16 | 261B ± 28 |

| Improved varieties | |||||||

| ICRI-TABI | 287fghijkl ± 1 | 216abc ± 2(−25) | 263cdefghi ± 1 | 194ab ± 0(−32)[ −26] | 251cdefg ± 0 | 186a ± 8(−35)[−26] | 233A ± 39 |

| ICTP 8203 | 343mnopq ± 1 | 293ghijklm ± 2 | 323klmnop ± 0 | 238abcdef ± 7(−31)[ −26] | 281efghijkl ± 1(−18) | 195ab ± 26(−43)[ −48] | 279B ± 53 |

| IBV 8004 | 404rs ± 9 | 229abcde ± 167(−43) | 363opqr ± 1 | 316jklmno ± 3(−22)[ −13] | 311ijklmno ± 2(−23) | 262cdefghi ± 10(−35) | 314C ± 79 |

| GB 8735 | 355nopqr ± 1 | 196ab ± 4(−45) | 292ghijklm ± 1(−18) | 265cdefghij ± 3(−25) | 288fghijkl ± 0(−19) | 221abc ± 18(−38)[ −23] | 269B ± 54 |

| Kuphanjala-2 | 416s ± 10 | 281efghijkl ± 29(−32) | 389qrs ± 2 | 327klmnop ± 2(−21) | 374pqrs ± 2 | 307hijklmn ± 1(−26)[ −18] | 349D ± 51 |

| Hybrids | |||||||

| ICMH 1201 | 358nopqr ± 4 | 282fghijkl ± 3(−21) | 276defghijk ± 5(−23) | 246bcdefg ± 5(−31) | 255cdefgh ± 0(−29) | 260cdefghi ± 8(−27) | 279B ± 39 |

| Dhanashakti | 370pqrs ± 7 | 333lmnop ± 3 | 308ijklmn ± 2(−17) | 282fghijkl ± 1(−24) | 323klmnop ± 4 | 230abcde ± 39(−38)[ −29] | 308C ± 47 |

| Means and effect of processing (P) | 354E ± 44 | 258B ± 63(−27) | 313D ± 42(−12) | 262B ± 44(−26)[ −16] | 294C ± 40(−17) | 239A ± 41(−32)[ −19] | PxT P ≤ 0.05 |

| Magnesium | |||||||

| Traditional variety | |||||||

| Mil Souna | 113lm ± 4 | 93hi ± 1(−18) | 140tuvw ± 0(+24) | 81def ± 2(−28)[ −42] | 131qrs ± 8(+16) | 107kl ± 2(−5)[ −18] | 111D ± 21 |

| Improved varieties | |||||||

| ICRI−TABI | 103jk ± 0 | 74cd ± 1(−28) | 127pqr ± 1(+23) | 67bc ± 1(−35)[ −47] | 114lmn ± 0(+11) | 61ab ± 1(−41)[ −46] | 91A ± 26 |

| ICTP 8203 | 114lm ± 4 | 95hij ± 0(−17) | 142uvw ± 1(+25) | 79de ± 2(−31)[ −44] | 120mnop ± 1 | 66bc ± 2(−42)[ −45] | 103C ± 27 |

| IBV 8004 | 146w ± 3 | 123opq ± 1(−16) | 169x ± 1(+16) | 113lm ± 3(−23)[ −33] | 138stuv ± 2 | 89fgh ± 2(−39)[ −36] | 130G ± 27 |

| GB 8735 | 118mno ± 2 | 55a ± 0(−53) | 127pqr ± 2(+8) | 91ghi ± 3(−23)[−28] | 122nop ± 1 | 77de ± 2(−35)[−37] | 98B ± 27 |

| Kuphanjala-2 | 139stuvw ± 2 | 89fgh ± 3(−36) | 165x ± 4(+19) | 102jk ± 3(−27)[−38] | 143vw ± 1 | 106kl ± 2(−24)[−26] | 124F ± 28 |

| Hybrids | |||||||

| ICMH 1201 | 134rstu ± 2 | 101jk ± 0(−25) | 138stuv ± 0 | 96hij ± 1(−28)[ −30] | 122nop ± 1(−9) | 96hij ± 1(−38)[−21] | 114E ± 19 |

| Dhanashakti | 132rst ± 4 | 116mno ± 3(−12) | 141uvw ± 2(+7) | 99ijk ± 2(−25)[ −30] | 139tuvw ± 0 | 84efg ± 1(−36)[ −40] | 118E ± 22 |

| Means and effect of processing (P) | 125C ± 15 | 93B ± 21(−26) | 144E ± 15(+15) | 91B ± 14(−27)[−37] | 129D ± 10(+3) | 86A ± 17(−31)[−33] | PxT P ≤ 0.001 |

Means of analysis of two independent samples (n = 2) ± 1 SD.

abcValues with different superscripts differ significantly (P ≤ 0.001) for iron, zinc, calcium, magnesium and differ significantly (P ≤ 0.05) for phosphorus.

ABCLeast significant mean values from main effects factorial Anova with different superscripts in the same row/column, differ significantly (P ≤ 0.001) for iron, zinc, calcium, magnesium and differ significantly (P ≤ 0.05) for phosphorus.

() Values in brackets are the differences (% change where significant – P ≤ 0.001) in the mineral content of processed whole-grain (steeped or parboiled) and decorticated raw and processed grain (steeped or parboiled) compared to the raw whole-grain pearl millet.

[] Values in square brackets are the differences (% change where significant – P ≤ 0.001) in the mineral content of decorticated processed grain (steeped or parboiled) compared to whole-grain processed (steeped or parboiled) pearl millet.

The two biofortified hybrids also had the highest zinc contents, with the improved variety IBV 8004 having the next highest content and all the other varieties, including Mil Souna, having low zinc content. However, the increase in zinc contents was much lower than iron content, with the hybrids only having approx. 50% more zinc than the other varieties. As with iron, Hama et al. (2012) reported much higher contents of zinc in the improved varieties ICRI-TABI and GB 8735, that is, 4.11 and 5.63 mg/100 g vs. 3.17 and 3.61 mg/100 g found in this present work. These differences are presumably also due to the effect of cultivation environment. Regarding other minerals, the two hybrids showed the highest calcium contents, but the amounts of phosphorus and magnesium were not exceptional.

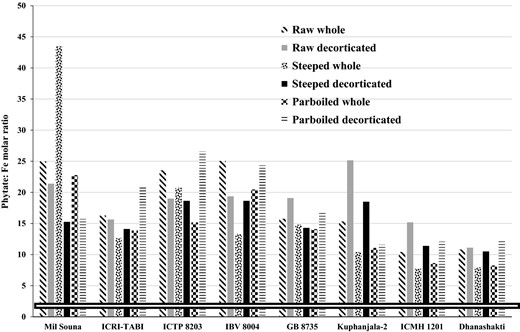

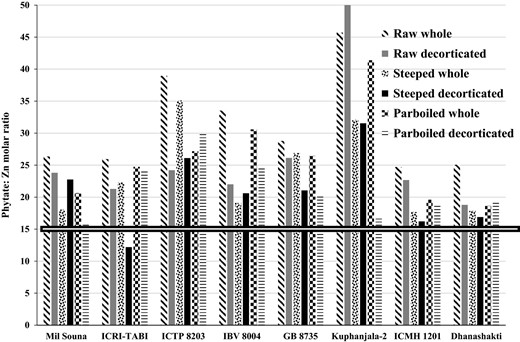

Concerning antinutrients, the content of phytate in the two hybrids was intermediate, whereas Mil Souna and ICRI-TABI were low in phytate, <900 mg/100 g (Table 3). The phytate values obtained in this study for ICRI-TABI and GB 8735 are quite similar to those reported by Hama et al. (2012), 830 ± 20 and 1048 ± 7 mg/100 g vs. 780 and 950 mg/100 g, respectively. The two hybrids had the highest total phenolic contents, 331 ± 20 and 403 ± 9 mg/100 g in ICMH 1201 and Dhanashakti, respectively. The contents of total phenolics in ICRI-TABI and GB 8735 (263 ± 18 and 251 ± 19 mg/100 g) were similar to those reported by Hama et al. (2012) (290 and 260 mg/100 g, respectively).

Effects of abrasive decortication, pearl millet type, steeping/fermentation in back-slopped liquor, and parboiling on phytate and total phenolic contents (mg/100 g, db)

| Type . | Raw grain . | Steeped/fermented grain . | Parboiled grain . | Means and effect of type (T) . | |||

|---|---|---|---|---|---|---|---|

| Whole . | Decorticated . | Whole . | Decorticated . | Whole . | Decorticated . | ||

| Phytate | |||||||

| Traditional variety | |||||||

| Mil Souna | 896hijklmn ± 14 | 816fghij ± 7 | 684cde ± 20(−24) | 627bcd ± 38(−30) | 763efg ± 8(−15) | 667bcde ± 10(−26) | 742B ± 98 |

| Improved varieties | |||||||

| ICRI-TABI | 830ghijk ± 20 | 571b ± 15(−31) | 762efg ± 14 | 457a ± 11(−45)[ −40] | 812fghi ± 13 | 676cde ± 18(−19)[ −17] | 685A ± 141 |

| ICTP 8203 | 1251r ± 18 | 748efg ± 20(−40) | 1228r ± 28 | 726ef ± 6(−42)[ −41] | 907ijklmn ± 47(−27) | 846ghijkl ± 7(−32) | 951D ± 223 |

| IBV 8004 | 1395s ± 8 | 833ghijk ± 33(−40) | 821fghij ± 6(−41) | 807fgh ± 41(−42) | 1188r ± 58(−15) | 913jklmno ± 10(−35)[ −23] | 1063F ± 238 |

| GB 8735 | 1048pq ± 7 | 760efg ± 8(−27) | 1011opq ± 58 | 748efg ± 56(−27)[ −26] | 971nop ± 17 | 724def ± 43 (−31) [−25] | 877C ± 144 |

| Kuphanjala-2 | 1360s ± 30 | 1254r ± 21(−8) | 1008opq ± 2(−26) | 936lmno ± 35(−30) | 1254r ± 9(−8) | 620ab ± 19 (−54)[ −51] | 1002E ± 260 |

| Hybrids | |||||||

| ICMH 1201 | 1088q ± 8 | 943lmno ± 27(−13) | 754efg ± 29(−31) | 698cde ± 33(−36) | 832ghijk ± 12(−24) | 762efg ± 11(−30) | 846C ± 140 |

| Dhanashakti | 1221r ± 43 | 943lmno ± 46(−23) | 870hijklm ± 52 (−29) | 832ghijk ± 31(−32) | 953mnop ± 16(−22) | 928klmno ± 40(−24) | 958D ± 134 |

| Means and effect of processing (P) | 1136E ± 200 | 859C ± 193 (−24) | 892C ± 175 (−21) | 729A ± 142 (−36) [−18] | 960D ± 172(−15) | 767B ± 114 (−32)[ −20] | P×T P ≤ 0.001 |

| Total phenolics | |||||||

| Traditional variety | |||||||

| Mil Souna | 293opqrst ± 13 | 182bcdef ± 7(−38) | 277nopqrs ± 22 | 197cdefg ± 7(−33)[ −29] | 268mnopqr ± 18 | 202cdefghi ± 14(−31)[ −25] | 236AB ± 47 |

| Improved varieties | |||||||

| ICRI-TABI | 263lmnopq ± 18 | 219efghijkl ± 8 | 349uv ± 13(+33) | 182bcdef ± 14(−31)[ −48] | 186cdef ± 14(−29) | 126a ± 12(−52)[ −32] | 221A ± 74 |

| ICTP 8203 | 297pqrst ± 14 | 233ghijklmn ± 13(−22) | 246ijklmn ± 13(−17) | 141ab ± 11(−53)[ −43] | 244hijklmn ± 8(−18) | 169abcd ± 6(−43)[ −31] | 222A ± 55 |

| IBV 8004 | 293opqrst ± 6 | 273nopqr ± 13 | 319stuv ± 15 | 172bcd ± 15(−41)[ −46] | 274nopqr ± 8 | 189cdefg ± 6(−35)[ −31] | 253BC ± 57 |

| GB 8735 | 251jklmno ± 19 | 160abc ± 15(−36) | 253klmnop ± 7 | 209defghijk ± 6(−17)[ −17] | 242hijklmn ± 11 | 220efghijkl ± 13 | 222A ± 35 |

| Kuphanjala-2 | 354v ± 13 | 234ghijklmn ± 12 (−34) | 307qrstu ± 6(−13) | 207defghij ± 6(−42)[ −33] | 191cdefg ± 7(−46) | 178bc ± 10(−50)[ −7] | 245B ± 67 |

| Hybrid | |||||||

| ICMH 1201 | 331tuv ± 20 | 276nopqrs ± 7(−17) | 326tuv ± 6 | 226fghijkl ± 5(−32)[ −31] | 247ijklmn ± 14(−25) | 195cdefg ± 6(−41)[ −21] | 267C ± 53 |

| Dhanashakti | 403w ± 9 | 307qrstu ± 9(−24) | 310rstuv ± 29(−23) | 199cdefgh ± 10(−51)[ −36] | 275nopqrs ± 26(−32) | 264lmnopq ± 7(−34) | 293D ± 65 |

| Means and effect of processing (P) | 311C ± 49 | 235B ± 49(−24) | 298C ± 37 | 192A ± 26(−38)[ −36] | 241B ± 35 | 193A ± 39(−38)[ −20] | P×T P ≤ 0.001 |

| Type . | Raw grain . | Steeped/fermented grain . | Parboiled grain . | Means and effect of type (T) . | |||

|---|---|---|---|---|---|---|---|

| Whole . | Decorticated . | Whole . | Decorticated . | Whole . | Decorticated . | ||

| Phytate | |||||||

| Traditional variety | |||||||

| Mil Souna | 896hijklmn ± 14 | 816fghij ± 7 | 684cde ± 20(−24) | 627bcd ± 38(−30) | 763efg ± 8(−15) | 667bcde ± 10(−26) | 742B ± 98 |

| Improved varieties | |||||||

| ICRI-TABI | 830ghijk ± 20 | 571b ± 15(−31) | 762efg ± 14 | 457a ± 11(−45)[ −40] | 812fghi ± 13 | 676cde ± 18(−19)[ −17] | 685A ± 141 |

| ICTP 8203 | 1251r ± 18 | 748efg ± 20(−40) | 1228r ± 28 | 726ef ± 6(−42)[ −41] | 907ijklmn ± 47(−27) | 846ghijkl ± 7(−32) | 951D ± 223 |

| IBV 8004 | 1395s ± 8 | 833ghijk ± 33(−40) | 821fghij ± 6(−41) | 807fgh ± 41(−42) | 1188r ± 58(−15) | 913jklmno ± 10(−35)[ −23] | 1063F ± 238 |

| GB 8735 | 1048pq ± 7 | 760efg ± 8(−27) | 1011opq ± 58 | 748efg ± 56(−27)[ −26] | 971nop ± 17 | 724def ± 43 (−31) [−25] | 877C ± 144 |

| Kuphanjala-2 | 1360s ± 30 | 1254r ± 21(−8) | 1008opq ± 2(−26) | 936lmno ± 35(−30) | 1254r ± 9(−8) | 620ab ± 19 (−54)[ −51] | 1002E ± 260 |

| Hybrids | |||||||

| ICMH 1201 | 1088q ± 8 | 943lmno ± 27(−13) | 754efg ± 29(−31) | 698cde ± 33(−36) | 832ghijk ± 12(−24) | 762efg ± 11(−30) | 846C ± 140 |

| Dhanashakti | 1221r ± 43 | 943lmno ± 46(−23) | 870hijklm ± 52 (−29) | 832ghijk ± 31(−32) | 953mnop ± 16(−22) | 928klmno ± 40(−24) | 958D ± 134 |

| Means and effect of processing (P) | 1136E ± 200 | 859C ± 193 (−24) | 892C ± 175 (−21) | 729A ± 142 (−36) [−18] | 960D ± 172(−15) | 767B ± 114 (−32)[ −20] | P×T P ≤ 0.001 |

| Total phenolics | |||||||

| Traditional variety | |||||||

| Mil Souna | 293opqrst ± 13 | 182bcdef ± 7(−38) | 277nopqrs ± 22 | 197cdefg ± 7(−33)[ −29] | 268mnopqr ± 18 | 202cdefghi ± 14(−31)[ −25] | 236AB ± 47 |

| Improved varieties | |||||||

| ICRI-TABI | 263lmnopq ± 18 | 219efghijkl ± 8 | 349uv ± 13(+33) | 182bcdef ± 14(−31)[ −48] | 186cdef ± 14(−29) | 126a ± 12(−52)[ −32] | 221A ± 74 |

| ICTP 8203 | 297pqrst ± 14 | 233ghijklmn ± 13(−22) | 246ijklmn ± 13(−17) | 141ab ± 11(−53)[ −43] | 244hijklmn ± 8(−18) | 169abcd ± 6(−43)[ −31] | 222A ± 55 |

| IBV 8004 | 293opqrst ± 6 | 273nopqr ± 13 | 319stuv ± 15 | 172bcd ± 15(−41)[ −46] | 274nopqr ± 8 | 189cdefg ± 6(−35)[ −31] | 253BC ± 57 |

| GB 8735 | 251jklmno ± 19 | 160abc ± 15(−36) | 253klmnop ± 7 | 209defghijk ± 6(−17)[ −17] | 242hijklmn ± 11 | 220efghijkl ± 13 | 222A ± 35 |

| Kuphanjala-2 | 354v ± 13 | 234ghijklmn ± 12 (−34) | 307qrstu ± 6(−13) | 207defghij ± 6(−42)[ −33] | 191cdefg ± 7(−46) | 178bc ± 10(−50)[ −7] | 245B ± 67 |

| Hybrid | |||||||

| ICMH 1201 | 331tuv ± 20 | 276nopqrs ± 7(−17) | 326tuv ± 6 | 226fghijkl ± 5(−32)[ −31] | 247ijklmn ± 14(−25) | 195cdefg ± 6(−41)[ −21] | 267C ± 53 |

| Dhanashakti | 403w ± 9 | 307qrstu ± 9(−24) | 310rstuv ± 29(−23) | 199cdefgh ± 10(−51)[ −36] | 275nopqrs ± 26(−32) | 264lmnopq ± 7(−34) | 293D ± 65 |

| Means and effect of processing (P) | 311C ± 49 | 235B ± 49(−24) | 298C ± 37 | 192A ± 26(−38)[ −36] | 241B ± 35 | 193A ± 39(−38)[ −20] | P×T P ≤ 0.001 |

Means of analysis of two independent samples (n = 2) ± 1 SD.

abcValues with different superscripts differ significantly (P ≤ 0.05).

ABCLeast significant mean values from main effects factorial Anova with different superscripts in the same row/column differ significantly (P ≤ 0.05).

() Values in brackets are the differences (% change where significant – P ≤ 0.001) in the phytate or total phenolic content of processed whole-grain (steeped or parboiled) and decorticated raw and processed grain (steeped or parboiled) compared to the raw whole-grain pearl millet.

[] values in square brackets are the differences (% change where significant – P ≤ 0.001) in the phytate and total phenolic content of decorticated processed grain (steeped or parboiled) compared to whole-grain processed (steeped or parboiled) pearl millet.

Effects of abrasive decortication, pearl millet type, steeping/fermentation in back-slopped liquor, and parboiling on phytate and total phenolic contents (mg/100 g, db)

| Type . | Raw grain . | Steeped/fermented grain . | Parboiled grain . | Means and effect of type (T) . | |||

|---|---|---|---|---|---|---|---|

| Whole . | Decorticated . | Whole . | Decorticated . | Whole . | Decorticated . | ||

| Phytate | |||||||

| Traditional variety | |||||||

| Mil Souna | 896hijklmn ± 14 | 816fghij ± 7 | 684cde ± 20(−24) | 627bcd ± 38(−30) | 763efg ± 8(−15) | 667bcde ± 10(−26) | 742B ± 98 |

| Improved varieties | |||||||

| ICRI-TABI | 830ghijk ± 20 | 571b ± 15(−31) | 762efg ± 14 | 457a ± 11(−45)[ −40] | 812fghi ± 13 | 676cde ± 18(−19)[ −17] | 685A ± 141 |

| ICTP 8203 | 1251r ± 18 | 748efg ± 20(−40) | 1228r ± 28 | 726ef ± 6(−42)[ −41] | 907ijklmn ± 47(−27) | 846ghijkl ± 7(−32) | 951D ± 223 |

| IBV 8004 | 1395s ± 8 | 833ghijk ± 33(−40) | 821fghij ± 6(−41) | 807fgh ± 41(−42) | 1188r ± 58(−15) | 913jklmno ± 10(−35)[ −23] | 1063F ± 238 |

| GB 8735 | 1048pq ± 7 | 760efg ± 8(−27) | 1011opq ± 58 | 748efg ± 56(−27)[ −26] | 971nop ± 17 | 724def ± 43 (−31) [−25] | 877C ± 144 |

| Kuphanjala-2 | 1360s ± 30 | 1254r ± 21(−8) | 1008opq ± 2(−26) | 936lmno ± 35(−30) | 1254r ± 9(−8) | 620ab ± 19 (−54)[ −51] | 1002E ± 260 |

| Hybrids | |||||||

| ICMH 1201 | 1088q ± 8 | 943lmno ± 27(−13) | 754efg ± 29(−31) | 698cde ± 33(−36) | 832ghijk ± 12(−24) | 762efg ± 11(−30) | 846C ± 140 |

| Dhanashakti | 1221r ± 43 | 943lmno ± 46(−23) | 870hijklm ± 52 (−29) | 832ghijk ± 31(−32) | 953mnop ± 16(−22) | 928klmno ± 40(−24) | 958D ± 134 |

| Means and effect of processing (P) | 1136E ± 200 | 859C ± 193 (−24) | 892C ± 175 (−21) | 729A ± 142 (−36) [−18] | 960D ± 172(−15) | 767B ± 114 (−32)[ −20] | P×T P ≤ 0.001 |

| Total phenolics | |||||||

| Traditional variety | |||||||

| Mil Souna | 293opqrst ± 13 | 182bcdef ± 7(−38) | 277nopqrs ± 22 | 197cdefg ± 7(−33)[ −29] | 268mnopqr ± 18 | 202cdefghi ± 14(−31)[ −25] | 236AB ± 47 |

| Improved varieties | |||||||

| ICRI-TABI | 263lmnopq ± 18 | 219efghijkl ± 8 | 349uv ± 13(+33) | 182bcdef ± 14(−31)[ −48] | 186cdef ± 14(−29) | 126a ± 12(−52)[ −32] | 221A ± 74 |

| ICTP 8203 | 297pqrst ± 14 | 233ghijklmn ± 13(−22) | 246ijklmn ± 13(−17) | 141ab ± 11(−53)[ −43] | 244hijklmn ± 8(−18) | 169abcd ± 6(−43)[ −31] | 222A ± 55 |

| IBV 8004 | 293opqrst ± 6 | 273nopqr ± 13 | 319stuv ± 15 | 172bcd ± 15(−41)[ −46] | 274nopqr ± 8 | 189cdefg ± 6(−35)[ −31] | 253BC ± 57 |

| GB 8735 | 251jklmno ± 19 | 160abc ± 15(−36) | 253klmnop ± 7 | 209defghijk ± 6(−17)[ −17] | 242hijklmn ± 11 | 220efghijkl ± 13 | 222A ± 35 |

| Kuphanjala-2 | 354v ± 13 | 234ghijklmn ± 12 (−34) | 307qrstu ± 6(−13) | 207defghij ± 6(−42)[ −33] | 191cdefg ± 7(−46) | 178bc ± 10(−50)[ −7] | 245B ± 67 |

| Hybrid | |||||||

| ICMH 1201 | 331tuv ± 20 | 276nopqrs ± 7(−17) | 326tuv ± 6 | 226fghijkl ± 5(−32)[ −31] | 247ijklmn ± 14(−25) | 195cdefg ± 6(−41)[ −21] | 267C ± 53 |

| Dhanashakti | 403w ± 9 | 307qrstu ± 9(−24) | 310rstuv ± 29(−23) | 199cdefgh ± 10(−51)[ −36] | 275nopqrs ± 26(−32) | 264lmnopq ± 7(−34) | 293D ± 65 |

| Means and effect of processing (P) | 311C ± 49 | 235B ± 49(−24) | 298C ± 37 | 192A ± 26(−38)[ −36] | 241B ± 35 | 193A ± 39(−38)[ −20] | P×T P ≤ 0.001 |

| Type . | Raw grain . | Steeped/fermented grain . | Parboiled grain . | Means and effect of type (T) . | |||

|---|---|---|---|---|---|---|---|

| Whole . | Decorticated . | Whole . | Decorticated . | Whole . | Decorticated . | ||

| Phytate | |||||||

| Traditional variety | |||||||

| Mil Souna | 896hijklmn ± 14 | 816fghij ± 7 | 684cde ± 20(−24) | 627bcd ± 38(−30) | 763efg ± 8(−15) | 667bcde ± 10(−26) | 742B ± 98 |

| Improved varieties | |||||||

| ICRI-TABI | 830ghijk ± 20 | 571b ± 15(−31) | 762efg ± 14 | 457a ± 11(−45)[ −40] | 812fghi ± 13 | 676cde ± 18(−19)[ −17] | 685A ± 141 |

| ICTP 8203 | 1251r ± 18 | 748efg ± 20(−40) | 1228r ± 28 | 726ef ± 6(−42)[ −41] | 907ijklmn ± 47(−27) | 846ghijkl ± 7(−32) | 951D ± 223 |

| IBV 8004 | 1395s ± 8 | 833ghijk ± 33(−40) | 821fghij ± 6(−41) | 807fgh ± 41(−42) | 1188r ± 58(−15) | 913jklmno ± 10(−35)[ −23] | 1063F ± 238 |

| GB 8735 | 1048pq ± 7 | 760efg ± 8(−27) | 1011opq ± 58 | 748efg ± 56(−27)[ −26] | 971nop ± 17 | 724def ± 43 (−31) [−25] | 877C ± 144 |

| Kuphanjala-2 | 1360s ± 30 | 1254r ± 21(−8) | 1008opq ± 2(−26) | 936lmno ± 35(−30) | 1254r ± 9(−8) | 620ab ± 19 (−54)[ −51] | 1002E ± 260 |

| Hybrids | |||||||

| ICMH 1201 | 1088q ± 8 | 943lmno ± 27(−13) | 754efg ± 29(−31) | 698cde ± 33(−36) | 832ghijk ± 12(−24) | 762efg ± 11(−30) | 846C ± 140 |

| Dhanashakti | 1221r ± 43 | 943lmno ± 46(−23) | 870hijklm ± 52 (−29) | 832ghijk ± 31(−32) | 953mnop ± 16(−22) | 928klmno ± 40(−24) | 958D ± 134 |

| Means and effect of processing (P) | 1136E ± 200 | 859C ± 193 (−24) | 892C ± 175 (−21) | 729A ± 142 (−36) [−18] | 960D ± 172(−15) | 767B ± 114 (−32)[ −20] | P×T P ≤ 0.001 |

| Total phenolics | |||||||

| Traditional variety | |||||||

| Mil Souna | 293opqrst ± 13 | 182bcdef ± 7(−38) | 277nopqrs ± 22 | 197cdefg ± 7(−33)[ −29] | 268mnopqr ± 18 | 202cdefghi ± 14(−31)[ −25] | 236AB ± 47 |

| Improved varieties | |||||||

| ICRI-TABI | 263lmnopq ± 18 | 219efghijkl ± 8 | 349uv ± 13(+33) | 182bcdef ± 14(−31)[ −48] | 186cdef ± 14(−29) | 126a ± 12(−52)[ −32] | 221A ± 74 |

| ICTP 8203 | 297pqrst ± 14 | 233ghijklmn ± 13(−22) | 246ijklmn ± 13(−17) | 141ab ± 11(−53)[ −43] | 244hijklmn ± 8(−18) | 169abcd ± 6(−43)[ −31] | 222A ± 55 |

| IBV 8004 | 293opqrst ± 6 | 273nopqr ± 13 | 319stuv ± 15 | 172bcd ± 15(−41)[ −46] | 274nopqr ± 8 | 189cdefg ± 6(−35)[ −31] | 253BC ± 57 |

| GB 8735 | 251jklmno ± 19 | 160abc ± 15(−36) | 253klmnop ± 7 | 209defghijk ± 6(−17)[ −17] | 242hijklmn ± 11 | 220efghijkl ± 13 | 222A ± 35 |

| Kuphanjala-2 | 354v ± 13 | 234ghijklmn ± 12 (−34) | 307qrstu ± 6(−13) | 207defghij ± 6(−42)[ −33] | 191cdefg ± 7(−46) | 178bc ± 10(−50)[ −7] | 245B ± 67 |

| Hybrid | |||||||

| ICMH 1201 | 331tuv ± 20 | 276nopqrs ± 7(−17) | 326tuv ± 6 | 226fghijkl ± 5(−32)[ −31] | 247ijklmn ± 14(−25) | 195cdefg ± 6(−41)[ −21] | 267C ± 53 |

| Dhanashakti | 403w ± 9 | 307qrstu ± 9(−24) | 310rstuv ± 29(−23) | 199cdefgh ± 10(−51)[ −36] | 275nopqrs ± 26(−32) | 264lmnopq ± 7(−34) | 293D ± 65 |

| Means and effect of processing (P) | 311C ± 49 | 235B ± 49(−24) | 298C ± 37 | 192A ± 26(−38)[ −36] | 241B ± 35 | 193A ± 39(−38)[ −20] | P×T P ≤ 0.001 |

Means of analysis of two independent samples (n = 2) ± 1 SD.

abcValues with different superscripts differ significantly (P ≤ 0.05).

ABCLeast significant mean values from main effects factorial Anova with different superscripts in the same row/column differ significantly (P ≤ 0.05).

() Values in brackets are the differences (% change where significant – P ≤ 0.001) in the phytate or total phenolic content of processed whole-grain (steeped or parboiled) and decorticated raw and processed grain (steeped or parboiled) compared to the raw whole-grain pearl millet.

[] values in square brackets are the differences (% change where significant – P ≤ 0.001) in the phytate and total phenolic content of decorticated processed grain (steeped or parboiled) compared to whole-grain processed (steeped or parboiled) pearl millet.

Regarding associations between pearl millet iron and zinc contents and grain quality parameters, iron content was significantly positively correlated (P ≤ 0.05) with kernel weight, large kernels, and fat content, and inversely with percentage dehulling loss (i.e. positively with grain hardness; Table 4A). With cereal grains, fat content is related to the proportion of the kernel that is germ, i.e. high fat content is indicative of a proportionally larger germ. The relationship between iron and zinc and fat content is because the pearl millet germ is rich in these minerals (Minnis-Ndimba et al., 2015). Regarding antinutrients, phytate content was significantly correlated with protein content, presumably because of its high concentration in the protein-rich germ. Total phenolics were significantly correlated with kernel weight, large kernels, and fat and protein content, similar to that of iron because they are both concentrated in the outer layers of the grain.

Pearson correlation matrixes of pearl millet grain micronutrient content and quality attributes under differing processing conditions (values in bold are significant at P ≤ 0.05)

| Variables . | Kernel weight . | Large kernels . | % Dehulling loss . | Crude fibre . | Fat . | Protein . | Phytate . | Total phenolics . | Fe . | Zn . | Mg . |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A-Whole grain | |||||||||||

| Large kernels | 0.976 | ||||||||||

| % Dehulling loss | −0.648 | −0.593 | |||||||||

| Crude fibre | −0.008 | −0.008 | 0.405 | ||||||||

| Fat | 0.642 | 0.671 | −0.815 | −0.476 | |||||||

| Protein | 0.460 | 0.482 | −0.728 | −0.607 | 0.756 | ||||||

| Phytate | 0.439 | 0.403 | −0.702 | −0.203 | 0.373 | 0.723 | |||||

| Total phenolics | 0.722 | 0.805 | −0.705 | −0.471 | 0.845 | 0.729 | 0.476 | ||||

| Fe | 0.977 | 0.958 | −0.713 | −0.154 | 0.753 | 0.505 | 0.371 | 0.790 | |||

| Zn | 0.576 | 0.537 | −0.461 | −0.476 | 0.715 | 0.647 | 0.203 | 0.519 | 0.629 | ||

| Mg | 0.564 | 0.530 | −0.752 | −0.325 | 0.588 | 0.886 | 0.811 | 0.556 | 0.554 | 0.505 | |

| P | 0.612 | 0.574 | −0.705 | −0.017 | 0.413 | 0.704 | 0.924 | 0.481 | 0.532 | 0.264 | 0.903 |

| B-Decorticated grain | |||||||||||

| Large kernels | 0.976 | ||||||||||

| % Dehulling loss | −0.648 | −0.593 | |||||||||

| Crude fibre | −0.008 | −0.008 | 0.405 | ||||||||

| Fat | 0.642 | 0.671 | −0.815 | −0.476 | |||||||

| Protein | 0.460 | 0.482 | −0.728 | −0.607 | 0.756 | ||||||

| Phytate | 0.626 | 0.690 | −0.552 | −0.109 | 0.419 | 0.593 | |||||

| Total phenolics | 0.553 | 0.517 | −0.901 | −0.664 | 0.907 | 0.781 | 0.328 | ||||

| Fe | 0.832 | 0.867 | −0.634 | −0.389 | 0.877 | 0.642 | 0.458 | 0.762 | |||

| Zn | 0.479 | 0.484 | −0.421 | −0.661 | 0.732 | 0.683 | 0.100 | 0.723 | 0.820 | ||

| Mg | 0.183 | 0.190 | −0.671 | −0.848 | 0.705 | 0.894 | 0.301 | 0.837 | 0.515 | 0.698 | |

| P | 0.602 | 0.650 | −0.637 | −0.586 | 0.678 | 0.565 | 0.516 | 0.732 | 0.776 | 0.574 | 0.595 |

| C-steeped decorticated grain | |||||||||||

| Large kernels | 0.976 | ||||||||||

| % Dehulling loss | −0.648 | −0.593 | |||||||||

| Crude fibre | −0.008 | −0.008 | 0.405 | ||||||||

| Fat | 0.642 | 0.671 | −0.815 | −0.476 | |||||||

| Protein | 0.460 | 0.482 | −0.728 | −0.607 | 0.756 | ||||||

| Phytate | 0.627 | 0.652 | −0.539 | −0.022 | 0.354 | 0.679 | |||||

| Total phenolics | 0.543 | 0.565 | −0.067 | 0.168 | 0.254 | 0.100 | 0.145 | ||||

| Fe | 0.887 | 0.915 | −0.480 | −0.205 | 0.714 | 0.575 | 0.536 | 0.532 | |||

| Zn | 0.630 | 0.578 | −0.547 | −0.226 | 0.787 | 0.459 | 0.072 | 0.376 | 0.725 | ||

| Mg | 0.533 | 0.504 | −0.616 | −0.197 | 0.486 | 0.845 | 0.824 | 0.273 | 0.511 | 0.358 | |

| P | 0.508 | 0.516 | −0.588 | 0.031 | 0.387 | 0.726 | 0.933 | 0.149 | 0.399 | 0.132 | 0.915 |

| D-Parboiled Decorticated Grain | |||||||||||

| Large Kernels | 0.976 | ||||||||||

| % Dehulling loss | −0.648 | −0.593 | |||||||||

| Crude fibre | −0.008 | −0.008 | 0.405 | ||||||||

| Fat | 0.642 | 0.671 | −0.815 | −0.476 | |||||||

| Protein | 0.460 | 0.482 | −0.728 | −0.607 | 0.756 | ||||||

| Phytate | 0.252 | 0.187 | −0.452 | −0.498 | 0.492 | 0.600 | |||||

| Total phenolics | 0.587 | 0.651 | −0.105 | 0.149 | 0.414 | 0.528 | 0.464 | ||||

| Fe | 0.863 | 0.914 | −0.521 | −0.281 | 0.763 | 0.579 | 0.222 | 0.731 | |||

| Zn | 0.539 | 0.638 | −0.244 | −0.373 | 0.611 | 0.669 | 0.238 | 0.844 | 0.850 | ||

| Mg | 0.197 | 0.293 | −0.132 | −0.287 | 0.190 | 0.524 | −0.275 | 0.345 | 0.446 | 0.669 | |

| P | 0.344 | 0.395 | −0.396 | −0.146 | 0.277 | 0.601 | −0.229 | 0.223 | 0.416 | 0.516 | 0.911 |

| Variables . | Kernel weight . | Large kernels . | % Dehulling loss . | Crude fibre . | Fat . | Protein . | Phytate . | Total phenolics . | Fe . | Zn . | Mg . |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A-Whole grain | |||||||||||

| Large kernels | 0.976 | ||||||||||

| % Dehulling loss | −0.648 | −0.593 | |||||||||

| Crude fibre | −0.008 | −0.008 | 0.405 | ||||||||

| Fat | 0.642 | 0.671 | −0.815 | −0.476 | |||||||

| Protein | 0.460 | 0.482 | −0.728 | −0.607 | 0.756 | ||||||

| Phytate | 0.439 | 0.403 | −0.702 | −0.203 | 0.373 | 0.723 | |||||

| Total phenolics | 0.722 | 0.805 | −0.705 | −0.471 | 0.845 | 0.729 | 0.476 | ||||

| Fe | 0.977 | 0.958 | −0.713 | −0.154 | 0.753 | 0.505 | 0.371 | 0.790 | |||

| Zn | 0.576 | 0.537 | −0.461 | −0.476 | 0.715 | 0.647 | 0.203 | 0.519 | 0.629 | ||

| Mg | 0.564 | 0.530 | −0.752 | −0.325 | 0.588 | 0.886 | 0.811 | 0.556 | 0.554 | 0.505 | |

| P | 0.612 | 0.574 | −0.705 | −0.017 | 0.413 | 0.704 | 0.924 | 0.481 | 0.532 | 0.264 | 0.903 |

| B-Decorticated grain | |||||||||||

| Large kernels | 0.976 | ||||||||||

| % Dehulling loss | −0.648 | −0.593 | |||||||||

| Crude fibre | −0.008 | −0.008 | 0.405 | ||||||||

| Fat | 0.642 | 0.671 | −0.815 | −0.476 | |||||||

| Protein | 0.460 | 0.482 | −0.728 | −0.607 | 0.756 | ||||||

| Phytate | 0.626 | 0.690 | −0.552 | −0.109 | 0.419 | 0.593 | |||||

| Total phenolics | 0.553 | 0.517 | −0.901 | −0.664 | 0.907 | 0.781 | 0.328 | ||||

| Fe | 0.832 | 0.867 | −0.634 | −0.389 | 0.877 | 0.642 | 0.458 | 0.762 | |||

| Zn | 0.479 | 0.484 | −0.421 | −0.661 | 0.732 | 0.683 | 0.100 | 0.723 | 0.820 | ||

| Mg | 0.183 | 0.190 | −0.671 | −0.848 | 0.705 | 0.894 | 0.301 | 0.837 | 0.515 | 0.698 | |

| P | 0.602 | 0.650 | −0.637 | −0.586 | 0.678 | 0.565 | 0.516 | 0.732 | 0.776 | 0.574 | 0.595 |

| C-steeped decorticated grain | |||||||||||

| Large kernels | 0.976 | ||||||||||

| % Dehulling loss | −0.648 | −0.593 | |||||||||

| Crude fibre | −0.008 | −0.008 | 0.405 | ||||||||

| Fat | 0.642 | 0.671 | −0.815 | −0.476 | |||||||

| Protein | 0.460 | 0.482 | −0.728 | −0.607 | 0.756 | ||||||

| Phytate | 0.627 | 0.652 | −0.539 | −0.022 | 0.354 | 0.679 | |||||

| Total phenolics | 0.543 | 0.565 | −0.067 | 0.168 | 0.254 | 0.100 | 0.145 | ||||

| Fe | 0.887 | 0.915 | −0.480 | −0.205 | 0.714 | 0.575 | 0.536 | 0.532 | |||

| Zn | 0.630 | 0.578 | −0.547 | −0.226 | 0.787 | 0.459 | 0.072 | 0.376 | 0.725 | ||

| Mg | 0.533 | 0.504 | −0.616 | −0.197 | 0.486 | 0.845 | 0.824 | 0.273 | 0.511 | 0.358 | |

| P | 0.508 | 0.516 | −0.588 | 0.031 | 0.387 | 0.726 | 0.933 | 0.149 | 0.399 | 0.132 | 0.915 |

| D-Parboiled Decorticated Grain | |||||||||||

| Large Kernels | 0.976 | ||||||||||

| % Dehulling loss | −0.648 | −0.593 | |||||||||

| Crude fibre | −0.008 | −0.008 | 0.405 | ||||||||

| Fat | 0.642 | 0.671 | −0.815 | −0.476 | |||||||

| Protein | 0.460 | 0.482 | −0.728 | −0.607 | 0.756 | ||||||

| Phytate | 0.252 | 0.187 | −0.452 | −0.498 | 0.492 | 0.600 | |||||

| Total phenolics | 0.587 | 0.651 | −0.105 | 0.149 | 0.414 | 0.528 | 0.464 | ||||

| Fe | 0.863 | 0.914 | −0.521 | −0.281 | 0.763 | 0.579 | 0.222 | 0.731 | |||

| Zn | 0.539 | 0.638 | −0.244 | −0.373 | 0.611 | 0.669 | 0.238 | 0.844 | 0.850 | ||

| Mg | 0.197 | 0.293 | −0.132 | −0.287 | 0.190 | 0.524 | −0.275 | 0.345 | 0.446 | 0.669 | |

| P | 0.344 | 0.395 | −0.396 | −0.146 | 0.277 | 0.601 | −0.229 | 0.223 | 0.416 | 0.516 | 0.911 |

Pearson correlation matrixes of pearl millet grain micronutrient content and quality attributes under differing processing conditions (values in bold are significant at P ≤ 0.05)

| Variables . | Kernel weight . | Large kernels . | % Dehulling loss . | Crude fibre . | Fat . | Protein . | Phytate . | Total phenolics . | Fe . | Zn . | Mg . |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A-Whole grain | |||||||||||

| Large kernels | 0.976 | ||||||||||

| % Dehulling loss | −0.648 | −0.593 | |||||||||

| Crude fibre | −0.008 | −0.008 | 0.405 | ||||||||

| Fat | 0.642 | 0.671 | −0.815 | −0.476 | |||||||

| Protein | 0.460 | 0.482 | −0.728 | −0.607 | 0.756 | ||||||

| Phytate | 0.439 | 0.403 | −0.702 | −0.203 | 0.373 | 0.723 | |||||

| Total phenolics | 0.722 | 0.805 | −0.705 | −0.471 | 0.845 | 0.729 | 0.476 | ||||

| Fe | 0.977 | 0.958 | −0.713 | −0.154 | 0.753 | 0.505 | 0.371 | 0.790 | |||

| Zn | 0.576 | 0.537 | −0.461 | −0.476 | 0.715 | 0.647 | 0.203 | 0.519 | 0.629 | ||

| Mg | 0.564 | 0.530 | −0.752 | −0.325 | 0.588 | 0.886 | 0.811 | 0.556 | 0.554 | 0.505 | |

| P | 0.612 | 0.574 | −0.705 | −0.017 | 0.413 | 0.704 | 0.924 | 0.481 | 0.532 | 0.264 | 0.903 |

| B-Decorticated grain | |||||||||||

| Large kernels | 0.976 | ||||||||||

| % Dehulling loss | −0.648 | −0.593 | |||||||||

| Crude fibre | −0.008 | −0.008 | 0.405 | ||||||||

| Fat | 0.642 | 0.671 | −0.815 | −0.476 | |||||||

| Protein | 0.460 | 0.482 | −0.728 | −0.607 | 0.756 | ||||||

| Phytate | 0.626 | 0.690 | −0.552 | −0.109 | 0.419 | 0.593 | |||||

| Total phenolics | 0.553 | 0.517 | −0.901 | −0.664 | 0.907 | 0.781 | 0.328 | ||||

| Fe | 0.832 | 0.867 | −0.634 | −0.389 | 0.877 | 0.642 | 0.458 | 0.762 | |||

| Zn | 0.479 | 0.484 | −0.421 | −0.661 | 0.732 | 0.683 | 0.100 | 0.723 | 0.820 | ||

| Mg | 0.183 | 0.190 | −0.671 | −0.848 | 0.705 | 0.894 | 0.301 | 0.837 | 0.515 | 0.698 | |

| P | 0.602 | 0.650 | −0.637 | −0.586 | 0.678 | 0.565 | 0.516 | 0.732 | 0.776 | 0.574 | 0.595 |