-

PDF

- Split View

-

Views

-

Cite

Cite

Ryota Yamamoto, Katsumi Hagita, Kazuya Morishita, Hirofumi Senga, Tetsuo Tominaga, Hiroshi Jinnai, PM-12

3D-structural distributions of silica aggregates in styrene-butadiene rubber obtained by FIB-SEM, Microscopy, Volume 68, Issue Supplement_1, November 2019, Page i40, https://doi.org/10.1093/jmicro/dfz104Close - Share Icon Share

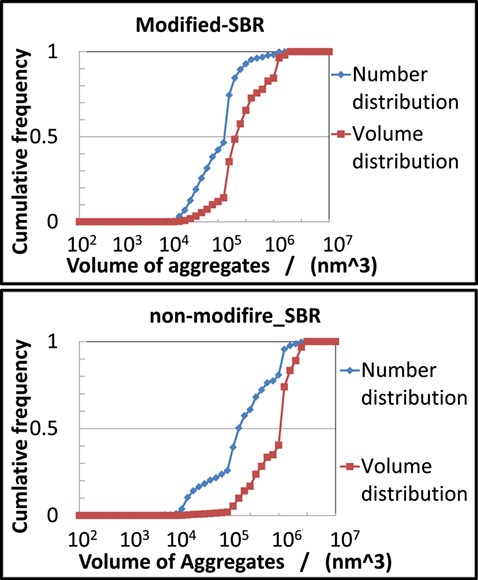

Filler aggregates in rubber play important role to their physical property of filler-filled styrene-butadiene rubber (SBR) that is used as tire rubber. FIB-SEM is a powerful tool to observe 3D-structure of aggregates directly in wide region (micrometer cubic) with single nanometer resolution [1]. In this study, we extracted individual 3D-structures of aggregates from FIB-SEM images of filler-filled SBRs. Here, we evaluated the characteristics of 3D watershed segmentation to these images. In commercial tire rubbers, polymer-filler interactions due to chain end modifications in SBR were used to improve 3D-structural distributions of silica aggregates. As the first test, we compared size distributions of silica aggregates in modified and non-modified SBR vulcanizates. Figure 1 shows cumulative frequency of number and volume of silica aggregates. In modified-SBR, the number distribution of small aggregates (<105 nm2) reaches 50%, but only 20% in non-modified SBR. Contrary, large aggregates (>106 nm2) exist in non-modified SBR, although its probability in modified SBR was very small. These results suggest that the polymer-filler interactions may affect size distribution of silica aggregates in wide volume range (104-106 nm2).

Distributions of number and volume of aggregates in modified SBR (upper) and non-modified SBR (lower)

1. K. Hagita, T. Higuchi and H. Jinnai, Scientific Reports 8 (2018) 5877.