-

PDF

- Split View

-

Views

-

Cite

Cite

Wayne Martindale, Tom Æ Hollands, Sandeep Jagtap, Essam Hebishy, Linh Duong, Turn-key research in food processing and manufacturing for reducing the impact of climate change, International Journal of Food Science and Technology, Volume 58, Issue 10, October 2023, Pages 5568–5577, https://doi.org/10.1111/ijfs.16543

Close - Share Icon Share

Abstract

This study addresses the critical need to report original and current findings on the global food system's ability to meet the growing natural resource demands of an estimated 9 billion global population. The objective is to provide guidance for researchers in developing strategies to reduce climate change risks in the food and beverage supply. To achieve this, we propose integrating innovative industry insights and digital applications into existing food system models as industrial demonstrators. Our research encompasses six impactful themes, demonstrating effective delivery methodologies. We highlight that human-centred activities and practices, often overlooked in sustainability assessments, hinder improved security and sustainability in the food system. Through our work, we showcase how smarter food production processes, along with active citizen engagement, can achieve desired outcomes outlined in frameworks, such as the Sustainable Development Goals. A crucial aspect is the development of Internet of Things (IoT) platforms, integrating workforce practices into manufacturing activities, and driving the necessary cultural changes for a sustainable food system. This study illuminates challenges faced by the global food system and provides actionable insights and methodologies to guide researchers and industry stakeholders in creating a more sustainable and secure future for food production and consumption.

Introduction

The requirement to develop a sustainable food system has a legacy of over a century that has been embedded in ecological science, as social and economic development necessitates projecting the outcomes of changes in natural resources and populations. Science has provided tools that assist in natural resource management, and significant efforts have been focused on assessing energy balance across systems within this field. To highlight the rich legacy in this area, Transeau first communicated an energy balance of crop biomass production in 1926, revealing not only the dependence of our food system on solar energy conversion but also its operating efficiency of less than 5% conversion to biomass (Transeau, 1926). Defining the energy balance has spurred improvements in crop breeding and agronomy, yet the conversion of biomass into food remains inefficient due to the constraints imposed by the laws of thermodynamics and resource limitations. These efficiency limits can change in response to external factors and various management strategies.

A well-described strategy for addressing these limiting factors is the use of fertiliser recommendation, where plant nutrients are incorporated into the biomass production system as fertilisers or manures to improve production efficiencies (Smil, 2002). Notably, this strategy relies on industrial nitrogen fixation and the extraction of phosphate and potash, with their industrial energy balances also being characterised (Küstermann et al., 2010). Each of these studies has played a crucial role in revealing inefficiencies in energy flows and emphasising the importance of understanding energy balances across the food system.

Rather than repetitively applying the same methods to obtain similar outcomes, it is now imperative for researchers to build upon these studies and focus on addressing pressing challenges such as adapting to climate change. The application of research in these areas is of utmost importance and urgency.

Factories serve as the starting point for rigidly controlling inefficiencies within energy balances, as the manufacturing environment offers standardisation, control, and accurate measurement (Ladha-Sabur et al., 2019). The advent of digitalisation and data management is revolutionising agricultural production, and now these digital technologies are being applied to the manufacturing system to develop smarter factories. Despite the greater control of energy flow in manufacturing environments, the variability in workforce movement, material procurement, and responsive production leads to variable and chaotic data sets that undergo regular changes. However, the ability to measure these data sets in real-time is now accessible and affordable to food and beverage businesses, enabling them to be responsive to change and improve production outcomes (Jagtap et al., 2021a).

One example of this application is the development of new manufacturing strategies, such as the production of fresh produce as ingredients in Controlled Environment Agriculture (CEA) facilities, also known as vertical farms. These facilities are reshaping manufacturing operations by ensuring a timely and predictable supply of fresh ingredients (Hollands et al., 2022). The development of these manufacturing systems as control points for food system data flow offers opportunities to enhance energy balance across supply chains. By routing key ingredients through specific processors and manufacturers more efficiently, these systems have been measured and evaluated using connectivity calculations (Martindale et al., 2020).

The control points within the food system are significantly fewer in number compared to agricultural producers or food businesses involved in product distribution to consumers. To illustrate this, let us consider the statistics: there are ~40 000 farm businesses operating on over 100 hectares in the UK, with around 150 000 registered farm holdings. In England and Wales alone, there are ~660 000 Food Business Operators (FSA, 2023). At the heart of this of this supply system, we find ~11 500 food and beverage manufacturers in the UK, representing critical control points for data and material flow within the food system. These manufacturers present a turn-key opportunity for developing sustainability reporting, essential for establishing a secure food system.

It is of utmost importance that food and beverage manufacturers, who supply this system, possess the necessary tools to provide insights that drive strategies for reducing material loss and greenhouse gas (GHG) emissions. Moreover, manufacturers operate at a critical financial or pricing pinch-point within these control points. Therefore, they are immediately exposed to financial shocks or fiscal policy changes that impact their workforce and material procurement. This exposure arises from their dependence on suppliers engaged in the production or processing of primary agricultural products, who seek to obtain the highest prices for their goods, and consumer-facing services and retail providers who aim for the lowest prices for manufactured goods. Failing to incorporate innovations within these control points across all supply chains puts the business activities and their value at risk.

The digital realm and the transition from Industry 4.0–5.0 have brought increased visibility to the gatekeeper role of manufacturing supply chain data. The advent of digital twins allows for reliable pressure testing of digital scenarios within the food system (Martindale et al., 2022).

The impact of over a century of material and energy balance analysis in ecosystem studies demonstrates its usefulness in developing strategies for our future food system, as its effectiveness has been proven. The utilisation Science Based Targets (SBTs) in managing natural resource exploitation, including harvesting, mining and circular economic production, originated from theoretical ecology research. A notable achievement in this regard is the development of the Maximum Sustainable Yield (MSY) model, which utilises growth rates (r-strategies) and carrying capacity (K-strategies) measurements to ensure sustainable fisheries harvesting. MSY has been employed for over 50 years and has become firmly established in natural resource management and fishery harvesting. It serves as an analytical tool for conservation programmes and is referenced in on-pack claims made by organisations, such as the Marine Stewardship Council (Beddington & May, 1977).

May demonstrated the application of theoretical models supporting MSY by using the logistic equation and relatively simple differential equations to project system-wide changes in populations over thousands of iterations (generations) (May, 1976). This work was facilitated by the development of computers and increased processing capacity, which enabled the generation of scenario generators, predecessors to our modern digital twins. The inventories of natural resources established during this period are now being revisited in our current research, leveraging analytical tools and real-time measurement sensors for natural resource production. For instance, tasks that once required detailed image data from Landsat satellite images can now be performed using open-source data engines powered by Artificial Intelligence (AI) and Machine Learning (ML) tools, utilising data from Sentinel satellites download over 20 petaBytes of open-access data daily (Brown et al., 2022; Muduli et al., 2023).

We present six research studies in this report that detail how the food processing and manufacturing industries are positioned to respond to a changing climate, making them pivotal in delivering requirements of the 21st-century food system. These studies serve as necessary drivers that not only highlight the urgency of providing strategic tools but also develop frameworks to mitigate the impact of severe climate change. These strategies will enable a robust response to a multitude of highly relevant risks, including supply disruptions caused by extreme weather events, immediate workforce changes in response to public health alerts, and geopolitical conflicts affecting the global distribution of critical ingredients.

In our report, we emphasise that the food and beverage sector now possess the capacity to:

Utilise digital twin simulations of food systems and apply control theory to project vulnerabilities and risks;

Utilise real-time sensed data from manufacturing environments to enable responsive procurement, demand management, and adapt to market changes, thus reducing losses;

Provide assessment frameworks for GHG reporting, facilitating the projection of climate change risks and their commercial impacts;

Harness biotechnology to enhance GHG reporting and reduce losses in supply chains;

Offer Earth Observation insights on biomass supply and provenance for manufacturers and processors;

Integrate people and the workforce into all these processes, ensuring engagement with our greatest challenges becomes a reality. Without such integration, the full potential of these actions will not be realised.

These six research impact studies effectively shift the management of climate change risks in food and beverage enterprises from a descriptive hazard approach to a responsive mode where businesses are equipped with strategies ready to tackle crisis, thus increasing resilience.

Methodology

The study reports on current research led by the authors, and the case studies demonstrate how specific research, utilising recent developments in open Earth Observation data, can transform the projection of food quality and quantity due to the availability of data through platforms like the Google Earth Engine Portal (Research Impact Study 1). Research Impact Study 2 provides a clarification of the application of IoT platforms, which are a focal point for transformative factors in future food security and supply. Climate change poses a significant risk to production and the efficient functioning of supply chains. The global food system is now experiencing more acute weather changes, disrupting food supply, physical assets and the workforce. Placing climate change adaptation strategies as core practices in food and beverage companies is an immediate and necessary requirement as highlighted in Research Impact Study 3.

Research Impact Study 4 defines how fermentation technology can produce protein to supplement current supply chains and alleviate security pressures. Naturally, the capability to sense value and carry out assessments between processes and products is critical in measuring security and sustainability. Methods such as Life Cycle Assessment (LCA) accomplish this, and IoT platforms are beginning to enable to real-time measurement and assessment of dynamic consumer goods and services within supply chains, as discussed in Research Impact Study 5. This approach transforms impact measurements such as carbon footprints, accounting for product variances and their diverse utilisation by customers and consumers.

The final Research Impact Study 6 is an emerging area of study, considering the impact of human movement and utilisation of food and beverage products, which is often overlooked in sustainability assessment. The S3 Project, a current research programme, aims to determine the impact of human interaction in manufacturing. It is believed that this approach will have broader applications in the food system, particularly in the transition from Industry 4.0 to 5.0 systems or the digitalisation to semantic (and AI) technology arenas. The selection of research impact studies was made by the authors, who focused on one attribute of the food system requiring immediate transformative action. Research Impact Study 6, centres around an ongoing research programme, the S3 Project.

Results

Research impact study for food system control points

Our research has identified control points in food supply chains (FSCs) (Martindale et al., 2020). These control points are associated with processing factories where biomass commodities are prepared as ingredients for food and beverages. We have developed analytical methods that measure connectivity between nodes in supply chains. The ability to measure critical control at these points is crucial for the development of strategies that enhance resilience (Shanker et al., 2022).

At the time of our initial publication in 2020, the main limitation to application was the collection of real-time supply chain data. Although the methods for analysis were established, data acquisition was limited. However, this limitation has been overcome as the accessibility to supply chain data and sensors across supply chains has improved. Therefore, our first research demonstrator provides methods to quantify limits to connectivity and identify control points in the food system. It highlights the importance of a tiered function between producers, processors and manufacturers in identifying or warning of limiting factors that can reduce supply and/or consumption.

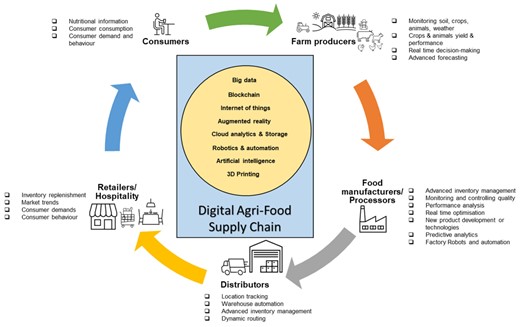

These analytical methods have become more relevant as sensing and IoT technologies have become more affordable and accessible to manufacturers, especially in terms of remote-sensed Earth Observation data for crop production. Fig. 1 illustrates how data collected from the Earth Observation platform provided by the MODIS Satellite can be used to project wheat production by analysing the relationship between leaf canopy reflectance and eventual wheat grain production. We are continuing to develop this research to incorporate more detailed weather records and fertiliser application data, which can help identify critical control points where grain production is either reduced or increased. The ability to utilise this data for food security and projection is crucial for developing greater confidence in yield models and enhancing food security strategies.

The production of wheat in the UK and the Vegetation Health Index for England between 1984 and 2021 demonstrating the relationship between observed leaf cover from MODIS and production of wheat.

Research impact study for IoT, industry 4.0 technology and crisis management; what will digitalisation bring us?

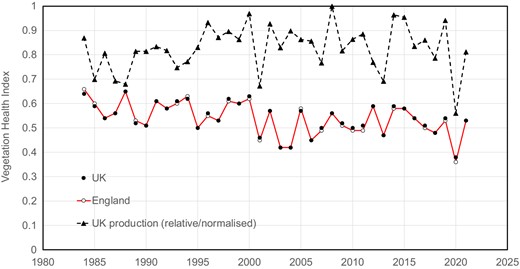

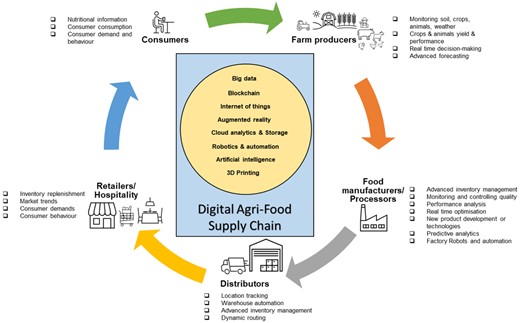

The FSC is facing immense pressure to improve sustainability, food security, and resilience due to climate change, a growing global population, and various disasters such as floods, droughts, earthquake, conflicts, and pandemics (Jagtap et al., 2022; Mishra et al., 2023). Consequently, all stakeholders within the FSC, including producers, distributors, manufacturers, retailers, consumers, and policymakers, are actively seeking novel solutions to enhance the sustainability, resilience and security of the food system. In this context, digitalisation, as a growing trend, is increasingly seen as a crucial element in addressing the challenges faced by the FSC.

Empowered by Industry 4.0, digital technologies such as Artificial Intelligence (AI), Big Data (BD), Internet of Things (IoT), Cloud computing, Robotics and automation, Blockchain, Augmented reality and 3D printing are gaining broader adoption in the agri-food sector (Rahimifard et al., 2022). The adoption of digitalisation in the agri-food sector aims to produce more, but with better quality, and reduced resource utilisation (Martindale et al., 2022). This approach not only leads to lower environmental impacts and decreased use of pesticides and fertilisers but also enhances productivity and biodiversity. Although data-driven farming is still in its early stages, it is expected to evolve in the coming years and transform traditional farms into smart farms. Some farmers in developed and developing nations already have access to farm management systems powered by information technology, precision agriculture techniques, and robotics and automation in their farming operations.

IoT has provided numerous solutions for gathering data at each stage of the FSC using sensing technologies and transmitting it to cloud/or centralised systems. Current IoT applications available for farmers include: (i) monitoring of soil, water, climate, crops and animals; (ii) evaluating yields and performance in crops, animals, and labour; (iii) data-driven decision-making based on analytics; (iv) accurate forecasting of consumer demands and market trends. However, integrating data from various sources such as Earth Observation data, on-farm sensor data, inventory data, invoice data, transportation data, and other transactional data from the FSC remains a challenge. Nevertheless, the technical knowledge required to integrate these data sources and derive meaningful insights exists, and some IoT-based monitoring systems are being developed to achieve this (Fig. 2). Given the substantial amount of data generated in the FSC, digitisation is necessary to collect, process and analyse data efficiently (Hassoun et al., 2023).

Research impact study for climate change risks to supply and demand; what are the best tools for business?

Climate change presents significant risks to the FSC in terms of both supply and demand (Khanal et al., 2021). On the supply side, extreme weather events such as floods, droughts, and heat waves, caused by climate change, can result in crop failures, reduced yields, and damage to crops (Gaupp et al., 2019). Additionally, climate change is expected to worsen water scarcity in many regions (Hristov et al., 2021), impacting food production by making irrigation systems less reliable, and increasing the water requirements for crops. Rising temperatures can also lead to the proliferation of pests and diseases, further endangering crops and reducing yields (Shahzad et al., 2021).

On the demand side, climate change can contribute to price volatility, making it harder for consumers to predict food costs and causing shifts in consumer behaviour and demand patterns (Friel et al., 2020). Economic disruptions resulting from climate change can also impact consumer demand for food and the ability of businesses to produce and distribute food. Additionally, as consumers become more conscious of the environmental impact of climate change on food production (Hartmann & Siegrist, 2017), their preferences may shift toward more sustainable and environmentally friendly products, leading to changes in demand for specific types of food.

To address these significant challenges, food businesses can adopt several tools and strategies to better prepare for and adapt to the risks of climate change, ultimately building a more resilient and sustainable FSC. These tools include sustainable sourcing practices, innovation and technology adoption, risk assessment, and collaboration (Sharma et al., 2022). For instance, businesses can invest in innovation and technology to develop new crop varieties that are more resistant to heat and drought, implement precision farming techniques to optimise crop yields, and utilise renewable energy sources for food production facilities (Adenle et al., 2019). Collaboration among stakeholders, including suppliers, farmers, and government agencies, can facilitate the sharing of best practices, pooling of resources, and development of solutions to common challenges (Duong et al., 2020; Das et al., 2023b). Diversifying suppliers, improving supply chain infrastructure to enhance resilience, and establishing contingency plans to manage disruptions are also important steps that businesses can take (Duong & Chong, 2020).

Research impact study for emerging food trends

The application of biological Industry 4.0 processing technologies (traditional, precision and biomass fermentation) and enzymatic hydrolysis, holds great potential for recovering a wide range of valuable functional and bioactive ingredients from food waste and underutilised food streams. For example, cheese whey can be transformed through fermentation technologies to fortify different complex food matrices, resulting in improved texture and flavour (Martindale et al., 2013). Biomass fermentation utilises microorganisms to efficiently convert high protein content in feedstock into protein-rich food. An example of this is the use of the filamentous fungus Fusarium venenatum to produce nutritious mycoprotein alternative meat products (Martindale et al., 2013).

Precision fermentation (PF) takes advantage of microorganisms as cell factories to synthesise specific molecules for large-scale and cost-effective production of food ingredients. PF has been successfully employed to produce alternative proteins to animal proteins, such as cultured meat or milk, using diverse feedstocks (Buchanan et al., 2023). This approach enables the development of circular production processes that are both sustainable and scalable (Pescuma et al., 2015).

However, despite the numerous advantages of these new raw materials and emerging technologies, they face challenges to consumer acceptance. Consumers are often unfamiliar with the sensory characteristics, safety, and quality of products derived from these technologies. To promote consumer engagement and interest, fully characterising alternative protein sources will be crucial in the transition toward sustainable food development (Vainio et al., 2016).

The supply of high-quality protein is essential for future nutritional outcomes and the efficient utilisation food system resources. The use of PF, cell culture and insect protein as alternative protein sources can help supplement current sources and alleviate pressures on the food system (Martindale et al., 2022).

Research impact study for data analytics for reporting sustainability and product claims

The utilisation of real-time data that can track and trace the movement of materials across supply chains has the potential to transform static representations of carbon footprints into a dynamic real-time reporting arena. This becomes increasingly important in the reporting of supply chain GHG emissions and product claims. Our research has focused on developing regional maps of consumption spaces for cities, showcasing how GHG and waste footprints vary based on population, consumption patterns, and dietary preferences (Martindale & Lucas, 2022).

However, the implementation of real-time reporting for production, manufacturing, and consumption footprints often faces limitations due to the integration and interoperability of functions and data (Martindale et al., 2018b). To overcome these challenges, our research closely collaborates with manufacturers, as they play a crucial role between producers and consumer-facing functions in the food system. Manufacturers have the capacity to develop sustainable products that aim to strike an optimal balance between minimising waste, reducing GHG emissions, and efficient resource utilisation. We refer to this approach as meta-New Product Development, where product meta data incorporates consideration of GHG emissions, waste management and resource utilisation (Martindale et al., 2019).

Research impact study for the human dimension

An important focus of our future research in delivering secure and sustainable food supply and consumption is to actively engage people within our food system. The workforce and labour dynamics have often been overlooked in sustainability assessments, despite offering significant value to the food system. It is within the workforce where innovative ideas and efforts originate, making it crucial to involve them in shaping the development of the food system. This is precisely what the S3 Project aims to achieve, utilising the technologies described here, including sensing at all scales in the food system, connected technologies for knowledge sharing, minimising environmental impact, utilising new biotechnologies and reporting real-time impact (S3 Project, 2023).

Discussion

The 21st century food system faces many issues, and attempts to solve them have not yet created the secure and sustainable food system we need. These issues have been recognised by policy makers since the 1960s, and various essays and works have demonstrated this. However, none have the authority of the North vs South study, which established that High Income Countries (HICs) have the means to exploit the natural resources of Low- and Middle-Income Countries (LMICs), while LMICs do not have equal access to these services. The division between high income and low income nations, known as the Brandt Line, still persists, reflecting the legacies of geopolitical administration and colonisation. Despite the efforts of globalisation to disrupt this division, wealth and resource disparities remain, leading to ongoing conflicts (Lees, 2021).

By considering these perspectives, we can project future resource utilisation, wealth generation, and envision the food system, particularly in the face of environmental changes that disproportionately affect the financially vulnerable and transcend national borders (Hollands et al., 2022). It is widely accepted that a system-wide approach is needed to address the impact of climate change, and cooperation among food and beverage supply chains is crucial in achieving common goals, such as reducing GHG emissions and food losses through waste. The role of processors and manufacturers should be clearly defined in current policies to facilitate this collaboration, as they have the potential to contribute more than just GHG emission reduction, as demonstrated in this report. Ensuring food security in a changing world requires a clear strategy that enables organisations to be prepared for crisis, as climate change and geopolitical conflict will persist. Being prepared with a robust strategy demonstrates resilience, and there are important universal rules that can lead to optimal outcomes. These rules rely on interoperability between processes, robust data analysis methods, and adherence to standards, while also recognising the need for innovation to push boundaries and deliver assurance and trust.

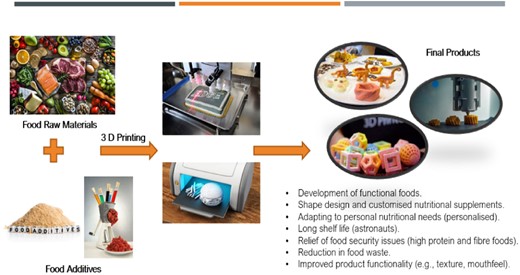

The fourth industrial revolution (Industry 4.0) has garnered significant interest since 2015, revolutionising the production, transportation, storage, perception, and consumption of food worldwide. Industry 4.0 technologies are aligned with the Sustainable Development Goals (SDG) of the United Nations (UN), particularly those related to the food processing industry, nutrition, and consumption. This highlights the importance for the food industry to adopt new food trends and embrace more sustainable production standards (Hassoun et al., 2022; Das et al., 2023a). Figs. 2 and 3 provide an overview of various digital technologies and solutions used in agri-food supply chains, along with their functions. The sustainable utilisation and valorisation of food coproduct streams and food waste can contribute to global food security, biodiversity, and human health. Achieving this requires a combination of traditional and Industry 4.0 technologies.

Principles of 3D food printing and its potential applications and advantages.

Among the emerging Industry 4.0 technologies, additive manufacturing, or 3D food printing, has shown promise in enabling the production of more diverse printable foods for effective food fortification, particularly for challenging consumer groups such as children and the elderly (Enfield et al., 2022). At the production scale, farmers can leverage digital tools to gather data on various aspects such as soil status (pH, moisture level, nutrient level), pesticides and fertilisers application, crop and animal yield and performance, advanced weather forecasting, machinery and animal health. This data support better planning and real-time decision-making, as well as farm management by consolidating data from different tasks, activities, production, and finances in one central location (Hassoun et al., 2022). For farmers involved in animal farming, digital tools assist in cattle management and the collection and management of health data, resulting in cost savings, streamlined task management, and increased productivity. Additionally, these tools facilitate knowledge-based, informed decision-making and the enhancement of food product quality.

Smart farming revolves around the continuous collection of data, such as water and nutrient application and light intensity for crops, which improves resource efficiency, increases yields, and has positive environmental impacts compared to traditional farming methods (Jagtap et al., 2021b). Blockchain technology is being utilised in the FSC to track food products from farm to fork and record tamperproof, timestamped transactions in multi-actor and complex FSCs. It enables the visualisation and mapping of all activities within the entire FSC. For example, cloud analytics combined with GPS technology and satellite imagery data allow for easy tracing of the FSCs carbon footprint and food miles (Martindale et al., 2018a).

Conclusion

There are complex interactions of data, people and materials in the food system and our analysis reviews these across six impact case studies that we present as transformative. What is increasingly apparent in dealing with big data relevant to the food industry is access to data is now rarely a barrier to progress because open access is often available. It is the acquisition of timely and relevant data that confounds progress. This is the very thing that IoT can solve if commercial confidentiality is controlled or maintained. As with everything in the food industry, the difficult part of getting the IoT to work well is harnessing the human perspectives, and it is not completely dependent on the technological challenges facing us. We present this in our final case study where we are currently delivering demonstrators of sustainable manufacturing across food and beverage products, and these will utilise well-established methodologies such as Life Cycle Assessment (LCA), footprinting and energy balance. An important development in our future research is the engagement of the workforce, customers and consumers in sustainability strategies. These are being enabled by the more accessible and affordable use of IoT, sensor technologies and gamification frameworks for sustainability. What is critical is the communication of guidance that enables the utilisation of the new tools and methodologies presented because it is the human dimensions of technological change that typically limit application.

Conflict of interest

The authors declare no competing interests.

Author contributions

Wayne Martindale: Conceptualization (equal); data curation (equal); formal analysis (equal); investigation (equal); methodology (equal); project administration (equal); resources (equal); software (equal); supervision (equal); validation (equal); visualization (equal); writing – original draft (equal); writing – review and editing (equal). Tom Æ Hollands: Conceptualization (equal); data curation (equal); formal analysis (equal); investigation (equal); methodology (equal); project administration (equal); resources (equal); validation (equal); visualization (equal); writing – original draft (equal); writing – review and editing (equal). Jagtap Sandeep: Data curation (equal); formal analysis (equal); investigation (equal); methodology (equal); project administration (equal); resources (equal); validation (equal); visualization (equal); writing – original draft (equal); writing – review and editing (equal). Essam Hebishy: Conceptualization (equal); data curation (equal); formal analysis (equal); investigation (equal); methodology (equal); project administration (equal); resources (equal); validation (equal); visualization (equal); writing – original draft (equal); writing – review and editing (equal). Linh Duong: Conceptualization (equal); data curation (equal); formal analysis (equal); investigation (equal); methodology (equal); project administration (equal); supervision (equal); validation (equal); visualization (equal); writing – original draft (equal); writing – review and editing (equal).

Peer review

The peer review history for this article is available at https://www.webofscience.com/api/gateway/wos/peer-review/10.1111/ijfs.16543.

References

Enfield et al. explores the potential of 3D printing technology to create custom-made foods for space missions, addressing the challenges of limited resources and providing valuable insights.

Khanal et al. investigates the impact of climate change adaptations by smallholder farmers on food production and demonstrates their potential to contribute to poverty eradication and zero hunger, providing valuable insights.

(edited by

Smil's research has provided valuable insights into the energetics of ammonia synthesis and fixation.

Transeau's work established a strong foundation for assessing solar energy balance.